WO2007001926A2 - Low-swelling hydrogel sealants for wound repair - Google Patents

Low-swelling hydrogel sealants for wound repair Download PDFInfo

- Publication number

- WO2007001926A2 WO2007001926A2 PCT/US2006/023639 US2006023639W WO2007001926A2 WO 2007001926 A2 WO2007001926 A2 WO 2007001926A2 US 2006023639 W US2006023639 W US 2006023639W WO 2007001926 A2 WO2007001926 A2 WO 2007001926A2

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- occurrence

- represents independently

- compound

- formula

- alkyl

- Prior art date

Links

- 0 C*P(C)(N(*)O*)OC Chemical compound C*P(C)(N(*)O*)OC 0.000 description 74

- JDFXJJLFADUZIY-UHFFFAOYSA-N CON(C(CC1)=O)C1=O Chemical compound CON(C(CC1)=O)C1=O JDFXJJLFADUZIY-UHFFFAOYSA-N 0.000 description 2

- MYMDPTPDEXPFMS-FNORWQNLSA-N CC(C=C)/N=C/C Chemical compound CC(C=C)/N=C/C MYMDPTPDEXPFMS-FNORWQNLSA-N 0.000 description 1

- MFGZEHUHXJBUOR-UHFFFAOYSA-N CC(CCNC(C(CCCCNC(CCC([N+](C(CC1)=O)(C1=O)[O-])=O)=O)NC(CCC([N+](C(CC1)=O)(C1=O)[O-])=O)=O)=O)OCCOCCNC(C(CCCCNC(CCC([N+](C(CC1)=O)(C1=O)[O-])=O)=O)NC(CCC([OH+][NH2+]C(CCC=O)=O)=O)=O)=O Chemical compound CC(CCNC(C(CCCCNC(CCC([N+](C(CC1)=O)(C1=O)[O-])=O)=O)NC(CCC([N+](C(CC1)=O)(C1=O)[O-])=O)=O)=O)OCCOCCNC(C(CCCCNC(CCC([N+](C(CC1)=O)(C1=O)[O-])=O)=O)NC(CCC([OH+][NH2+]C(CCC=O)=O)=O)=O)=O MFGZEHUHXJBUOR-UHFFFAOYSA-N 0.000 description 1

- KFYKZKISJBGVMR-UHFFFAOYSA-N CCC(C)NCC Chemical compound CCC(C)NCC KFYKZKISJBGVMR-UHFFFAOYSA-N 0.000 description 1

- WQZPUWMOQOEQHK-UHFFFAOYSA-N CON(C(CC1S(O)(=O)=O)=O)C1=O Chemical compound CON(C(CC1S(O)(=O)=O)=O)C1=O WQZPUWMOQOEQHK-UHFFFAOYSA-N 0.000 description 1

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K47/00—Medicinal preparations characterised by the non-active ingredients used, e.g. carriers or inert additives; Targeting or modifying agents chemically bound to the active ingredient

- A61K47/30—Macromolecular organic or inorganic compounds, e.g. inorganic polyphosphates

- A61K47/34—Macromolecular compounds obtained otherwise than by reactions only involving carbon-to-carbon unsaturated bonds, e.g. polyesters, polyamino acids, polysiloxanes, polyphosphazines, copolymers of polyalkylene glycol or poloxamers

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/06—Ointments; Bases therefor; Other semi-solid forms, e.g. creams, sticks, gels

Definitions

- Sealants and adhesives play an important role in helping patients recover from surgery or trauma. Sealants and adhesives are useful in treating patients suffering from a variety of in vivo or topical conditions, including lacerations, tears, wounds, ulcers, and surgical procedures. Sealants or adhesives can generally be used in any indication or application that a suture is presently used, and the sealant or adhesive often provides a better outcome than when a suture is used. Sealants or adhesives can also be applied more quickly to the injury site and often provide a better seal over the wound. Various medicinal applications for sealants and adhesives are described below.

- Skin lacerations are tears in the skin produced by accidents, trauma, or as a result of a surgical procedure. Lacerations often require treatment in order to close the hole in the skin, stop bleeding, and prevent infection. Minor lacerations in the skin may be treated using an adhesive tissue to cover the wound. However, larger laceractions often require sutures or a glue to help seal the wound. For example, it is generally recommended that sutures or a glue be used to treat lacerations deeper than 0.25 inches having a jagged edge or loose flap of tissue. The location of the laceration may also affect the form of treatment. For example, it is advantageous to treat a skin laceration on a joint using a glue because adhesive tissue tends to limit mobility of the joint. The use of sutures or glues to treat skin lacerations can also reduce the chance of scar formation.

- Lacerations of the liver can occur from trauma or as a result of a surgical procedure.

- the liver is a highly vascularized organ and bleeds profusely when lacerated or traumatized.

- Liver lacerations are difficult to repair owing to the nature of liver tissue.

- Liver tissue has very weak cohesive strength, and, consequently, sutures and staples are not satisfactory because they may pull through the liver tissue.

- the lack of satisfactory wound treatment methods for liver lacerations combined with the fact that it is difficult to reach the veins that feed the liver renders liver lacerations particularly serious. In fact, severe lacerations of the liver often result in the patient's death due to bleeding. Thus, new materials to treat liver lacerations are needed. Cornea - Corneal Lacerations/Perforations

- Corneal perforations/lacerations are produced by a variety of medical conditions (e.g., infection, inflammation, xerosis, neurotrophication, and degeneration) and traumas (e.g., chemical, thermal, surgical, and penetrating).

- medical conditions e.g., infection, inflammation, xerosis, neurotrophication, and degeneration

- traumas e.g., chemical, thermal, surgical, and penetrating.

- corneal perforations often lead to loss of vision and a decrease in an individual's quality of life.

- different treatments are currently available ranging from suturing the wound to a cornea graft.

- the surgical procedures are difficult given the delicate composition of the cornea and the severity of the wound which increases the likelihood for leakage and severe astigmatism after surgery.

- tissue adhesives glues

- This type of treatment is advantageous because the method is simple, quick, safe, and provides quick restoration of globe integrity, thereby avoiding further complications.

- an adhesive should: 1) bind to the tissue (necrosed or not, very often wet) with an adequate adhesion force; 2) be non-toxic; 3) be biodegradable or resorbable; 4) be sterilizable; and 5) not interfere with the healing process.

- alkyl-cyanoacrylates are available for the repair of small perforations.

- these "super glues” have several disadvantages.

- the monomers used to form the alkyl-cyanoacrylate polymer adhesive can be toxic with formation of formaldehyde.

- Alkyl-cyanoacrylates can also polymerize too quickly, which complicates administering the adhesive to the wound.

- the alkyl-cyanoacrylate polymer also has a hard, rough surface causing patient discomfort and the need to wear a contact lens.

- Adhesive hemostats based on fibrin, are usually constituted of fibrinogen, thrombin and factor XIII. Systems with fibrinogen and photosensitizers activated with light are also being tested. If adhesive hemostats have intrinsic properties which meet the requirements for a tissue adhesive, autologous products (time consuming in an emergency) or severe treatments before clinical use are needed to avoid any contamination to the patient.

- Sealants for corneal perforations generally should 1) not impair normal vision, 2) quickly restore the intraocular pressure '1OP), 3) maintain the structural integrity of the eye, 4) promote healing, 5) adhere to moist issue surfaces, 6) possess solute diffusion properties which are molecular weight dependent md favorable for normal cornea function, 7) possess rheological properties that allow for iontroUed placement of the polymer on the wound, and 8) polymerize under mild ;onditions.

- sutures for wound repair has several limitations and disadvantages.

- sutures such as 10-0 nylon (which s often the preferred suture for corneal repair as well as in other in vivo areas) can act as a iidus for infection and incite corneal inflammation and vascularization.

- the Dropensity for corneal scarring increases with persistent inflammation and vascularization.

- corneal suturing often yields uneven healing and resultant regular and irregular astigmatism.

- sutures are prone to becoming loose and/or broken and may require additional attention for prompt removal.

- effective suturing requires technical skills that vary widely from surgeon to surgeon and can also involve prolonged operative time.

- a trephine a special round cutting tool called a trephine.

- the donor cornea is cut to a matching size. Then, the donor cornea is placed upon the eye and secured in place with approximately 16 sutures around the transplant.

- a sutureless procedure would be highly desirable and would offer the following advantages: 1) sutures provide a site for infection, 2) the sutured cornea takes about 3 months to heal before the sutures need to be removed, and 3) the strain applied to the new cornea tissue from the sutures can distort the cornea.

- an ocular adhesive could serve as an adjuvant to sutures and/or reduce the necessary number of sutures.

- phacoemulsification Clear corneal incisions in the temporal cornea offer several advantages with phacoemulsification.

- the major advantage associated with phacoemulsification is the reduction in size of the entrance wound. Smaller wounds require fewer sutures or even no sutures at all, minimizing induction of astigmatis ⁇ i j decreasing bleeding and subconjunctival hemorrhage, and speeding the recovery of visual acuity. See Agapitos, P. J. Curr. Opin. Ophthalmol. 1993, 4, 39-43 and LyIe, W. A.; Jin, G. J. J. Cataract Refract. Surg. 1996, 22, 1456-1460.

- OCT optical coherence tomography

- Laser-assisted in situ keratomileusis is the popular refractive surgical procedure where a thin, hinged corneal flap is created by a microkeratome blade. This flap is then moved aside to allow an excimer laser beam to ablate the corneal stromal tissue with extreme precision for the correction of myopia and astigmatism. At the conclusion of the procedure, the flap is then repositioned and allowed to heal. However, with trauma, this flap can become dislocated prior to healing, resulting in flap striae (folds) and severe visual loss. When this complication occurs, treatment involves prompt replacement of the flap and flap suturing. The use of sutures has limitations and drawbacks as discussed above.

- Cataracts or other diseases or injuires that lead to a poorly functioning or damaged lens require the natural lens to be replaced.

- the optical properties of the normal eye lens are the consequence of a high concentration of proteins called "crystallins" forming a natural hydrogel.

- crystallins proteins that form a natural hydrogel.

- the anatomical basis of accommodation includes the lens substance, lens capsule, zonular fibers, ciliary muscle and the elastic part of the choroid. Accommodation occurs through accurately controlled adjustments in the shape and thickness of the lens.

- the capsular bag is essential in transmitting the various extralenticular forces to the lens substance.

- Modern cataract surgery can be done through a small incision (usually 2.5-3.5 mm). Once the incision is made, the anterior chamber is filled with a viscoelastic and the capsular bag is pricked with a needle. From this incision, a small continuous circular capsulorhexis (CCC) approximately 1.5 mm in diameter is performed using capsulorhexis forceps. Next endocapsular phacoemulsification is performed and the lens epithelial cells are removed by aspiration.

- CCC circular capsulorhexis

- the polymerization can be slowed by adding iophendylate to the monomers, but the reaction still occurs in two to three seconds. Risks of retinal tear at the edge of the treated hole can also be observed because of the hardness of the polymerized cyanoacrylate.

- the vitreous is normally a clear, gel-like substance that fills the center of the eye. It makes up approximately 2/3 of the eye's volume, giving it form and shape before birth. Certain problems affecting the back of the eye may require a vitrectomy, or surgical removal of the vitreous.

- a vitrectomy the surgeon creates small incisions/punctures in the eye (sclerotomies) for separate instruments. These incisions are placed in the pars plana of the eye, which is located just behind the iris but in front of the retina.

- the instruments which pass through these incisions include a light pipe, an infusion port, and the vitrectomy cutting device.

- each sclerotomy site is closed with a single interrupted suture of 8-0 silk or 7-0 polyglycolic acid suture.

- the eye is filled with fluid until the vitreous is replaced as the eye secretes aqueous and nutritive fluids.

- Some of the most common eye conditions that require vitrectomy include 1) complications from diabetic retinopathy, such as retinal detachment or bleeding, 2) macular hole, 3) retinal detachment, 4) pre-retinal membrane fibrosis, 5) bleeding inside the eye (vitreous hemorrhage), 6) injury or infection, and 7) certain problems related to previous eye surgery.

- Leaking filtering blebs after glaucoma surgery are difficult to manage and can lead to serious, vision-threatening complications. Leaking blebs can result in hypotony and shallowing of the anterior chamber, choroidal effusion, maculopathy, retinal, and choroidal folds, suprachoroidal hemorrhage, corneal decompensation, peripheral anterior synechiae, and cataract formation. A leaking bleb can also lead to the loss of bleb function and to the severe complications of endophthalmaitis. The incidence of bleb leaks increases with the use of antimetabolites. Bleb leaks in eyes treated with 5-fluorouracil or mitomycin C may occur in as many as 20% to 40% of patients.

- Bleb leaks in eyes treated with antimetabolities may be difficult to heal because of thin avascular tissue and because of abnormal fibrovascular response. If the leak persists despite the use of conservative management, a 9-0 to 10-0 nylon or absorbable suture on a tapered vascular needle can be used to close the conjunctival wound. In a thin-walled or avascular bleb, a suture may not be advisable because it could tear the tissue and cause a larger leak.

- Fibrin adhesives have been used to close bleb leaks.

- the adhesive is applied to conjunctival wound simultaneously with thrombin to form a fibrin clot at the application site.

- the operative field must be dry during the application because fibrin will not adhere to wet tissue.

- Cyanoacrylate glue may be used to close a conjuctival opening.

- To apply the glue the surrounding tissue must be dried and a single drop of the cyanoacrylate is placed.

- the operative must be careful not to seal the applicator to the tissue or to seal surrounding tissue with glue given its quick reaction.

- a soft contact lens is then applied over the glue to decrease patient discomfort. However, this procedure can actually worsen the problem if the cyanoacrylate tears from the bleb and causes a larger wound.

- Blepharoplasty is an operation to remove excess skin, fat and muscle from around the eyes to correct droopy eyelids and bagginess under the eyes. It can be performed on the upper lids and lower lids, at the same time or separately. The operation may be done using either conventional or laser techniques. For surgery on the upper eyelids, cuts are made into the natural lines and creases in the lid, and into the laughter lines at the corner of the eye. For surgery on the lower eyelids, a cut is usually made just below the eyelashes. This means the scars run along the eye's natural folds, concealing them as much as possible. Excess fat, muscle and loose skin are removed, and the cut is closed using sutures. If only fat is being removed, sometimes the cut is made on the inside of the lower eyelid, leaving no visible scar. A tissue adhesive could provide a more effective means to secure the cuts made during these procedures. Summary of the Invention

- the present invention broadly relates to methods and compositions for sealing a wound on a patient using a hydrogel sealant/adhesive.

- a sealant comprising dendrimeric macromolecules that form a hydrogel.

- the sealants of the present invention further comprise a polymer, such as polyvinylpyrrolidone, poly(N-isopropylacrylamide), or a copolymer of poly(ethylene glycol) and poly(propylene glycol).

- the sealants of the present invention further comprise a pharmaceutical agent, such as an antibiotic, antimicrobial agent, or antiinflammatory agent.

- the sealants of the invention comprise a hydrogel that swells less than about 400 wt% upon hydration.

- the sealants of the present invention may be used to treat a wound on a patient that is topical or in vivo.

- the sealants of the present invention can act as a barrier to bacteria and other organisms.

- the sealants of the invention comprise a dendrimeric macromolecule and an alkyl diacid compound, wherein the alkyl diacid compound has a molecular weight of less than about 1000 g/mol.

- the compositions used to seal a wound comprise at least one dendrimeric macromolecule and at least one polyethylene glycol polymer.

- the dendrimeric compounds used to form the hydrogel sealant have an acrylate group attached at the periphery of the dendrimer. Treatment of acrylate-capped dendrimeric compounds with ultraviolet radiation or a chemical initiator causes the dendrimeric compounds to polymerize, thereby forming a seal.

- the dendrimeric compounds have a lysine, cysteine, isocysteine residue or other nucleophilic group attached to the periphery of the dendrimer.

- a dendrimeric compound containing two or more electrophilic groups such as an aldehyde, activated ester, or acrylate

- a linear or dendrimeric polyethyelene glycol containing two or more electrophilic groups such as an aldehyde, activated ester, or acrylate

- compositions used to seal the wound comprise a compound that has a polylysine core to which cysteine, isocysteine, or other nucleophilic groups are attached.

- Another aspect of the present invention relates to a method of sealing a wound on a patient comprising the steps of applying an effective amount of a dendrimeric compound to a wound on a patient and treating the dendrimeric compound with a polymerization agent.

- the dendrimeric compound is administered in the form of an aqueous solution.

- the polymerization agent is ultraviolet light or visible light.

- the dendrimeric compound is administered in the form of a gel.

- the dendrimeric compound is administered in the form of a patch.

- Another aspect of the present invention relates to a method of sealing a wound on a patient comprising the steps of treating a dendrimeric compound with a polymerization agent to form a repair agent, and applying the repair agent to a wound on a patient.

- the method further comprises the step of sterilizing the dendrimeric compound or repair agent.

- kits for sealing a wound comprising a polymerizable dendrimeric compound that forms a hydrogel and a system for delivering the polymerizable dendrimeric compound to a wound on a patient.

- the kit further comprises a polymerization agent.

- the system is a syringe.

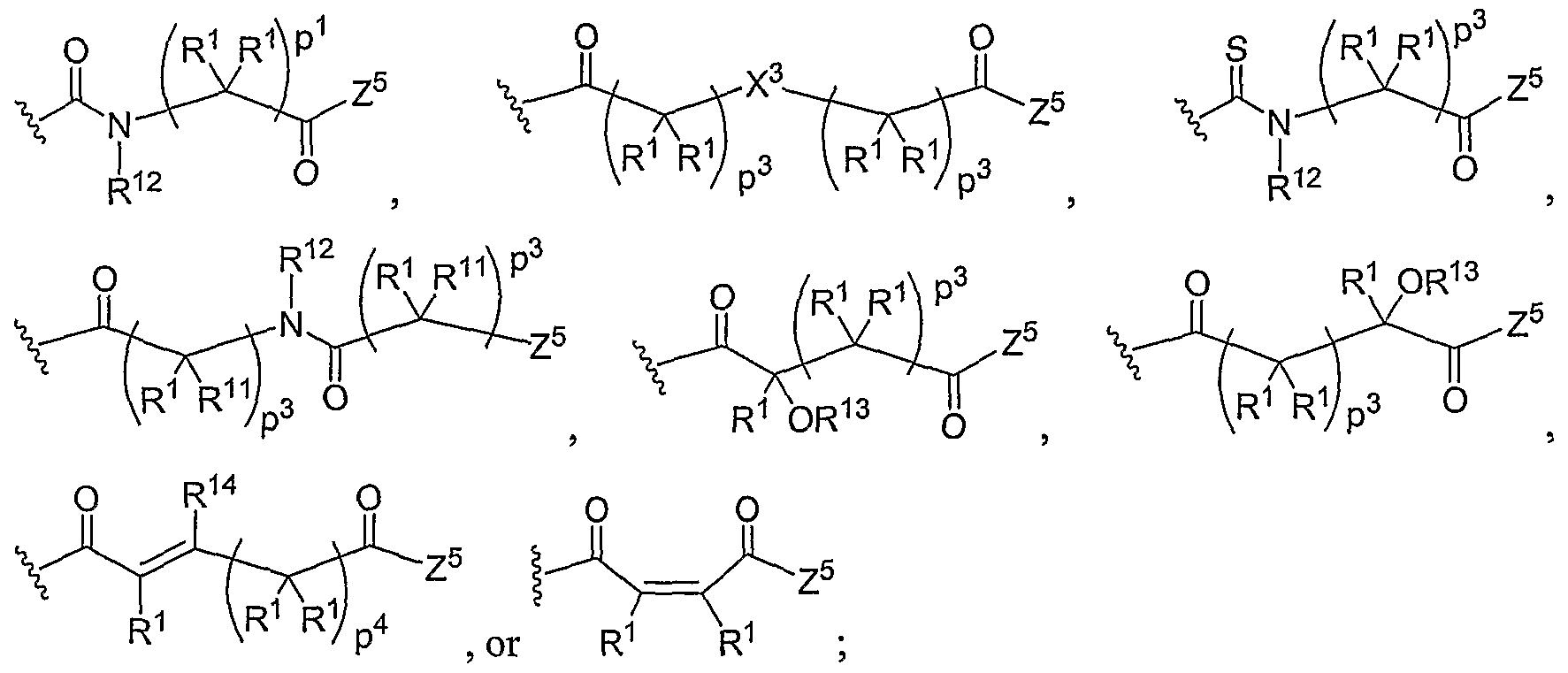

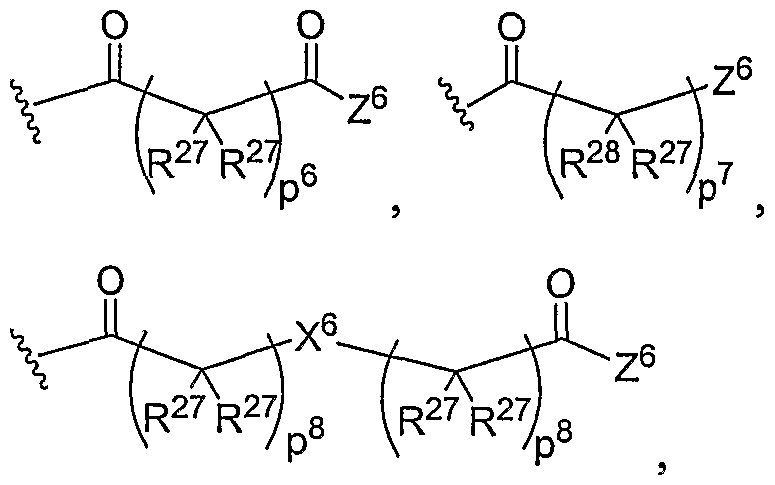

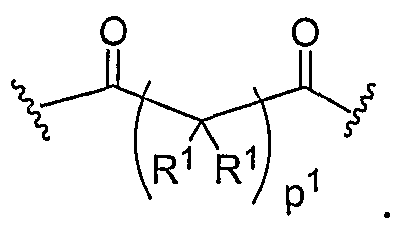

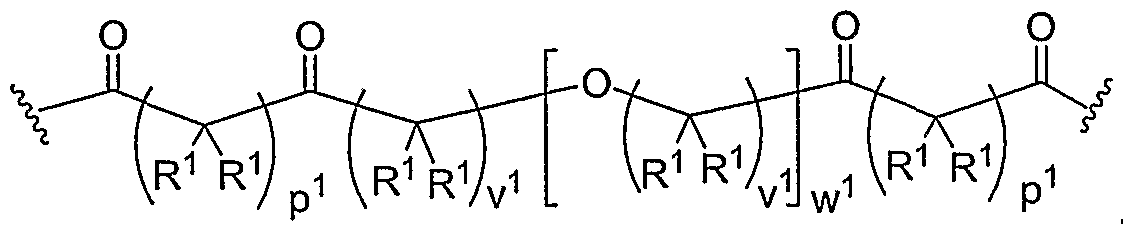

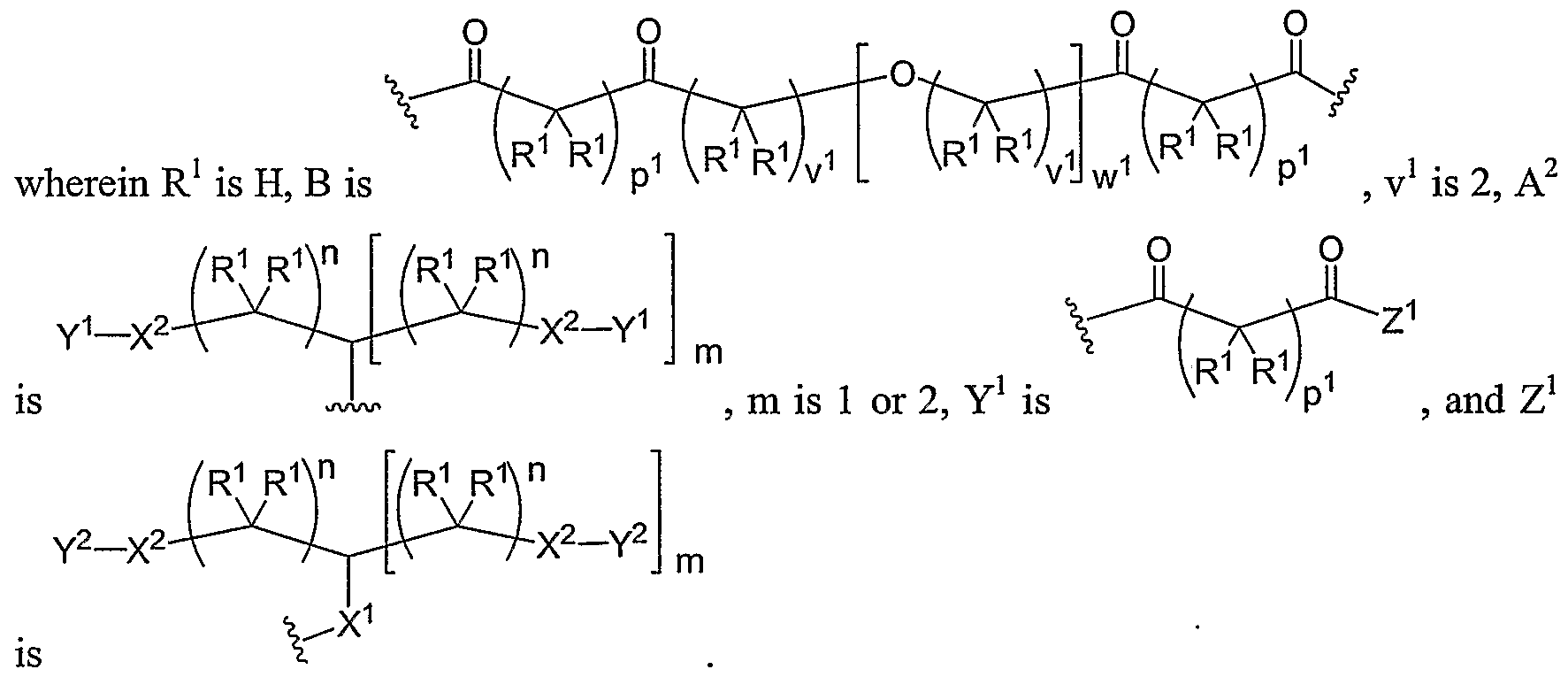

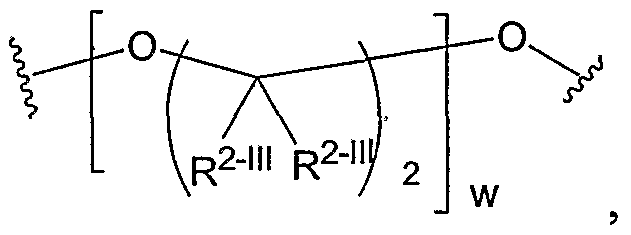

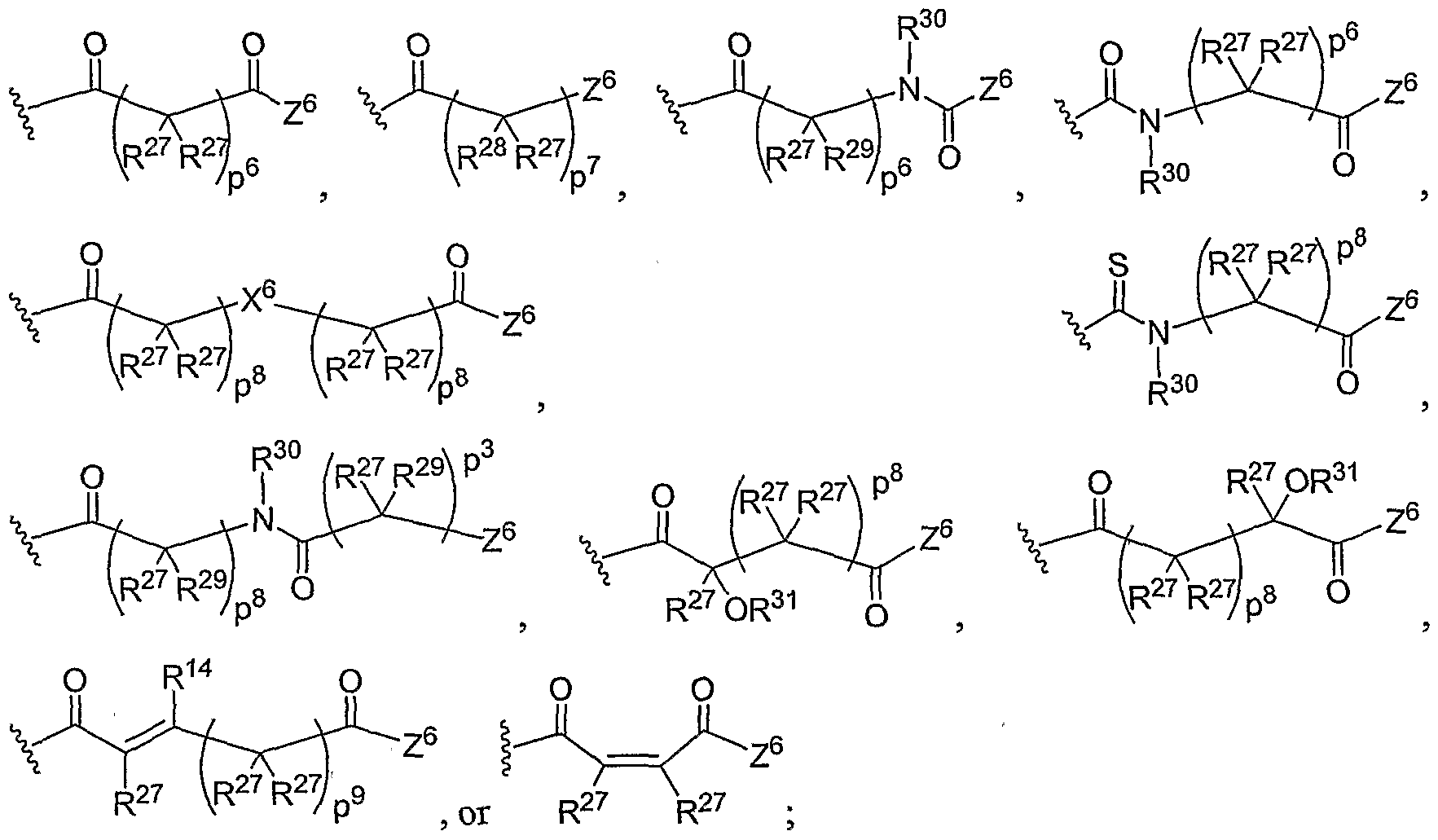

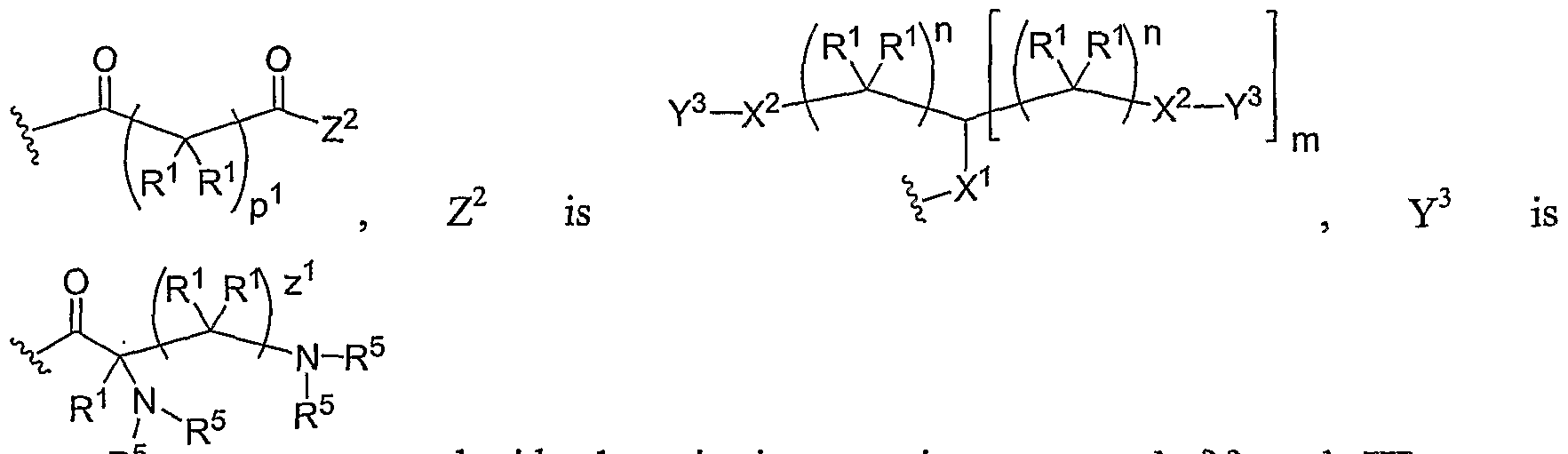

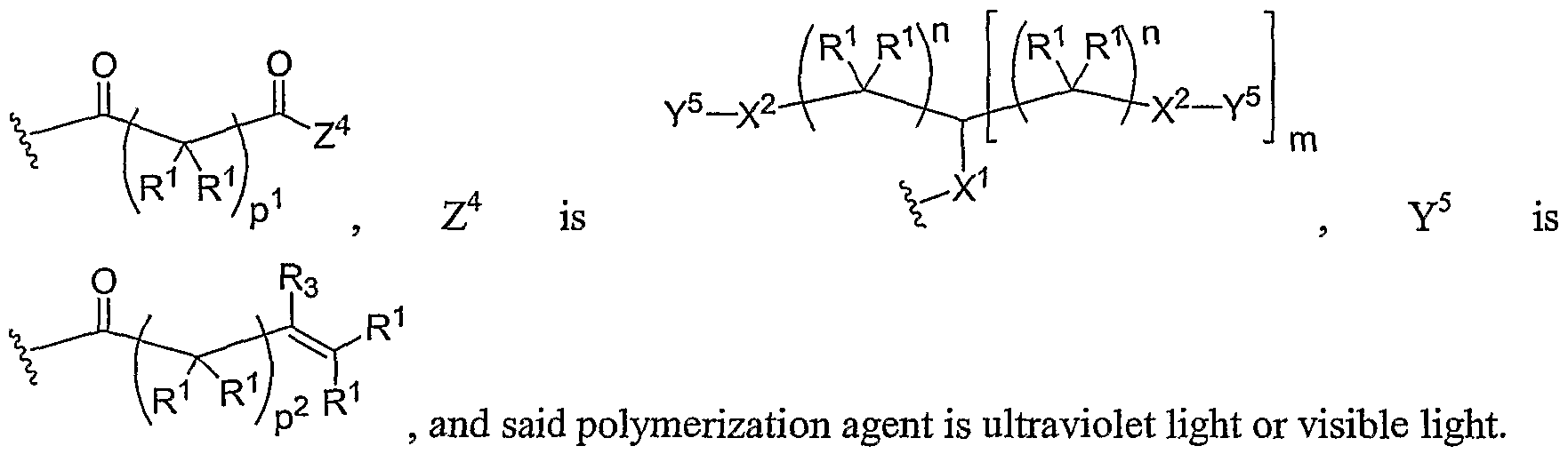

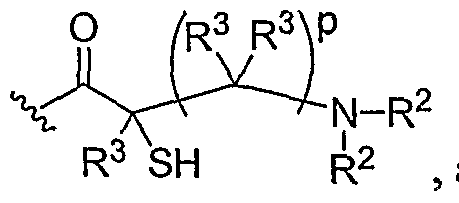

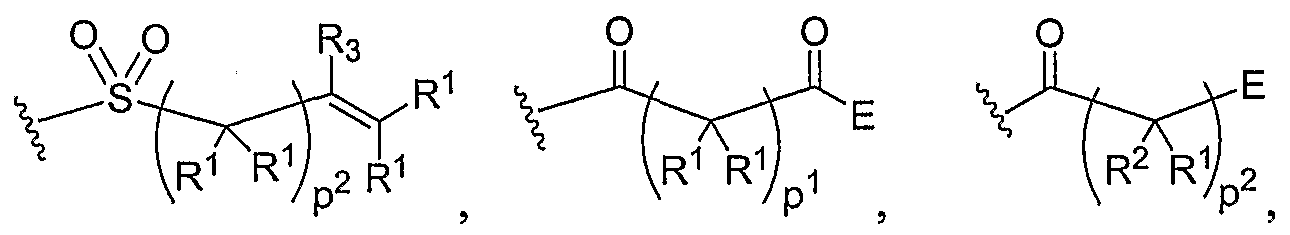

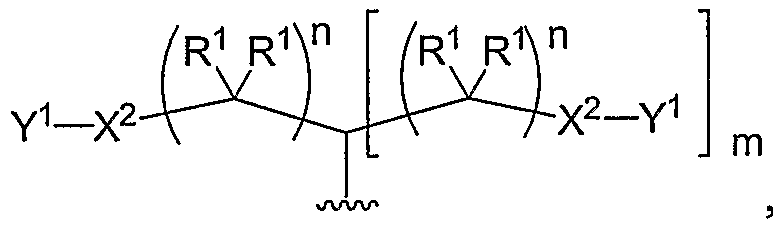

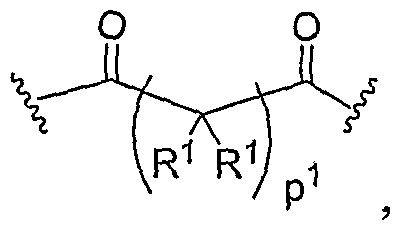

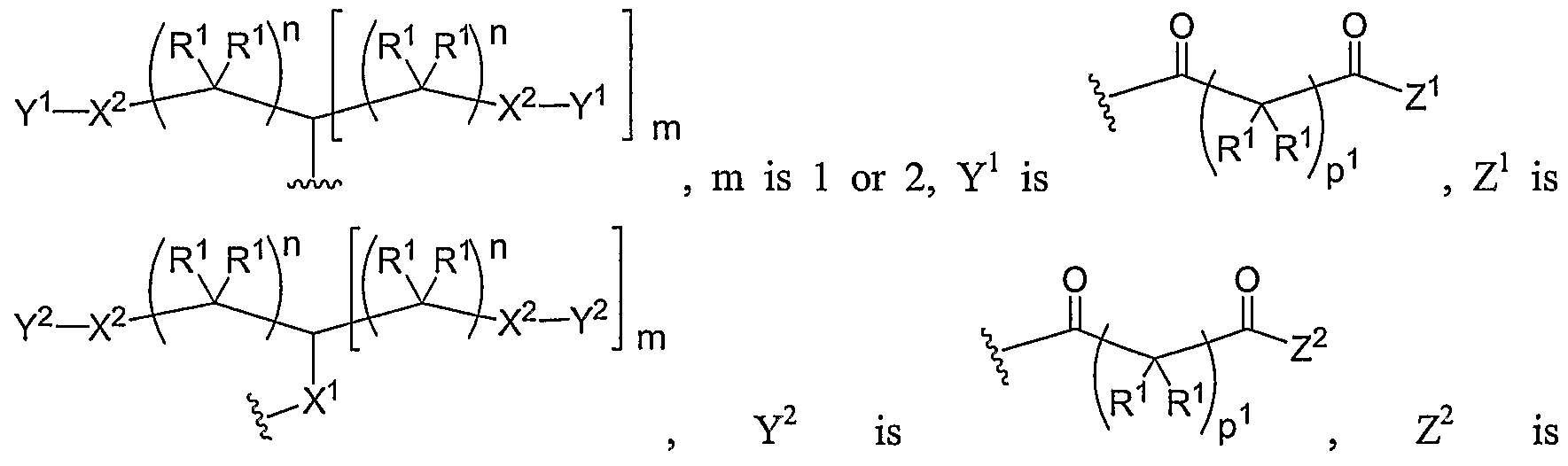

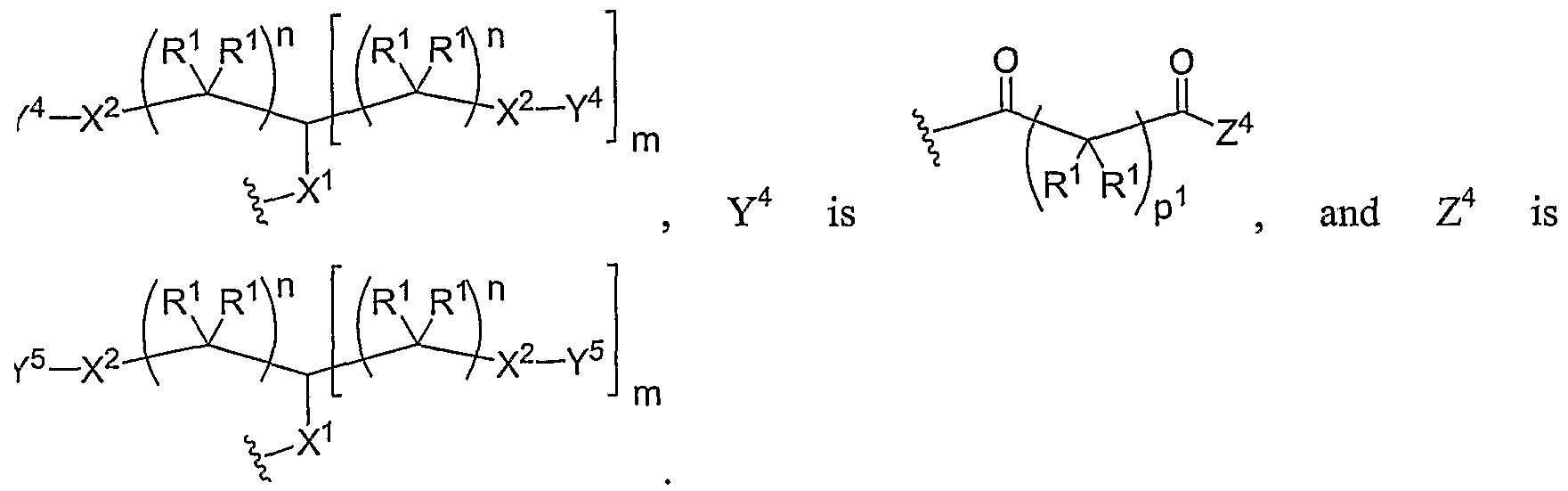

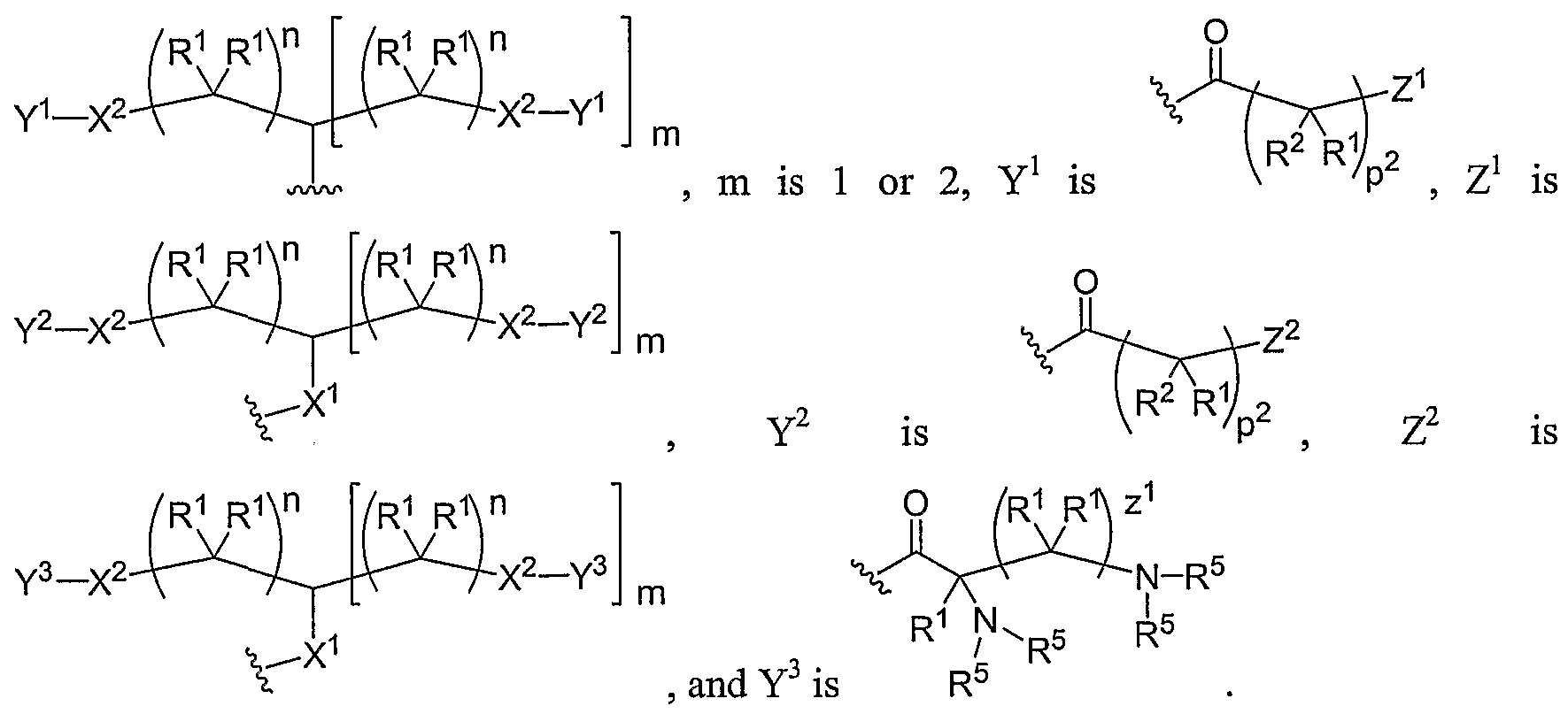

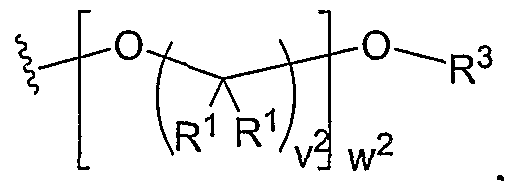

- Figure 1 depicts various monomers that can be used to prepare dendrimers used in methods of the invention.

- Figure 2 depicts various monomers that can be used to prepare dendrimers used in methods of the invention.

- Figure 3 depicts various monomers that can be used to prepare dendrimers used in methods of the invention.

- Figure 4 depicts various monomers that can be used to prepare dendrimers used in methods of the invention.

- Figure 5 depicts various monomers that can be used to prepare dendrimers used in methods of the invention.

- Figure 6 depicts various monomers that can be used to prepare dendrimers used in methods of the invention.

- Figure 7 depicts various monomers that can be used to prepare dendrimers used in methods of the invention.

- Figure 8 depicts a dendrimer terminated with nucleoside groups amenable to the invention.

- Figure 9 depicts dendrimers and compounds useful for making dendrimers amenable to the present invention.

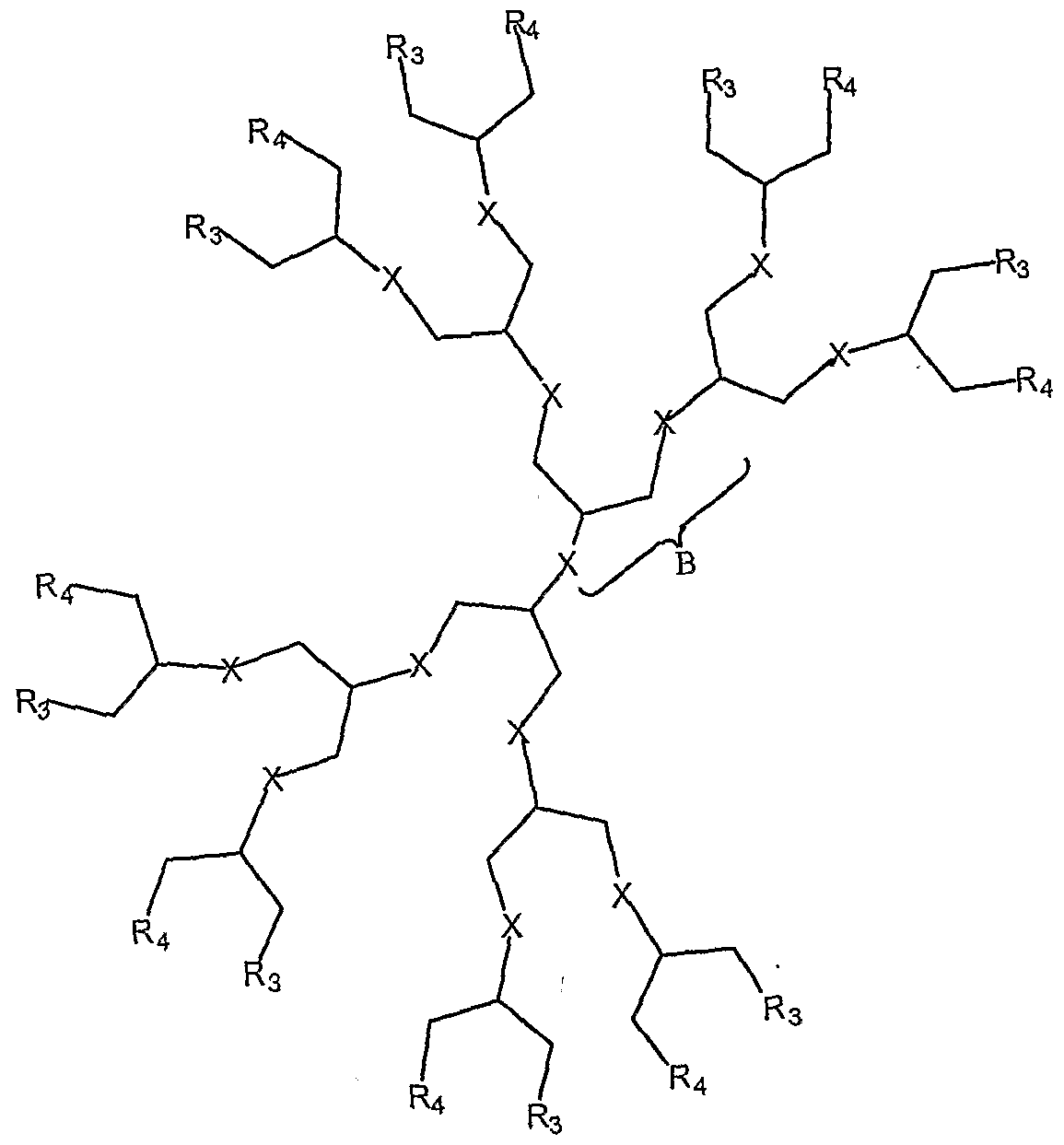

- Figure 10 depicts a dendrimer amenable to the present invention.

- Figure 11 depicts photocrosslinkable PEG 34 oo-(PGLSA-MA 4 ) 2 macromer 1 for hydrogel formation.

- Figure 13 depicts the complex modulus ⁇ G* ⁇ , storage modulus G', loss modulus G" and loss angle ⁇ of crosslinked hydrogel samples at 4 different concentrations of macromer 1 in PBS.

- Figure 14 depicts a determination of the compressive modulus E, as a function of concentration of macromer 1 in PBS.

- the compression-relaxation experiment for 20 % 1 is shown on the left, the linear curve fits for all concentrations and the resulting compressive modulus E is shown on the right.

- Figure 15 depicts histological sections of 7.5 % and 15 % macromer 1 concentration hydrogels after 2 and 4 weeks incubation. Top: Red indicates proteoglycans in the Safranin-0 stained sections, green indicates collagen in the Masson's Trichrome stained sections. Bottom: Red indicates type I or II collagen in the immunostained sections, no significant type I collagen was detected at either concentration. The length of the inserted bar is 100 ⁇ m.

- Figure 16 depicts a plot of swelling versus time for occular sealants in Example 120.

- Figure 17 depicts a plot of average swelling results versus time for occular sealants in Example 120.

- Figure 18 depicts a response surface plot of pH and buffer ratio effects for sealants in Example 121.

- Figure 19 depicts a contour plot of pH and buffer ratio effects for sealants in Example 121.

- Figure 20 depicts a response surface plot for swelling at 48 hours for sealants in Example 121.

- Figure 21 depicts a contour plot for swelling at 48 hours for sealants in Example 121.

- Figure 22 depicts a response surface plot for swelling at 72 hours for sealants in Example 121.

- Figure 23 depicts a contour plot for swelling at 72 hours for sealants in Example 121.

- Figure 24 depicts the effect of dendron buffer pH on swelling after 48 hours for sealants in Example 122.

- Figure 25 depicts the effect of dendron buffer pH on cure time for sealants in Example 122.

- Figure 26 depicts a swelling response surface plot for manually mixed samples for sealants in Example 123.

- Figure 27 depicts a swelling response surface plot for mix-tip samples for sealants in Example 123.

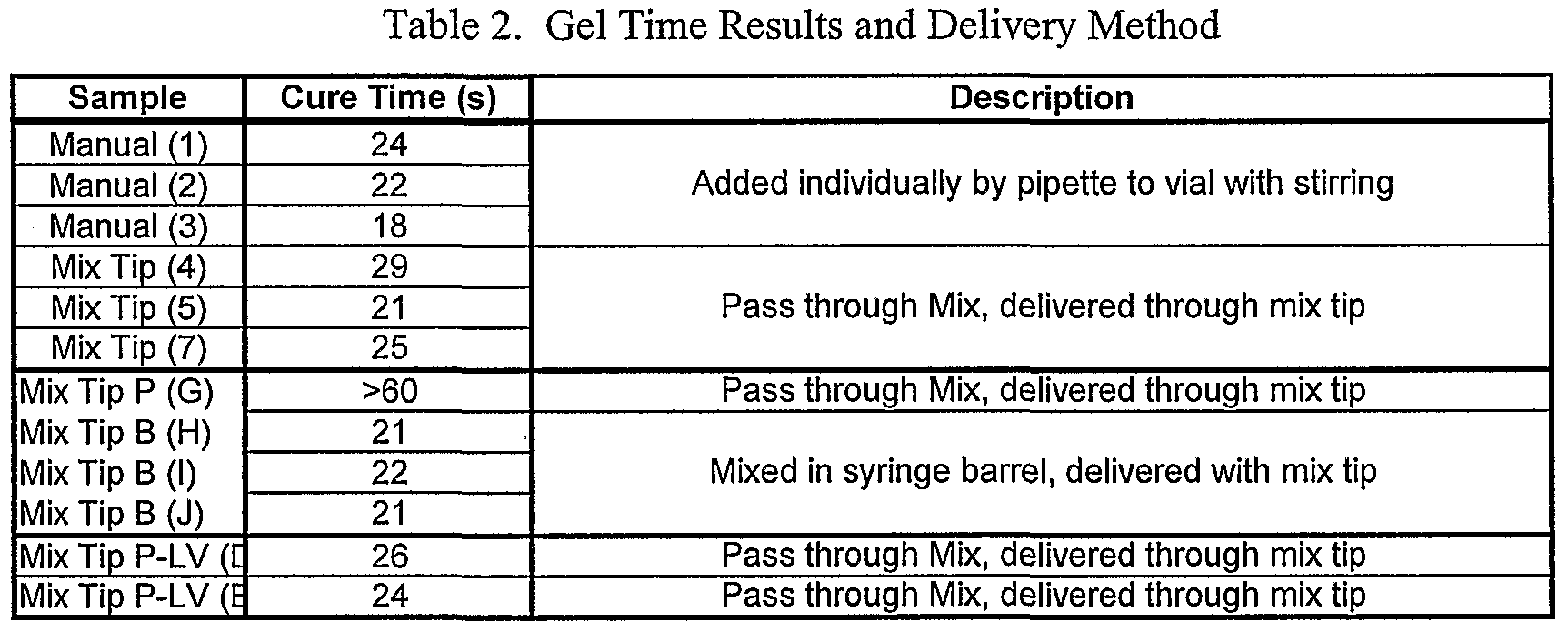

- Figure 28 depicts a cure time response surface plot for manually mixed samples (with contour plot) for sealants in Example 123.

- Figure 29 depicts a cure time response surface plot for mix-tip samples for sealants in Example 123.

- Figure 30 depicts a double-acting, single-barrel syringe.

- Figure 31 depicts a double-barrel syringe.

- the present invention broadly relates to methods and compositions for sealing a wound on a patient using a hydrogel sealant/adhesive.

- the sealant compositions of the present invention may be used in clinical treatments, such as sealing or repairing traumatic or surgical wounds.

- the sealants may be used for topical wounds or in vivo wounds, and the sealants may be formed in situ.

- the sealants of the invention may be used in situations where the site of the wound is not easily accessible and when sutureless surgery is desirable.

- the sealants of the present invention comprise dendrimeric macromolecules. In certain instances, the dendrimeric macromolecules form a hydrogel that swells less than about 400 wt% upon hydration.

- the dendrimeric macromolecular sealants of the present invention optionally comprise a polymer, such as polyvinylpyrrolidone, polyethylene glycol, poly(N-isopropylacrylamide), or a copolymer of poly(ethylene glycol) and poly(propylene glycol).

- the sealants of the invention comprise a dendrimeric macromolecule and an alkyl diacid compound, wherein the alkyl diacid compound has a molecular weight of less than about 1000 g/mol.

- the formulations used to prepare the sealant may be mixed with a pharmaceutical agent to aid in the repair of damaged tissue or organs.

- the pharmaceutical agent is a growth factor, antibiotic, antimicrobial agent, or antiinflammatory agent.

- the pharmaceutical agent may be encapsulated by the sealant or it may be bonded to the polymeric compounds forming the sealant.

- the dendrimeric macromolecules can be seeded with cells, and then used to repair the damaged tissue or organs.

- the polymers and cells can be mixed and then injected into the in vivo site and crosslinked in situ for tissue repair or replacement.

- the crosslinked polymers provide a three dimensional template for new cell growth.

- Crosslinking such as with a methacrylated functionalized denditic polymer, can be achieved using light or a chemical reaction.

- the crosslinkable biodendritic macromolecules can undergo a covalent or non- covalent crosslinking reaction to form a three-deminsional crosslinked gel or network.

- the crosslinking reaction is performed using light.

- the crosslinking reaction does not require light.

- the formulations used to prepare the hydrogel sealants/adhesives of the invention may be aqueous mixtures.

- the pH of the aqueous mixture may be adjusted to give hydrogel sealants with different physical properties. In certain instances, the pH of the mixture ranges from about 6.0 to about 10.0.

- the pH of the mixture ranges from about 7.5 to about 8.5.

- the aqueous mixture may further comprise a carbonate, phosphate, 1-piperazineethane sulfonic acid, 4-(2-hydroxyethyl)-monosodium salt (HEPES), or a citrate to modulate the pH of the mixture.

- the aqueous mixture further comprises a carbonate or phosphate.

- Dendritic polymers are globular monodispersed polymers composed of repeated branching units emitting from a central core. See US5714166; US4289872; US4435548; US5041516; US5362843; US5154853; US05739256; US5602226; US5514764; Bosman, A. W.; Janssen, H. M.; Meijer, E. W. Chem. Rev. 1999, 99, 1665-1688; Fischer, M.; Vogtle, F. Angew. Chem. Int. Ed. 1999, 38, 884-905; Zeng, F.; Zimmerman, S. C. Chem. Rev. 1997, 97, 1681-1712; Tomalia, D.

- dendrimers are highly ordered, possess high surface area to volume ratios, and exhibit numerous end groups for functionalization. Consequently, dendrimers display several favorable physical properties for both industrial and biomedical applications including: small polydispersity indexes (PDI), low viscosities, high solubility and miscibility, and excellent adhesive properties.

- PDI polydispersity indexes

- the majority of dendrimers investigated for biomedical/biotechnology applications e.g., MRI, gene delivery, and cancer treatment

- are derivatives of aromatic polyether or aliphatic amides are not ideal for in vivo uses. See Service, R. F.

- Biodendrimers are a novel class of dendritic macromolecules composed entirely of building blocks known to be biocompatible or degradable to natural metabolites in vivo.

- the synthesis, characterization, and use of biodendrimers composed of biocompatible or natural metabolite monomers such as glycerol, lactic acid, glycolic acid, succinic acid, ribose, adipic acid, malic acid, glucose, citric acid, glycine, lysine, cysteine, alanine, etc. are described herein.

- the dendritic structures of the invention contain glycerol and one or more of lactic acid, glycolic acid, succinic acid, ribose, adipic acid, malic acid, glucose, citric acid, glycine, lysine, cysteine, alanine, and the like as a building block.

- the dendrimer is terminated with a photoreactive group or nucleophilic group.

- the terminus of the dendrimer contains a nucleoside.

- An additional embodiment of the invention is a dendritic structure that is composed of all lysine resides, such that it is a generation one or higher, or it is a lysine dendritic macromolecule terminated with cystene residues such that it is a generation one or higher.

- One aspect of the present invention relates to the synthesis and fabrication of dendritic polymers and copolymers of polyesters, polyethers, polyether-esters, and polyamino acids or combinations thereof.

- linear poly(glycolic acid), ⁇ oly(lactic acid), and their copolymers are synthetic polyesters that have been approved by the FDA for certain uses, and have been used successfully as sutures, drug delivery carriers, and tissue engineering scaffold for organ failure or tissue loss (Gilding and Reed, Polymer, 20:1459 (1979); Mooney et al., Cell Transpl., 2:203 (1994); and Lewis, D. H.

- a further embodiment of this invention is to attach biological recognition units for cell recognition to the end groups or within the dendrimer structure.

- the tripeptide arginine-glycine-aspartic (RGD) can be added to the structure for cell binding.

- RGD tripeptide arginine-glycine-aspartic

- Barrera et al. described the synthesis of a poly(lactic acid) (pLAL) containing a low concentration of N-epsilon-carbobenzoxy-L-lysine units. The polymers were chemically modified through reaction of the lysine units to introduce arginine-glycine-aspartic acid peptide sequences or other growth factors to improve polymer-cell interactions (Barrera et al., J. Am. Chem.

- a dendritic polymer includes multiple end-groups for functionalization, crosslinked gels with high crosslinking-densities at low polymer concentration, globular structure, low viscosities, and a well-defined composition.

- Conventional linear polymers for medical applications cannot be controlled easily or modified through changes in the polymer's structure because these polymers (e.g., PLA) do not possess functional groups, other than end groups, that permit chemical modification to change their properties.

- these polymers do not adopt a well-defined structure in solution, thereby limiting the applications of these polymers. Consequently, the novel polymers described herein are substantially different.

- Gels are 3D polymeric materials which exhibit the ability to swell in water and to retain a fraction of water within the structure without dissolving.

- the physical properties exhibited by gels such as water content, sensitivity to environmental conditions ⁇ e.g., pH, temperature, solvent, and stress), softness, adhesivity, and rubbery consistency are favorable for biomedical and biotechnological applications.

- gels may be used as coatings ⁇ e.g. biosensors, catheters, and sutures), as "homogeneous" materials ⁇ e.g.

- one aspect of the present invention relates to a gel comprising cells to create an artificial cornea to replace or aid in the repair of a damaged cornea.

- the gel is formed from a dendrimeric compound.

- Another aspect of the present invention relates to a method and means for designing, constructing, and utilizing artificial dendritic matrices as temporary scaffolding for cellular growth and implantation.

- a further embodiment of the invention to provide biodegradable, non-toxic matrices which can be utilized for cell growth, both in vitro, in vivo, and in situ.

- the cell scaffold/matrix/gel can be formed in vitro or in situ by crosslinking.

- the present invention relates to a method for configuring and constructing biodegradable artificial matrices such that they not only provide a support for cell growth, but also allow and enhance vascularization and differentiation of the growing cell mass following implantation.

- the present invention relates to matrices in different configurations so that cell behavior and interaction with other cells, cell substrates, and molecular signals can be studied in vitro.

- the dendritic macromolecules of the present invention are useful as a tissue sealant or adhesive.

- the polymers of the invention may be used as an ophthalmic sealant or adhesive for corneal lacerations, retinal tears, corneal transplants, cataract procedures, and the like.

- the macromolecules of the invention may be used to seal a large variety of different types of wounds, and one of skill in the art will recognize that the sealant/adhesive has wide-spread application in ophthalmic and general surgeries.

- the sealants of the invention are used to seal a wound that is less than about 10 cm 2 , 5 cm 2 , or 1 cm 2 in size.

- the sealants of the invention are used to seal a wound that is less than about 5 cm, 2 cm, or 1 cm in length. In certain instances, the sealants of the invention are used to seal a wound that is less than about 0.5 cm, 0.2 cm, 0.1, or 0.05 cm in length.

- a further embodiment of this invention is to use biodendritic crosslinkable polymers for sealing corneal perforations.

- a further embodiment of this invention is to use biodendritic crosslinkable polymers for sealing retinal holes.

- a further embodiment of this invention is to use biodendritic crosslinkable polymers for sealing leaking blebs.

- a further embodiment of this invention is to use biodendritic crosslinkable polymers for sealing a corneal transplant.

- the crosslinkable polymers of the invention may be used when the site of the wound is not easily accessible or when sutureless surgery is desired.

- the crosslinkable sealants may also be useful in cardiovascular surgery (aortic dissection or anastomotic bleeding), urinary tract surgery (nephrotomy closure, urethral repair, or hypospadia repair), pulmonary surgery (sealing parenchymal & bronchial leaks, bronchopleural fistula repair, or persistent air leak repairs), G.I.

- Low-swelling hydrogels are advantagous because hydrogel sealants/adhesives that swell significantly can become dislodged from the application site and lose their adhesive strength.

- a hydrogel that swells about 700 wt% in aqueous solution can have poor performance in an ocular laceration.

- the low-swelling hydrogel is a hydrogel that swells less than about 400 wt% in an aqueous solution.

- the low-swelling hydrogel swells less than about 300 wt% or 200 wt% in an aqueous solution.

- the hydrogel sealants of the invention can form in less than about 30 minutes. In certain instances, the hydrogel sealants of the invention form in less than about 15 minutes, 5 minutes, or 1 minute.

- Biologically active agents may be incorporated in the dendritic gel.

- Biologically active agents amenable to the present invention include, without limitation, medicaments; vitamins; mineral supplements; substances used for the treatment, prevention, diagnosis, cure or mitigation of disease or illness; or substances which affect the structure or function of the body; or pro-drugs, which become biologically active or more active after they have been placed in a predetermined physiological environment.

- Preferred active agents amenable for use in the compositions of the present invention include growth factors, such as transforming growth factors (TGFs), fibroblast growth factors (FGFs), platelet derived growth factors (PDGFs), epidermal growth factors (EGFs), connective tissue activated peptides (CTAPs), osteogenic factors, and biologically active analogs, fragments, and derivatives of such growth factors.

- TGFs transforming growth factors

- FGFs fibroblast growth factors

- PDGFs platelet derived growth factors

- EGFs epidermal growth factors

- CTAPs connective tissue activated peptides

- osteogenic factors and biologically active analogs, fragments, and derivatives of such growth factors.

- TGF transforming growth factor

- TGF- ⁇ l transforming growth factor

- TGF- ⁇ 2 transforming growth factor- ⁇ 3

- bone morphogenetic proteins for example, BMP-I, BMP-2, BMP-3, BMP-4, BMP-5, BMP-6, BMP-7, BMP-8, and BMP-9

- heparin-binding growth factors for example, fibroblast growth factor (FGF), epidermal growth factor (EGF), platelet-derived growth factor (PDGF), and insulin-like growth factor (IGF)

- inhibins for example, Inhibin A, Inhibin B

- growth differentiating factors for example, GDF- 1

- activins for example, Activin A, Activin B, and Activin AB

- Representative categories of biologically active compounds amenable to the present invention also include anti-infective agents, anti-inflammatory agents, anti-neoplastic agents, analgesic agents, anti-thrombotic agents, diagnostic agents, mineral supplements, vitamins, and prodrugs.

- Representative analgesics include nonsteroidal anti-inflammatory drugs, opiate agonists and salicylates.

- anti-infective agents include anthelmintics, antianaerobics, antibiotics, aminoglycoside antibiotics, antifungal antibiotics, cephalosporin antibiotics, macrolide antibiotics, various beta-lactam antibiotics, penicillin antibiotics, quinolone antibiotics, sulfonamide antibiotics, tetracycline antibiotics, antimycobacterials, antituberculosis antimycobacterials, antiprotozoals, antimalarial antiprotozoals, antiviral agents, anti-retroviral agents, scabicides, and urinary anti- infectives.

- Representative antineoplastic agents include alkylating agents, nitrogen mustard alkylating agents, nitrosourea alkylating agents, antimetabolites, purine analog antimetabolites, pyrimidine analog antimetabolites, hormonal antineoplastics, natural antineoplastics, antibiotic natural antineoplastics, and vinca alkaloid natural antineoplastics.

- Specific compounds for the aforementioned categories are listed in U.S. 6,600,010 and Merck Index, 12 th Edition; S. Budavari, M. J. O'Neil, A. Smith, P. E. Heckelman, J. F. Kinneary, Ed.; Merck Research Laboratories: Whitehouse Station, NJ, 1996, both of which are hereby incorporated by reference.

- the biomaterials of the present invention are also useful as a wound dressing.

- tissue adhesives e.g., glues, sealants, patches, films and the like

- an ideal adhesive should 1) bind to the tissue (necrosed or not, sometimes wet) with an adequate adhesion force, 2) be non-toxic, 3) biodegradable or resorbable, 4) sterilizable, 5) selectively permeable to gases, 6) impermeable to bacteria, and 7) able to control evaporative water loss.

- the main function of the adhesive is to protect the wound and to enhance the healing process, or at least not prevent it.

- Adhesive hemostats based on fibrin

- fibrinogen/photosensitizers systems If their intrinsic properties meet the requirements for a tissue adhesive, autologous products (which are time consuming in emergency) or severe treatments before clinical use are needed to avoid any contamination to the patient.

- Synthetic materials mainly polymers and hydrogels, have also been developed for wound closure.

- Alkyl-cyanoacrylates are available for the repair of cornea perforations.

- One investigator observed no difference in healed skin incisions that were treated by suture or by ethyl-2-cyanoacrylate-"Mediglue” application.

- these "super glues” have disadvantages.

- Their monomers, in particular those with short alkyl chains, can be toxic, and they can polymerize too quickly leading to difficulty in treating the wound. Once polymerized, the surface of the glue is rough and hard. This can cause discomfort to the patient, and in case of cornea perforation treatment, a contact lens is often required.

- the low-swelling, polymeric dendritic sealants of the present invention can be prepared by crosslinking dendrimers or dendritic polymers using either light or a chemical crosslinking reaction.

- the dendritic polymers are cross-linked with linear polymers to form a crosslinked gel or network.

- the gels can be highly hydrated and hydrophilic.

- the adhesive/sealant is mixed with a linear or dendritic polymer, such as polyvinylpyrrolidone, to form an adhesive/sealant that is an interpentrating network adhesive/sealant.

- Such adhesives/sealants often have a higher viscosity, and thus can be applied to the injury site in a more controlled fashion.

- the polymer may be polyvinylpyrrolidone iodide, starch, 2-hydroxyethyl cellulose or other cellulose derivatives, poly(propylene glycol), poly(ethylene glycol), poly(vinyl alcohol), poly(lactic acid), poly(glycolic acid), polycaprolactone, poly(n- isopropylacrylamide), polyacrylamide, polyacrylic acid, a polymethylmethacrylate, latex, hyaluronic acid, an alginate, a gelatin, or a copolymer of one or more of the aforementioned polymers.

- the polymer may also be a copolymer of polyvinylpyrrolidone and one or more of the aforementioned polymers.

- the polymers are functionalized to contain groups that will react with each other to form the gel.

- the dendritic polymers can be chemically modified to have more than two functional groups.

- the dendritic polymers have nucleophilic groups, such as primary amino (-NH 2 ) groups or thiol (-SH) groups, which can react with electrophilic groups such as an acrylate, succinimidyl ester, maleimide, or aldehyde.

- Each functional group on a multifunctionally dendritic polymer is capable of covalently binding with another polymer, thereby effecting formation of the network by crosslmking between the polymers.

- covalently crosslinked networks can be formed by reacting an activated ester, such as a succinimidyl ester, with an amine or thiol, e.g., a terminal primary or secondary amine, lys, cys, and the like.

- an activated ester such as a succinimidyl ester

- an amine or thiol e.g., a terminal primary or secondary amine, lys, cys, and the like.

- Thiol- or cysteine-terminated dendritic structures that form a disulfide crosslinked network with another thiol- or cysteine- terminated dendritic or linear polymer will also form a gel.

- a gel is formed during the reaction of an aldehyde-functionalized small molecule or polymer and an amine- or cysteine-functionalized polymer.

- An additional method is to have a maleimide- or vinylsulfone-functionalized dendritic polymer react with a thiol-functionalized dendritic, linear, comb, or other polymer to form the gel.

- a functionalized succinimidyl glutarate dendritic polymer reacts with an acid-terminated dendritic, linear, comb, or other polymer to form the gel.

- An acrylate-functionalized polymer reacts with an amine- or thiol- functionalized polymer to form the crosslinked gel.

- a further embodiment of this invention is the use of a chemical peptide ligation reaction to create a crosslinked gel involving a dendritic polymer.

- the dendritic polymers have nucleophilic groups, such as primary amino groups or thiol groups, which can react with electrophilic groups such as an acrylate, succinimidyl ester, maleimide, or aldehyde on a small molecule.

- the dendritic polymer has nucleophilic groups capable of reacting with an activated diester of sebabic acid.

- Biodendrimers are often based on a core unit and contain branches.

- the core and branches may be composed of glycerol and lactic acid, glycerol and glycolic acid, glycerol and succinic acid, glycerol and adipic acid, and glycerol, succinic acid, and PEG.

- polymers such as PEG and PLA can be attached to the core unit or to a branch to make large starburst or dendritic polymers.

- the biodendrimeric macromolecular sealants of the present invention optionally comprise a polymer, such as polyvinylpyrrolidone, polyethylene glycol, poly(N-isopro ⁇ ylacrylamide), or a copolymer of polyethylene glycol) and poly(propylene glycol).

- the sealants of the invention comprise a dendrimeric macromolecule and an alkyl diacid compound, wherein the alkyl diacid compound has a molecular weight of less than about 1000 g/mol.

- One aspect of the present invention relates to a method for preparing and administrating in situ a biocompatible gel ex vivo, in vitro, or in vivo, comprising:

- a reactive composition by admixing a biocompatible crosslinking polymer having two different nucleophilic groups such as sulfhydryl and amine groups where there is at least one amine or sulfhydryl group on the polymer with a biocompatible crosslinking polymer B having amine and sulfhydryl-reactive groups, and further wherein the amine and sulfhydryl-reactive groups are capable of covalent reaction with the amine and sulfhydryl groups upon admixture of polymers A and B under effective crosslinking conditions to form a gel in less than one day; and

- Another aspect of the present invention relates to dendritic or branched polymers or copolymers composed of monomers synthesized by combining branching compounds with other linear or branched building blocks.

- Both components are known to be biocompatible or are natural metabolites in vivo including but not limited to glycerol, citric acid, lactic acid, glycolic acid, adipic acid, caproic acid, ribose, glucose, succinic acid, malic acid, amino acids, peptides, synthetic peptide analogs, poly(ethylene glycol), poly(hydroxyacids) [e.g., PGA. PLA], including where one of the monomers is a branched structure such as glycerol combined with one of the other components.

- the present invention relates to the aforementioned polymers derivatized with peripheral compounds possessing an olefin, including, but not limited to, acrylate and methacrylate.

- the present invention relates to the aforementioned polymers derivatized with peripheral compounds including, but not limited to, cysteine, lysine, other amino acids, or any other compounds that would provide terminal nucleophiles (including, but not limited to, amines, thiols, and hydroxyl groups) or electrophiles (including, but not limited to, NHS esters, maleimides, aldehydes, and ketones).

- peripheral compounds including, but not limited to, cysteine, lysine, other amino acids, or any other compounds that would provide terminal nucleophiles (including, but not limited to, amines, thiols, and hydroxyl groups) or electrophiles (including, but not limited to, NHS esters, maleimides, aldehydes, and ketones).

- the present invention relates to the aforementioned polymers for subsequent polymerization/crosslinking/reaction with another linear or branched structure with either olefmic, electrophilic or nucleophilic groups, respectively to form a gel.

- the present invention relates to the aforementioned polymers for subsequent polymerization/crosslinking/reaction with another linear or branched structure via a photopolymerization process (single or multi-photon process) to form a gel.

- Another aspect of the present invention relates to a branching structure with at least three functional groups composed of, but not limited to, glycerol, citric acid, malic acid, amino acids, peptides, synthetic peptide analogs, or other dendritic structures synthesized to produce terminal olefins (including but not limited to acrylate or methacrylate groups), nucleophiles (including but not limited to amines, thiols, and hydroxyl groups) or electrophiles (including but not limited to NHS esters, maleimides, aldehydes, and ketones) for subsequent polymerization/crosslinking with another linear or branched structure with either olefmic, electrophilic or nucleophilic groups, respectively.

- Another aspect of the present invention relates to a branching structure with at least three functional groups composed of, but not limited to, glycerol, citric acid, malic acid, amino acids, peptides, synthetic peptide analogs, or other dendritic structures derivatized with peripheral compounds including, but not limited to, cysteine, lysine, other amino acids, or any other compounds that would provide terminal olefins (including but not limited to acrylate or methacrylate groups), nucleophiles (including but not limited to amines, thiols, and hydroxyl groups) or electrophiles (including but not limited to NHS esters, maleimides, aldehydes, and ketones) for subsequent polymerization/crosslinking with another linear or branched structure with either olefmic, electrophilic or nucleophilic groups, respectively.

- functional groups composed of, but not limited to, glycerol, citric acid, malic acid, amino acids, peptides, synthetic peptide analogs

- Another aspect of the present invention relates to a branching structure composed of three lysine amino acids with four cysteine amino acids on the periphery with the structure CysLys(Cys)Lys(CysLys(Cys))OMe*4HCl as described in the examples.

- Another aspect of the present invention relates to a branching structure composed of three lysine amino acids with amines on the periphery with the structure (Lys)Lys(Lys)OMe»4HCl as described in the examples.

- the present invention relates to the aforementioned polymers for subsequent polymerization/crosslinking/reaction with another linear or branched structure with olefmic, electrophilic or nucleophilic groups to form a gel.

- the present invention relates to the aforementioned polymers for subsequent polymerization/crosslinking/reaction with another linear or branched structure through thiazolidine linkages to form a gel.

- the present invention relates to the aforementioned polymers undergoing polymerization/crosslinking with a poly(ethylene glycol) having a molecular weight of about 200 to about 200,000 g/mol with at least two electrophilic groups.

- the present invention relates to the aforementioned polymers undergoing polymerization/crosslinking with a poly(ethylene glycol) having a molecular weight of about 200 to about 200,000 g/mol with at least two nucleophilic groups

- the present invention relates to the aforementioned polymers undergoing polymerization/crosslinking with a poly(ethylene glycol) having a molecular weight of about 200 to about 200,000 g/mol with functional groups including but not limited to olefins, aldehydes, maleimides, or NHS esters.

- the present invention relates to the aforementioned polymers undergoing polymerization/crosslinking with a poly(ethylene glycol) having a molecular weight of about 200 to about 200,000 g/mol with aldehyde functional groups to form hydrogels through the formation of thiazolidine linkages.

- the present invention relates to the aforementioned polymers undergoing polymerization/crosslinking with a copolymer comprising poly(ethylene glycol) and polypropylene glycol, wherein the copolymer has a molecular weight of about 200 to about 200,000 g/mol with functional groups including, but not limited to, olefins, aldehydes, maleimides, and NHS esters.

- the present invention relates to the aforementioned polymers undergoing polymerization/crosslinking with an alkyl diacid, wherein the alkyl diacid has a molecular weight of about 50 to about 1,000 g/mol and the alkyl diacid contains functional groups comprising NHS-esters.

- the present invention relates to the aforementioned formulations in which each of the components are dissolved or suspended in an aqueous solution wherein the said aqueous solution is selected from water, buffered aqueous media, saline, buffered saline, solutions of amino acids, solutions of sugars, solutions of vitamins, solutions of carbohydrates or combinations of any two or more thereof.

- the present invention relates to the application of the aforementioned formulation through a delivery device which physically separates the components until the components are physically mixed by the end user, including but not limited to a dual barrel syringe with a mixing device.

- Another aspect of the present invention relates to packaging of the aforementioned branching compounds in an aqueous solution at a preselected pH and molarity selected from the aqueous solutions described above and the packaging of the second compound in an aqueous solution at another preselected pH and molarity selected from the aqueous solutions described above.

- the pH and molarities of the two solutions produce a final desired solution with a different pH.

- the aqueous solution comprising the branching compounds further comprises a polymer, such as polyvinylpyrrolidone .

- Another aspect of the present invention relates to packaging of the aforementioned branching compounds in an aqueous solution at a preselected pH and molarity selected from the aqueous solutions described above and the packaging of the second compound in an aqueous solution at another preselected pH and molarity selected from the aqueous solutions described above.

- the contents are packaged free of oxygen and shielded from light.

- the pH and molarities of the two solutions produce a final desired solution with a different pH.

- Another aspect of the present invention relates to packaging of the aforementioned branching compounds as a powder and adding an aqueous solution at a preselected pH and molarity selected from the aqueous solutions described above before use.

- the second component may either be packaged by dissolving the second compound in an aqueous solution at another preselected pH and molarity selected from the aqueous solutions described above or packaged similar to the first compound in which the compound stored as a powder and an aqueous solution at a preselected pH and molarity selected from the aqueous solutions described above is added before use.

- the contents are packaged free of oxygen and shielded from light.

- the pH and molarities of the two solutions produce a final desired solution with a different pH.

- Another aspect of the present invention relates to the storage of the aforementioned cysteine-terminated polymers in an acidic, oxygen-free solution to minimize the formation of disulfide bonds.

- Another aspect of the present invention relates to the storage of the aforementioned aldehyde-terminated polymers in an acidic, oxygen-free solution to maximize the percent reactivity of the polymer and minimize aldol condensation and reverse Michael additions.

- Another aspect of the present invention relates to the addition of various additives that might be incorporated into the polymer formulations including, but not limited to, antioxidants, colorants, viscosity modifiers, plasticizers, small molecule carbohydrates, large molecule carbohydrates, amino acids, peptides, or other water soluble polymers (linear or branched).

- additives may be added to increase the shelf life, increase the polymerization rate, modify the pH or molarity of the solution, change the refractive index, modify the mechanical properties, change crosslinking density, decrease swelling, or aid in visualization.

- Another aspect of the present invention relates to the addition of various additives or anti-microbial agents such has polyhexamethylene biguanide (PHMB) that might be incorporated into the polymer formulations.

- PHMB polyhexamethylene biguanide

- Another aspect of the present invention relates to the resulting hydrogels formed by mixing the aforementioned compounds as described and prepared herein.

- the present invention relates to hydrogels formed by photopolymerization of the aforementioned compounds.

- Another aspect of the present invention relates to a method of using crosslinkable/polymerizable/reactionary dendritic polymers, branching structures, and their hydrogels for delivery of therapeutics.

- Another aspect of the present invention relates to a method of using a crosslinlcable/polymerizable/reactionary dendritic polymer or monomer for seeding with cells and subsequent in situ polymerization in vivo.

- Another aspect of the present invention relates to a crosslinkable/polymerizable/reactionary dendritic polymer or monomer wherein the crosslinking is of covalent, ionic, electrostatic, and/or hydrophobic nature.

- Another aspect of the present invention relates to a crosslinkable dendritic polymer or monomer wherein the crosslinking reaction involves a nucleophile and electrophile.

- Another aspect of the present invention relates to a crosslinkable dendritic polymer or monomer wherein the crosslinking reaction is a peptide ligation reaction.

- Another aspect of the present invention relates to a crosslinkable dendritic polymer or monomer wherein the crosslinking reaction is a Diels-Alder reaction.

- Another aspect of the present invention relates to a crosslinkable dendritic polymer or monomer wherein the crosslinking reaction is a Michael Addition reaction.

- Another aspect of the present invention relates to a crosslinkable dendritic polymer or monomer wherein the crosslinking reaction is a photochemical reaction using a UV or visible photoinitator chromophore.

- Another aspect of the present invention relates to a crosslinkable branched or dendritic polymer in combination with a crosslinkable linear, comb, multi-block, star, or dendritic polymer(s) for a medical or tissue engineering application.

- Another aspect of the present invention relates to a crosslinkable branched or dendritic polymer in combination with a crosslinkable monomer(s) for a medical or tissue engineering application.

- Another aspect of the present invention relates to a method of using a crosslinkable branched or dendritic polymer combined with a crosslinkable small molecule(s) (molecule weight less than about 1000 Daltons) for a medical or tissue engineering application.

- Another aspect of the present invention relates to a crosslinkable branched or dendritic polymer or monomer wherein the said crosslinking dendritic polymer is combined with one or more linear, comb, multi-block, star polymers or crosslinkable comb, multi- block, star polymers.

- Another aspect of the present invention relates to a crosslinkable dendritic polymer or monomer wherein the final polymeric form is a gel, film, fiber, or woven sheet.

- Another aspect of the present invention relates to the aforementioned polymers, branching structures, and their resulting hydrogels wherein the final polymeric form is a gel, film, fiber, or woven sheet.

- Another aspect of the present invention relates to the aforementioned polymers, branching structures, and their resulting hydrogels wherein the polymer or crosslinkable monomer is D or L configuration or a mixture.

- Another aspect of the present invention relates to the aforementioned polymers, branching structures, and their hydrogels wherein the dendritic structure is asymmetric at the surface such as a surface block structure where a carboxylate acid(s) and alkyl chains, or acrylate(s) and PEG(s) are present, for example, or within the core and inner layers of the dendrimer such as amide and ester linkages in the structure.

- Another aspect of the present invention relates to the aforementioned crosslinkable or noncrosslinkable polymer wherein the polymer is a star biodendritic polymer or copolymer as shown in at least one of the formulas below: where Y and X are the same or different at each occurrence and are O, S, Se, N(H), or P(H) and where R 1 , R 2 , R 3 , R 4 , R 5 , R ⁇ , R 7 , R 8 , A or Z are the same or different and include -H, -CH 3 , -OH, carboxylic acid, sulfate, phosphate, aldehyde, methoxy, amine, amide, thiol, disulfide, straight or branched chain alkane, straight or branched chain alkene, straight or branched chain ester, straight or branched chain ether, straight or branched chain silane, straight or branched chain urethane, straight or branched chain, carbonate,

- Another aspect of the present invention relates to the aforementioned crosslinkable or noncrosslinkable polymer where the straight or branched chain is of about 1-50 carbon atoms wherein the chain is fully saturated, fully unsaturated or any combination therein

- the present invention relates to the aforementioned crosslinkable or noncrosslinkable polymer where the straight or branched chain is of about 1-50 carbon atoms wherein the chain is fully saturated, fully unsaturated or any combination therein.

- the present invention relates to the aforementioned crosslinkable or noncrosslinkable polymer wherein straight or branched chains are the same number of carbons or different wherein R 1 , R 2 , R 3 , R 4 , R 5 , R 6 , R 7 , Rs, A or Z are any combination of the linkers including ester, silane, urea, amide, amine, carbamate, urethane, thiol-urethane, carbonate, thio-ether, thio-ester, sulfate, phosphate and ether.

- the present invention relates to the aforementioned crosslinkable or noncrosslinkable polymer which includes at least one chain selected from the group consisting of hydrocarbons, fluorocarbons, halocarbons, alkenes, and alkynes.

- the present invention relates to the aforementioned crosslinkable or noncrosslinkable polymer which includes at least one chain selected from the group consisting of linear and dendritic polymers.

- the present invention relates to the aforementioned crosslinkable or noncrosslinkable polymer wherein said linear and dendritic polymers include at least one selected from the group consisting of polyethers, polyesters, polyamines, polyacrylic acids, polycarbonates, polyamino acids, polynucleic acids and polysaccharides of molecular weight ranging from about 200-1,000,000 g/mol, and wherein said chain contains 0, 1 or more than 1 photopolymerizable group.

- Another aspect of the present invention relates to a crosslinkable or noncrosslinkable polymer, wherein the polyether is PEG, and wherein the polyester is PLA, PGA or PLGA.

- Another aspect of the present invention relates to a linear polymer wherein the chain is a polymer or copolymer of a polyester, polyamide, polyether, or polycarbonate of or the aforementioned polymer in combination with a polyester, polyamide, polyether, or polycarbonate of:

- the present invention relates to the aforementioned polymer comprised of repeating units of General Structure I, where A is O, S, Se, or N-R 7 .

- the present invention relates to the aforementioned polymer, where W, X, and Z are the same or different at each occurrence and are O, S, Se, N(H), or P(H).

- the present invention relates to the aforementioned polymer, where R 1 is hydrogen, a straight or branched alkyl chain of about 1-20 carbons, cycloalkyl, aryl, olefin, silyl, alkylsilyl, arylsilyl, alkylaryl, or arylalkyl group.

- the present invention relates to the aforementioned polymer, where Ri is hydrogen, a straight or branched alkyl chain of about 1-20 carbons, cycloalkyl, aryl, olefin, silyl, alkylsilyl, arylsilyl, alkylaryl, or arylalkyl group substituted internally or terminally by one or more hydroxyl, hydroxyether, carboxyl, carboxyester, carboxyamide, amino, mono- or di-substituted amino, thiol, thioester, sulfate, phosphate, phosphonate, or halogen substituents.

- Ri is hydrogen, a straight or branched alkyl chain of about 1-20 carbons, cycloalkyl, aryl, olefin, silyl, alkylsilyl, arylsilyl, alkylaryl, or arylalkyl group substituted internally or terminally by one or more hydroxyl, hydroxyether, carb

- the present invention relates to the aforementioned polymer, where Ri is a polymer (such as poly(ethylene glycol), poly(ethylene oxide), or a poly(hydroxyacid)), a carbohydrate, a protein, a polypeptide, an amino acid, a nucleic acid, a nucleotide, a polynucleotide, any DNA or RNA segment, a lipid, a polysaccharide, an antibody, a pharmaceutical agent, or any epitope for a biological receptor.

- Ri is a polymer (such as poly(ethylene glycol), poly(ethylene oxide), or a poly(hydroxyacid)), a carbohydrate, a protein, a polypeptide, an amino acid, a nucleic acid, a nucleotide, a polynucleotide, any DNA or RNA segment, a lipid, a polysaccharide, an antibody, a pharmaceutical agent, or any epitope for a biological receptor.

- Ri is a polymer (such

- the present invention relates to the aforementioned polymer, where Ri is a photocrosslinkable, chemically, or ionically crosslinkable group.

- the present invention relates to the aforementioned polymer, in which D is a straight or branched alkyl chain of about 1-5 carbons, m is 0 or 1, and R 2 , R 3 , R 4 , R 5 , R 6 , and R 7 are the same or different at each occurrence and are hydrogen, a straight or branched alkyl chain of about 1-20 carbons, cycloalkyl, aryl, alkoxy, aryloxy, olefin, alkylamine, dialkylamine, arylamine, diarylamine, alkylamide, dialkylamide, arylamide, diarylamide, alkylaryl, or arylalkyl group.

- the present invention relates to the aforementioned polymer comprised of repeating units of General Structure II, where L, N, and J are the same or different at each occurrence and are O, S, Se, N(H), or P(H).

- the present invention relates to the aforementioned polymer where Rj is hydrogen, a straight or branched alkyl chain of about 1-20 carbons, cycloalkyl, aryl, olefin, silyl, alkylsilyl, arylsilyl, alkylaryl, or arylalkyl group.

- the present invention relates to the aforementioned polymer where Ri is hydrogen, a straight or branched alkyl chain of about 1-20 carbons, cycloalkyl, aryl, olefin, silyl, alkylsilyl, arylsilyl, alkylaryl, or arylalkyl group substituted internally or terminally by one or more hydroxyl, hydroxyether, carboxyl, carboxyester, carboxyamide, amino, mono- or di-substituted amino, thiol, thioester, sulfate, phosphate, phosphonate, or halogen substituents.

- the present invention relates to the aforementioned polymer where Ri is a polymer selected from the group consisting of poly(ethylene glycols), poly(ethylene oxides), and poly(hydroxyacids, or is a carbohydrate, a protein, a polypeptide, an amino acid, a nucleic acid, a nucleotide, a polynucleotide, a DNA or RNA segment, a lipid, a polysaccharide, an antibody, a pharmaceutical agent, or an epitope for a biological receptor.

- Ri is a polymer selected from the group consisting of poly(ethylene glycols), poly(ethylene oxides), and poly(hydroxyacids, or is a carbohydrate, a protein, a polypeptide, an amino acid, a nucleic acid, a nucleotide, a polynucleotide, a DNA or RNA segment, a lipid, a polysaccharide, an antibody, a pharmaceutical agent, or an epitope for a

- the present invention relates to the aforementioned polymer where R] is a photocrosslinkable, chemically, or ionically crosslinkable group.

- the present invention relates to the aforementioned polymer, where D is a straight or branched alkyl chain of about 1-5 carbons, q and r are the same or different at each occurrence and are 0 or 1, and R 7 , R 8 , R9, Rio, Rn, Ri 2 , Ri 3 , and R] 4 are the same or different at each occurrence and are hydrogen, a straight or branched alkyl chain of about 1-20 carbons, cycloalkyl, aryl, alkoxy, aryloxy, olefin, alkylamine, dialkylamine, arylamine, diarylamine, alkylamide, dialkylamide, arylamide, diarylamide, alkylaryl, or arylalkyl group.

- the present invention relates to the aforementioned block or random copolymer comprised of repeating units of General Structure III, where M, T, and Q are the same or different at each occurrence and are O, S, Se, N(H), or P(H), e is 0 or 1-9, and Ri5 is a straight or branched alkyl chain of about 1-5 carbons, unsubstituted or substituted with one or more hydroxyl, hydroxyether, carboxyl, carboxyester, carboxyamide, amino, mono- or di-substituted amino, thiol, thioester, sulfate, phosphate, phosphonate, or halogen substituents.

- M, T, and Q are the same or different at each occurrence and are O, S, Se, N(H), or P(H)

- e is 0 or 1-9

- Ri5 is a straight or branched alkyl chain of about 1-5 carbons, unsubstituted or substituted with one or more

- the present invention relates to the aforementioned block or random copolymer comprised of repeating units of General Structure III, where M, T, and Q are the same or different at each occurrence and are O, S, Se, N(H), or P(H), and Rj 5 is a straight or branched alkyl chain of about 1-5 carbons, unsubstituted or substituted with one or more hydroxyl, hydroxyether, carboxyl, carboxyester, carboxyamide, amino, mono- or di-substituted amino, thiol, thioester, sulfate, phosphate, phosphonate, or halogen substituents.

- the present invention relates to the aforementioned block or random copolymer comprised of repeating units of General Structure III, where M, T, and Q are the same or different at each occurrence and are O, S, Se, N(H), or P(H), and Rl 5 is a straight or branched alkyl chain of about 1-5 carbons, unsubstituted or substituted with one or more hydroxyl, hydroxyether, carboxyl, carboxyester, carboxyamide, amino, mono- or di-substituted amino, thiol, thioester, sulfate, phosphate, phosphonate, or halogen substituents.

- Another aspect of the present invention relates to a higher order block or random copolymer comprised of three or more different repeating units, and having one or more repeating units described above, such as a polyglyerol glycine carbonate-polyglycerol succinic acid copolymer.

- Another aspect of the present invention relates to a block or random copolymer as described above, which includes at least one terminal crosslinkable group selected from the group consisting of amines, thiols, amides, phosphates, sulfates, hydroxides, alkenes, and alkynes.

- the present invention relates to the aforementioned block or random copolymer where X, Y, M is O, S, N-H, N-R, and wherein R is -H, CH 2 , CR 2 , Se or an isoelectronic species of oxygen.

- the present invention relates to the aforementioned block or random copolymer wherein an amino acid(s) is attached to Ri, R 2 , R 3 , R 4 , R 5 , A, and/or Z.

- the present invention relates to the aforementioned block or random copolymer wherein a polypeptide(s) is attached to Ri, R 2 , R 3 , R 4 , R 5 , A, and/or Z.

- the present invention relates to the aforementioned block or random copolymer wherein an antibody(ies) is attached to Ri, R 2 , R 3 , R 4 , R5, A, and/or Z. In certain instances, the present invention relates to the aforementioned block or random copolymer wherein a nucleotide(s) is attached to R 1 , R 2 , R 3 , R 4 , R 5 A, and/or Z.

- the present invention relates to the aforementioned block or random copolymer wherein a nucleoside(s) is attached to R 1 , R 2 , R 3 , R 4 , R 5> A, and/or Z.

- the present invention relates to the aforementioned block or random copolymer wherein an oligonucleotide(s) is attached to R 1 , R 2 , R 3 , R 4 , R 5, A, and/or Z.

- the present invention relates to the aforementioned block or random copolymer wherein a ligand(s) is attached to R 1 , R 2 , R 3 , R 4 , R 5 , A, and/or Z that binds to a biological receptor.

- the present invention relates to the aforementioned block or random copolymer wherein a pharmaceutical agent(s) is attached to R 1 , R 2 , R 3 , R 4 , R 5, A, and/or Z.

- the present invention relates to the aforementioned crosslinkable or noncrosslinkable polymer or copolymer wherein the polymer is a dendritic macromolecule including at least one polymer selected from the group consisting of dendrimers, hybrid linear-dendrimers, dendrons, or hyperbranched polymers according to one of the general formulas or such similar structures below: where R 3 , R 4 , which may be the same or different, are a repeat pattern of B, and n is about 0 to 50.

- the present invention relates to the aforementioned polymer, wherein X, Y, M is O, S, N-H, N-R, wherein R is -H, CH 2 , CR 2 or a chain as defined above, Se or any isoelectronic species of oxygen

- the present invention relates to the aforementioned polymer, wherein X, Y, M is O, S, N-H, N-R, wherein R is -H, CH 2 , CR 2 or a chain as defined above, Se or any isoelectronic species of oxygen.

- the present invention relates to the aforementioned polymer where R 3 and R 4 are carboxylic acid with a protecting group such as but not limited to a phthalimidomethyl ester, a t-butyldimethylsilyl ester, or a t-butyldiphenylsilyl ester.

- a protecting group such as but not limited to a phthalimidomethyl ester, a t-butyldimethylsilyl ester, or a t-butyldiphenylsilyl ester.

- the present invention relates to the aforementioned polymer where R 3 , R 4 , A, and Z are the same or different, R 3 and R 4 are repeated a certain number of times, and terminate in -H, -OH, -CH 3 , carboxylic acid, sulfate, phosphate, aldehyde, activated ester, methoxy, amine, amide, thiol, disulfide, straight or branched chain allcane, straight or branched chain alkene, straight or branched chain ester, straight or branched chain ether, straight or branched chain silane, straight or branched chain urethane, straight or branched chain, carbonate, straight or branched chain sulfate, straight or branched chain phosphate, straight or branched chain thiol urethane, straight or branched chain amine, straight or branched chain thiol urea, straight or branched chain thiol ether, straight or

- the present invention relates to the aforementioned polymer having a straight or branched chain of 1-50 carbon atoms and wherein the chain is fully saturated, fully unsaturated or any combination therein.

- the present invention relates to the aforementioned polymer wherein straight or branched chains are the same number of carbons or different and wherein R 3 , R 4 , A, Z are any combination of linkers selected from the group consisting of esters, silanes, ureas, amides, amines, urethanes, thiol-urethanes, carbonates, carbamates, thio-ethers, thio-esters, sulfates, phosphates and ethers.

- the present invention relates to the aforementioned polymer wherein chains include at least one selected from hydrocarbons, fluorocarbons, halocarbons, alkenes, and alkynes.

- the present invention relates to the aforementioned polymer wherein said chains include polyethers, polyesters, polyamines, polyacrylic acids, polyamino acids, polynucleic acids and polysaccharides of molecular weight ranging from 200-1,000,000, and wherein said chain contains 1 or more crosslinkable or photopolymerizable group.

- the present invention relates to the aforementioned polymer wherein the chains include at least one of PEG, PLA, PGA, PGLA, and PMMA.

- the present invention relates to the aforementioned block or random copolymer, which includes at least one terminal crosslinkable or photopolymerizable group selected from the group consisting of amines, thiols, amides, phosphates, sulfates, hydroxides, alkenes, activated esters, malemides, aldehydes, and alkynes.

- the present invention relates to the aforementioned polymer wherein R 3 and R 4 are repeated a certain number of times and terminates with amino acid(s), such as cysteine, attached to Z, A, R 3 , and/or R 4 .

- the present invention relates to the aforementioned polymer wherein R 3 and R 4 are repeated a certain number of times and terminates with polypeptide(s) attached to Z, A, R 3 , and/or R 4 . In certain instances, the present invention relates to the aforementioned polymer wherein R 3 and R 4 are repeated a certain number of times and terminates with an antibody(ies) or single chain antibody(ies) attached to Z, A, R 3 , and/or R 4 .

- the present invention relates to the aforementioned polymer wherein R 3 and R 4 are repeated a certain number of times and terminates with a nucleotide(s) attached to Z, A, R 3 , and/or R 4 .

- the present invention relates to the aforementioned polymer wherein R 3 and R 4 are repeated a certain number of times and terminates with a nucleoside(s) attached to Z, A, R 3 , and/or R 4 .

- the present invention relates to the aforementioned polymer wherein R 3 and R 4 are repeated a certain number of times and terminates with oligonucleotide(s) attached to Z 5 A, R 3 , and/or R 4 .

- the present invention relates to the aforementioned polymer wherein R 3 and R 4 are repeated a certain number of times and terminates with ligand(s) attached to Z, A, R 3 , and/or R 4 that binds to a biological receptor.

- the present invention relates to the aforementioned polymer wherein R 3 and R 4 are repeated a certain number of times and terminates with a pharmaceutical agent(s) attached to Z, A, R 3 , and/or R 4 .

- the present invention relates to the aforementioned polymer wherein R 3 and R 4 are repeated a certain number of times and terminates with a pharmaceutical agent attached to Z, A, R 3 , and/or R 4 and is at least one selected from the group consisting of antibacterial, anticancer, anti-inflammatory, and antiviral.

- the present invention relates to the aforementioned polymer wherein R 3 and R 4 are repeated a certain number of times to produce a polymer in which a pharmaceutical agent(s) is encapsulated or chemically bound to the polymer.

- the present invention relates to the aforementioned polymer wherein camptothecin or a derivative of campothethcm is encapsulated

- the present invention relates to the aforementioned polymer wherein R 3 and R 4 are repeated a certain number of times and terminates with a carbohydrate(s) attached to Z, A, R 3 , and/or R 4 . In certain instances, the present invention relates to the aforementioned polymer wherein R 3 and R 4 are repeated a certain number of times and terminates with the carbohydrate mannose or sialic acid attached to the polymer.

- the present invention relates to the aforementioned polymer which includes a polymer or copolymer of a polyester, polyamide, polyether, or polycarbonate at the center or periphery of the polymers above taken from the structures below.

- the present invention relates to the aforementioned polymer block or random copolymer which includes at least one terminal or internal crosslinkable group selected from the group consisting of amines, thiols, amides, phosphates, sulfates, hydroxides, alkenes, and alkynes.

- the present invention relates to the aforementioned polymer wherein X, Y, M is O, S, N-H, N-R, wherein R is -H, CH 2 , CR 2 or a chain as defined above, Se or any isoelectronic species of oxygen.

- the present invention relates to the aforementioned polymer wherein an amino acid(s) is attached to Z, A, R 3 , and/or R 4 . In certain instances, the present invention relates to the aforementioned polymer wherein a polypeptide(s) is attached to Z, A, R 3 , and/or R 4 .

- the present invention relates to the aforementioned polymer wherein an antibody(ies) or single chain antibody(ies) is attached to Z, A, R 3 , and/or R 4 .

- the present invention relates to the aforementioned polymer wherein a nucleotide(s) is attached to Z, A, R 3 , and/or R 4 .

- the present invention relates to the aforementioned polymer wherein a nucleoside(s) is attached to Z, A, R 3 , and/or R 4 .

- the present invention relates to the aforementioned polymer wherein an oligonucleotide(s) is attached to Z, A, R 3 , and/or R 4 .