DESCRIPTION

"LIGNOSULFONATE-BASED PLASTICIZER ADMIXTURES"

Field of the Invention

This invention relates to a concrete admixture (as it is classified by ASTM C-494-81), in particular a water-reducing agent. The specified adjuvants make it possible to balance the concrete mobility and casting characteristics, the concrete mobility retention time and the cementation and hardening rate, owing to the reduction in water consumption, and also to enhance the qualitative characteristics of the concrete (strength, impermeability, durability etc.).

Background of the Invention

A high-quality concrete cannot be made without using chemical admixtures which make it possible to alter in a controlled way the desired properties of the substance. Such admixtures comprise a wide variety of components, which are usually plasticizing or superplasticizing admixtures.

One of the most well known and popular admixtures of that type are lignosulfonates, produced as by-products of the pulp-and-paper industry. Industrial lignosulfonates are a complex system consisting of sulfonated lignine as a builder, with a molecular weight from 1 to 100 kDa, and a mixture of low- molecular products including lignine, cellulose and hemicellulose biodegradation fragments (monosaccharides and oligosaccharides, phenol spirits, ethers etc.) [1]. Lignosulfonates do not contain any substances with are hazardous to health and, when used correctly, they are important for the environment.

Lignosulfonates are high-performance plasticizers for concrete- containing systems. However, their use in concrete technology is restricted by two significant drawbacks: air entraining and concrete strength reduction, where the latter effect is conditioned both by the entrained air and by the structural singularities of the lignosulfonate macromolecule itself (specifically, by molecular weight distribution and the sulfonation rate of the phenylpropane elementary units) [1].

Various different methods are known for solving these problems.

One of the methods consists in mixing lignosulfonates with other admixtures of similar action. For example, U.S. Patent 4239550 introduces an efficient plasticizing agent for concrete and building mortars. The agent comprises a mixture of lignosulfonates with sulfonated or sulfomethylated ring aromatics. Another patent (US patent 4460720) proposes for Portland cement compositions an admixture based on a combination of alkali salts of low-molecular polyacrylates with alkali or alkali-earth salts of polymethylene naphthalenesulfonates and/or alkali or alkali-earth salts of lignosulfonates. Patent EP 0845444 proposes a composition of lignosulfonates with a water-soluble polymer, thus extending the concrete mix high-mobility period without retardation of cementation and reduction of strength.

Another method is based on fractionation of lignosulfonates [2] used for the production of kraft-lignine plasticizer [3] characterised by narrower molecular mass distribution and a limited content of low-molecular agents. Both methods provide for admixtures with advanced plasticizing properties and less retarded hydration and hardening, but they do not eliminate undesirable air entraining.

Surface active agents - higher fatty spirits or their derivatives - are suggested for use with lignosulfonates in order to reduce their air-entraining effects. For example, U.S. patent 4205993 introduces an admixture consisting of a plasticizing agent based on mixture of lignosulfonates with oxycarboxylates and/or polycarboxylates with a non-ionic surface active agent of the polyoxyalkenylated alkyl or alkylaryl group of ethers.

Another efficient anti-air-entraining agent is tributyl phosphate [4].

The effectiveness of the above-mentioned admixtures is proportional to their dosage, meaning that the amount of air in concrete systems can be considerably reduced. According to patent WO 9713372, the addition of 2-4% tributyl phosphate makes it possible to reduce the air content in the concrete to 3-5%, i.e. the amount permitted by ASTM standards for concrete containing admixtures intended to reduce the water content and limit air entraining.

The principal drawback of the above-mentioned surface active agents is their low solubility in water and low stability of the resulting solutions.

The disintegration of lignosulfonates modified in this way presents a major storage problem, firstly because the process is accompanied by increased air- entraining effect by concrete admixtures and, secondly, it may lead to the penetration into the concrete of a significant amount of surface active agents with unfavourable effects on the properties of the concrete.

Detailed Description of the Invention

In order to overcome these drawbacks and create a high- performance plasticizing agent with permanently low air entraining, the present invention uses a composition comprising thermally-modified lignosulfonate and a

water-consistent non-ionic high-molecular organo-silicon surface active agent in the following proportion (parts by weight):

thermally-modified lignosulfonate 1.0

water-consistent non-ionic high-molecular organo-silicon surface active agent 0.001-0.01

Lignosulfonates are thermally modified in order to convert the impurity monosaccharides into less biodegradable ohgosaccharides with a more favourable influence on the properties of the concrete.

Thermal modification of lignosulfonates is carried out during the process of spray drying, thus producing a microgranulated substance free from reducing sugars.

Commercially available polysiloxane emulsions may be used as water-consistent non-ionic high-molecular organo-silicon surface active agents.

The builder of the aforementioned organo-silicon surface active agents comprises polyalkylsiloxanes with a molecular weight of 1-20 kDa (predominantly 5-15 kDa) with the alkyl radical Ci-C5.

The following examples further illustrate the invention, though they do not limit the scope thereof.

Example 1. Production of thermally-modified lignosulfonates.

Thermally-modified lignosulfonates are obtained by spray drying industrial lignosulfonates (sulfite waste liquor after fermentation) in accordance

with TU (technical standards) 54-028-00279580-97. The characteristics of the initial and the resulting products are given in Table 1.

Table 1

Example 2. Production of plasticizing compositions.

628 g of warm water (35-45°C) is poured into a blender, after which, under continuous stirring, 372 g of microgranulated hgnosulfonate (around 6% humidity) is added. After completely dissolving and forming a uniform viscous deep brown solution, 0.35-5.35g of a high-molecular antifoaming emulsion (0.1-1.5%) for dry hgnosulfonate) is added. After further mixing for 1-3 minutes, 1 kg of 35% low- foaming hgnosulfonate solution is obtained and this product will be used in the following examples.

Example 3.

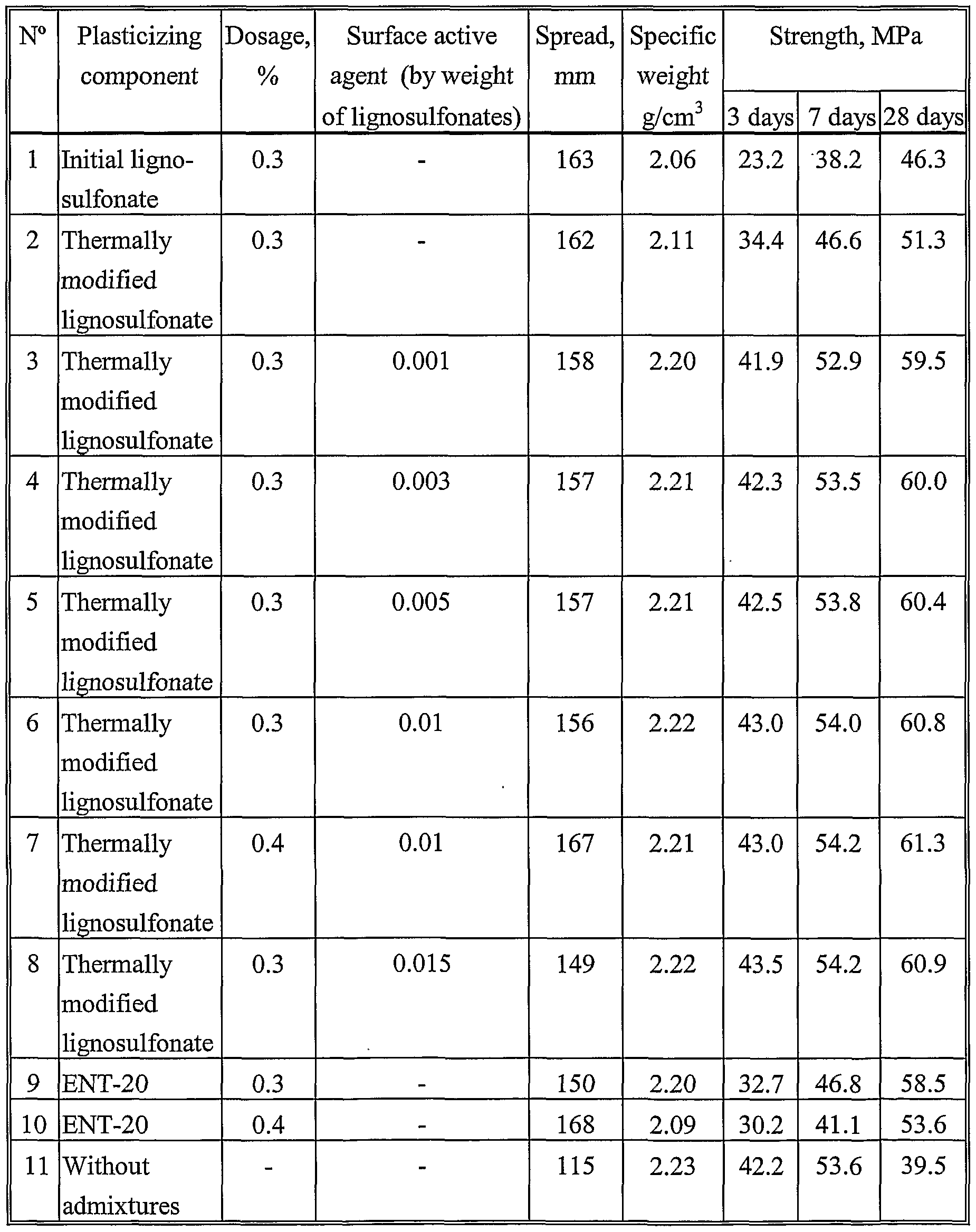

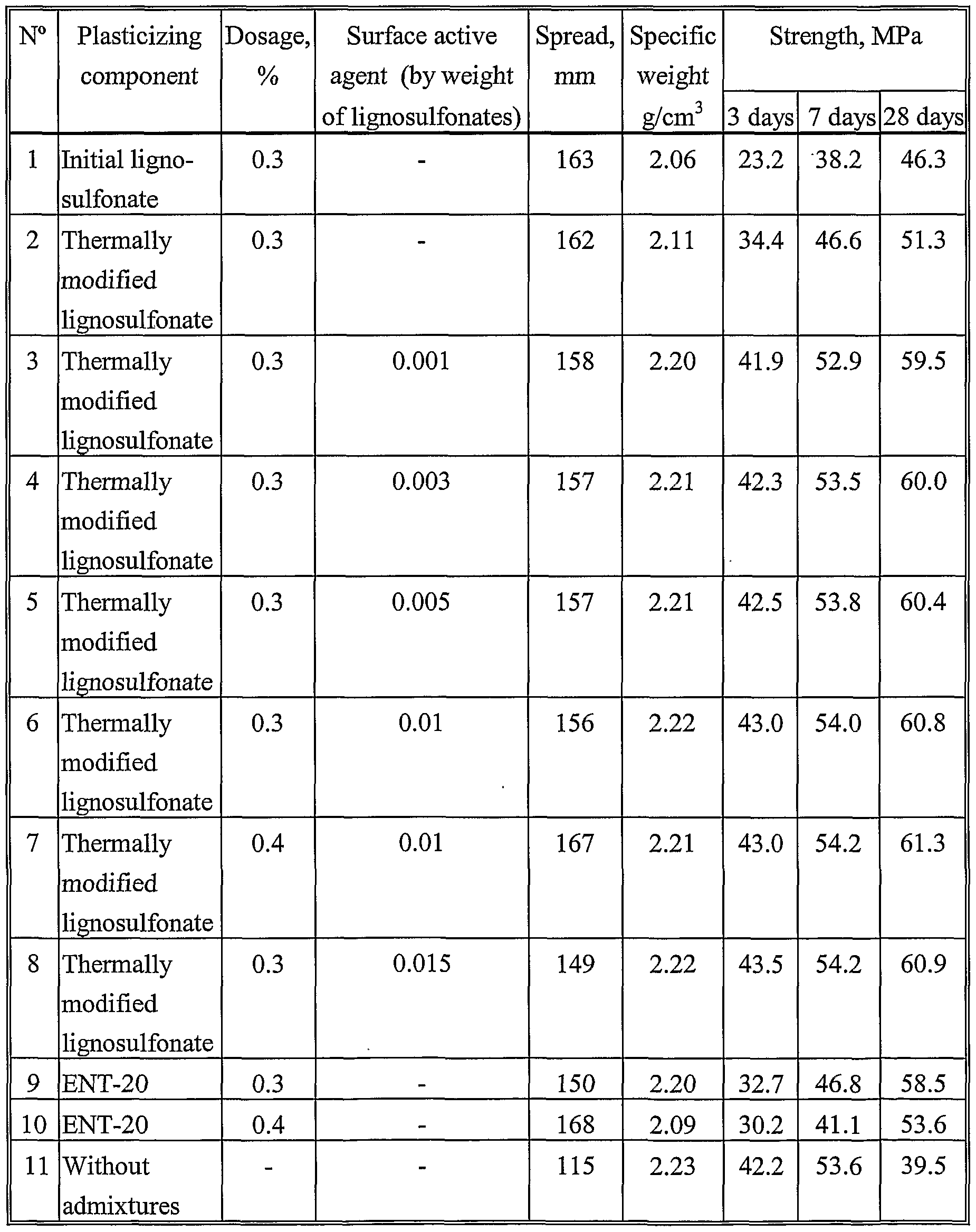

The plasticizing compositions obtained in Example 1 have been tested for standard sand-cement mortars. The ingredients were commercially available lignosulfonates-based superplasticizers under the registered trademark

ENT-20, manufactured by Enermit (Israel) in accordance with national standard

896 (corresponding to ASTM C 494). The comparative results of the air-

entraining effects of the admixtures, as well as the mobility and strength properties of the mortars, are given in Table 2.

Table 2

The data presented shows that the initial lignosulfonates (line 1) possess a high plasticizing capacity but, due to air entraining, they significantly decrease the specific weight of the sand-cement mortar (compare with line 11) and weaken its strength at all periods of hardening. Thermal modification of the lignosulfonates (line 2) does not alter their plasticizing properties, but improves their strength characteristics, especially at early stages. However, strength generally remains lower in comparison to the standard value, because of the significant air-entraining effect caused by the lignosulfonates. The addition of a high-molecular organo-silicon surface active agent to the composition of the plasticizing agent sharply decreases air entraining (lines 3-8), thus altering the specific weight of the samples, as well as their strength, which is now amply comparable with the strength of the admixture- free mortar at all stages. It should be noted that the addition of 0.01 parts or more in weight of the water-consistent high-molecular organo-silicon surface active agent no longer alters the amount of entrained air (compare lines 6 and 8), but leads to a considerable reduction in the spread of the mortar and a significant increase in the cost of the actual admixture. At the same time, the addition of 0.01 parts by weight of the high-molecular organo-silicon surface active agent effectively suppresses air entraining even with a dosage of 0.4%.

The comparison with a well-known superplasticizer ENT (see lines

9-10) shows that the composition of thermally modified lignosulfonates with

0.001-0.01 parts by weight of the water-consistent high-molecular organo-silicon surface active agent ensures higher plasticizing capacity and better mortar strength characteristics.

Example 4.

The admixtures obtained in Example 1 have been tested with regard

to. their storage stability. The solutions indicated were placed in separating funnels and after certain periods of time aliquots were taken from the lower parts of the funnels and used as admixtures for sand-cement mortars. The hgnosulfonate with addition of the well-known tributyl phosphate was taken as a reference sample. The results obtained are given in Table 3.

Table 3

* S= Spread

** γ = Specific weight

Conclusions

Water-consistent non-ionic high-molecular organo-silicon surface active agents, used for producing lower-air-entraining plasticizing compositions, are surface active agents manufactured by the chemical industry and used in various fields of industry. Due to their structural particularities (polymeric

composition and high hydrophobicity, owing to low HLB values), it is preferable for these compounds not to remain dissolved in water, but rather to remain at the surface of the hydrophilic and hydrophobic phase boundary.

Under normal conditions, the surface area of the boundary between the admixture solution and the air is too insufficient for all the molecules of the surface active agent to be placed on it, which is why most of the surface active agents must be maintained in the bulk solution as colloidal soluble aggregates - micelles.

During the foam creating processes, such as the preparation of sand-cement mortars or concrete with hgnosulfonate admixtures, the total surface area of the boundary between the liquid phase and the air increases by order of magnitude or even more. The molecules of the surface active agent are adsorbed at the surface of foam bubbles and, due to their surface activity, reduce the surface tension of the water film, thus lowering its mechanical strength and giving rise to fast and efficient defoaming.

The results of our tests show that similar characteristics are typical for polyalkylsiloxanes with a molecular weight of 1000-20000 Da (predominantly 5-15 kDa) with alkyl radicals C1-C5.

Organo-silicon surface active agents with a lower molecular weight do not possess sufficient activity and do not ensure fast and complete defoaming. With their molecular weight of more than 20 kDa, organo-silicon surface active agents, due to their hydrophobicity, create unstable emulsions and are unable to guarantee the storage stability of plasticizing compositions.

References

1. Sapotnitsky S.A. Use of sulfite alkaline solutions. Moscow, "Lesnaya promyshlennost", 1981.

2. I. Zhor, T.W. Bremner. Influence of lignosulfonates molecular weight fractions on the properties of fresh cement. ACI SP 173-39, p. 781-805.

3. I. Zhor, T.W. Bremner, J.H. Lora. Effect of chemical characteristics of Alcell® lignine-based methylsulfonates on the performance as water- reducing admixtures. ACI SP 148-19, p. 3-351.

4. M.R. Rixom, N.P. Mailvaganam. Chemical admixtures for concrete. London - New York. E&F.N. SPON, 1986.