WO2014164381A1 - Method of drilling boreholes with invert emulsion drilling fluids characterized by flat rheology - Google Patents

Method of drilling boreholes with invert emulsion drilling fluids characterized by flat rheology Download PDFInfo

- Publication number

- WO2014164381A1 WO2014164381A1 PCT/US2014/022214 US2014022214W WO2014164381A1 WO 2014164381 A1 WO2014164381 A1 WO 2014164381A1 US 2014022214 W US2014022214 W US 2014022214W WO 2014164381 A1 WO2014164381 A1 WO 2014164381A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- drilling

- drilling fluid

- fluid

- invert emulsion

- lime

- Prior art date

Links

Classifications

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K8/00—Compositions for drilling of boreholes or wells; Compositions for treating boreholes or wells, e.g. for completion or for remedial operations

- C09K8/02—Well-drilling compositions

- C09K8/32—Non-aqueous well-drilling compositions, e.g. oil-based

- C09K8/36—Water-in-oil emulsions

Definitions

- the present invention relates to compositions and methods for drilling, cementing and casing boreholes in subterranean formations, particularly hydrocarbon bearing formations. More particularly, the present invention relates to methods for improving the rheology of invert emulsion drilling fluids, particularly at broad temperature ranges such as encountered in deep water, and to compositions for invert emulsion drilling fluids with good stability and high performance properties.

- a drilling fluid or mud is a specially designed fluid that is circulated through a wellbore as the wellbore is being drilled to facilitate the drilling operation.

- the various functions of a drilling fluid include removing drill cuttings from the wellbore, cooling and lubricating the drill bit, aiding in support of the drill pipe and drill bit, and providing a hydrostatic head to maintain the integrity of the wellbore walls and prevent well blowouts.

- drilling fluid An important property of the drilling fluid is its rheology, and specific rheological parameters are intended for drilling and circulating the fluid through the well bore.

- the fluid should be sufficiently viscous to suspend barite and drilled cuttings and to carry the cuttings to the well surface. However, the fluid should not be so viscous as to interfere with the drilling operation.

- Specific drilling fluid systems are selected to optimize a drilling operation in accordance with the characteristics of a particular geological formation.

- Oil based muds are normally used to drill swelling or sloughing shales, salt, gypsum, anhydrite and other evaporate formations, hydrogen sulfide-containing formations, and hot (greater than about 300 degrees Fahrenheit (“° F") holes, but may be used in other holes penetrating a subterranean formation as well.

- An oil-based or invert emulsion-based drilling fluid may commonly comprise between about 50:50 to about 95:5 by volume oil phase to water phase.

- Such oil-based muds used in drilling typically comprise: a base oil comprising the external phase of an invert emulsion; a saline, aqueous solution (typically a solution comprising about 30% calcium chloride) comprising the internal phase of the invert emulsion; emulsifiers at the interface of the internal and external phases; and other agents or additives for suspension, weight or density, oil-wetting, fluid loss or filtration control, and rheology control.

- additives commonly included organophilic clays and organophilic lignites.

- the term "clay- free” means a drilling fluid formulated without addition of any organophilic clays or organophilic lignites to the drilling fluid composition.

- such "clay- free” drilling fluids may acquire clays and/or lignites from the formation or from mixing with recycled fluids containing clays and/or lignites.

- contamination of "clay-free” drilling fluids is preferably avoided and organophilic clays and organophilic lignites should not be deliberately added to "clay-free” drilling fluids during drilling.

- Invert emulsion-based muds or drilling fluids (also called invert drilling muds or invert muds or fluids) comprise a key segment of the drilling fluids industry, and "clay- free” invert emulsion-based muds, particularly those capable of "fragile gel” behavior as described in U.S. Patent Nos. 7,462,580 and 7,488,704 to Kirsner, et al., are becoming increasingly popular.

- "Fragile gel” behavior or "fragile gel” strength generally refers to the ability of the drilling fluid to both suspend drill cuttings at rest and show a lack of a pressure spike upon resumption of drilling.

- Clay-free invert emulsion drilling fluids like INNOVERT® drilling fluid available from Halliburton Energy Services, Inc., in Duncan, Oklahoma and Houston, Texas, for example, have been shown to yield high performance in drilling, with "fragile gel” strengths and rheology leading to lower equivalent circulating density (ECDs) and improved rate of penetration (ROP).

- ECDs equivalent circulating density

- ROP improved rate of penetration

- a limiting factor in drilling a particular portion of a well is the mud weight

- a particularly critical drilling scenario is one that combines deepwater and shallow overburden, as is typical of ultra deepwater fields in Brazil.

- clay-free invert emulsion drilling fluids may have less than preferred rheology at low mud weights, that is, mud weights ranging from about 9 ppg to about 12 ppg, with temperatures up to about 375 °F or higher.

- Addition of inert solids may improve the rheology, but result in a decreased rate of penetration during drilling and loss of or decline in other benefits seen with a clay free system.

- Such inert solids include for example, fine sized calcium carbonate, and the term as used herein is not meant to be understood to include or refer to drill cuttings.

- Low mud weight or reduced density clay-free oil based invert emulsion drilling fluids also may show a decline in the desired "fragile gel" strength characteristic of clay-free invert emulsion drilling fluids.

- low rheology invert emulsion drilling fluids are used for deepwater drilling at cold temperatures (typically about 40°F). Thinners are typically added to an invert emulsion drilling fluid for use in deepwater cold temperatures (typically about 40°F), to prevent a substantial increase in the rheology of the fluid. Low rheology, however, affects the drilling fluid's ability to clean the borehole and the fluid's ability to suspend barite and drill cuttings.

- An ideal deepwater invert emulsion drilling fluid exhibits sufficiently high and similar rheology from the rig floor to the riser and along the depth of the well. Such an invert emulsion drilling fluid is typically called a "flat rheology drilling fluid" or a "flat rheology fluid.”

- An invert emulsion drilling fluid having and maintaining a similar rheology along the depth of a borehole would lead to controlled equivalent circulating densities (ECDs) along the depth of the well-bore.

- ECDs equivalent circulating densities

- the improved flow properties of such a fluid having similar or flat rheology would reduce the equivalent circulating density (ECD) and subsequent losses of the fluid to induced fractures in the subterranean formation.

- the yield point (YP) of the fluid would be easily maintained and this would contribute to efficient cuttings clearance.

- There would be a reduced pressure drop in the drill pipe and increased pump output in using such a fluid which would also improve hole cleaning and reduce the cuttings load.

- the present invention provides oil-based invert emulsion drilling fluids with improved rheology at temperatures ranging from about 40°F to about 375 °F or higher.

- the drilling fluids of the present invention provide a relatively controlled rheology that does not increase to levels that may fracture a subterranean formation when reduced temperatures and increased pressures are encountered, such as may occur in deepwater (at least about 1000 ft depth).

- the drilling fluids of the present invention also exhibit similar yield points and gel strengths at temperatures ranging from about 40°F to about 375°F or higher in a typical well.

- the present invention also provides improved methods of drilling wellbores in subterranean formations employing oil-based invert emulsion muds or drilling fluids having a relatively flat rheological profile over a broad temperature range.

- drilling or “drilling wellbores” shall be understood in the broader sense of drilling operations, which includes running casing and cementing as well as drilling, unless specifically indicated otherwise.

- the invert emulsion drilling fluid of the present invention comprises an oil:water ratio preferably in the range of 50:50 to 95:5 and preferably employs a natural oil, such as for example without limitation diesel oil or mineral oil, or a synthetic base, as the oil or oleaginous phase and water comprising a salt such as, for example, calcium chloride, as the aqueous phase.

- the drilling fluid further comprises a rheology modifier or additive for rheology stability and particularly for a relatively flat rheological profile over a broad temperature range.

- rheology modifier is a fatty dimer diamine in the absence of lime.

- the fatty dimer diamine used in the invention is preferably a C36 fatty dimer diamine having the following molecular structure:

- a preferred commercially available C36 dimer diamine contains CI 8 fatty monoamine and C54

- fatty trimer triamine which are obtained during the commercial production of the dimer diamine.

- quantities of such a hydrophobic amine ranging from about 1 ppb to about 6 ppb are preferred and are effective even when the surrounding temperature is as low as 40°F or above 180°F, or at a temperature in between.

- the present invention provides an oleaginous or oil -based, invert emulsion drilling fluid with a relatively flat rheological profile over a broad temperature range, and a method of drilling boreholes in subterranean formations employing that drilling fluid.

- "Relatively flat" as used herein with respect to a rheological profile is a relative term based on comparison to the rheological profile of known prior art fluids employing lime.

- the drilling fluids of the invention are effective in a temperature range of about 40°F to at least about 375 °F or higher.

- the oil base or oleaginous part of the invert emulsion drilling fluid may be a natural oil such as for example diesel oil or mineral oil, or a synthetic base such as, for example, ACCOLADE® base comprising esters or ENCORE® base comprising isomerized olefins, both available from Halliburton Energy Services, Inc., in Houston, Texas and Duncan, Oklahoma.

- a natural oil such as for example diesel oil or mineral oil

- a synthetic base such as, for example, ACCOLADE® base comprising esters or ENCORE® base comprising isomerized olefins, both available from Halliburton Energy Services, Inc., in Houston, Texas and Duncan, Oklahoma.

- An aqueous solution containing a water activity lowering compound, composition or material comprises the internal phase of the invert emulsion.

- Such solution is preferably a saline solution comprising calcium chloride (typically about 25% to about 30%, depending on the subterranean formation water salinity or activity), although other salts such as for example calcium bromide, sodium chloride, sodium bromide, and formate, or water activity lowering materials such as for example alcohol, such as for example glycerol, or sugar, known in the art may alternatively or additionally be used.

- Water preferably comprises less than 50%, or as much as about 50%, of the drilling fluid and the oikwater ratio preferably ranges from about 50:50 to about 95:5.

- Drilling fluids of the present invention uniquely include a fatty dimer diamine additive as a rheology modifer, as will be discussed further below. Further, the drilling fluids of, or for use in, the present invention, have added to them or mixed with their invert emulsion oil base, other fluids or materials needed to comprise complete drilling fluids.

- Such other materials optionally may include, for example: additives for enhancing viscosity, for example, an additive having the trade name RHEMOD LTM (modified fatty acid); additives for providing temporary increased viscosity for shipping (transport to the well site) and for use in sweeps, for example, an additive having the trade name TEMPERUSTM (modified fatty acid); additives for filtration control, for example, additives having the trade names ADAPTA® and BDF-366; additives for high temperature high pressure control (HTHP) and emulsion stability, for example, an additive having the trade name FACTANTTM (highly concentrated tall oil derivative); additives for emulsification, for example, an additive having the trade name EZ MUL® NT (polyaminated fatty acid); and additives for corrosion control.

- additives for enhancing viscosity for example, an additive having the trade name RHEMOD LTM (modified fatty acid); additives for providing temporary increased viscosity for shipping (transport to the well site) and for use in

- the drilling fluids of the invention may comprise weighting agents, such as for example barium sulfate, heamatite, calcium carbonate, and combinations thereof.

- weighting agents such as for example barium sulfate, heamatite, calcium carbonate, and combinations thereof.

- the exact formulations of the fluids of the invention vary with the particular requirements of the subterranean formation.

- the present invention advantageously eliminates the need to include additives to provide thinning at cold temperatures, for example, additives having the trade names COLDTROL®, ATC®, and OMC2TM.

- the present invention also advantageously eliminates the need to include an emulsifier activator such as lime. Rather, with the invert emulsion drilling fluids of the present invention, lime should preferably not be used or added, and such fluids should contain no more than about 0.3ppb amount of lime if any at all.

- a preferred commercially available drilling fluid system for use in the invention is the INNOVERT® drilling fluid system, having a paraffin/mineral oil base, available from Baroid, a Halliburton Company, in Houston, Texas and Duncan, Oklahoma.

- the INNOVERT® drilling fluid system may typically comprise one or more of the following additives, in addition to the paraffin/mineral oil base and brine, for use as an invert emulsion drilling fluid: RHEMODTM L modified fatty acid suspension and viscosifying agent, BDF- 366TM or AD APT ATM copolymer for HPHT filtration control, particularly for use at high temperatures, and EZ MUL® NT polyaminated fatty acid emulsifier/oil wetting agent, also particularly for use at high temperatures.

- TAU-MODTM amorphous/fibrous material as a viscosifier and suspension agent.

- TAU- MODTM material is optional.

- Invert emulsion drilling fluids of the present invention comprising fatty dimer diamine, maintain acceptable and even preferred rheology measurements in deepwater drilling and do not experience a decreased rate of penetration (and with clay-free invert emulsion drilling fluids, also do not experience a decline in desired fragile gel strength) when in use in drilling even at high pressures and high temperatures (HPHT).

- HPHT high pressures and high temperatures

- the invert emulsion drilling fluids of the present invention comprising the fatty dimer diamine

- Yield point yield point

- These advantages of the present invention are believed to be due to the addition of the fatty dimer diamine to the drilling fluid without the addition of or the presence of any significant amount of lime.

- the advantages of the present invention are especially appreciated when the drilling fluid does not also contain organophilic clay or lignite.

- Preferred commercially available hydrophobic amines suitable for use in the present invention include without limitation VERSAMINE® 552 hydrogenated fatty C36 dimer diamine, and VERS AMINE® 551 fatty C36 dimer diamine, both available from Cognis Corporation (functional products) of Monheim, Germany and Cincinnati, Ohio. Typically, an amount of such dimer diamine in the range of about 1 pound per barrel (ppb) to about 3 ppb is sufficient for purposes of the invention.

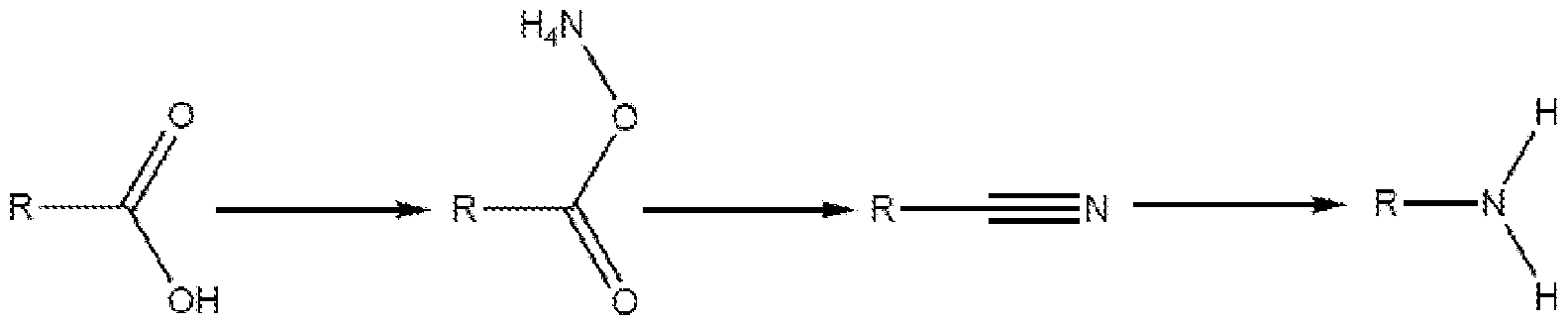

- These fatty dimer diamines are prepared commercially from fatty dimer diacids which have been produced from dimerisation of vegetable oleic acid or tall oil fatty acid by thermal or acid catalyzed methods

- C36 dimer acids This material is a mixture of monocyclic dicarboxylic acid, acyclic dicarboxylic acid and bicyclic dicarboxylic acid along with small quantities of trimeric triacids. These diacids are converted into diamines via the reaction scheme given below:

- diamines are further converted into compounds that fall under the scope of fatty dimer diamines.

- These diamines are converted into cyanoethyl derivatives via cyanoethylation with acrylonitrile; these cyanoethyl derivatives are further reduced into aminopropyl amines via reduction as shown in the reaction scheme II below, as taught in United States Patent No. 4,250,045, issued February 10, 1981 to Coupland, et al.

- Dicyanoethylated dimer diamine is available commercially as Kemamine DC 3680 and 3695 and di N-aminopropylated dimer diamine is available commercially as Kemamine DD 3680 and 3695 from Chemtura Corporation USA.

- Different structures of the dimeric fatty dimer diamines are given below:

- fatty dimer diamines suitable for use in the present invention include

- C28 fatty dimer diamines to C48 fatty dimer amines which are correspondingly prepared via dimerization of the relevant C14 to C24 fatty acids. It should be understood that C14 means the molecule contains in total 14 carbon atoms.

- PV plastic viscosity

- cp centipoise

- Yield point is yield point, which is another variable used in the calculation of viscosity characteristics of drilling fluids, measured in pounds per 100 square feet (lb/100 ft.sup.2), as further discussed below.

- GELS is a measure of the suspending characteristics, or the thixotripic properties of a drilling fluid, measured in pounds per 100 square feet (lb/100 ft.sup.2).

- HTHP is the term used for high-temperature high-pressure fluid loss, measured in milliliters (ml) according to Recommended Practice 13B-2, Recommended Practice for Field Testing of Oil-based Drilling Fluids, Fourth Edition, American Petroleum Institute, March 1 , 2005.

- the components of the claimed drilling fluids include an oil or oleaginous fluid, an aqueous or a non-oleaginous fluid, an emulsifier package and a rheology modifier.

- Other chemicals used to make-up the system are basically the same as those typically used in formulating conventional invert emulsion drilling fluids.

- the Plastic Viscosity (PV) and Yield Point (YP) of the invert emulsion drilling fluid were determined on a direct-indicating rheometer, a FANN 35 rheometer, powered by an electric motor.

- the rheometer consists of two concentric cylinders, the inner cylinder is called a bob, while the outer cylinder is called a rotor sleeve.

- the drilling fluid sample is placed in a thermostatically controlled cup and the temperature of the fluid is adjusted to 120 (+ 5) °F or the temperature of interest + 5 °F .

- the drilling fluid in the thermostatically controlled cup is then placed in the annular space between the two concentric cylinders of the FANN 35.

- the outer cylinder or rotor sleeve is driven at a constant rotational velocity.

- the rotation of the rotor sleeve in the fluid produces a torque on the inner cylinder or bob.

- a torsion spring restrains the movement of the bob, and a dial attached to the bob indicates displacement of the bob.

- the dial readings are measured at different rotor sleeve speeds of 3, 6, 100, 200, 300 and 600 revolutions per minute (rpm).

- Yield Point is defined as the value obtained from the Bingham-Plastic rheological model when extrapolated to a shear rate of zero. It may be calculated using 300 rpm and 600 rpm shear rate readings as noted above on a standard oilfield rheometer, such as a FANN 35 or a FANN 75 rheometer.

- Yield Stress or Tau zero is the stress that must be applied to a material to make it begin to flow (or yield), and may commonly be calculated from rheometer readings measured at rates of 3, 6, 100, 200, 300 and 600 rpm. The extrapolation may be performed by applying a least-squares fit or curve fit to the Herchel-Bulkley rheological model.

- a more convenient means of estimating the Yield Stress is by calculating the Low-Shear Yield Point (LSYP) by the formula shown below in Equation 2 except with the 6 rpm and 3 rpm readings substituted for the 600-rpm and 300-rpm readings, respectively.

- Plastic Viscosity (PV) is obtained from the Bingham-Plastic rheological model and represents the viscosity of a fluid when extrapolated to infinite shear rate. The PV is obtained from the 600 rpm and the 300 rpm readings as given below in Equation 1.

- a low PV may indicate that a fluid is capable of being used in rapid drilling because, among other things, the fluid has low viscosity upon exiting the drill bit and has an increased flow rate.

- a high PV may be caused by a viscous base fluid, excess colloidal solids, or both.

- the PV and YP are calculated by the following set of equations:

- Experiment 1 Two 12 ppg Invert Emulsion Fluids (IEFs) were formulated with a 2 ppb C36 fatty dimer diamine additive (BDF 570) (available from Halliburton Energy Services, Inc., in Duncan, Oklahoma and Houston, Texas) in 12 ppg INNOVERT® clay-free invert emulsion drilling fluid (available from Halliburton Energy Services, Inc., in Duncan, Oklahoma and Houston, Texas) in a 70:30 oil-water ratio having a 250K ppm CaCl 2 Water Phase Salinity (WPS).

- IEFs included no lime and the other included 0.75 ppb lime.

- Table 1 shows that the invert emulsion fluid containing no lime (Fluid

- Formulation 1 an Invert Emulsion Fluid (IEF) of the present invention) had a YP of 41 +/- 4 from 40°F to 150°F and a GEL at 10 min in the range of 41 +/- 4 from 40°F to 150°F.

- the invert emulsion fluid with 0.75 ppb lime (Fluid Formulation 2) had a YP of 34 at 40°F which decreased gradually to 4 at 150°F and a GEL at 10 min of 17 that decreased gradually to 10 at 150°F.

- the temperature gradient would be as follows:

- Table 2 indicates that the YP for this IEF was in the range of 54 +/-4 for this temperature range, and was relatively flat across the temperature and pressure profile. The differences in the FANN 75 YP and the FANN 35 YP are believed to be due to instrumental errors, since the determinations were performed on two different occasions on two different instruments. [0035] When the results set forth in Tables 1 and 2 are considered with respect to the temperature gradient, they indicate that the yield point and 10 minute gel strength of the fluid of the invention will be about the same along the depth of a well during drilling, for example from 0 feet to 20,000, with the temperature in the well increasing at a rate of about 1°F to about 2.1°F per 100 feet of depth.

- the C36 dimer diamine additive of the invention showed an LC50 value greater than 10 mg/1 for each of the toxicity tests conducted and also showed 66.5% biodegradability after 28 days.

- a drilling fluid of the invention may be employed in drilling operations.

- the drilling fluid removes drill cuttings from the wellbore, cools and lubricates the drill bit, aids in support of the drill pipe and drill bit, and provides a hydrostatic head to maintain the integrity of the wellbore walls and prevent well blowouts.

- the specific formulation of the drilling fluid in accordance with the present invention is optimized for the particular drilling operation and for the particular subterranean formation characteristics and conditions (such as temperatures).

- the fluid is weighted as appropriate for the formation pressures and thinned as appropriate for the formation temperatures.

- the fluids of the invention afford real-time monitoring and rapid adjustment of the fluid to accommodate changes in such subterranean formation conditions.

- the fluids of the invention may be recycled during a drilling operation such that fluids circulated in a wellbore may be recirculated in the wellbore after returning to the surface for removal of drill cuttings for example.

- the drilling fluid of the invention may even be selected for use in a drilling operation to reduce loss of drilling mud during the drilling operation and/or to comply with environmental regulations governing drilling operations in a particular subterranean formation.

Abstract

Description

Claims

Priority Applications (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP14732654.0A EP2964719A1 (en) | 2013-03-09 | 2014-03-09 | Method of drilling boreholes with invert emulsion drilling fluids characterized by flat rheology |

| AU2014249450A AU2014249450B2 (en) | 2013-03-09 | 2014-03-09 | Method of drilling boreholes with invert emulsion drilling fluids characterized by flat rheology |

| BR112015017960A BR112015017960A2 (en) | 2010-03-06 | 2014-03-09 | method for drilling a well in an underground formation, and inverted emulsion drilling fluid |

| MX2015009769A MX2015009769A (en) | 2010-03-06 | 2014-03-09 | Method of drilling boreholes with invert emulsion drilling fluids characterized by flat rheology. |

| CA2900563A CA2900563A1 (en) | 2013-03-09 | 2014-03-09 | Method of drilling boreholes with invert emulsion drilling fluids characterized by flat rheology |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US13/791,958 | 2013-03-09 | ||

| US13/791,958 US9296937B2 (en) | 2010-03-06 | 2013-03-09 | Method of drilling boreholes with invert emulsion drilling fluids having enhanced rheology |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2014164381A1 true WO2014164381A1 (en) | 2014-10-09 |

Family

ID=50983100

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/US2014/022214 WO2014164381A1 (en) | 2010-03-06 | 2014-03-09 | Method of drilling boreholes with invert emulsion drilling fluids characterized by flat rheology |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP2964719A1 (en) |

| AU (1) | AU2014249450B2 (en) |

| CA (1) | CA2900563A1 (en) |

| WO (1) | WO2014164381A1 (en) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN109054782A (en) * | 2018-08-03 | 2018-12-21 | 长江大学 | Temperature sensitive polymer rheology control agent and constant current are denaturalized water-base drilling fluid |

| US10266745B2 (en) | 2017-02-03 | 2019-04-23 | Saudi Arabian Oil Company | Anti-bit balling drilling fluids, and methods of making and use thereof |

| US10858568B1 (en) | 2019-07-11 | 2020-12-08 | Saudi Arabian Oil Company | Rheology modifier for organoclay-free invert emulsion drilling fluid systems |

| US11933119B1 (en) | 2023-01-25 | 2024-03-19 | Halliburton Energy Services, Inc. | Curing lost circulation of oil-based drilling muds |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4250045A (en) | 1979-06-22 | 1981-02-10 | Exxon Research & Engineering Co. | Polymerized fatty acid amine derivatives useful as friction and wear-reducing additives |

| US20030144153A1 (en) * | 2000-12-29 | 2003-07-31 | Jeff Kirsner | Invert drilling fluids and methods of drilling boreholes |

| US20040102332A1 (en) * | 2002-11-25 | 2004-05-27 | Elementis Specialties, Inc. | Compositions for drilling fluids useful to provide flat temperature rheology to such fluids over a wide temperature range and drilling fluids containing such compositions |

| US7939470B1 (en) * | 2010-03-27 | 2011-05-10 | Halliburton Energy Services Inc. | Invert emulsion drilling fluids comprising quaternary ammonium emulsifiers and argillaceous solids and methods of drilling boreholes |

| US20110214864A1 (en) * | 2010-03-06 | 2011-09-08 | Halliburton Energy Services, Inc. | Invert drilling fluids having enhanced rheology and methods of drilling boreholes |

-

2014

- 2014-03-09 WO PCT/US2014/022214 patent/WO2014164381A1/en active Application Filing

- 2014-03-09 EP EP14732654.0A patent/EP2964719A1/en not_active Withdrawn

- 2014-03-09 AU AU2014249450A patent/AU2014249450B2/en active Active

- 2014-03-09 CA CA2900563A patent/CA2900563A1/en not_active Abandoned

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4250045A (en) | 1979-06-22 | 1981-02-10 | Exxon Research & Engineering Co. | Polymerized fatty acid amine derivatives useful as friction and wear-reducing additives |

| US20030144153A1 (en) * | 2000-12-29 | 2003-07-31 | Jeff Kirsner | Invert drilling fluids and methods of drilling boreholes |

| US7462580B2 (en) | 2000-12-29 | 2008-12-09 | Halliburton Energy Services, Inc. | Flat rheology drilling fluids |

| US7488704B2 (en) | 2000-12-29 | 2009-02-10 | Halliburton Energy Services, Inc. | Invert drilling fluids for use in drilling in subterranean formations |

| US20040102332A1 (en) * | 2002-11-25 | 2004-05-27 | Elementis Specialties, Inc. | Compositions for drilling fluids useful to provide flat temperature rheology to such fluids over a wide temperature range and drilling fluids containing such compositions |

| US20110214864A1 (en) * | 2010-03-06 | 2011-09-08 | Halliburton Energy Services, Inc. | Invert drilling fluids having enhanced rheology and methods of drilling boreholes |

| US7939470B1 (en) * | 2010-03-27 | 2011-05-10 | Halliburton Energy Services Inc. | Invert emulsion drilling fluids comprising quaternary ammonium emulsifiers and argillaceous solids and methods of drilling boreholes |

Non-Patent Citations (2)

| Title |

|---|

| "Recommended Practice for Field Testing of Oil-based Drilling Fluids", 1 March 2005, AMERICAN |

| "Recommended Practice for Field Testing of Oil-based Drilling Fluids", 1 March 2005, AMERICAN PETROLEUM INSTITUTE |

Cited By (37)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US10703957B2 (en) | 2017-02-03 | 2020-07-07 | Saudi Arabian Oil Company | Development of retarded acid system |

| US11365339B2 (en) | 2017-02-03 | 2022-06-21 | Saudi Arabian Oil Company | Development of retarded acid system |

| US10287476B2 (en) | 2017-02-03 | 2019-05-14 | Saudi Arabian Oil Company | Cement slurries, cured cements and methods of making and use thereof |

| US10822534B2 (en) | 2017-02-03 | 2020-11-03 | Saudi Arabian Oil Company | Retarded acid systems, emulsions, and methods for using in acidizing carbonate formations |

| US10351750B2 (en) | 2017-02-03 | 2019-07-16 | Saudi Arabian Oil Company | Drilling fluid compositions with enhanced rheology and methods of using same |

| US10377939B2 (en) | 2017-02-03 | 2019-08-13 | Saudi Arabian Oil Company | Development of anti-bit balling fluids |

| US10392550B2 (en) | 2017-02-03 | 2019-08-27 | Saudi Arabian Oil Company | Spacer fluid compositions, methods, and systems for aqueous based drilling mud removal |

| US10487254B2 (en) | 2017-02-03 | 2019-11-26 | Saudi Arabian Oil Company | Enhanced filtration control packages, wellbore servicing fluids utilizing the same, and methods of maintaining the structure of a wellbore |

| US10494559B2 (en) | 2017-02-03 | 2019-12-03 | Saudi Arabian Oil Company | Cement slurries, cured cement and methods of making and use thereof |

| US10494560B2 (en) | 2017-02-03 | 2019-12-03 | Saudi Arabian Oil Company | Development of anti-bit balling fluids |

| US10526520B2 (en) | 2017-02-03 | 2020-01-07 | Saudi Arabian Oil Company | Anti-bit balling drilling fluids, and methods of making and use thereof |

| US10538692B2 (en) | 2017-02-03 | 2020-01-21 | Saudi Arabian Oil Company | Development of anti-bit balling fluids |

| US10563110B2 (en) | 2017-02-03 | 2020-02-18 | Saudi Arabian Oil Company | Methods of using drilling fluid compositions with enhanced rheology |

| US10570324B2 (en) | 2017-02-03 | 2020-02-25 | Saudi Arabian Oil Company | Emulsifier compositions for invert emulsion fluids and methods of using the same |

| US10590325B2 (en) | 2017-02-03 | 2020-03-17 | Saudi Arabian Oil Company | Spacer fluid compositions that include surfactants |

| US10640695B2 (en) | 2017-02-03 | 2020-05-05 | Saudi Arabian Oil Company | Dispersant in cement formulations for oil and gas wells |

| US10662363B2 (en) | 2017-02-03 | 2020-05-26 | Saudi Arabian Oil Company | Lubricants for water-based drilling fluids |

| US10683447B2 (en) | 2017-02-03 | 2020-06-16 | Saudi Arabian Oil Company | Invert emulsion based drilling fluid and methods of using same |

| US10287477B2 (en) | 2017-02-03 | 2019-05-14 | Saudi Arabian Oil Company | Dispersant in cement formulations for oil and gas wells |

| US10266745B2 (en) | 2017-02-03 | 2019-04-23 | Saudi Arabian Oil Company | Anti-bit balling drilling fluids, and methods of making and use thereof |

| US10851281B2 (en) | 2017-02-03 | 2020-12-01 | Saudi Arabian Oil Company | Development of anti-bit balling fluids |

| US10844266B2 (en) | 2017-02-03 | 2020-11-24 | Saudi Arabian Oil Company | Spacer fluids and cement slurries that include surfactants |

| US11248157B2 (en) | 2017-02-03 | 2022-02-15 | Saudi Arabian Oil Company | Emulsifier compositions for invert emulsion fluids and methods of using the same |

| US10876028B2 (en) | 2017-02-03 | 2020-12-29 | Saudi Arabian Oil Company | Enhanced filtration control packages, wellbore servicing fluids utilizing the same, and methods of maintaining the structure of a wellbore |

| US11098232B2 (en) | 2017-02-03 | 2021-08-24 | Saudi Arabian Oil Company | Lubricants for water-based drilling fluids |

| US10961426B2 (en) | 2017-02-03 | 2021-03-30 | Saudi Arabian Oil Company | Development of anti-bit balling fluids |

| US11015104B2 (en) | 2017-02-03 | 2021-05-25 | Saudi Arabian Oil Company | Cement slurries, cured cements and methods of making and use thereof |

| US11015105B2 (en) | 2017-02-03 | 2021-05-25 | Saudi Arabian Oil Company | Cement slurries, cured cements and methods of making and use thereof |

| US11034875B2 (en) | 2017-02-03 | 2021-06-15 | Saudi Arabian Oil Company | Enhanced filtration control packages, wellbore servicing fluids utilizing the same, and methods of maintaining the structure of a wellbore |

| US11098231B2 (en) | 2017-02-03 | 2021-08-24 | Saudi Arabian Oil Company | Spacer fluid compositions that include surfactants |

| US11078396B2 (en) | 2017-02-03 | 2021-08-03 | Saudi Arabian Oil Company | Spacer fluid compositions, methods, and systems for aqueous based drilling mud removal |

| US11078397B2 (en) | 2017-02-03 | 2021-08-03 | Saudi Arabian Oil Company | Spacer fluid compositions, methods, and systems for aqueous based drilling mud removal |

| CN109054782B (en) * | 2018-08-03 | 2021-03-09 | 长江大学 | Thermo-sensitive polymer rheological regulator suitable for ocean and constant-current modified water-based drilling fluid |

| CN109054782A (en) * | 2018-08-03 | 2018-12-21 | 长江大学 | Temperature sensitive polymer rheology control agent and constant current are denaturalized water-base drilling fluid |

| US11072736B2 (en) | 2019-07-11 | 2021-07-27 | Saudi Arabian Oil Company | Rheology modifier for organoclay-free invert emulsion drilling fluid systems |

| US10858568B1 (en) | 2019-07-11 | 2020-12-08 | Saudi Arabian Oil Company | Rheology modifier for organoclay-free invert emulsion drilling fluid systems |

| US11933119B1 (en) | 2023-01-25 | 2024-03-19 | Halliburton Energy Services, Inc. | Curing lost circulation of oil-based drilling muds |

Also Published As

| Publication number | Publication date |

|---|---|

| AU2014249450A1 (en) | 2015-07-16 |

| AU2014249450B2 (en) | 2016-08-11 |

| EP2964719A1 (en) | 2016-01-13 |

| CA2900563A1 (en) | 2014-10-09 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US9296937B2 (en) | Method of drilling boreholes with invert emulsion drilling fluids having enhanced rheology | |

| CA2884829C (en) | Method for improving high temperature rheology in drilling fluids | |

| US9988569B2 (en) | Methods and materials to enhance high temperature rheology in invert emulsions | |

| US9469803B2 (en) | Invert emulsion fluids | |

| US20130303410A1 (en) | Invert Emulsion Drilling Fluids for Flat Rheology Drilling | |

| CA2772133C (en) | Improved suspension characteristics in invert emulsions | |

| AU2014249450B2 (en) | Method of drilling boreholes with invert emulsion drilling fluids characterized by flat rheology | |

| AU2012364697B2 (en) | Invert drilling fluids having enhanced rheology and methods of drilling boreholes | |

| WO2015006101A1 (en) | Invert emulsion drilling fluids for flat rheology drilling |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 14732654 Country of ref document: EP Kind code of ref document: A1 |

|

| REEP | Request for entry into the european phase |

Ref document number: 2014732654 Country of ref document: EP |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 2014732654 Country of ref document: EP |

|

| ENP | Entry into the national phase |

Ref document number: 2014249450 Country of ref document: AU Date of ref document: 20140309 Kind code of ref document: A |

|

| WWE | Wipo information: entry into national phase |

Ref document number: MX/A/2015/009769 Country of ref document: MX |

|

| ENP | Entry into the national phase |

Ref document number: 2900563 Country of ref document: CA |

|

| REG | Reference to national code |

Ref country code: BR Ref legal event code: B01A Ref document number: 112015017960 Country of ref document: BR |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| ENP | Entry into the national phase |

Ref document number: 112015017960 Country of ref document: BR Kind code of ref document: A2 Effective date: 20150728 |