WO2006110899A2 - Integration of alternative feedstreams in biomass treatment and utilization - Google Patents

Integration of alternative feedstreams in biomass treatment and utilization Download PDFInfo

- Publication number

- WO2006110899A2 WO2006110899A2 PCT/US2006/014144 US2006014144W WO2006110899A2 WO 2006110899 A2 WO2006110899 A2 WO 2006110899A2 US 2006014144 W US2006014144 W US 2006014144W WO 2006110899 A2 WO2006110899 A2 WO 2006110899A2

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- biomass

- ammonia

- integrated

- integrated feedstock

- saccharification

- Prior art date

Links

Classifications

-

- C—CHEMISTRY; METALLURGY

- C12—BIOCHEMISTRY; BEER; SPIRITS; WINE; VINEGAR; MICROBIOLOGY; ENZYMOLOGY; MUTATION OR GENETIC ENGINEERING

- C12M—APPARATUS FOR ENZYMOLOGY OR MICROBIOLOGY; APPARATUS FOR CULTURING MICROORGANISMS FOR PRODUCING BIOMASS, FOR GROWING CELLS OR FOR OBTAINING FERMENTATION OR METABOLIC PRODUCTS, i.e. BIOREACTORS OR FERMENTERS

- C12M45/00—Means for pre-treatment of biological substances

- C12M45/02—Means for pre-treatment of biological substances by mechanical forces; Stirring; Trituration; Comminuting

-

- C—CHEMISTRY; METALLURGY

- C12—BIOCHEMISTRY; BEER; SPIRITS; WINE; VINEGAR; MICROBIOLOGY; ENZYMOLOGY; MUTATION OR GENETIC ENGINEERING

- C12M—APPARATUS FOR ENZYMOLOGY OR MICROBIOLOGY; APPARATUS FOR CULTURING MICROORGANISMS FOR PRODUCING BIOMASS, FOR GROWING CELLS OR FOR OBTAINING FERMENTATION OR METABOLIC PRODUCTS, i.e. BIOREACTORS OR FERMENTERS

- C12M27/00—Means for mixing, agitating or circulating fluids in the vessel

- C12M27/02—Stirrer or mobile mixing elements

-

- C—CHEMISTRY; METALLURGY

- C12—BIOCHEMISTRY; BEER; SPIRITS; WINE; VINEGAR; MICROBIOLOGY; ENZYMOLOGY; MUTATION OR GENETIC ENGINEERING

- C12M—APPARATUS FOR ENZYMOLOGY OR MICROBIOLOGY; APPARATUS FOR CULTURING MICROORGANISMS FOR PRODUCING BIOMASS, FOR GROWING CELLS OR FOR OBTAINING FERMENTATION OR METABOLIC PRODUCTS, i.e. BIOREACTORS OR FERMENTERS

- C12M27/00—Means for mixing, agitating or circulating fluids in the vessel

- C12M27/18—Flow directing inserts

- C12M27/20—Baffles; Ribs; Ribbons; Auger vanes

-

- C—CHEMISTRY; METALLURGY

- C12—BIOCHEMISTRY; BEER; SPIRITS; WINE; VINEGAR; MICROBIOLOGY; ENZYMOLOGY; MUTATION OR GENETIC ENGINEERING

- C12M—APPARATUS FOR ENZYMOLOGY OR MICROBIOLOGY; APPARATUS FOR CULTURING MICROORGANISMS FOR PRODUCING BIOMASS, FOR GROWING CELLS OR FOR OBTAINING FERMENTATION OR METABOLIC PRODUCTS, i.e. BIOREACTORS OR FERMENTERS

- C12M45/00—Means for pre-treatment of biological substances

- C12M45/09—Means for pre-treatment of biological substances by enzymatic treatment

-

- C—CHEMISTRY; METALLURGY

- C12—BIOCHEMISTRY; BEER; SPIRITS; WINE; VINEGAR; MICROBIOLOGY; ENZYMOLOGY; MUTATION OR GENETIC ENGINEERING

- C12P—FERMENTATION OR ENZYME-USING PROCESSES TO SYNTHESISE A DESIRED CHEMICAL COMPOUND OR COMPOSITION OR TO SEPARATE OPTICAL ISOMERS FROM A RACEMIC MIXTURE

- C12P19/00—Preparation of compounds containing saccharide radicals

- C12P19/02—Monosaccharides

-

- C—CHEMISTRY; METALLURGY

- C12—BIOCHEMISTRY; BEER; SPIRITS; WINE; VINEGAR; MICROBIOLOGY; ENZYMOLOGY; MUTATION OR GENETIC ENGINEERING

- C12P—FERMENTATION OR ENZYME-USING PROCESSES TO SYNTHESISE A DESIRED CHEMICAL COMPOUND OR COMPOSITION OR TO SEPARATE OPTICAL ISOMERS FROM A RACEMIC MIXTURE

- C12P7/00—Preparation of oxygen-containing organic compounds

- C12P7/02—Preparation of oxygen-containing organic compounds containing a hydroxy group

- C12P7/04—Preparation of oxygen-containing organic compounds containing a hydroxy group acyclic

- C12P7/06—Ethanol, i.e. non-beverage

- C12P7/08—Ethanol, i.e. non-beverage produced as by-product or from waste or cellulosic material substrate

-

- C—CHEMISTRY; METALLURGY

- C12—BIOCHEMISTRY; BEER; SPIRITS; WINE; VINEGAR; MICROBIOLOGY; ENZYMOLOGY; MUTATION OR GENETIC ENGINEERING

- C12P—FERMENTATION OR ENZYME-USING PROCESSES TO SYNTHESISE A DESIRED CHEMICAL COMPOUND OR COMPOSITION OR TO SEPARATE OPTICAL ISOMERS FROM A RACEMIC MIXTURE

- C12P2201/00—Pretreatment of cellulosic or lignocellulosic material for subsequent enzymatic treatment or hydrolysis

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E50/00—Technologies for the production of fuel of non-fossil origin

- Y02E50/10—Biofuels, e.g. bio-diesel

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E50/00—Technologies for the production of fuel of non-fossil origin

- Y02E50/30—Fuel from waste, e.g. synthetic alcohol or diesel

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02W—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO WASTEWATER TREATMENT OR WASTE MANAGEMENT

- Y02W10/00—Technologies for wastewater treatment

- Y02W10/40—Valorisation of by-products of wastewater, sewage or sludge processing

Definitions

- the invention relates to the general field of biomass processing.

- methods are provided for integrating alternative feedstreams including low-value co-products and waste streams from industrial processing, such as grain and other seed processing, into biomass for treatment and utilization in processes to produce high-value products.

- Cellulosic and lignocellulosic feedstocks and wastes such as agricultural residues, wood, forestry wastes, sludge from paper manufacture, and municipal and industrial solid wastes, provide potentially large renewable feedstocks for the production of chemicals, plastics, fuels and feeds.

- Cellulosic and lignocellulosic feedstocks and wastes composed of carbohydrate polymers comprising cellulose, hemicellulose, glucans and lignin are generally treated by a variety of chemical, mechanical and enzymatic means to release primarily hexose and pentose sugars, which can then be fermented to useful products.

- Pretreatment methods are used to make the carbohydrate polymers of cellulosic and lignocellulosic materials more readily available to saccharification enzymes for such hydrolysis.

- Standard pretreatment methods have historically utilized primarily strong acids at high P c " !el ⁇ i( ⁇ Mafiibf howlvWflfiie to high energy costs, high equipment costs, high pretreatment catalyst recovery costs and incompatibility with saccharification enzymes, alternative methods are being developed, such as enzymatic pretreatment, or the use of acid or base at milder 5 temperatures where decreased hydrolysis of biomass carbohydrate polymers occurs during pretreatment, requiring improved enzyme systems to saccharify both cellulose and hemicellulose.

- the present invention provides a method for treating biomass 30 composed of integrated feedstocks to produce fermentable sugars.

- One aspect of the methods described herein includes a pretreatment step wherein biomass is integrated with an alternative feedstream and the resulting integrated feedstock, at relatively high concentrations, is treated with a low concentration of ammonia relative to In another aspect, a high solids concentration of pretreated biomass is integrated with an alternative feedstream for saccharifiaction.

- biomass is treated in a method comprising: 5 a) providing biomass; b) adding to the biomass of a) at least one alternative feedstream to produce an integrated feedstock; c) contacting the integrated feedstock of b) with an aqueous solution comprising ammonia to form an integrated feedstock -

- ammonia is present at a concentration at least sufficient to maintain alkaline pH of the integrated feedstock -aqueous ammonia mixture but wherein said ammonia is present at less than about 12 weight percent relative to dry weight of integrated feedstock, and further

- integrated feedstocks are treated and saccharified in a method comprising: a) providing biomass; 5 b) subjecting the biomass of a) to a pretreatment process to produce a pretreated biomass product; c) adding to the pretreated biomass product of b) at least one alternative feedstream to produce a first or second integrated feedstock; and 0 d) contacting the first or second integrated feedstock of c) with a saccharification enzyme consortium under suitable conditions, to produce a fermentable sugar product.

- the pretreatment process in b) includes contacting the biomass with an aqueous solution comprising ammonia to form a biomass-aqueous P IL I ' rfiili&n ⁇ wikturlfi/ ⁇ ierei ' H ' the ammonia is present at a concentration at least sufficient to maintain alkaline pH of the biomass-aqueous ammonia mixture but wherein said ammonia is present at less than about 12 weight percent relative to dry weight of biomass, and further wherein the dry

- the alternative feedstream that is added to the pretreated biomass product of b) comprises stillage produced during seed processing.

- the biomass of 0 a) may or may not be an integrated feedstock as described herein.

- fermentable sugars resulting from the methods described herein can then be used for the production of value-added chemicals, fuels or other high-value products.

- the present invention provides methods for treating biomass and alternative feedstreams, collectively referred to as "integrated feedstocks" 0 to produce fermentable sugars.

- the fermentable sugars can then be used for the production of value added chemicals, fuels or other high-value products.

- the alternative feedstreams include at least one low-value co- product, a processing stream and/or industrial processing waste stream.

- feedstreams may be combined to form an integrated feedstock for pretreatment processing to achieve concurrent pretreatment of biomass and the co-product or process stream.

- a non-integrated biomass may be pretreated, then the co- 5 product or process stream added to the pretreated biomass forming a second integrated feedstock for saccharification.

- a pretreatment step is included wherein non-integrated biomass or integrated feedstock at relatively high concentration is treated with a relatively low concentration of ammonia relative to the dry weight of the 10 initial material, and the ammonia-treated product is then digested with a saccharification enzyme consortium to produce fermentable sugars.

- the fermentable sugars are converted by biocatalysts to high value target products such as chemicals, plastics, and fuels.

- transferable sugar refers to oligosaccharides and monosaccharides that can be used as a carbon source by a 20 microorganism in a fermentation process.

- lignocellulosic refers to a composition comprising both lignin and cellulose. Lignocellulosic material may also comprise hemicellulose.

- dry weight of biomass is meant the weight of the biomass having all or essentially all water removed. Dry weight is typically measured according to American Society for Testing and Materials (ASTM) Standard E1756-01 (Standard Test Method for Determination of Total Solids in Biomass) or Technical Association of the Pulp and Paper 30 Industry, Inc. (TAPPI) Standard T-412 om-02 (Moisture in Pulp, Paper and Paperboard).

- ASTM American Society for Testing and Materials

- TAPPI Technical Association of the Pulp and Paper 30 Industry, Inc.

- target chemical refers to a chemical produced by fermentation. Chemical is used in a broad sense and includes molecules P 1 L , IF ⁇ ⁇ ' ⁇ yH' Pf ' r'biei is ' i ⁇ c ⁇ ' cling, for example, peptides, enzymes and antibodies.

- a target chemical that is "derivable from biomass” is a target chemical produced by a process whereby biomass is hydrolyzed to release 5 fermentable sugars, and the fermentable sugars are fermented using at least one biocatalyst to produce a desired target chemical.

- plasticizer and "softening agent” refer to materials that cause a reduction in the cohesive intermolecular forces along or between polymer chains. Such materials may act, for example, to decrease

- lignin 10 crystallinity, or disrupt bonds between lignin and non-lignin carbohydrate fibers (e.g., cellulose or hemicellulose).

- non-lignin carbohydrate fibers e.g., cellulose or hemicellulose.

- sacharification refers to the production of fermentable sugars from polysaccharides.

- pretreated biomass means biomass that has been

- Biomass refers to any cellulosic or lignocellulosic material and includes materials comprising cellulose, and optionally further comprising hemicellulose, lignin, starch, oligosaccharides and/or monosaccharides. Biomass may also comprise additional components, such as protein

- biomass may be derived from a single source, or biomass can comprise a mixture derived from more than one source; for example, biomass could comprise a mixture of corn cobs and com stover, or a mixture of grass and leaves.

- biomass includes, but is not limited to, bioenergy crops, agricultural residues, municipal solid

- biomass examples include, but are not limited to, com grain, corn cobs, crop residues such as corn husks, corn stover, grasses, wheat, wheat straw, hay, barley, barley straw, rice straw, switchgrass, waste paper, sugar cane bagasse, sorghum, soy, trees,

- biomass that is useful for the invention includes biomass that has a relatively high carbohydrate value, is relatively dense, and/or is relatively easy to collect, transport, store and/or handle.

- biomass includes corn cobs, corn stover and sugar cane bagasse.

- “Alternative feedstream” or “alternative feedstock” includes a variety of materials that could benefit the overall process of converting biomass to 5 fermentable sugars for the production of value added chemicals and/or fuels.

- Such feedstreams may be produced by industrial processing, including grain or seed processing, food processing, paper/pulp processing, etc.

- One type of such material includes co-products and wastes of grain or other seed processing, including corn dry grind 0 processing, corn dry milling, and corn wet milling.

- agricultural waste and/or industrial processing provide fibrous material that can be incorporated into pretreatment processing.

- industrial processing streams or other feedstreams can be incorporated into biomass 5 post-pretreatment to benefit further biomass processing steps including saccharification and fermentation.

- Non-limiting sources of low-value and wastes streams that may make-up an alternative feedstream include agricultural residues, such as corn or other crop hulls, municipal solid waste, industrial solid waste, sludge from paper manufacture, yard waste, 0 wood and forestry waste.

- Integrated feedstocks or "integrated feedstreams” means a combination of biomass and at least one alternative feedstream or feedstock.

- an "aqueous solution comprising 5 ammonia” refers to the use of ammonia gas (NH 3 ), compounds comprising ammonium ions (NH 4 + ) such as ammonium hydroxide or ammonium sulfate, compounds that release ammonia upon degradation such as urea, and combinations thereof in an aqueous medium.

- ammonia gas NH 3

- compounds comprising ammonium ions NH 4 +

- ammonium hydroxide or ammonium sulfate compounds that release ammonia upon degradation such as urea, and combinations thereof in an aqueous medium.

- An aspect of the present method includes combining any biomass feedstock with at least one alternative feedstream that is comprised of a low-value co-product or industrial processing stream, such as a waste stream.

- processing for the production of high value products such as, oil, starch, protein, sugar syrup and ethanol, often produces low-value co-products, in-process streams and waste streams.

- these co-products are captured for recycling back 5 into high value product processing streams or utilized to benefit processing for value added chemical and fuel production.

- grain or other seed processing co-product or process stream that includes fiber may be combined with other biomass to provide an integrated feedstock that is 0 pretreated.

- the materials of interest comprising the alternative feedstock include low-value co-products, in-process streams and waste streams; which together are referred to as alternative streams.

- a low- value co-product is one that is sold for animal feed.

- low 5 starch or high oil seed process streams include hull streams that are separated in the processing of soybeans, sunflower seeds, peanuts and cottonseeds. Waste streams that contain fibrous material may also be used in preparing an integrated feedstock for pretreatment.

- Integrated feedstocks for pretreatment may include material containing fiber 0 produced in the processing of any seed, for example, corn, oat, wheat, barley, rice, canola, sunflower, cotton, pea, soybean, and other legumes

- Soybeans are typically processed in the United States by solvent- extraction with hexane to recover the oil. Beans are cleaned and may be dried and allowed to equilibrate at 10-11% moisture to facilitate loosening 5 of the seed coat or hull. They are then cracked, dehulled by screening and aspiration, and conditioned by treatment with steam (qv) to facilitate flaking. The conditioned meats are flaked and extracted with hexane to remove the oil.

- Hexane and the oil in the miscella are separated by evaporation and the hexane is recovered. (Kirk-Othmer Encylopedia of 0 Chemical Technology, 4th edition 1997).

- the seed coats or hulls removed during such processing may be used as an integrated feedstream in the present method.

- Processing of sunflowers consists of screw-pressing, direct extraction with hexane, or prepress-solvent extraction.

- the latter is most P M

- the first step is cleaning, followed by dehulling.

- the dehulled seed is conditioned by heating and then goes to screw presses or is flaked as in the case of direct solvent extraction with hexane.

- the screw-pressed cake is ground for use in feeds or granulated 5 and extracted by hexane to recover the remaining oil. (Kirk-Othmer Encylopedia of Chemical Technology, 4th edition 1997).

- the hulls removed during such processing may be used as an integrated feedstream in the present method.

- Processing of peanuts for peanut oil is carried out by screw-

- Cottonseed in the U.S. is processed into oil and meal by screw- pressing or solvent extraction.

- screw-pressing the seed is cleaned, delinted, dehulled, flaked, and cooked prior to pressing. Screw-pressing yields a cake containing 2.5-4.0% residual oil. The cake is ground into a

- Grain process streams include a fiber stream composed of hulls that is produced during dry milling, fibrous milling residue from wet milling, Ip'eljl gfa ' lfl 1 streWm s'-p ' ro ⁇ ced in various processes, and the distiller dry grains and solubles (DDGS) and distiller dry grains (DDG) resulting from the dry grind processes.

- DDGS includes fiber, oil, protein and yeast and is the material remaining after removing ethanol from the fermentation mixture. The solids are filtered out to produce the DDG fraction, which is sold for animal feed. The remaining liquid fraction (stillage) may be recycled back as an in-process stream, or evaporated and combined with the DDG to form the DDGS co-product.

- Another example of a potential source for alternative feedstreams includes root processing, such as processing of sugar beets, potatoes (white or sweet) etc.

- sugar beet processing for sugar production sugar is removed by a countercurrent extraction with water.

- the residual beet solids, or pulp, that exits the extraction apparatus are pressed to remove water and reduce the moisture level to approximately 75%.

- This pressed pulp can be sold as-is to local feed operations, but is more commonly mixed with molasses, dried to approximately 10% moisture and sold as cattle feed. (Kirk-Othmer Encylopedia of Chemical Technology, 4th edition 1997).

- This pressed pulp may be used as an integrated feedstream in the present method.

- the alternative feedstreams used in the present method in addition to fibrous process material, may also contain smaller amounts of components including protein, oil, and/or starch.

- Applicants have found that combining processed seed materials, starch, and/or oil with biomass that is typically used in pretreatment, does not negatively impact the yield of fermentable sugars produced in the following saccharification treatment of the pretreated integrated feedstock using the present method. Further, expected sugar yield produced from the integrated feedstock in the present method may be based on the total cellulosic (including hemicellulosic) content of the integrated feedstock.

- the seed process streams may be added to other biomass for pretreatment, and the fiber in the process stream is pretreated along with the other biomass in preparation for saccharification to produce fermentable sugars. The effectiveness of using this integrated feedstock p c abundant, low-cost and continuously available feedstock for biomass processing facilities.

- the concentration of ammonia used in pretreatment of integrated feedstock in the present method is minimally a concentration that is sufficient to maintain the pH of the integrated feedstock -aqueous ammonia mixture alkaline and maximally less than about 12 weight percent relative to dry weight of integrated feedstock. This low

- 10 concentration of ammonia is sufficient for pretreatment, and the low concentration may also be less than about 10 weight percent relative to dry weight of integrated feedstock.

- alkaline is meant a pH of greater than 7.0.

- a pH of the integrated feedstock -aqueous ammonia mixture that is greater than 8.

- ammonia is present at less than about 8 weight percent relative to dry weight of integrated feedstock.

- ammonia is present at less than about 10 weight percent relative to dry weight of integrated feedstock.

- suitable is ammonia at less than about 6 weight percent relative to dry weight of integrated feedstock.

- Ammonia as used in the present process provides advantages over other bases.

- Ammonia partitions into a liquid phase and vapor phase. Gaseous ammonia can diffuse more easily through biomass than a liquid

- ammonia can also be recycled to the pretreatment reactor during pretreatment or following pretreatment, thus enabling a more economical process. For example, following pretreatment, as the temperature is decreased to that suitable for saccharification, ammonia gas may be released, optionally in the presence of a vacuum, and may be recycled. In a continuous process, ammonia may be continuously recycled.

- the aqueous solution comprising ammonia may optionally comprise at least one additional base, such as sodium hydroxide, sodium carbonate, potassium hydroxide, potassium carbonate, calcium hydroxide and calcium carbonate.

- the at least one additional base may be added in an amount that is combined with ammonium to form an amount of total base that is less than about 20 weight percent relative to dry weight of biomass.

- the total second base plus ammonia is in an amount that is less than about 15 weight percent.

- Additional base(s) may be utilized, for example, to neutralize acids in biomass, to provide metal ions for the saccharification enzymes, or to provide metal ions for the fermentation growth medium.

- the dry weight of integrated feedstock is at an initial concentration of at least about 15% up to about 80% of the weight of the integrated feedstock -aqueous ammonia mixture. More suitably, the dry weight of integrated feedstock is at a concentration of from about 15% to about 60% of the weight of the integrated feedstock - aqueous ammonia mixture.

- the percent of integrated feedstock in the integrated feedstock -aqueous ammonia mixture is kept high to minimize the need for concentration of sugars resulting from saccharification of the pretreated integrated feedstock, for use in fermentation.

- the high integrated feedstock concentration also reduces the total volume of pretreatment material, making the process more economical.

- the integrated feedstock may be used directly as obtained from the sources, or energy may be applied to the integrated feedstock to reduce the size, increase the exposed surface area, and/or increase the availability of cellulose, hemicellulose, and/or oligosaccharides present in " " ⁇ "*" ⁇ " lhe Integrated feedstock ' to ammonia and to saccharification enzymes used in the second step of the method.

- Energy means useful for reducing the size, increasing the exposed surface area, and/or increasing the availability of cellulose, hemicellulose, and/or oligosaccharides present in 5 the integrated feedstock to ammonia and to saccharification enzymes include, but are not limited to, milling, crushing, grinding, shredding, chopping, disc refining, ultrasound, and microwave. This application of energy may occur before or during pretreatment, before or during saccharification, or any combination thereof.

- Pretreatment of integrated feedstock with ammonia solution is carried out in any suitable vessel.

- the vessel is one that can withstand pressure, has a mechanism for heating, and has a mechanism for mixing the contents.

- Commercially available vessels include, for example, the Zipperclave ® reactor (Autoclave Engineers, Erie, PA), the

- vacuum Prior to contacting the integrated feedstock with an aqueous solution comprising ammonia, vacuum may be applied to the vessel containing the integrated feedstock. By evacuating air from the pores of

- the time period for applying vacuum and the amount of negative pressure that is applied to the integrated feedstock will depend on the type of integrated feedstock and can be determined empirically so as to achieve optimal pretreatment of the

- the contacting of the integrated feedstock with an aqueous solution comprising ammonia is carried out at a temperature of from about 4 °C to iP O of the integrated feedstock with ammonia at 4 0 C, allowing impregnation at this temperature, was found to increase the efficiency of saccharification.

- said contacting of the integrated feedstock is carried out at a temperature of from about 75 5 °C to about 150 0 C.

- said contacting of the integrated feedstock is carried out at a temperature of from greater than 90 0 C to about 150 °C.

- the contacting of the integrated feedstock with an aqueous solution comprising ammonia is carried out for a period of time up to about 8 hrs. 0 Longer periods of pretreatment are possible, however a shorter period of time is preferable for practical, economic reasons.

- the pretreatment process may be performed at a relatively high temperature for a relatively short period of time, for example at from about 100 °C to about 150 °C for about 5 min to about 2 5 hr. In another embodiment, the pretreatment process may be performed at lower temperature for a relatively long period of time, for example from about 75 °C to about 100 °C for about 2 hr to about 8 hr. In still another embodiment, the pretreatment process may be performed at room temperature (approximately 22-26 °C) for an even longer period of time of 0 about 24 hr. Other temperature and time combinations intermediate to these may also be used.

- the temperature, time for pretreatment, ammonia concentration, concentration of one or more additional bases, integrated feedstock concentration, integrated feedstock 5 type and integrated feedstock particle size are related; thus these variables may be adjusted as necessary to obtain an optimal product to be contacted with a saccharification enzyme consortium.

- a plasticizer, softening agent, or combination thereof such as polyols (e.g., glycerol, ethylene glycol), esters of polyols (e.g., glycerol 0 monoacetate), glycol ethers (e.g., diethylene glycol), acetamide, ethanol, and ethanolamines, may be added in the pretreatment process (i.e., step (a)).

- a plasticizer may be added as a component of the aqueous ammonia solution, as a separate solution, or as a dry component.

- P C " TX O may be performed in any suitable vessel, such as a batch reactor or a continuous reactor.

- a pressure vessel is required.

- the suitable vessel may be equipped with a means, such as 5 impellers, for agitating the biomass-aqueous ammonia mixture.

- a means such as 5 impellers, for agitating the biomass-aqueous ammonia mixture.

- Reactor design is discussed in Lin, K.-H., and Van Ness, H. C. (in Perry, R.H. and Chilton, C. H. (eds), Chemical Engineer's Handbook, 5 th Edition (1973) Chapter 4, McGraw-Hill, NY).

- the pretreatment reaction may be carried out as a batch process, or as a continuous process.

- ammonia gas may be evacuated from the pretreatment reactor and recycled.

- the integrated feedstock may be pretreated with an aqueous 5 ammonia solution one time or more than one time.

- a saccharification reaction can be performed one or more times. Both pretreatment and saccharification processes may be repeated if desired to obtain higher yields of sugars.

- the theoretical 0 yield of sugars derivable from the starting integrated feedstock can be determined and compared to measured yields.

- the product comprises a mixture of ammonia, partially degraded integrated feedstock and fermentable sugars.

- ammonia may be removed from the pretreated integrated feedstock by applying a vacuum. Removing ammonia lowers the pH, and thus less neutralizing acid is used to obtain the desired pH for saccharification and fermentation. This results in a lower salt load in the 5 pretreatment mixture. Typically some ammonia remains, which is desired to provide a nitrogen source for fermentation.

- the entire pretreatment mixture comprising both soluble and insoluble fractions is utilized in a saccharification reaction.

- the aqueous fraction comprising ammonia and solubilized sugars may be separated from insoluble particulates remaining in the mixture. Methods for separating the soluble from the insoluble fractions include, but are not limited to, decantation and filtration.

- the insoluble particulates may be recycled to the pretreatment reactor.

- the insoluble particulates may 5 optionally be washed with an aqueous solvent (e.g. water) to remove adsorbed sugars prior to being recycled to the pretreatment reactor.

- the insoluble fraction may then be subjected to additional treatment with aqueous ammonia solution as described above for pretreatment, followed by saccharification with a saccharification enzyme consortium.

- the 0 soluble fraction may also be concentrated prior to saccharification using a suitable process, such as evaporation.

- an alternative feedstream, 5 such as a seed process stream, is combined with pretreated biomass to provide a second integrated feedstock that is saccharified.

- the pretreated biomass is material that has been pretreated as described herein, substituting biomass for integrated feedstock, or, an alternative feedstream, such as mentioned above, a seed process stream, is 0 combined with pretreated integrated feedstock to provide a second integrated feedstock that is saccharified.

- the seed process stream that may be combined with pretreated material includes material that is generally low in fiber, such as the stillage stream P f l [ ;::: ' ie's ⁇ iiS :i Wir'eiri L aft ' ⁇ e lt or ]

- a seed process stream that provides a characteristic or component that is a benefit to saccharification, and/or to a fermentation sugar product.

- a benefit that may be provided by a seed process stream is in adjusting the 5 pH of the pretreated material.

- a seed process stream that is acidic is of particular use where the pretreatment process is carried out at an alkaline pH.

- the stillage from dry grinding and ethanol fermentation described 0 above typically has a pH of between about 3 and 5. Addition of stillage to pretreated material will reduce the pH for the saccharification process.

- the method of pretreatment is non-limiting.

- the 5 pretreated biomass may have undergone other conventional methods of pretreatment, such as acid hydrolysis or other methods of pretreatment known in the art (see, e.g, U.S. Patent No. 5,916,780).

- the alternative feedstream is composed of stillage.

- Stillage typically contains amino acids and other nutrients from 0 yeast fermentation that is beneficial in a fermentation sugar product.

- the fermentation sugar product resulting from saccharification of an integrated feedstock may contain fermentable sugars as well as other nutrients derived from a seed process stream. The presence of the nutrients may result in a reduced requirement for additional nutrients in the 5 saccharification product prior to its use in biocatalyst fermentations.

- the following feedstocks may be saccharified: 1) a pretreated integrated feedstock; 2) a pretreated 0 integrated feedstock that is combined post-pretreatment with at least one alternative feedstream to form a second integrated feedstock that is saccharified; or 3) a pretreated non-integrated biomass that is combined with at least one alternative feedstream post-pretreatment to form a second integrated feedstock.

- one or more of the P c above, numbering 1-3 is hydrolyzed in the presence of a saccharification enzyme consortium to release oligosaccharides and/or monosaccharides in a hydrolyzate. Saccharification in the present method is of an integrated feedstock, 5 whether integration occurs prior to pretreatment, after pretreatment, or both. Saccharification enzymes and methods for biomass treatment are reviewed in Lynd, L. R., et al. (Microbiol. MoI. Biol. Rev. (2002) 66:506- 577).

- the 0 aqueous fraction comprising ammonia and solubilized sugars may be separated from insoluble particulates remaining in the mixture.

- Methods for separating the soluble from the insoluble fractions include, but are not limited to, decantation and filtration.

- the insoluble particulates may be recycled to a pretreatment reactor.

- the insoluble particulates may 5 optionally be washed with an aqueous solvent (e.g., water) to remove adsorbed sugars prior to being recycled to the pretreatment reactor.

- the insoluble fraction may then be subjected to additional treatment with aqueous ammonia solution as described above for pretreatment, followed by saccharification with a saccharification enzyme consortium.

- the 0 soluble fraction may also be concentrated prior to saccharification using a suitable process, such as evaporation.

- the pretreatment product Prior to saccharification, the pretreatment product may be treated to alter the pH, composition or temperature such that the enzymes of the saccharification enzyme consortium will be active.

- the pH may be altered 5 through the addition of an alternative feedstream, as described herein above, or of acids in solid or liquid form.

- carbon dioxide (CO 2 ) which may be recovered from fermentation, may be utilized to lower the pH.

- CO 2 may be collected from a fermenter and fed, such as by bubbling, into the pretreatment product while monitoring the 0 pH, until the desired pH is achieved.

- the temperature may be brought to a temperature that is compatible with saccharification enzyme activity, as noted below. Any cofactors required for activity of enzymes used in saccharification may be added.

- IH 1 IL Il / enzyme consortium comprises one or more enzymes selected primarily, but not exclusively, from the group "glycosidases” which hydrolyze the ether linkages of di-, oligo-, and polysaccharides and are found in the enzyme classification EC 3.2.1.x 5 (Enzyme Nomenclature 1992, Academic Press, San Diego, CA with Supplement 1 (1993), Supplement 2 (1994), Supplement s (1995, Supplement 4 (1997) and Supplement 5 [in Eur. J. Biochem. (1994) 223:1- 5, Eur. J. Biochem. (1995) 232:1-6, Eur. J. Biochem. (1996) 237:1-5, Eur. J. Biochem. (1997) 250:1-6, and Eur. J. Biochem.

- Glycosidases useful in the present method can be categorized by the integrated feedstocks that they hydrolyze.

- Glycosidases useful for the present method include cellulose-hydrolyzing glycosidases (for example, cellulases, endoglucanases, exoglucanases, cellobiohydrolases, ⁇ - 15 glucosidases), hemicellulose-hydrolyzing glycosidases (for example, xylanases, endoxylanases, exoxylanases, /?-xylosidases, arabinoxylanases, mannases, galactases, pectinases, glucuronidases), and starch-hydrolyzing glycosidases (for example, amylases, ⁇ -amylases, ⁇ -amylases, glucoamylase

- peptidases EC 3.4.x.y

- lipases EC 3.1.1.x and 3.1.4.x

- ligninases EC 1.11.1.x

- feruloyl esterases EC 3.1.1.73

- a "cellulase” from a microorganism may comprise a group of enzymes, all of which may contribute to the cellulose-degrading activity.

- Commercial or non- 30 commercial enzyme preparations, such as cellulase may comprise numerous enzymes depending on the purification scheme utilized to obtain the enzyme.

- the saccharification enzyme consortium of the present method may comprise enzyme activity, such as "celluiase", recogniile ⁇ ' that this activity may be catalyzed by more than one enzyme.

- Saccharification enzymes may be obtained commercially, such as Spezyme ® CP cellulase (Genencor International, Rochester, NY) and 5 Multifect ® xylanase (Genencor).

- saccharification enzymes may be produced biologically, including using recombinant microorganisms.

- One skilled in the art would know how to determine the effective amount of enzymes to use in the consortium and adjust conditions for optimal enzyme activity.

- One skilled in the art would also know how to

- feedstocks may include a component of starch.

- This starch may be broken down into fermentable sugars using the starch-hydrolyzing glycosidases (for example, amylases, D-amylases, D-amylases, glucoamylases, D-glucosidases, isoamylases).

- glycosidases for example, amylases, D-amylases, D-amylases, glucoamylases, D-glucosidases, isoamylases.

- starch-hydrolyzing enzymes during saccharification in the present process to enhance fermentable sugar production.

- the alternative feedstreams that may be used to form integrated feedstocks in the present methods may include a component of protein.

- Protein may be broken down using peptidases.

- a grain process stream that includes protein is incorporated either prior to or after pretreatment, it may be suitable to include protein-hydrolyzing enzymes during saccharification in the present process to enhance the fermentable sugar product with amino acids

- the saccharification reaction is performed at or near the temperature and pH optima for the saccharification enzymes.

- the temperature optimum used with the saccharification enzyme consortium in the present method ranges from about 15 °C to about 100 °C. In another optimum ranges from about 20 0 C to about 80 °C.

- the pH optimum can range from about 2 to about 11. In another embodiment, the pH optimum used with the saccharification enzyme consortium in the present method ranges from about 4 to about 10. 5

- the saccharification can be performed for a time of about several minutes to about 120 hr, and preferably from about several minutes to about 48 hr. The time for the reaction will depend on enzyme concentration and specific activity, as well as the substrate used and the environmental conditions, such as temperature and pH.

- the saccharification can be performed batch-wise or as a continuous process.

- the saccharification can also be performed in one

- a primary treatment can be performed with enzyme(s) at one temperature and pH, followed by secondary or tertiary (or more) treatments with different enzyme(s) at different temperatures and/or pH.

- secondary or tertiary (or more) treatments with different enzyme(s) at different temperatures and/or pH.

- 20 different enzymes in sequential steps may be at the same pH and/or temperature, such as using hemicellulases followed by cellulases.

- the degree of solubilization of sugars from the integrated feedstocks or the second integrated feedstocks following saccharification can be monitored by measuring the release of monosaccharides and

- oligosaccharides 25 oligosaccharides.

- concentration of reducing sugars can be determined using the 1 ,3- dinitrosalicylic (DNS) acid assay (Miller, G. L., Anal. Chem. (1959) 31 :426- 428).

- sugars can be measured by HPLC using an

- Fermentable sugars released from the integrated feedstocks or the second integrated feedstocks can be used by suitable microorganisms to produce target chemicals. Following saccharification, but prior to pMC mixture may be concentrated by evaporation, for example, to increase the concentration of fermentable sugars.

- liquid in the saccharification product may be separated from solids in a batch or continuous method.

- the liquid or the 5 entire saccharification product may be sterilized prior to fermentation.

- the pH may be adjusted to that suitable for fermentation.

- the saccharification mixture may be supplemented with additional nutrients required for microbial growth.

- Supplements may include, for example, yeast extract, specific amino acids, phosphate, nitrogen sources, salts, and trace elements.

- Components required for production of a specific product made by a specific biocatalyst may also be included, such as an antibiotic to maintain a plasmid or a cofactor required in an enzyme catalyzed reaction.

- 5 additional sugars may be included to increase the total sugar concentration.

- the saccharification mixture may be used as a component of a fermentation broth, for example, making up between about 90% and about 10% of the final medium.

- Temperature and/or headspace gas may also be adjusted, 0 depending on conditions useful for the fermentation microorganism(s). Fermentation may be aerobic or anaerobic. Fermentation may occur subsequent to saccharification, or may occur concurrently with saccharification by simultaneous saccharification and fermentation (SSF). SSF can keep the sugar levels produced by saccharification low, thereby 5 reducing potential product inhibition of the saccharification enzymes, reducing sugar availability for contaminating microorganisms, and improving the conversion of pretreated biomass to monosaccharides and/or oligosaccharides.

- SSF simultaneous saccharification and fermentation

- Target chemicals that may be produced by fermentation include, for 0 example, acids, alcohols, alkanes, alkenes, aromatics, aldehydes, ketones, biopolymers, proteins, peptides, amino acids, vitamins, antibiotics, and pharmaceuticals.

- Alcohols include, but are not limited to methanol, ethanol, propanol, isopropanol, butanol, ethylene glycol, propanediol, butanediol, glycerol, erythritol, xylitol, and sorbitol.

- Amino acids include glutamic acid, aspartic acid, methionine, lysine, glycine, arginine, threonine, phenylalanine and tyrosine.

- Additional target 5 chemicals include methane, ethylene, acetone and industrial enzymes.

- Biocatalysts may be microorganisms selected from bacteria, filamentous fungi and yeast. Biocatalysts may be wild type 0 microorganisms or recombinant microorganisms, and include Escherichia, Zymomonas, Saccharomyces, Candida, Pichia, Streptomyces, Bacillus, Lactobacillus, and Clostridium.

- biocatalysts may be selected from the group consisting of recombinant Escherichia coli, Zymomonas mobilis, Bacillus stearothermophilus, Saccharomyces 5 cerevisiae, and Pichia stipitis.

- biocatalysts used in fermentation to produce target chemicals have been described and others may be discovered, produced through mutation, or engineered through recombinant means. Any biocatalyst that uses fermentable sugars produced in the present method may be used to 0 make the target chemical(s) that it is known to produce, by fermentation in the present method.

- Recombinant strains 5 of E. coli have been used as biocatalysts in fermentation to produce 1 ,3 propanediol (US 6013494, US 6514733), and adipic acid (Niu et al., (2002) Biotechnol. Prog. 18:201-211 ).

- Acetic acid has been made by fermentation using recombinant Clostridia (Cheryan et al., (1997) Adv. Appl. Microbiol. 43:1-33), and newly identified yeast strains (Freer (2002) 0 World J. Microbiol. Biotechnol. 18:271-275). Production of succinic acid by recombinant E.

- a mutant of Propionibacterium acidipropionici has been used in 0 fermentation to produce propionic acid (Suwannakham and Yang (2005) Biotechnol. Bioeng. 91 :325-337), and butyric acid has been made by Clostridium tyrobutyricum (Wu and Yang (2003) Biotechnol. Bioeng. 82:93-102).

- Propionate and propanol have been made by fermentation from threonine by Clostridium sp. strain 17cr1 (Janssen (2004) Arch. 5 Microbiol. 182:482-486).

- a yeast-like Aureobasidium pullulans has been used to make gluconic acid (Anantassiadis et al., (2005) Biotechnol. Bioeng. 91 :494-501 ), by a mutant of Aspergillis niger (Singh et al., (2001 ) Indian J. Exp. Biol. 39:1136-43).

- 5-keto-D-gluconic acid was made by a mutant of Gluconobacter oxydans (Elfari et al., (2005) Appl Microbiol. 0 Biotech. 66:668-674), itaconic acid was produced by mutants of

- citric acid was produced by a mutant Aspergillus niger strain (Ikram- Ul-Haq et al., (2005) Bioresour. Technol. 96:645-648), and xylitol was produced by Candida guilliermondii FTI 20037 (Mussatto and Roberto 12OMfPMpFu' M ⁇ Mof ' '95:331 -337).

- 4-hydroxyvalerate-containing biopolyesters also containing significant amounts of 3-hydroxybutyric acid and 3-hydroxyvaleric acid, were produced by recombinant Pseudomonas putida and Ralstonia eutropha (Gorenflo et al., (2001 ) Biomacromolecules 2:45-57).

- L-2,3-butanediol was made by recombinant E. coli (Ui et al., (2004) Lett. Appl. Microbiol. 39:533-537).

- Production of amino acids by fermentation has been accomplished using auxotrophic strains and amino acid analog-resistant strains of Corynebacterium, Brevibacterium, and Serratia.

- production of histidine using a strain resistant to a histidine analog is described in Japanese Patent Publication No. 8596/81 and using a recombinant strain is described in EP 136359.

- Production of tryptophan using a strain resistant to a tryptophan analog is described in Japanese Patent Publication Nos. 4505/72 and 1937/76.

- Production of isoleucine using a strain resistant to an isoleucine analog is described in Japanese Patent Publication Nos. 38995/72, 6237/76, 32070/79.

- Phenylalanine was also produced by fermentation in Eschericia coli strains ATCC 31882, 31883, and 31884. Production of glutamic acid in a recombinant coryneform bacterium is described in US 6962805. Production of threonine by a mutant strain of E. coli is described in Okamoto and lkeda (2000) J. Biosci Bioeng. 89:87-79. Methionine was produced by a mutant strain of Corynebacterium lilium (Kumar et al, (2005) Bioresour. Technol. 96: 287-294).

- Biocatalysts for example, in US6861237, US6777207, US6228630.

- the pretreatment and saccharification of biomass to fermentable sugars, followed by fermentation of the sugars to a target chemical is P C ' l ⁇ eM

- the method of the present invention can also be used for the production of 1 ,3- 5 propanediol from biomass. Biomass undergoes pretreatment and saccharification according to the present invention; following (or during) saccharification, E. coli is used to produce 1 ,3-propanediol as described in CL2825 (Example 10).

- Target chemicals produced in fermentation by biocatalysts may be 0 recovered using various methods known in the art.

- Products may be separated from other fermentation components by centrifugation, filtration, microfiltration, and nanofiltration.

- Products may be extracted by ion exchange, solvent extraction, or electrodialysis.

- Flocculating agents may be used to aid in product separation.

- bioproduced 5 1-butanol may be isolated from the fermentation medium using methods known in the art for ABE fermentations (see for example, Durre, Appl. Microbiol. Biotechnol. 49:639-648 (1998), Groot et al., Process. Biochem. 27:61-75 (1992), and references therein).

- solids may be removed from the fermentation medium by centrifugation, filtration, 0 decantation, or the like.

- the 1-butanol may be isolated from the fermentation medium using methods such as distillation, azeotropic distillation, liquid-liquid extraction, adsorption, gas stripping, membrane evaporation, or pervaporation.

- Purification of 1 ,3-propanediol from fermentation media may be accomplished, for example, by subjecting the 5 reaction mixture to extraction with an organic solvent, distillation, and column chromatography (U.S. 5,356,812).

- a particularly good organic solvent for this process is cyclohexane (U.S. 5,008,473).

- Amino acids may be collected from fermentation medium by methods such as ion-exchange resin adsorption and/or crystallization. 0 U SUB / 1. 1 MhI n ⁇ - ⁇ - EXAMPLES

- Sulfuric acid, ammonium hydroxide, acetic acid, acetamide, yeast extract, 2-morpholinoethanesulfonic acid (MES), potassium phosphate, glucose, xylose, tryptone, sodium chloride and citric acid were obtained from Sigma-Aldrich (St. Louis, MO).

- a biomass treatment apparatus with dimensions and features as shown in Figure 2 and described herein above is called the PEHReactor and was used in the following Examples.

- the 9L PEHReactor (constructed at NREL, Golden, CO; described in detail in co-pending application CL3447) has an approximately 15 cm x 51 cm stainless steel reaction vessel with an injection lance for introduction of processing reactants.

- the injection lance is connected using a rotary joint to a port in a cover on one end of the vessel, which has an additional port for vessel access.

- Four baffles run the length of the vessel wall, and are attached perpendicularly to the wall.

- the PEHReactor is placed on a Bellco Cell-Production Roller Apparatus (Bellco Technology, Vineland, NJ) which provides a mechanism for rotation, and the reactor with roller apparatus is housed in a temperature controlled chamber which provides heat.

- the temperature controlled chamber consists of an aluminum frame to support cork IP C sbrWAIA ⁇ ng the Bellco Cell Production Apparatus, to which a heater is attached that is controlled by thermocouples inserted through the center of the injection lance. Vacuum and pressure may be applied to the reaction vessel by attaching external sources to the lance-connected 5 port in the cover.

- Soluble sugars (glucose, cellobiose, xylose, galactose, arabinose and mannose) in saccharification liquor were measured by HPLC (Agilent Model 1100, Agilent Technologies, Palo Alto, CA) using Bio-Rad HPX-87P and Bio-Rad HPX-87H columns (Bio-Rad Laboratories, Hercules, CA) with appropriate guard columns.

- the sample pH was measured and adjusted 15 to 5-6 with sulfuric acid if necessary.

- the sample was then passed through a 0.2 ⁇ m syringe filter directly into an HPLC vial.

- the HPLC run conditions were as follows:

- Injection volume 10 - 50 ⁇ L, dependent on concentration and 20 detector limits

- Run time 35 minute data collection plus 15 minute post run (with possible adjustment for later eluting compounds)

- Spent grains refers to residual solids from grain processing in which starch is converted to sugar. Spent grains were produced essentially by a basic whiskey process. The different starting materials were treated with starch-

- the starting materials were ground in a Foss (North American HQ: Eden Prarie, MN) Cyclotec 1093 sample mill (starting materials 1 and 2 above) to 250 ⁇ m or in a blender (starting materials 3 and 4 above), then

- the reactor was depressurized, opened and the pH 5 of the contents was adjusted to approximately 5.5 by injecting 75 ml of 1 M citric acid buffer, pH 4.8, into which citric acid monohydrate was added and dissolved.

- the citric acid buffer was injected into each reactor following heating to 50 0 C and then allowed to equilibrate by incubating the reactors at 50 0 C and 19 rpm for 1 hour.

- the reactors were removed from 0 the incubator, opened, and the pH of a sample determined. If the pH was above 5.5, then additional solid citric acid monohydrate was added and the reactors were incubated with rotation at 50 0 C for an additional hour. This process was repeated as often as necessary to obtain a pH for each reactor of ⁇ 5.5.

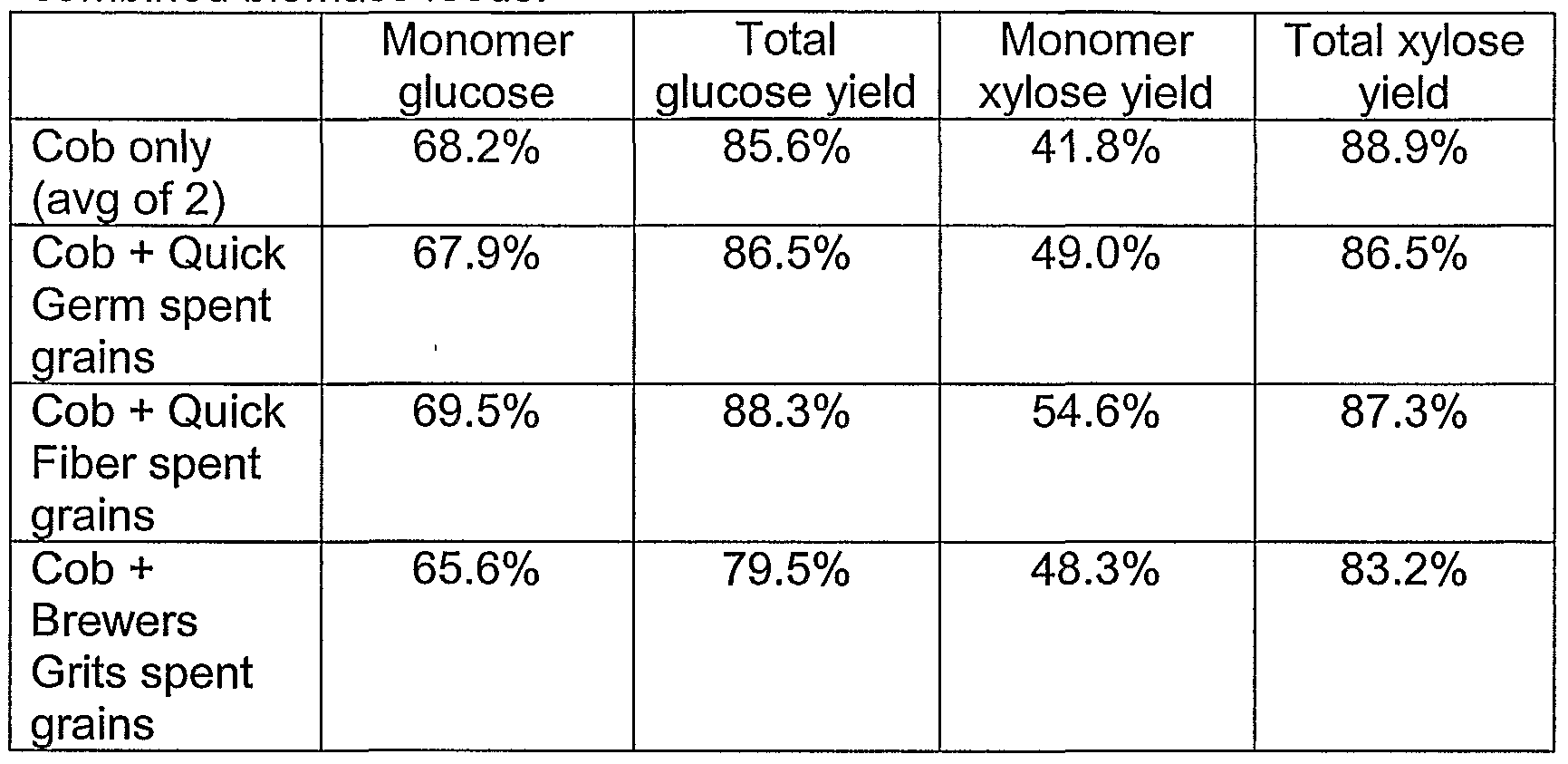

- Table 4 Sugar yields resulting from pretreatment of corn cobs combined with corn fiber.

Abstract

Description

Claims

Priority Applications (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CA 2604100 CA2604100C (en) | 2005-04-12 | 2006-04-12 | Integration of alternative feedstreams in biomass treatment and utilization |

| CN2006800111845A CN101155928B (en) | 2005-04-12 | 2006-04-12 | Integration of alternative feedstreams for biomass treatment and utilization |

| JP2008506758A JP5804666B2 (en) | 2005-04-12 | 2006-04-12 | Concentration of separate supply streams in biomass processing and utilization |

| EP06750234.4A EP1869201B1 (en) | 2005-04-12 | 2006-04-12 | Integration of alternative feedstreams in biomass treatment and utilization |

| BRPI0612939-0A BRPI0612939B1 (en) | 2005-04-12 | 2006-04-12 | BIOMASS TREATMENT METHODS COMPOSED OF INTEGRATED RAW MATERIALS |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US67043705P | 2005-04-12 | 2005-04-12 | |

| US60/670,437 | 2005-04-12 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| WO2006110899A2 true WO2006110899A2 (en) | 2006-10-19 |

| WO2006110899A3 WO2006110899A3 (en) | 2007-03-29 |

Family

ID=36782581

Family Applications (5)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/US2006/014146 WO2006110901A2 (en) | 2005-04-12 | 2006-04-12 | Treatment of biomass to obtain fermentable sugars |

| PCT/US2006/014020 WO2006110891A2 (en) | 2005-04-12 | 2006-04-12 | Treatment of biomass to obtain a target chemical |

| PCT/US2006/014144 WO2006110899A2 (en) | 2005-04-12 | 2006-04-12 | Integration of alternative feedstreams in biomass treatment and utilization |

| PCT/US2006/014145 WO2006110900A2 (en) | 2005-04-12 | 2006-04-12 | Treatment of biomass to obtain ethanol |

| PCT/US2006/014147 WO2006110902A1 (en) | 2005-04-12 | 2006-04-12 | System and process for biomass treatment |

Family Applications Before (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/US2006/014146 WO2006110901A2 (en) | 2005-04-12 | 2006-04-12 | Treatment of biomass to obtain fermentable sugars |

| PCT/US2006/014020 WO2006110891A2 (en) | 2005-04-12 | 2006-04-12 | Treatment of biomass to obtain a target chemical |

Family Applications After (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/US2006/014145 WO2006110900A2 (en) | 2005-04-12 | 2006-04-12 | Treatment of biomass to obtain ethanol |

| PCT/US2006/014147 WO2006110902A1 (en) | 2005-04-12 | 2006-04-12 | System and process for biomass treatment |

Country Status (7)

| Country | Link |

|---|---|

| US (3) | US7932063B2 (en) |

| EP (5) | EP1869197A2 (en) |

| JP (5) | JP5149785B2 (en) |

| CN (5) | CN101160388B (en) |

| BR (5) | BRPI0612966B1 (en) |

| CA (5) | CA2603128C (en) |

| WO (5) | WO2006110901A2 (en) |

Cited By (127)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2008134259A1 (en) | 2007-04-24 | 2008-11-06 | Novozymes North America, Inc. | Detoxifying pre-treated lignocellulose-containing materials |

| JP2010524473A (en) * | 2007-04-19 | 2010-07-22 | マスコマ コーポレイション | Combined thermochemical pretreatment and refining of lignocellulose biomass |

| WO2010138754A1 (en) | 2009-05-29 | 2010-12-02 | Novozymes, Inc. | Methods for enhancing the degradation or conversion of cellulosic material |

| JP2010536376A (en) * | 2007-08-22 | 2010-12-02 | イー・アイ・デュポン・ドウ・ヌムール・アンド・カンパニー | Improved biomass pretreatment |

| WO2011002832A1 (en) | 2009-06-30 | 2011-01-06 | Novozymes A/S | Biomass hydrolysis process |

| WO2011035029A1 (en) | 2009-09-18 | 2011-03-24 | Novozymes, Inc. | Polypeptides having beta-glucosidase activity and polynucleotides encoding same |

| WO2011039319A1 (en) | 2009-09-30 | 2011-04-07 | Novozymes A/S | Polypeptides having cellulolytic enhancing activity and polynucleotides encoding same |

| JP2011515066A (en) * | 2007-10-30 | 2011-05-19 | イー・アイ・デュポン・ドウ・ヌムール・アンド・カンパニー | Zymomonas with improved ethanol production capacity in medium containing high concentrations of sugars and acetates |

| JP2011515067A (en) * | 2007-10-30 | 2011-05-19 | イー・アイ・デュポン・ドウ・ヌムール・アンド・カンパニー | Method for producing ethanol from a medium containing xylose using a recombinant zymomonas strain with reduced expression of himA |

| WO2011126897A2 (en) | 2010-03-30 | 2011-10-13 | Novozymes A/S | Methods for enhancing by-products from fermentation processes |

| WO2012003379A1 (en) | 2010-06-30 | 2012-01-05 | Novozymes A/S | Polypeptides having beta-glucosidase activity and polynucleotides encoding same |

| WO2012006642A1 (en) | 2010-07-07 | 2012-01-12 | Novozymes North America, Inc. | Fermentation process |

| WO2012012590A2 (en) | 2010-07-23 | 2012-01-26 | Novozymes A/S | Processes for producing fermentation products |

| WO2012030844A1 (en) | 2010-08-30 | 2012-03-08 | Novozymes A/S | Polypeptides having endoglucanase activity and polynucleotides encoding same |

| WO2012030799A1 (en) | 2010-08-30 | 2012-03-08 | Novozymes A/S | Polypeptides having cellulolytic enhancing activity and polynucleotides encoding same |

| WO2012030811A1 (en) | 2010-08-30 | 2012-03-08 | Novozymes A/S | Polypeptides having cellobiohydrolase activity and polynucleotides encoding same |

| WO2012030849A1 (en) | 2010-08-30 | 2012-03-08 | Novozymes A/S | Polypeptides having xylanase activity and polynucleotides encoding same |

| WO2012030858A2 (en) | 2010-08-30 | 2012-03-08 | Novozymes A/S | Polypeptides having hemicellulolytic activity and polynucleotides encoding same |

| WO2012030845A2 (en) | 2010-08-30 | 2012-03-08 | Novozymes A/S | Polypeptides having beta-glucosidase activity, beta-xylosidase activity, or beta-glucosidase and beta-xylosidase activity and polynucleotides encoding same |

| WO2012044835A1 (en) | 2010-09-30 | 2012-04-05 | Novozymes, Inc. | Variants of polypeptides having cellulolytic enhancing activity and polynucleotides encoding same |

| WO2012044836A1 (en) | 2010-09-30 | 2012-04-05 | Novozymes, Inc. | Variants of polypeptides having cellulolytic enhancing activity and polynucleotides encoding same |

| WO2012044915A2 (en) | 2010-10-01 | 2012-04-05 | Novozymes, Inc. | Beta-glucosidase variants and polynucleotides encoding same |

| WO2012058293A1 (en) | 2010-10-26 | 2012-05-03 | Novozymes North America, Inc. | Methods of saccharifying sugarcane trash |

| WO2012061517A1 (en) | 2010-11-02 | 2012-05-10 | Novozymes, Inc. | Methods of pretreating cellulosic material with a gh61 polypeptide |

| WO2012059053A1 (en) | 2010-11-04 | 2012-05-10 | Novozymes A/S | Polypeptides having cellobiohydrolase activity and polynucleotides encoding same |

| WO2012062220A1 (en) | 2010-11-12 | 2012-05-18 | Novozymes A/S | Polypeptides having endoglucanase activity and polynucleotides encoding same |

| WO2012068509A1 (en) | 2010-11-18 | 2012-05-24 | Novozymes, Inc. | Chimeric polypeptides having cellulolytic enhancing activity and polynucleotides encoding same |

| JP2012512658A (en) * | 2008-12-19 | 2012-06-07 | イー・アイ・デュポン・ドウ・ヌムール・アンド・カンパニー | Organic solvent pretreatment of biomass to promote enzymatic saccharification |

| WO2012103350A1 (en) | 2011-01-26 | 2012-08-02 | Novozymes A/S | Polypeptides having cellobiohydrolase activity and polynucleotides encoding same |

| WO2012103322A1 (en) | 2011-01-26 | 2012-08-02 | Novozymes A/S | Polypeptides having endoglucanase activity and polynucleotides encoding same |

| WO2012103293A1 (en) | 2011-01-26 | 2012-08-02 | Novozymes A/S | Polypeptides having cellobiohydrolase activity and polynucleotides encoding same |

| WO2012103288A1 (en) | 2011-01-26 | 2012-08-02 | Novozymes A/S | Polypeptides having cellobiohydrolase activity and polynucleotides encoding same |

| WO2012103300A2 (en) | 2011-01-26 | 2012-08-02 | Novozymes A/S | Polypeptides having cellobiohydrolase activity and polynucleotides encoding same |

| WO2012113340A1 (en) | 2011-02-23 | 2012-08-30 | Novozymes Inc. | Polypeptides having cellulolytic enhancing activity and polynucleotides encoding same |

| WO2012122518A1 (en) | 2011-03-09 | 2012-09-13 | Novozymes A/S | Methods of increasing the cellulolytic enhancing activity of a polypeptide |

| WO2012122477A1 (en) | 2011-03-10 | 2012-09-13 | Novozymes A/S | Polypeptides having cellulolytic enhancing activity and polynucleotides encoding same |

| WO2012135719A1 (en) | 2011-03-31 | 2012-10-04 | Novozymes, Inc. | Cellulose binding domain variants and polynucleotides encoding same |

| WO2012130120A1 (en) | 2011-03-25 | 2012-10-04 | Novozymes A/S | Method for degrading or converting cellulosic material |

| WO2012135659A2 (en) | 2011-03-31 | 2012-10-04 | Novozymes A/S | Methods for enhancing the degradation or conversion of cellulosic material |

| WO2012149192A1 (en) | 2011-04-28 | 2012-11-01 | Novozymes, Inc. | Polypeptides having endoglucanase activity and polynucleotides encoding same |

| WO2012149344A1 (en) | 2011-04-29 | 2012-11-01 | Novozymes, Inc. | Methods for enhancing the degradation or conversion of cellulosic material |

| WO2012159007A1 (en) | 2011-05-19 | 2012-11-22 | Novozymes, Inc. | Methods for enhancing the degradation of cellulosic material with chitin binding proteins |

| WO2012159009A1 (en) | 2011-05-19 | 2012-11-22 | Novozymes, Inc. | Methods for enhancing the degradation of cellulosic material with chitin binding proteins |

| WO2013016115A1 (en) | 2011-07-22 | 2013-01-31 | Novozymes North America, Inc. | Processes for pretreating cellulosic material and improving hydrolysis thereof |

| WO2013019780A2 (en) | 2011-08-04 | 2013-02-07 | Novozymes A/S | Polypeptides having endoglucanase activity and polynucleotides encoding same |

| WO2013019827A2 (en) | 2011-08-04 | 2013-02-07 | Novozymes A/S | Polypeptides having xylanase activity and polynucleotides encoding same |

| WO2013028927A1 (en) | 2011-08-24 | 2013-02-28 | Novozymes, Inc. | Aspergillus fumigatus cellulolytic enzyme compositions and uses thereof |

| WO2013028928A1 (en) | 2011-08-24 | 2013-02-28 | Novozymes, Inc. | Cellulolytic enzyme compositions and uses thereof |

| WO2013043981A1 (en) | 2011-09-23 | 2013-03-28 | Novozymes A/S | Cellulolytic enzyme compositions and uses thereof |

| WO2013043910A1 (en) | 2011-09-20 | 2013-03-28 | Novozymes A/S | Polypeptides having cellulolytic enhancing activity and polynucleotides encoding same |

| WO2013064075A1 (en) | 2011-10-31 | 2013-05-10 | Novozymes, Inc. | Polypeptides having cellulolytic enhancing activity and polynucleotides encoding same |

| WO2013074956A2 (en) | 2011-11-18 | 2013-05-23 | Novozymes, Inc. | Polypeptides having beta-glucosidase activity, beta-xylosidase activity, or beta-glucosidase and beta-xylosidase activity and polynucleotides encoding same |

| WO2013075644A1 (en) | 2011-11-22 | 2013-05-30 | Novozymes, Inc. | Polypeptides having beta-xylosidase activity and polynucleotides encoding same |

| WO2013079015A1 (en) | 2011-12-01 | 2013-06-06 | Novozymes, Inc. | Polypeptides having beta-xylosidase activity and polynucleotides encoding same |

| WO2013083801A2 (en) | 2011-12-09 | 2013-06-13 | Novozymes A/S | Biogas from substrates comprising animal manure and enzymes |

| WO2013087027A1 (en) | 2011-12-16 | 2013-06-20 | Novozymes, Inc. | Polypeptides having laccase activity and polynucleotides encoding same |

| WO2013089889A2 (en) | 2011-09-30 | 2013-06-20 | Novozymes, Inc. | Chimeric polypeptides having beta-glucosidase activity and polynucleotides encoding same |

| WO2013096603A2 (en) | 2011-12-20 | 2013-06-27 | Novozymes, Inc. | Cellobiohydrolase variants and polynucleotides encoding same |

| WO2013096652A1 (en) | 2011-12-21 | 2013-06-27 | Novozymes, Inc. | Methods for determining the degradation of a biomass material |

| WO2013091547A1 (en) | 2011-12-19 | 2013-06-27 | Novozymes, Inc. | Polypeptides having catalase activity and polynucleotides encoding same |

| WO2013096369A1 (en) | 2011-12-19 | 2013-06-27 | Novozymes A/S | Processes and compositions for increasing the digestibility of cellulosic materials |

| WO2013102054A1 (en) * | 2011-12-30 | 2013-07-04 | Sloiron, Llc | Methods for isolation, use and analysis of ferritin |

| WO2013119302A2 (en) | 2011-11-21 | 2013-08-15 | Novozymes, Inc. | Gh61 polypeptide variants and polynucleotides encoding same |

| JP2013176393A (en) * | 2007-01-30 | 2013-09-09 | Verenium Corp | Enzyme for treatment of lignocellulosics, nucleic acid encoding the same, and method for making and using the same |

| WO2013148504A2 (en) | 2012-03-26 | 2013-10-03 | Novozymes North America, Inc. | Methods of preconditioning cellulosic material |

| WO2013160248A2 (en) | 2012-04-23 | 2013-10-31 | Novozymes A/S | Polypeptides having alpha-glucuronidase activity and polynucleotides encoding same |

| WO2013160247A2 (en) | 2012-04-23 | 2013-10-31 | Novozymes A/S | Polypeptides having glucuronyl esterase activity and polynucleotides encoding same |

| WO2013163590A2 (en) | 2012-04-27 | 2013-10-31 | Novozymes, Inc. | Gh61 polypeptide variants and polynucleotides encoding same |

| WO2014058896A1 (en) | 2012-10-08 | 2014-04-17 | Novozymes A/S | Polypeptides having cellulolytic enhancing activity and polynucleotides encoding same |

| WO2014066141A2 (en) | 2012-10-24 | 2014-05-01 | Novozymes A/S | Polypeptides having cellulolytic enhancing activity and polynucleotides encoding same |

| WO2014070841A1 (en) | 2012-10-31 | 2014-05-08 | Danisco Us Inc. | Compositions and methods of use |

| WO2014070837A1 (en) | 2012-10-31 | 2014-05-08 | Danisco Us Inc. | Beta-glucosidase from magnaporthe grisea |

| WO2014070844A1 (en) | 2012-10-31 | 2014-05-08 | Danisco Us Inc. | Beta-glucosidase from neurospora crassa |

| WO2014092832A2 (en) | 2012-09-19 | 2014-06-19 | Novozymes, Inc. | Methods for enhancing the degradation or conversion of cellulosic material |

| WO2014093835A1 (en) | 2012-12-14 | 2014-06-19 | Novozymes A/S | Polypeptides having cellulolytic enhancing activity and polynucleotides encoding same |

| WO2014099798A1 (en) | 2012-12-19 | 2014-06-26 | Novozymes A/S | Polypeptides having cellulolytic enhancinc activity and polynucleotides encoding same |

| WO2014138672A1 (en) | 2013-03-08 | 2014-09-12 | Novozymes A/S | Cellobiohydrolase variants and polynucleotides encoding same |

| WO2014182990A1 (en) | 2013-05-10 | 2014-11-13 | Novozymes A/S | Polypeptides having xylanase activity and polynucleotides encoding same |

| JP2014239694A (en) * | 2005-09-30 | 2014-12-25 | レネサイエンス・アクティーゼルスカブRenescience A/S | Non-pressurized pretreatment, enzymatic hydrolysis and fermentation of waste fraction |

| WO2015035029A1 (en) | 2013-09-04 | 2015-03-12 | Novozymes A/S | Processes for increasing enzymatic hydrolysis of cellulosic material |

| WO2015066492A1 (en) | 2013-11-01 | 2015-05-07 | Novozymes A/S | Methods of saccharifying and fermenting a cellulosic material |

| WO2015081139A1 (en) | 2013-11-26 | 2015-06-04 | Novozymes A/S | Enzyme compositions and uses thereof |

| WO2015084596A1 (en) | 2013-12-04 | 2015-06-11 | Danisco Us Inc. | Compositions comprising a beta-glucosidase polypeptide and methods of use |

| WO2015105835A1 (en) | 2014-01-07 | 2015-07-16 | Novozymes A/S | Process for degrading mannan-containing cellulosic materials |

| WO2015187935A1 (en) | 2014-06-06 | 2015-12-10 | Novozymes A/S | Enzyme compositions and uses thereof |

| WO2016029107A1 (en) | 2014-08-21 | 2016-02-25 | Novozymes A/S | Process for saccharifying cellulosic material under oxygen addition |

| WO2016037096A1 (en) | 2014-09-05 | 2016-03-10 | Novozymes A/S | Carbohydrate binding module variants and polynucleotides encoding same |

| WO2016045569A1 (en) | 2014-09-23 | 2016-03-31 | Novozymes A/S | Processes for producing ethanol and fermenting organisms |

| WO2016069541A1 (en) | 2014-10-27 | 2016-05-06 | Danisco Us Inc | Compositions and methods related to beta-glucosidase |

| WO2016138167A2 (en) | 2015-02-24 | 2016-09-01 | Novozymes A/S | Cellobiohydrolase variants and polynucleotides encoding same |

| WO2016145350A1 (en) | 2015-03-12 | 2016-09-15 | Novozymes A/S | Multi-stage enzymatic hydrolysis of lignocellulosic biomass |

| WO2016145363A1 (en) | 2015-03-12 | 2016-09-15 | Novozymes A/S | Multi-stage enzymatic hydrolysis of lignocellulosic biomass employing an oxidoreductase with an aa9 polypeptide |

| WO2016145358A1 (en) | 2015-03-12 | 2016-09-15 | Novozymes A/S | Enzymatic hydrolysis with hemicellulolytic enzymes |

| WO2016188459A1 (en) | 2015-05-27 | 2016-12-01 | Novozymes A/S | Polypeptides having cellobiohydrolase activity and polynucleotides encoding same |

| WO2017019490A1 (en) | 2015-07-24 | 2017-02-02 | Novozymes Inc. | Polypeptides having arabinofuranosidase activity and polynucleotides encoding same |

| WO2017019491A1 (en) | 2015-07-24 | 2017-02-02 | Novozymes Inc. | Polypeptides having beta-xylosidase activity and polynucleotides encoding same |

| WO2017050242A1 (en) | 2015-09-22 | 2017-03-30 | Novozymes A/S | Polypeptides having cellobiohydrolase activity and polynucleotides encoding same |

| WO2017070219A1 (en) | 2015-10-20 | 2017-04-27 | Novozymes A/S | Lytic polysaccharide monooxygenase (lpmo) variants and polynucleotides encoding same |

| WO2017144670A1 (en) | 2016-02-24 | 2017-08-31 | Danmarks Tekniske Universitet | Improved process for producing a fermentation product from a lignocellulose-containing material |

| WO2017151957A1 (en) | 2016-03-02 | 2017-09-08 | Novozymes A/S | Cellobiohydrolase variants and polynucleotides encoding same |

| WO2017165760A1 (en) | 2016-03-24 | 2017-09-28 | Novozymes A/S | Cellobiohydrolase variants and polynucleotides encoding same |

| WO2017205535A1 (en) | 2016-05-27 | 2017-11-30 | Novozymes, Inc. | Polypeptides having endoglucanase activity and polynucleotides encoding same |

| WO2018026868A1 (en) | 2016-08-01 | 2018-02-08 | Novozymes, Inc. | Polypeptides having endoglucanase activity and polynucleotides encoding same |

| WO2018050300A1 (en) | 2016-09-13 | 2018-03-22 | Institut National De La Recherche Agronomique (Inra) | Polysaccharide-oxidizing composition and uses thereof |

| WO2018085370A1 (en) | 2016-11-02 | 2018-05-11 | Novozymes A/S | Processes for reducing production of primeverose during enzymatic saccharification of lignocellulosic material |

| WO2018106792A1 (en) | 2016-12-06 | 2018-06-14 | Novozymes A/S | Improved processes for production of ethanol from xylose-containing cellulosic substrates using engineered yeast strains |

| WO2018222990A1 (en) | 2017-06-02 | 2018-12-06 | Novozymes A/S | Improved yeast for ethanol production |

| WO2018220116A1 (en) | 2017-05-31 | 2018-12-06 | Novozymes A/S | Xylose fermenting yeast strains and processes thereof for ethanol production |

| WO2019025449A1 (en) | 2017-08-02 | 2019-02-07 | Institut National De La Recherche Agronomique (Inra) | Methods of defibrillating cellulosic substrates and producing celluloses using a new family of fungal lytic polysaccharide monooxygenases (lpmo) |

| EP3459975A1 (en) | 2011-02-28 | 2019-03-27 | Cadena Bio, Inc. | Polymeric acid catalysts and uses thereof |

| WO2019148192A1 (en) | 2018-01-29 | 2019-08-01 | Novozymes A/S | Microorganisms with improved nitrogen utilization for ethanol production |

| FR3083247A1 (en) | 2018-07-02 | 2020-01-03 | Institut National De La Recherche Agronomique (Inra) | POLYPEPTIDES AND COMPOSITIONS WITH LYSTIC OXIDASE POLYSACCHARIDE ACTIVITY |

| WO2020023411A1 (en) | 2018-07-25 | 2020-01-30 | Novozymes A/S | Enzyme-expressing yeast for ethanol production |

| US10590440B2 (en) | 2014-08-22 | 2020-03-17 | Cysbio Aps | Process for producing a fermentation product from a lignocellulose-containing material |

| WO2020076697A1 (en) | 2018-10-08 | 2020-04-16 | Novozymes A/S | Enzyme-expressing yeast for ethanol production |

| WO2020123463A1 (en) | 2018-12-12 | 2020-06-18 | Novozymes A/S | Polypeptides having xylanase activity and polynucleotides encoding same |

| WO2021021458A1 (en) | 2019-07-26 | 2021-02-04 | Novozymes A/S | Microorganisms with improved nitrogen transport for ethanol production |

| WO2021025872A1 (en) | 2019-08-06 | 2021-02-11 | Novozymes A/S | Fusion proteins for improved enzyme expression |

| WO2021026201A1 (en) | 2019-08-05 | 2021-02-11 | Novozymes A/S | Enzyme blends and processes for producing a high protein feed ingredient from a whole stillage byproduct |

| WO2021055395A1 (en) | 2019-09-16 | 2021-03-25 | Novozymes A/S | Polypeptides having beta-glucanase activity and polynucleotides encoding same |

| WO2021119304A1 (en) | 2019-12-10 | 2021-06-17 | Novozymes A/S | Microorganism for improved pentose fermentation |

| EP3848469A1 (en) | 2013-02-21 | 2021-07-14 | Novozymes A/S | Methods of saccharifying and fermenting a cellulosic material |

| WO2022049250A1 (en) | 2020-09-04 | 2022-03-10 | Novozymes A/S | Improved fermenting organism for ethanol production |

| WO2022090564A1 (en) | 2020-11-02 | 2022-05-05 | Novozymes A/S | Glucoamylase variants and polynucleotides encoding same |

| WO2022261003A1 (en) | 2021-06-07 | 2022-12-15 | Novozymes A/S | Engineered microorganism for improved ethanol fermentation |

| WO2023164436A1 (en) | 2022-02-23 | 2023-08-31 | Novozymes A/S | Process for producing fermentation products and biogas from starch-containing materials |

| WO2024064901A2 (en) | 2022-09-23 | 2024-03-28 | Novozymes A/S | Improved fermenting organism for ethanol production |

Families Citing this family (427)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7537826B2 (en) * | 1999-06-22 | 2009-05-26 | Xyleco, Inc. | Cellulosic and lignocellulosic materials and compositions and composites made therefrom |

| EP2154236A1 (en) | 2004-11-29 | 2010-02-17 | Inbicon A/S | Enzymatic hydrolysis of biomasses having a high dry matter (DM) content |

| US7708214B2 (en) * | 2005-08-24 | 2010-05-04 | Xyleco, Inc. | Fibrous materials and composites |

| US20150328347A1 (en) | 2005-03-24 | 2015-11-19 | Xyleco, Inc. | Fibrous materials and composites |

| US20070029252A1 (en) * | 2005-04-12 | 2007-02-08 | Dunson James B Jr | System and process for biomass treatment |

| EP1869197A2 (en) | 2005-04-12 | 2007-12-26 | E.I. Dupont De Nemours And Company | Treatment of biomass to obtain ethanol |

| US7781191B2 (en) * | 2005-04-12 | 2010-08-24 | E. I. Du Pont De Nemours And Company | Treatment of biomass to obtain a target chemical |

| US8945899B2 (en) | 2007-12-20 | 2015-02-03 | Butamax Advanced Biofuels Llc | Ketol-acid reductoisomerase using NADH |

| US20080274526A1 (en) | 2007-05-02 | 2008-11-06 | Bramucci Michael G | Method for the production of isobutanol |

| JP4734425B2 (en) * | 2006-01-27 | 2011-07-27 | ユニバーシティ オブ マサチューセッツ | Systems and methods for producing biofuels and related materials |

| US8968515B2 (en) * | 2006-05-01 | 2015-03-03 | Board Of Trustees Of Michigan State University | Methods for pretreating biomass |

| WO2007130337A1 (en) * | 2006-05-01 | 2007-11-15 | Michigan State University | Process for the treatment of lignocellulosic biomass |

| US9206446B2 (en) | 2006-05-01 | 2015-12-08 | Board Of Trustees Of Michigan State University | Extraction of solubles from plant biomass for use as microbial growth stimulant and methods related thereto |

| US8962298B2 (en) | 2006-05-02 | 2015-02-24 | Butamax Advanced Biofuels Llc | Recombinant host cell comprising a diol dehydratase |

| US7527941B1 (en) * | 2006-05-24 | 2009-05-05 | Clear Water Technologies, Inc. | Process for producing ethyl alcohol from cellulosic materials |

| WO2008004853A1 (en) * | 2006-07-03 | 2008-01-10 | Hendriks Antonius Theodorus Wi | Pre-treatment of biomass |

| JP5190858B2 (en) * | 2006-07-12 | 2013-04-24 | 独立行政法人農業・食品産業技術総合研究機構 | Production method of low molecular weight carbohydrates from materials containing polysaccharides |

| US8323923B1 (en) | 2006-10-13 | 2012-12-04 | Sweetwater Energy, Inc. | Method and system for producing ethanol |