EP0168331A2 - Machine for bending of tubes, bars or profiles - Google Patents

Machine for bending of tubes, bars or profiles Download PDFInfo

- Publication number

- EP0168331A2 EP0168331A2 EP85420086A EP85420086A EP0168331A2 EP 0168331 A2 EP0168331 A2 EP 0168331A2 EP 85420086 A EP85420086 A EP 85420086A EP 85420086 A EP85420086 A EP 85420086A EP 0168331 A2 EP0168331 A2 EP 0168331A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- bending

- axis

- mandrel

- jaw

- machine

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D7/00—Bending rods, profiles, or tubes

- B21D7/02—Bending rods, profiles, or tubes over a stationary forming member; by use of a swinging forming member or abutment

- B21D7/024—Bending rods, profiles, or tubes over a stationary forming member; by use of a swinging forming member or abutment by a swinging forming member

Definitions

- the present invention relates to a machine intended for bending tubes, bars or profiles. More particularly, this invention relates to a machine in which the bending tool mainly comprises a rotary forming roller of vertical axis, having an annular groove and supporting a first jaw - a second jaw carried by a bending arm mounted pivoting around the vertical axis mentioned above, the second jaw being able to be brought opposite the first jaw so as to grip the tube or the like to bend - a horizontal strip able to be applied against the tube or the like to bend, behind the jaws, this strip being movable, remaining parallel to itself, in the direction of its approach or its distance from the horizontal axis along which is positioned the tube or the like to bend.

- the part of the tube to be bent is clamped between the two jaws and driven forward by the rotation of the bending arm, so as to wind in the groove of the forming roller.

- the angle of rotation of the arm determines the angle of bending

- the radius of the forming roller determines the radius of the elbow that the tube will ultimately have.

- the movable strip applied against the tube behind the part to be bent, avoids any unwanted deformation of the tube outside the part to be bent.

- a bending head movable in the transverse direction of the frame of the machine, supports all the bending tools, that is to say the forming roller with the first jaw, the arm of bending carrying the second jaw, and the strip.

- the tube to be bent is pinched, in its part remaining rectilinear, by a clamping mandrel carried by a carriage movable in longitudinal direction, which keeps this part of the tube positioned along a determined horizontal axis, parallel to the longitudinal direction of the frame of the machine. .

- the present invention avoids these drawbacks.

- the assembly comprising the forming roller and the first associated jaw, as well as the bending arm pivoting with the second jaw, is carried by a movable bending head, under the action of control means, in a horizontal direction transversely to the frame of the machine and to the axis along which the tube or the like to be bent is positioned, while the movable strip, with its means of movement control, is mounted directly on the machine frame, without connection to the bending head.

- the strip is thus completely dissociated from the bending head which supports the forming roller, the bending arm and the two jaws.

- the means for controlling the transverse displacement of the bending head, carrying the forming roller, the bending arm and the two jaws comprise on the one hand a control means for the initial positioning of the bending head , placing the vertical axis of the forming roller in the appropriate position as a function of the radius of this roller, and on the other hand a control means for the offset of said bending head, capable of spreading the axis of the forming roller from the 'axis along which is positioned the tube or the like to bend.

- the initial position adjustment of the vertical axis of the forming roller, as a function of the diameter of this roller, can be carried out without influencing the position of the strip which is mounted on a support independent of the bending head.

- the shifting control of the bending head makes it possible to release the forming roller and the first jaw from the tube, which makes it possible to easily modify the orientation of the tube. between two successive bending operations, even if it is a section tube for example square.

- the offset of the bending head also facilitates a possible change of jaw between two successive bending operations.

- the means for controlling the transverse displacement of the bending head comprise, on the one hand, a mechanism with threaded rod and nut, with rotary drive of one of these elements, for the initial positioning of the bending head, and on the other hand a double-acting cylinder, for the offset of said bending head.

- the threaded rod is rotatably mounted and is engaged with a nut secured to the bending head, this threaded rod being linked in rotation with a primary drive shaft relative to which it is axially displaceable, while that the double-acting cylinder, arranged coaxially with the threaded rod, comprises an annular piston axially linked to the threaded rod.

- the annular piston is advantageously secured to a sleeve which slides in the two flanges of the jack and which is connected in translation with the rotary threaded rod by means of at least one bearing.

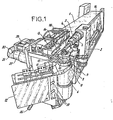

- the machine for bending tubes shown in the drawing, comprises an elongated frame (1) which supports longitudinal guides along which a carriage (2) can be moved in the horizontal direction. At the upper part of the carriage (2) is provided a clamping mandrel (3), able to pinch the bending tube (4) while maintaining it along a determined horizontal axis (5), while allowing the advancement of this tube (4) along the axis (5) and its rotation around said axis (5).

- a bending head (6) mounted horizontally movable, in a direction transverse to the frame (1).

- the tool which allows the bending to be carried out mainly comprises: a forming roller (7) with a vertical axis (8), having an annular groove (9) and supporting a first jaw (10) - a second jaw (11), carried by a bending arm (12) pivotally mounted about the vertical axis (8) - a strip (13) extending parallel to the horizontal axis (5) and having a longitudinal groove (14).

- This tool is completed by an olive (15) placed at the end of a horizontal rod (16) which passes through the clamping mandrel (3) and is introduced into the tube to be bent (4).

- the bending head (6) to which the vertical axis (8) is linked, is slidably mounted, by a dovetail part (17), along two sliders with inclined faces (18,19) fixed at the front of the frame (1) - see in particular figure 3.

- an electric motor (20) is provided which, by means of a reduction gear speed (21), rotates a primary shaft (22) hollow over a part of its length where it has internal longitudinal grooves. The latter are engaged with a grooved part (23) of a rotary threaded rod (24), coaxial with the shaft (22) and itself engaged with a nut (25) immobilized in rotation in the bending head.

- (6) - see figures 2 and 3.

- the speed reducer housing (21) is integral with the rear flange (26) of a double-acting cylinder (27) whose body (28), coaxial with the shaft (22) , is closed at the front by another flange (29).

- an annular piston (30) integral with a sleeve (31) which slides in the two flanges (26,29).

- the sleeve (31) is closed by a cover (32) which is crossed by the primary shaft (22).

- the front end of the sleeve (31) is linked in translation with the threaded rod (24), by means of bearings (33) and suitable stops.

- Channels (34, 35) are drilled in the two flanges (26, 29), to supply fluid to the two chambers of the jack (27) located on either side of the annular piston (30) - see figure 2.

- the strip (13) is movable relative to the frame (1) in a longitudinal direction, under the control of a feed cylinder (38), and also in a transverse direction, under the control of a cylinder approach (39).

- the bending head (6) with the forming roller (7) and the bending arm (12), is adjustable in transverse position by means of the motor (20), via the reduction gear (21), the primary shaft (22), threaded rod (24) and nut (25).

- the transverse movement of the bending head (6) thus controlled, makes it possible to position the vertical axis (8) adequately as a function of the diameter of the forming roller (7), itself chosen according to the characteristics desired for the elbow to train.

- the jack (27) makes it possible to move the bending head (6), still in transverse direction, over a stroke (C) determined so as to obtain an offset of this head (6), allowing free rotation of the tube to bend (4), in particular in the case of a tube of non-circular section, for example a tube (4) of square section.

- the displacement of the strip (13) is controlled independently of that of the bending head (6), by means of the two jacks (38, 39).

- the jack (36) makes it possible to raise the second jaw (11), to place it opposite the first jaw (10), or to lower it by moving it away from the first jaw (10), in order to allow the introduction of the bending tube. (4).

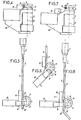

- FIGS. 4 to 12 show the successive stages of the double bending of a tube (4) of square section, on the bending machine object of the invention.

- the initially straight tube (4) is assumed, at the start, to be positioned in an angular position defined along the horizontal axis (5), and clamped by the mandrel (3) as well as, in its part to be bent first, by the two jaws (10.11).

- the bending arm (12) is initially oriented perpendicular to the axis (5), and the strip (13) is applied against the tube (4), behind the second jaw (11) - see Figures 4 and 5.

- the first bending of the tube (4) is then carried out, by controlling the rotation of the bending arm (12) around the vertical axis (8) according to the desired angle, the tube (4) then bending while being guided in the groove (9) of the forming roller (7) - see Figure 6. Then the second jaw (11) is retracted, and the bending arm (12) is returned to its initial angular position - see Figure 7. The strip (13) is moved away from the tube (4) which then has a first bend (40). The carriage with the mandrel (3) is advanced, so as to push the tube (4) forward, releasing the elbow (40) from the roller (7) - see Figure 8.

- the next phase consists in actuating the jack (27) in a given direction, which shifts the entire bending head (6) by the distance (C) relative to the horizontal axis (5) - see Figure 9.

- the tube (4) thus freed, is turned using the clamping mandrel (3) around the axis (5) according to the arrow (41 ), for example at an angle of rotation of 180 ° so that its end previously bent to the right is turned to the left - see Figures 9 and 10.

- the bending head (6) is reset to its initial position by actuating the jack (27) in the opposite direction; the second jaw (11) is again clamped against the tube (4) - see figure 11.

- the strip (13) is also applied again against the tube (4), and the bending arm (12) is actuated as previously.

- a second bend (42) is thus produced, in a direction opposite to the first and, in the case taken here for example, situated in the same plane as the first 'bend (40) - see FIG. 12.

- the offset of the bending head (6), controlled by the jack (27), can also be used to facilitate a change of jaws (10), for example during the production of close bends requiring the installation of recovery jaw on the forming roller (7).

- the machine according to the invention applies not only to the bending of tubes (4) of all sections, but also to the bending of bars, profiles and other similar objects.

- the invention is not limited to the sole embodiment of this machine for bending tubes, bars or profiles which has been described above, by way of example; on the contrary, it embraces all of the variant embodiments and applications respecting the same principle.

- the jack (27) can be replaced by any equivalent means, making it possible to control an offset of the bending head (6).

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Bending Of Plates, Rods, And Pipes (AREA)

Abstract

Description

La présente invention se rapporte à une machine destinée au cintrage de tubes, barres ou profilés. Plus particulièrement, cette invention concerne une machine dans laquelle l'outillage de cintrage comprend principalement un galet formeur rotatif d'axe vertical, présentant une gorge annulaire et supportant un premier mors - un second mors porté par un bras de cintrage monté pivotant autour de l'axe vertical précité, le second mors étant apte à être amené en regard du premier mors de manière à enserrer le tube ou similaire à cintrer - une réglette horizontale apte à être appliquée contre le tube ou similaire à cintrer, en arrière des mors, cette réglette étant déplaçable, en restant parallèle à elle-même, dans le sens de son rapprochement ou de son éloignement de l'axe horizontal suivant lequel est positionné le tube ou similaire à cintrer.The present invention relates to a machine intended for bending tubes, bars or profiles. More particularly, this invention relates to a machine in which the bending tool mainly comprises a rotary forming roller of vertical axis, having an annular groove and supporting a first jaw - a second jaw carried by a bending arm mounted pivoting around the vertical axis mentioned above, the second jaw being able to be brought opposite the first jaw so as to grip the tube or the like to bend - a horizontal strip able to be applied against the tube or the like to bend, behind the jaws, this strip being movable, remaining parallel to itself, in the direction of its approach or its distance from the horizontal axis along which is positioned the tube or the like to bend.

Dans une machine à cintrer de ce genre, la partie du tube devant être cintrée est serrée entre les deux mors et entraînée en avant par la rotation du bras de cintrage, de manière à s'enrouler dans la gorge du galet formeur. L'angle de rotation du bras détermine l'angle de cintrage, et le rayon du galet formeur détermine le rayon du coude que présentera finalement le tube. La réglette mobile, appliquée contre le tube en arrière de la partie à cintrer, évite toute déformation non désirée du tube en dehors de la partie à cintrer.In a bending machine of this kind, the part of the tube to be bent is clamped between the two jaws and driven forward by the rotation of the bending arm, so as to wind in the groove of the forming roller. The angle of rotation of the arm determines the angle of bending, and the radius of the forming roller determines the radius of the elbow that the tube will ultimately have. The movable strip, applied against the tube behind the part to be bent, avoids any unwanted deformation of the tube outside the part to be bent.

Dans certaines machines actuelles du genre ici considéré, une tête de cintrage, mobile suivant la direction transversale du bâti de la machine, supporte tout l'outillage de cintrage, c'est-à-dire le galet formeur avec le premier mors, le bras de cintrage portant le second mors, et la réglette. Le tube à cintrer est pincé, dans sa partie restant rectiligne, par un mandrin de serrage porté par un chariot déplaçable en direction longitudinale, qui maintient cette partie du tube positionnée suivant un axe horizontal déterminé, parallèle à la direction longitudinale du bâti de la machine.In some current machines of the kind considered here, a bending head, movable in the transverse direction of the frame of the machine, supports all the bending tools, that is to say the forming roller with the first jaw, the arm of bending carrying the second jaw, and the strip. The tube to be bent is pinched, in its part remaining rectilinear, by a clamping mandrel carried by a carriage movable in longitudinal direction, which keeps this part of the tube positioned along a determined horizontal axis, parallel to the longitudinal direction of the frame of the machine. .

Avec une telle construction, lorsque l'on doit changer de rayon de cintrage, il est nécessaire de refaire un réglage complet de la machine, l'opération de réglage en question étant longue et devant être répétée souvant dans le cas de travaux en petites séries. En particulier, si la tête de cintrage est déplacée transversalement de manière à permettre la mise en place d'un galet formeur de plus grand diamètre, la réglette entraînée par le déplacement de la tête de cintrage est amenée dans une position incorrecte, et doit être ramenée en position convenable par rapport à l'axe horizontal fixe suivant lequel est positionné le tube à cintrer. De plus, la disposition connue ici rappelée interdit pratiquement toute rotation du tube entre deux cintrages successifs, notamment dans le cas d'un tube de section non circulaire, ainsi que tout changement rapide de mors en laissant le tube en place.With such a construction, when it is necessary to change the bending radius, it is necessary to redo a complete adjustment of the machine, the adjustment operation in question being long and having to be repeated often in the case of work in small series . In particular, if the bending head is moved transversely so as to allow the establishment of a forming roller of larger diameter, the strip driven by the movement of the bending head is brought into an incorrect position, and must be brought back to a suitable position with respect to the fixed horizontal axis along which the tube to be bent is positioned. In addition, the arrangement known here recalled practically prohibits any rotation of the tube between two successive bends, in particular in the case of a tube of non-circular section, as well as any rapid change of jaws leaving the tube in place.

La présente invention évite ces inconvénients.The present invention avoids these drawbacks.

A cet effet, dans la machine pour le cintrage de tubes, barres ou profilés objet de l'invention, l'ensemble comprenant le galet formeur et le premier mors associé, ainsi que le bras de cintrage pivotant avec le second mors, est porté par une tête de cintrage déplaçable, sous l'action de moyens de commande, en direction horizontale transversalement au bâti de la machine et à l'axe suivant lequel est positionné le tube ou similaire à cintrer, tandis que la réglette mobile, avec ses moyens de commande de déplacement, est montée directement sur le bâti de la machine, sans liaison avec la tête de cintrage. La réglette est ainsi entièrement dissociée de la tête de cintrage qui supporte le galet formeur, le bras de cintrage et les deux mors.To this end, in the machine for bending tubes, bars or profiles object of the invention, the assembly comprising the forming roller and the first associated jaw, as well as the bending arm pivoting with the second jaw, is carried by a movable bending head, under the action of control means, in a horizontal direction transversely to the frame of the machine and to the axis along which the tube or the like to be bent is positioned, while the movable strip, with its means of movement control, is mounted directly on the machine frame, without connection to the bending head. The strip is thus completely dissociated from the bending head which supports the forming roller, the bending arm and the two jaws.

De préférence, les moyens de com:nande du déplacement transversal de la tête de cintrage, portant le galet formeur, le bras de cintrage et les deux mors, comprennent d'une part un moyen de commande pour le positionnement initial de la tête de cintrage, plaçant l'axe vertical du galet formeur dans la position appropriée en fonction du rayon de ce galet, et d'autre part un moyen de commande pour le décalage de ladite tête de cintrage, apte à écarter l'axe du galet formeur de l'axe suivant lequel est positionné le tube ou similaire à cintrer.Preferably, the means for controlling the transverse displacement of the bending head, carrying the forming roller, the bending arm and the two jaws, comprise on the one hand a control means for the initial positioning of the bending head , placing the vertical axis of the forming roller in the appropriate position as a function of the radius of this roller, and on the other hand a control means for the offset of said bending head, capable of spreading the axis of the forming roller from the 'axis along which is positioned the tube or the like to bend.

Grâce à cette disposition, le réglage initial de position de l'axe vertical du galet formeur, en fonction du diamètre de ce galet, peut être effectué sans influencer la position de la réglette qui est montée sur un support indépendant de la tête de cintrage. Ainsi, il n'est pas nécessaire de ramener par exemple la réglette en arrière dans le cas où l'axe du galet formeur a été avancé pour effectuer un cintrage suivant un rayon plus grand. De plus, lorsque la machine est utilisée pour obtenir des coudes d'un rayon donné, la commande de décalage delà tête de cintrage permet de dégager du tube le galet formeur et le premier mors, ce qui permet de modifier aisément l'orientation du tube entre deux opérations successives de cintrage, même s'il s'agit d'un tube de section par exemple carrée. Le décalage de la tête de cintrage facilite aussi un éventuel changement de mors entre deux opérations successives de cintrage.Thanks to this arrangement, the initial position adjustment of the vertical axis of the forming roller, as a function of the diameter of this roller, can be carried out without influencing the position of the strip which is mounted on a support independent of the bending head. Thus, it is not necessary to bring the strip back, for example, in the case where the axis of the forming roller has been advanced to perform bending along a larger radius. In addition, when the machine is used to obtain bends of a given radius, the shifting control of the bending head makes it possible to release the forming roller and the first jaw from the tube, which makes it possible to easily modify the orientation of the tube. between two successive bending operations, even if it is a section tube for example square. The offset of the bending head also facilitates a possible change of jaw between two successive bending operations.

Suivant une forme de réalisation particulière de l'invention, les moyens de commande du déplacement transversal de la tête de cintrage comprennent, d'une part, un mécanisme à tige filetée et écrou, avec entraînement rotatif de l'un de ces éléments, pour le positionnement initial de la tête de cintrage, et d'autre part un vérin à double effet, pour le décalage de ladite tête de cintrage. Dans un mode de construction particulier, la tige filetée est montée rotative et est en prise avec un écrou solidaire de la tête de cintrage, cette tige filetée étant liée en rotation avec un arbre primaire d'entraînement par rapport auquel elle est déplaçable axialement, tandis que le vérin à double effet, disposé coaxialement à la tige filetée, comporte un piston annulaire lié axialement à la tige filetée. Le piston annulaire est avantageusement solidaire d'un manchon qui coulisse dans les deux flasques du vérin et qui est lié en translation avec la tige filetée rotative par l'intermédiaire d'au moins un roulement. Quelle que soit la position initiale imposée à la tête de cintrage par le mécanisme à tige filetée et écrou, l'actionnement du vérin dans un sens donné décale la tige filetée donc l'ensemble de la tête de mesure. Le vérin étant à double effet, son actionnement dans le sens inverse ramène la tête de' cintrage dans sa position initiale.According to a particular embodiment of the invention, the means for controlling the transverse displacement of the bending head comprise, on the one hand, a mechanism with threaded rod and nut, with rotary drive of one of these elements, for the initial positioning of the bending head, and on the other hand a double-acting cylinder, for the offset of said bending head. In a particular construction method, the threaded rod is rotatably mounted and is engaged with a nut secured to the bending head, this threaded rod being linked in rotation with a primary drive shaft relative to which it is axially displaceable, while that the double-acting cylinder, arranged coaxially with the threaded rod, comprises an annular piston axially linked to the threaded rod. The annular piston is advantageously secured to a sleeve which slides in the two flanges of the jack and which is connected in translation with the rotary threaded rod by means of at least one bearing. Whatever the initial position imposed on the bending head by the threaded rod and nut mechanism, actuation of the cylinder in a given direction shifts the threaded rod and therefore the entire measuring head. The cylinder being double-acting, its actuation in the opposite direction brings the head of the bending in its initial position.

De toute façon, l'invention sera mieux comprise à l'aide de la description qui, suit, en référence au dessin schématique annexé représentant, à titre d'exemple non limitatif, une forme d'exécution de cette machine pour le cintrage de tubes, barres ou profilés :

- Figure 1 est une vue d'ensemble, en perspective, d'une machine conforme à la présente invention ;

- Figure 2 est une vue en bout, partiellement en coupe, de cette machine ;

- Figure 3 en est une vue en coupe, suivant 3-3 de figure 2 ;

- Figures 4 à 12 sont des schémas, en vue de face ou en plan par dessus, illustrant les étapes de fonctionnement successives de la machine dans le cas du double cintrage d'un tube de section carrée.

- Figure 1 is an overall perspective view of a machine according to the present invention;

- Figure 2 is an end view, partially in section, of this machine;

- Figure 3 is a sectional view along 3-3 of Figure 2;

- Figures 4 to 12 are diagrams, in front view or in plan from above, illustrating the successive stages of operation of the machine in the case of double bending of a tube of square section.

La machine pour le cintrage de tubes, représentée au dessin, comprend un bâti allongé (1) qui supporte des guides longitudinaux le long desquels est déplaçable, en direction horizontale, un chariot (2). A la partie supérieure du chariot (2) est prévu un mandrin de serrage (3), apte à pincer le tube à cintrer (4) en le maintenant suivant un axe horizontal (5) déterminé, tout en permettant l'avancement de ce tube (4) le long de l'axe (5) ainsi que sa rotation autour dudit axe (5).The machine for bending tubes, shown in the drawing, comprises an elongated frame (1) which supports longitudinal guides along which a carriage (2) can be moved in the horizontal direction. At the upper part of the carriage (2) is provided a clamping mandrel (3), able to pinch the bending tube (4) while maintaining it along a determined horizontal axis (5), while allowing the advancement of this tube (4) along the axis (5) and its rotation around said axis (5).

A l'avant du bâti (1) de la machine, est prévue une tête de cintrage (6) montée mobile horizontalement, suivant une direction transversale au bâti (1). L'outillage qui permet de réaliser le cintrage comprend principalement : un galet formeur (7) d'axe vertical (8), présentant une gorge annulaire (9) et supportant un premier mors (10) - un second mors (11), porté par un bras de cintrage (12) monté pivotant autour de l'axe vertical (8) - une réglette (13) s'étendant parallèlement à l'axe horizontal (5) et présentant une gorge longitudinale (14). Cet outillage est complété par une olive (15) placée à l'extrémité d'une tige horizontale (16) qui traverse le mandrin de serrage (3) et est introduite dans le tube à cintrer (4).At the front of the frame (1) of the machine, there is provided a bending head (6) mounted horizontally movable, in a direction transverse to the frame (1). The tool which allows the bending to be carried out mainly comprises: a forming roller (7) with a vertical axis (8), having an annular groove (9) and supporting a first jaw (10) - a second jaw (11), carried by a bending arm (12) pivotally mounted about the vertical axis (8) - a strip (13) extending parallel to the horizontal axis (5) and having a longitudinal groove (14). This tool is completed by an olive (15) placed at the end of a horizontal rod (16) which passes through the clamping mandrel (3) and is introduced into the tube to be bent (4).

La tête de cintrage (6), à laquelle est lié l'axe vertical (8), est montée coulissante, par une partie en queue d'aronde (17), le long de deux glissières à faces inclinées (18,19) fixées à l'avant du bâti (1) - voir notamment figure 3. Pour la commande de déplacement en translation de la tête de cintrage (6), il est prévu un moteur électrique (20) qui, par l'intermédiaire d'un réducteur de vitesse (21), entraîne en rotation un arbre primaire (22) creux sur une partie de sa longueur où il présente des cannelures longitudinales intérieures. Ces dernières sont en prise avec une partie cannelée (23) d'une tige filetée rotative (24), coaxiale à l'arbre (22) et elle-même en prise avec un écrou (25) immobilisé en rotation dans la tête de cintrage (6) - voir figures 2 et 3.The bending head (6), to which the vertical axis (8) is linked, is slidably mounted, by a dovetail part (17), along two sliders with inclined faces (18,19) fixed at the front of the frame (1) - see in particular figure 3. For the control of translational movement of the bending head (6), an electric motor (20) is provided which, by means of a reduction gear speed (21), rotates a primary shaft (22) hollow over a part of its length where it has internal longitudinal grooves. The latter are engaged with a grooved part (23) of a rotary threaded rod (24), coaxial with the shaft (22) and itself engaged with a nut (25) immobilized in rotation in the bending head. (6) - see figures 2 and 3.

Le carter du réducteur de vitesse (21) est solidaire du flasque arrière (26) d'un vérin à double effet (27) dont le corps (28), coaxial à l'arbre (22), est fermé à l'avant par un autre flasque (29). A l'intérieur du corps (28) est monté coulissant un piston annulaire (30), solidaire d'un manchon (31) qui coulisse dans les deux flasques (26,29). A son extrémité arrière, le manchon (31) est ferme par un capot (32) qui est traversé par l'arbre primaire (22). L'extrémité avant du manchon (31) est liée en translation avec la tige filetée (24), par l'intermédiaire de roulements (33) et de butées convenables. Des canaux (34,35) sont percés dans les deux flasques (26, 29), pour alimenter en fluide les deux chambres du vérin (27) situées de part et d'autre du piston annulaire (30) - voir figure 2.The speed reducer housing (21) is integral with the rear flange (26) of a double-acting cylinder (27) whose body (28), coaxial with the shaft (22) , is closed at the front by another flange (29). Inside the body (28) is slidably mounted an annular piston (30), integral with a sleeve (31) which slides in the two flanges (26,29). At its rear end, the sleeve (31) is closed by a cover (32) which is crossed by the primary shaft (22). The front end of the sleeve (31) is linked in translation with the threaded rod (24), by means of bearings (33) and suitable stops. Channels (34, 35) are drilled in the two flanges (26, 29), to supply fluid to the two chambers of the jack (27) located on either side of the annular piston (30) - see figure 2.

D'autres moyens d'entraînement, non représentés, commandent la rotation du bras de cintrage (12) autour de l'axe vertical (8). Un vérin (36), logé dans l'épaisseur du bras (12), permet de relever ou d'abaisser le second mors (11), l'abaissement de celui-ci s'accompagnant d'un certain recul grâce à des glissières en arc de cercle (37) - voir figure 1.Other drive means, not shown, control the rotation of the bending arm (12) about the vertical axis (8). A jack (36), housed in the thickness of the arm (12), makes it possible to raise or lower the second jaw (11), the lowering of the latter being accompanied by a certain recoil thanks to slides in an arc (37) - see figure 1.

Enfin, la réglette (13) est déplaçable relativement au bâti (1) suivant une direction longitudinale, sous la commande d'un vérin d'avance (38), et aussi suivant une direction transversale, sous la commande d'un vérin d'approche (39).Finally, the strip (13) is movable relative to the frame (1) in a longitudinal direction, under the control of a feed cylinder (38), and also in a transverse direction, under the control of a cylinder approach (39).

La tête de cintrage (6), avec le galet formeur (7) et le bras de cintrage (12), est réglable en position transversale au moyen du moteur (20), par l'intermédiaire du réducteur (21), de l'arbre primaire (22), de la tige filetée (24) et de l'écrou (25). Le déplacement transversal de la tête de cintrage (6), ainsi commandé, permet de positionner de manière adéquate l'axe vertical (8) en fonction du diamètre du galet formeur (7), lui-même choisi selon les caractéristiques désirées pour le coude à former.The bending head (6), with the forming roller (7) and the bending arm (12), is adjustable in transverse position by means of the motor (20), via the reduction gear (21), the primary shaft (22), threaded rod (24) and nut (25). The transverse movement of the bending head (6), thus controlled, makes it possible to position the vertical axis (8) adequately as a function of the diameter of the forming roller (7), itself chosen according to the characteristics desired for the elbow to train.

En outre, le vérin (27) permet de déplacer la tête de cintrage (6), toujours en direction transversale, sur une course (C) déterminée de manière à obtenir un décalage de cette tête (6), permettant la libre rotation du tube à cintrer (4), notamment dans le cas d'un tube de section non circulaire, par exemple un tube (4) de section carrée.In addition, the jack (27) makes it possible to move the bending head (6), still in transverse direction, over a stroke (C) determined so as to obtain an offset of this head (6), allowing free rotation of the tube to bend (4), in particular in the case of a tube of non-circular section, for example a tube (4) of square section.

Le déplaçement de la réglette (13) est commandé indépendamment de celui de la tête de cintrage (6), au moyen des deux vérins (38,39).The displacement of the strip (13) is controlled independently of that of the bending head (6), by means of the two jacks (38, 39).

Le vérin (36) permet de relever le second mors (11), pour le placer en regard du premier mors (10), ou de l'abaisser en l'écartant du premier mors (10), afin de permettre l'introduction du tube à cintrer . (4).The jack (36) makes it possible to raise the second jaw (11), to place it opposite the first jaw (10), or to lower it by moving it away from the first jaw (10), in order to allow the introduction of the bending tube. (4).

Ces fonctions diverses sont illustrées par les schémas des figures 4 à 12, montrant les étapes successives du double cintrage d'un tube (4) de section carrée, sur la machine à cintrer objet de l'invention.These various functions are illustrated by the diagrams of FIGS. 4 to 12, showing the successive stages of the double bending of a tube (4) of square section, on the bending machine object of the invention.

Le tube (4) initialement rectiligne est supposé, au départ, positionné dans une position angulaire définie suivant l'axe horizontal (5), et serré par le mandrin (3) ainsi que, dans sa partie à cintrer en premier lieu, par les deux mors (10.11). Le bras de cintrage (12) est initialement orienté perpendiculairement à l'axe (5), et la réglette (13) se trouve appliquée contre le tube (4), en arrière du second mors (11) - voir figures 4 et 5.The initially straight tube (4) is assumed, at the start, to be positioned in an angular position defined along the horizontal axis (5), and clamped by the mandrel (3) as well as, in its part to be bent first, by the two jaws (10.11). The bending arm (12) is initially oriented perpendicular to the axis (5), and the strip (13) is applied against the tube (4), behind the second jaw (11) - see Figures 4 and 5.

Le premier cintrage du tube (4) est alors effectué, en commandant la rotation du bras de cintrage (12) autour de l'axe vertical (8) selon l'angle désiré, le tube (4) s'incurvant alors en étant guidé dans la gorge (9) du galet formeur (7) - voir figure 6. Ensuite, le second mors (11) est escamoté, et le bras de cintrage (12) est ramené dans sa position angulaire initiale - voir figure 7. La réglette (13) est écartée du tube (4) qui présente alors un premier coude (40). Le chariot avec le mandrin (3) est avancé, de manière à pousser le tube (4) vers l'avant, en dégageant le coude (40) du galet (7) - voir figure 8.The first bending of the tube (4) is then carried out, by controlling the rotation of the bending arm (12) around the vertical axis (8) according to the desired angle, the tube (4) then bending while being guided in the groove (9) of the forming roller (7) - see Figure 6. Then the second jaw (11) is retracted, and the bending arm (12) is returned to its initial angular position - see Figure 7. The strip (13) is moved away from the tube (4) which then has a first bend (40). The carriage with the mandrel (3) is advanced, so as to push the tube (4) forward, releasing the elbow (40) from the roller (7) - see Figure 8.

Pour dégager entièrement le tube (4) du galet formeur (7), la phase suivante consiste à actionner le vérin (27) dans un sens donné ce qui décale l'ensemble de la tête de cintrage (6) de la distance (C) par rapport à l'axe horizontal (5) - voir figure 9. Le tube (4), ainsi libéré, est tourné à l'aide du mandrin de serrage (3) autour de l'axe (5) suivant la flèche (41), par exemple selon un angle de rotation de 180° de sorte que son extrémité précédemment cintrée vers la droite se retrouve tournée vers la gauche - voir figures 9 et 10.To completely disengage the tube (4) from the forming roller (7), the next phase consists in actuating the jack (27) in a given direction, which shifts the entire bending head (6) by the distance (C) relative to the horizontal axis (5) - see Figure 9. The tube (4), thus freed, is turned using the clamping mandrel (3) around the axis (5) according to the arrow (41 ), for example at an angle of rotation of 180 ° so that its end previously bent to the right is turned to the left - see Figures 9 and 10.

Pour procéder à un deuxième cintrage du tube (4). après l'opération d'orientation, la tête de cintrage (6) est recalée dans sa position initiale en actionnant le vérin (27) dans le sens inverse ; le second mors (11) est de nouveau serré contre le tube (4) - voir figure 11. La réglette (13) est elle aussi appliquée de nouveau contre le tube (4), et le bras de cintrage (12) est actionné comme précédemment. On réalise ainsi un deuxième coude (42), de sens opposé au premier et, dans le cas pris ici pour exemple, situé dans le même plan que le premier' coude (40) - voir figure 12.To proceed to a second bending of the tube (4). after the orientation operation, the bending head (6) is reset to its initial position by actuating the jack (27) in the opposite direction; the second jaw (11) is again clamped against the tube (4) - see figure 11. The strip (13) is also applied again against the tube (4), and the bending arm (12) is actuated as previously. A second bend (42) is thus produced, in a direction opposite to the first and, in the case taken here for example, situated in the same plane as the first 'bend (40) - see FIG. 12.

Le décalage de la tête de cintrage (6), commandé par le vérin (27), peut également être mis à profit pour faciliter un changement de mors (10), par exemple lors de la réalisation de coudes rapprochés nécessitant la mise en place de mors de reprise sur le galet formeur (7).The offset of the bending head (6), controlled by the jack (27), can also be used to facilitate a change of jaws (10), for example during the production of close bends requiring the installation of recovery jaw on the forming roller (7).

La machine selon l'invention s'applique non seulement au cintrage de tubes (4) de toutes sections, mais aussi au cintrage de barres, de profilés et d'autres objets similaires.The machine according to the invention applies not only to the bending of tubes (4) of all sections, but also to the bending of bars, profiles and other similar objects.

Comme il va de soi et comme il résulte de ce qui précède, l'invention ne se limite pas à la seule forme d'exécution de cette machine pour le cintrage de tubes, barres ou profilés qui a été décrite ci-dessus, à titre d'exemple ; elle en embrasse, au contraire, toutes les variantes de réalisation et d'application respectant le même principe. En particulier, l'on ne s'éloignerait pas du cadre de l'invention en remplaçant le groupe moto-réducteur (20,21) par tout moyen de commande, motorisé ou manuel, pour le positionnement initial de la tête de cintrage (6). De même, le vérin (27) peut être remplacé par tout moyen équivalent, permettant de commander un décalage de la tête de cintrage (6).As is obvious and as follows from the above, the invention is not limited to the sole embodiment of this machine for bending tubes, bars or profiles which has been described above, by way of example; on the contrary, it embraces all of the variant embodiments and applications respecting the same principle. In particular, one would not depart from the scope of the invention by replacing the geared motor group (20,21) by any control means, motorized or manual, for the initial positioning of the bending head (6 ). Similarly, the jack (27) can be replaced by any equivalent means, making it possible to control an offset of the bending head (6).

Claims (6)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT85420086T ATE53950T1 (en) | 1984-07-10 | 1985-05-09 | MACHINE FOR BENDING TUBES, BARS OR PROFILES. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR8411321A FR2567429B1 (en) | 1984-07-10 | 1984-07-10 | MACHINE FOR BENDING TUBES, BARS OR PROFILES |

| FR8411321 | 1984-07-10 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0168331A2 true EP0168331A2 (en) | 1986-01-15 |

| EP0168331A3 EP0168331A3 (en) | 1986-10-08 |

| EP0168331B1 EP0168331B1 (en) | 1990-06-20 |

Family

ID=9306204

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP85420086A Expired - Lifetime EP0168331B1 (en) | 1984-07-10 | 1985-05-09 | Machine for bending of tubes, bars or profiles |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US4625531A (en) |

| EP (1) | EP0168331B1 (en) |

| JP (1) | JPS6138720A (en) |

| AT (1) | ATE53950T1 (en) |

| CA (1) | CA1291697C (en) |

| DE (1) | DE3578316D1 (en) |

| ES (1) | ES8607768A1 (en) |

| FR (1) | FR2567429B1 (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0319400A1 (en) * | 1987-12-02 | 1989-06-07 | Societe Nationale D'etude Et De Construction De Moteurs D'aviation, "S.N.E.C.M.A." | Pipe conduit bending machine and method of making a pipe conduit with a soldered joint |

| ITRM20130259A1 (en) * | 2013-05-02 | 2014-11-03 | Cml Int Spa | BENDING MACHINE OF THE MATRIX AND COUNTERMATCHING TYPE TO TURN RIGHT AND LEFT A PIECE STRETCHED |

Families Citing this family (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4959984A (en) * | 1989-08-17 | 1990-10-02 | Ap Parts Manufacturing Company | Precision bending apparatus |

| JP2947362B2 (en) * | 1989-09-07 | 1999-09-13 | 臼井国際産業株式会社 | Tube bending equipment |

| GB2247202B (en) * | 1990-07-26 | 1995-01-25 | Usui Kokusai Sangyo Kk | Method and apparatus for bending a small diameter metal tube |

| US5570508A (en) * | 1993-12-03 | 1996-11-05 | Itt Industries, Inc. | Method of making a high strength automotive seat frame |

| US6009737A (en) * | 1997-07-17 | 2000-01-04 | Arvin Industries, Inc. | Tube bender |

| US6155091A (en) * | 1999-02-26 | 2000-12-05 | Arvin Industries, Inc. | Mandrel assembly for tube-bending apparatus |

| NO311638B1 (en) | 1999-05-21 | 2001-12-27 | Skipskonsult As | Methods for Preparing Contiguous Stretches of Circular Cylindrical Bodies, Using a Tool, and Single Pipe Length and Pipe Parts |

| US6434995B1 (en) | 1999-10-15 | 2002-08-20 | Usui Kokusai Sangyo Kaisha Limited | Method of bending small diameter metal pipe and its apparatus |

| EP1380362B1 (en) * | 2002-07-13 | 2008-03-26 | Trumpf Werkzeugmaschinen GmbH + Co. KG | Tube bending machine with tube feed and mandrell pull back |

| JP4515056B2 (en) * | 2003-08-01 | 2010-07-28 | 三桜工業株式会社 | Pipe bending machine |

| IT1396456B1 (en) * | 2009-11-24 | 2012-11-23 | Piegatrici Macch Elettr | EQUIPMENT FOR BENDING OBLUNG METAL PRODUCTS, SUCH AS BARS, ROUNDS, OR METAL WIRES, AND RELATIVE BENDING PROCEDURE |

| ITRM20120619A1 (en) * | 2012-12-06 | 2014-06-07 | Libero Angelo Massaro | MACHINE PERFECTED TO CURVE METAL TUBES, BOTH ON THE RIGHT AND LEFT THROUGH THE DIRECTION OF TUBE INTRODUCTION. |

| US9908169B2 (en) * | 2013-09-06 | 2018-03-06 | Winton Machine Company | Process to cut coax cable |

| CN110202029B (en) * | 2019-06-18 | 2020-09-01 | 深圳市朗奥洁净科技股份有限公司 | Automatic numerical control multi-section bending device for pipes |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2537382A1 (en) * | 1975-08-22 | 1977-03-03 | Babcock Ag | DEVICE FOR BENDING PIPES |

| US4126030A (en) * | 1977-10-03 | 1978-11-21 | Eaton-Leonard Corporation | Retractable pressure die |

| US4178788A (en) * | 1978-03-24 | 1979-12-18 | Eaton-Leonard Corporation | Adjustable clamp die |

| DE2910174A1 (en) * | 1979-03-15 | 1980-09-25 | Benteler Werke Ag | Pipe bending and forming machine - bends pipes to different radii and has three forming rollers mounted on common shaft |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2740454A (en) * | 1952-10-02 | 1956-04-03 | Western Electric Co | Apparatus for making diagonal twisted or skew bends in wave guide tubing |

| DE1962590A1 (en) * | 1969-12-13 | 1971-06-24 | Hilgers Maschinen U App Bauans | Tube bending machine |

| DE2101162A1 (en) * | 1971-01-12 | 1972-07-20 | J. Banning Ag, 4700 Hamm | Tube bending machine |

| US4063441A (en) * | 1975-09-19 | 1977-12-20 | Eaton-Leonard Corporation | Apparatus for bending tubes |

| JPS5930325B2 (en) * | 1977-12-28 | 1984-07-26 | 日本電気株式会社 | isolator |

| JPS5858170B2 (en) * | 1979-06-20 | 1983-12-23 | 株式会社神戸製鋼所 | Shear press blade changing device |

-

1984

- 1984-07-10 FR FR8411321A patent/FR2567429B1/en not_active Expired - Lifetime

-

1985

- 1985-05-09 AT AT85420086T patent/ATE53950T1/en not_active IP Right Cessation

- 1985-05-09 EP EP85420086A patent/EP0168331B1/en not_active Expired - Lifetime

- 1985-05-09 DE DE8585420086T patent/DE3578316D1/en not_active Expired - Fee Related

- 1985-06-04 CA CA000483145A patent/CA1291697C/en not_active Expired - Fee Related

- 1985-06-12 ES ES85544059A patent/ES8607768A1/en not_active Expired

- 1985-07-09 US US06/753,314 patent/US4625531A/en not_active Expired - Fee Related

- 1985-07-09 JP JP14940085A patent/JPS6138720A/en active Pending

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2537382A1 (en) * | 1975-08-22 | 1977-03-03 | Babcock Ag | DEVICE FOR BENDING PIPES |

| US4126030A (en) * | 1977-10-03 | 1978-11-21 | Eaton-Leonard Corporation | Retractable pressure die |

| US4178788A (en) * | 1978-03-24 | 1979-12-18 | Eaton-Leonard Corporation | Adjustable clamp die |

| DE2910174A1 (en) * | 1979-03-15 | 1980-09-25 | Benteler Werke Ag | Pipe bending and forming machine - bends pipes to different radii and has three forming rollers mounted on common shaft |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0319400A1 (en) * | 1987-12-02 | 1989-06-07 | Societe Nationale D'etude Et De Construction De Moteurs D'aviation, "S.N.E.C.M.A." | Pipe conduit bending machine and method of making a pipe conduit with a soldered joint |

| FR2624038A1 (en) * | 1987-12-02 | 1989-06-09 | Snecma | PIPE BENDING TOOL AND METHOD FOR MANUFACTURING A WELDED TIP PIPE |

| ITRM20130259A1 (en) * | 2013-05-02 | 2014-11-03 | Cml Int Spa | BENDING MACHINE OF THE MATRIX AND COUNTERMATCHING TYPE TO TURN RIGHT AND LEFT A PIECE STRETCHED |

| EP2799158A1 (en) | 2013-05-02 | 2014-11-05 | CML International S.p.A. | Matrix and countermatrix type bending machine for right-hand and left-hand bending an elongated piece |

| US9878361B2 (en) | 2013-05-02 | 2018-01-30 | Cml International S.P.A. | Die and counter-die type bending machine for right-hand and left-hand bending an elongated piece |

Also Published As

| Publication number | Publication date |

|---|---|

| DE3578316D1 (en) | 1990-07-26 |

| FR2567429B1 (en) | 1992-03-27 |

| ES8607768A1 (en) | 1986-06-16 |

| US4625531A (en) | 1986-12-02 |

| CA1291697C (en) | 1991-11-05 |

| ES544059A0 (en) | 1986-06-16 |

| EP0168331A3 (en) | 1986-10-08 |

| EP0168331B1 (en) | 1990-06-20 |

| JPS6138720A (en) | 1986-02-24 |

| ATE53950T1 (en) | 1990-07-15 |

| FR2567429A1 (en) | 1986-01-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CA1291697C (en) | Bending machine for tubes, bars and shopes | |

| FR2530980A1 (en) | BENDER WITH MULTIPLE CURVES | |

| FR2575944A1 (en) | METHOD AND DEVICE FOR THE AUTOMATIC BENDING OF METALLIC TUBES | |

| EP0445044B1 (en) | Bending machine with two bending heads | |

| FR2630358A1 (en) | METHOD AND DEVICE FOR CONTROLLING THE ELASTIC RETURN AT THE BENDING OF AN INCREASED MEMBER SUCH AS A TUBE | |

| FR2747328A1 (en) | BENDING OR CAMPING MACHINE FOR A PROFILE, AND BENDING HEAD FOR SUCH A MACHINE | |

| WO2001074509A1 (en) | Bending machine for rods with resettable folding shank | |

| CA2641071A1 (en) | Device for bending tubes or profiled sections with symmetrical structure for two-way bending and machine equipped with same | |

| EP0141745B1 (en) | Automatic machine for bending thin and rectilinear elements, especially metal wire, into a spatial configuration | |

| EP0242309B1 (en) | Bending press with pivoting beam | |

| WO2008142252A2 (en) | Tube cambering unit | |

| CH647360A5 (en) | METHOD AND DEVICE FOR PRODUCING AN ELECTRIC CONNECTOR PIN. | |

| WO2010116052A1 (en) | Bending machine for the production of bent profile sections, in particular for exchanger tubes | |

| FR2685239A1 (en) | Machine for machining workpieces from very long sections | |

| FR2676947A1 (en) | Numerical-control machine for cutting metal sheets and tubes | |

| EP0281488A1 (en) | Turning bending head for a tube-bending machine | |

| EP1051268B1 (en) | Tube bending machine and magazine device thereof | |

| EP0320408B1 (en) | Control device for the reglet of a tube-bending machine | |

| EP0043750A1 (en) | Apparatus for forming tubes of small diameter | |

| EP0114774B1 (en) | Loader and unloader for work pieces with a single driving motor | |

| FR2483269A1 (en) | Reel unwinding starter and guide - has starting head passing under reel end actuated by hydraulic jack mounted on frame | |

| EP1904245A1 (en) | Crimping head | |

| FR2495972A1 (en) | MACHINE FOR BENDING TUBES | |

| FR2685228A1 (en) | Machine for bending a rod-, bar-, tube-, wire- or similar-type element | |

| EP0109905B1 (en) | Apparatus for bending tubes |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE GB IT LI LU NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE GB IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19870122 |

|

| 17Q | First examination report despatched |

Effective date: 19880121 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: EATON LEONARD PICOT S.A. |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE GB IT LI LU NL SE |

|

| REF | Corresponds to: |

Ref document number: 53950 Country of ref document: AT Date of ref document: 19900715 Kind code of ref document: T |

|

| ITF | It: translation for a ep patent filed |

Owner name: BARZANO' E ZANARDO MILANO S.P.A. |

|

| REF | Corresponds to: |

Ref document number: 3578316 Country of ref document: DE Date of ref document: 19900726 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| ITTA | It: last paid annual fee | ||

| 26N | No opposition filed | ||

| EPTA | Lu: last paid annual fee | ||

| EAL | Se: european patent in force in sweden |

Ref document number: 85420086.2 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 19950501 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19950505 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19950510 Year of fee payment: 11 Ref country code: BE Payment date: 19950510 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19950515 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19950516 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19950530 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19950531 Year of fee payment: 11 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19960509 Ref country code: GB Effective date: 19960509 Ref country code: AT Effective date: 19960509 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19960510 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19960531 Ref country code: CH Effective date: 19960531 Ref country code: BE Effective date: 19960531 |

|

| BERE | Be: lapsed |

Owner name: S.A. EATON LEONARD PICOT Effective date: 19960531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19961201 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19960509 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19970201 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 85420086.2 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 19961201 |