US3708945A - Syringe assembling method and machine - Google Patents

Syringe assembling method and machine Download PDFInfo

- Publication number

- US3708945A US3708945A US00104257A US3708945DA US3708945A US 3708945 A US3708945 A US 3708945A US 00104257 A US00104257 A US 00104257A US 3708945D A US3708945D A US 3708945DA US 3708945 A US3708945 A US 3708945A

- Authority

- US

- United States

- Prior art keywords

- barrel

- piston

- frame means

- liquid

- assembly line

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B3/00—Packaging plastic material, semiliquids, liquids or mixed solids and liquids, in individual containers or receptacles, e.g. bags, sacks, boxes, cartons, cans, or jars

- B65B3/003—Filling medical containers such as ampoules, vials, syringes or the like

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61M—DEVICES FOR INTRODUCING MEDIA INTO, OR ONTO, THE BODY; DEVICES FOR TRANSDUCING BODY MEDIA OR FOR TAKING MEDIA FROM THE BODY; DEVICES FOR PRODUCING OR ENDING SLEEP OR STUPOR

- A61M5/00—Devices for bringing media into the body in a subcutaneous, intra-vascular or intramuscular way; Accessories therefor, e.g. filling or cleaning devices, arm-rests

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B7/00—Closing containers or receptacles after filling

- B65B7/16—Closing semi-rigid or rigid containers or receptacles not deformed by, or not taking-up shape of, contents, e.g. boxes or cartons

- B65B7/28—Closing semi-rigid or rigid containers or receptacles not deformed by, or not taking-up shape of, contents, e.g. boxes or cartons by applying separate preformed closures, e.g. lids, covers

- B65B7/2821—Closing semi-rigid or rigid containers or receptacles not deformed by, or not taking-up shape of, contents, e.g. boxes or cartons by applying separate preformed closures, e.g. lids, covers applying plugs or threadless stoppers

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61M—DEVICES FOR INTRODUCING MEDIA INTO, OR ONTO, THE BODY; DEVICES FOR TRANSDUCING BODY MEDIA OR FOR TAKING MEDIA FROM THE BODY; DEVICES FOR PRODUCING OR ENDING SLEEP OR STUPOR

- A61M2207/00—Methods of manufacture, assembly or production

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/53—Means to assemble or disassemble

- Y10T29/53313—Means to interrelatedly feed plural work parts from plural sources without manual intervention

- Y10T29/53322—Means to assemble container

- Y10T29/53339—Hypodermic syringe

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/53—Means to assemble or disassemble

- Y10T29/53313—Means to interrelatedly feed plural work parts from plural sources without manual intervention

- Y10T29/53322—Means to assemble container

- Y10T29/53343—Means to assemble container including fluid component

Abstract

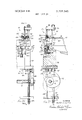

A method and apparatus for automatically assembling the various components of a syringe having a barrel, a stopper and a hub. Automatic means are provided at various points along the assembly line of the apparatus to effect the assembly of each syringe in a series of steps. The syringe is filled with a liquid during the assembly operation.

Description

United States Patent 1 1 'Klet'tke 1 51 *Jan.; 9, 1973' 1541 YLRI NGE ASSEMBLING METHOD AND [56] References cm MACHINE UNITED STATES PATENTS v a 3,245194 4/1966 Cars'ki.....1.. [.75] .lnventor: Walter G. Klettke, Kalamazoo, 0/1956 Brown H 3,503,113 3/1970 l agsdin "291208 B 73' A ssigh'ee I The Upjohn cmah ,'x515mzoo, Primary EmminerRoberfL- Spruill 1 v Mich. Atiomej1-Woodhams, Blanchard and Flynn, John Kekich and Ward F. Nixon Y 1 Notice: The portion 7 of the term of this patent subsequent to Feb. .23, I988, 7 ABSTRACT has been dlsclalmed- A method and apparatus for automatically assembling [22 Fil d; km 1971 the various components of a syringe havi'ng'a barrel, .a 3 stopper and a hub. Automatic means are provided at N 0 3 7 various points along the assembly line of-the apparatus I to effect the assembly of each syringe in 'aseries of [52] US. Cl. ..53/22 R, 29/208 B, 53/282 steps, The syringe is filled with a liquid during the [51] ope atior I v [58] Field of Search ..29/208 B; 53/22, 37, 43 67, v

53/112, 264, 281, 282, 319, 320, 328 8 Claims, 60 Drawing Figures F 'iv l /54 Q g i /27 /2a /a2 05 T I Y's-5 i 2 f 8! 09 5/4 5 1, ,1 1 I g E 2 575 ,23 4.4 .l v I I l H 42 51; 3/ 5w l I, 2 H F 34g .579 2/ i /6/ M /9, aa C '1 L 1' 3 43,? I I /Z z Ag 7 U BATENTEDJAM 9 ma SHEET 030F 26 INVENTOR. W/(A MP 6 M [ff/(Z PATENIEDJMI 9:915 3.708.945

SHEET 08UF 26 INVENTOR.

WAUZP G KANT/(E MfM$z v f PAIENIEUm 9191s 3,708,945

sum USUF 2s INVENTOR, M17696. MHZ

PATENTEDJAH ems 3.708.945

SHEET lSOF 26 XXXII W011" IOIOKI' XXXIE v INVENTOR.

553/ I mu rm a mum;

PATENTEUJAN 91975 SHEET 18UF 26 INVENTOR. WALTER .6 H577?! WM flaw/7%

Claims (8)

1. In a method for automatically assembling and filling a plurality of syringes having tubular barrels open at both ends, the steps comprising: sequentially advancing a plurality of upright barrels in spaced relationship intermittently along a substantially horizontal assembly line through a plurality of stations; mounting a tubular hub on the lower end of each barrel and covering said lower end of said barrel with a liquid-tight sealing member capable of penetration by a cannula; discharging a quantity of liquid into the upper end of each barrel; then inserting a piston into the upper end of each barrel without materially increasing the pressure on the liquid in the barrel; mounting a cannula and casing therefor on the lower end of the hub, the mounted cannula having a sharpened upper end adjacent to but spaced from the sealing member; and discharging the assembled syringes with liquid therein one at a time from said assembly line.

2. In a machine for automatically assembling and filling a syringe having a cylindrical barrel open at both ends, a sealing member closing one end of said barrel, a cylindrical hub affixed to said one end of said barrel, a piston within said barrel, the combination comprising: frame means; barrel advancing means including elongated means movably supported on said frame means for engaging simultaneously a plurality of spaced barrels disposed in upright positions along an assembly line and for simultaneously and intermittently advancing said plurality of barrels through a plurality of spaced stations arranged along said assembly line; a hub attaching mechanism mounted on frame means for applying a sealing member and a hub to the lower end of each barrel at a hub station near one end of said assembly line; a filling mechanism on said frame means at a filling station in said line for discharging a liquid into the upper end of each barrel after the hub is attached; a piston inserting mechanism oN said frame means for urging a piston into said upper end of each barrel in a piston station without materially increasing the pressure of the liquid in the barrel; a discharge mechanism on said frame means for removing an assembled syringe with liquid therein from the other end of said line; and drive means actuating and synchronizing said elongated means and said mechanism.

3. A machine according to claim 2, including an evacuation mechanism on said frame means for reducing the pressure within each barrel containing said liquid while a said piston is inserted into said barrel.

4. A machine according to claim 2, wherein said barrel advancing means includes a plurality of elongated parallel elements supported on said frame means and operating means operatively interconnected to at least one of said elongated elements for moving same whereby said plurality of barrels are advanced simultaneously and intermittently through a plurality of stations along said assembly line.

5. A machine according to claim 3, including a plunger applying mechanism on said frame means at a plunger station in said line for inserting a plunger into each barrel and attaching the plunger to said piston.

6. In a machine for automatically assembling and filling a syringe having a cylindrical barrel open at both ends, a sealing member closing one end of said barrel, and a piston within said barrel, the combination comprising: frame means; barrel advancing means including elongated means movably supported on said frame means for engaging simultaneously a plurality of spaced barrels disposed in upright positions along an assembly line and for simultaneously and intermittently advancing said plurality of barrels through a plurality of spaced stations arranged along said assembly line; a sealing mechanism mounted on frame means for applying a sealing member to the lower end of each barrel at a sealing station near one end of said assembly line; a filling mechanism on said frame means at a filling station in said line for discharging a liquid into the upper end of each barrel after the sealing member is attached; a piston inserting mechanism on said frame means for urging a piston into said upper end of each barrel in a piston station without materially increasing the pressure of the liquid in the barrel; a discharge mechanism on said frame means for removing an assembled syringe with liquid therein from the other end of said line; and drive means actuating and synchronizing said elongated means and said mechanisms.

7. A machine according to claim 6, further including detecting means mounted on said frame means and disposed downstream of said sealing mechanism for detecting the presence of a sealing member on each of said barrels.

8. A machine according to claim 6, further including means associated with said piston inserting mechanism for creating at least a partial vacuum within the barrel located at said piston station prior to insertion of a piston into said barrel, and means for sensing the existence of the vacuum within said barrel for indicating the presence of a piston which is to be inserted into said barrel.

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US10425771A | 1971-01-06 | 1971-01-06 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US3708945A true US3708945A (en) | 1973-01-09 |

Family

ID=22299465

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US00104257A Expired - Lifetime US3708945A (en) | 1971-01-06 | 1971-01-06 | Syringe assembling method and machine |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US3708945A (en) |

Cited By (29)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3807119A (en) * | 1972-06-21 | 1974-04-30 | W Shields | Method of assembling a multiple compartment hypodermic syringe |

| US4355495A (en) * | 1979-01-17 | 1982-10-26 | Norden Packaging Machinery Aktiebolag | Method and apparatus for handling packaging containers |

| US5884457A (en) * | 1997-02-05 | 1999-03-23 | Smithkline Beecham Corporation | Method and apparatus for automatically producing a plurality of sterile liquid filled delivery devices |

| US6065270A (en) * | 1996-12-18 | 2000-05-23 | Schott Glaswerke | Method of producing a filled plastic syringe body for medical purposes |

| US20030135978A1 (en) * | 2002-01-23 | 2003-07-24 | Safety Syringes, Inc. | Systems and methods for assembling injection device |

| US20040020163A1 (en) * | 1999-09-13 | 2004-02-05 | De Cardenas Gilbert L. | System and apparatus for an automated container filling production line |

| US20040088951A1 (en) * | 2000-08-10 | 2004-05-13 | Baldwin Brian Eugene | Method, system, and apparatus for handling, labeling, filling, and capping syringes |

| US6915619B2 (en) | 2001-08-10 | 2005-07-12 | Baxa Corporation | Method for handling syringe bodies |

| US20060219317A1 (en) * | 2000-08-10 | 2006-10-05 | Baldwin Brian E | Method, system, and apparatus for handling, labeling, filling, and capping syringes with improved cap |

| US20100139215A1 (en) * | 2008-12-09 | 2010-06-10 | Pierre Jacques Van Roy | Device and Method for Packing Syringes in Nests |

| US20100162548A1 (en) * | 2006-09-28 | 2010-07-01 | Juergen Leidig | Device and method for mounting a needle guard on a syringe body |

| US20100299904A1 (en) * | 2009-05-26 | 2010-12-02 | Angelo Ansaloni | Method and apparatus for screwing pistons of syringes |

| US8499531B2 (en) * | 2010-10-19 | 2013-08-06 | Aalba Dent Inc. | System and method for packaging dental ingots |

| US20130219710A1 (en) * | 2010-11-19 | 2013-08-29 | Michael Jugl | Assembly Device for Injection Needles |

| US20170112998A1 (en) * | 2007-10-02 | 2017-04-27 | Medimop Medical Projects Ltd. | Method of using a key to secure components of a drug delivery system during assembly |

| WO2018183039A1 (en) * | 2017-03-28 | 2018-10-04 | Amgen Inc. | Plunger rod and syringe assembly system and method |

| US10758679B2 (en) | 2015-05-29 | 2020-09-01 | West Pharma. Services IL, Ltd. | Linear rotation stabilizer for a telescoping syringe stopper driverdriving assembly |

| US10912891B2 (en) | 2015-09-22 | 2021-02-09 | West Pharma. Services IL, Ltd. | Rotation resistant friction adapter for plunger driver of drug delivery device |

| US10960131B2 (en) | 2007-10-02 | 2021-03-30 | West Pharma. Services IL, Ltd. | Apparatuses for securing components of a drug delivery system during transport and methods of using same |

| WO2021126677A1 (en) * | 2019-12-16 | 2021-06-24 | Merck Sharp & Dohme Corp. | Torque-limiting device for manual insertion of syringe plunger rods and methods of using same |

| US11311674B2 (en) | 2016-01-21 | 2022-04-26 | West Pharma. Services IL, Ltd. | Medicament delivery device comprising a visual indicator |

| US11318254B2 (en) | 2015-10-09 | 2022-05-03 | West Pharma. Services IL, Ltd. | Injector needle cap remover |

| US11338090B2 (en) | 2016-08-01 | 2022-05-24 | West Pharma. Services IL, Ltd. | Anti-rotation cartridge pin |

| US11364337B2 (en) | 2016-01-21 | 2022-06-21 | West Pharma. Services IL, Ltd. | Force containment in an automatic injector |

| US11389597B2 (en) | 2016-03-16 | 2022-07-19 | West Pharma. Services IL, Ltd. | Staged telescopic screw assembly having different visual indicators |

| US11504481B2 (en) | 2007-10-02 | 2022-11-22 | West Pharma. Services IL, Ltd. | Anti-rotation feature for infusion pump cartridge |

| US11547802B2 (en) | 2015-10-09 | 2023-01-10 | West Pharma. Services IL, Ltd. | Angled syringe patch injector |

| US11672904B2 (en) | 2016-01-21 | 2023-06-13 | West Pharma. Services IL, Ltd. | Needle insertion and retraction mechanism |

| US11819666B2 (en) | 2017-05-30 | 2023-11-21 | West Pharma. Services IL, Ltd. | Modular drive train for wearable injector |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2765606A (en) * | 1954-09-13 | 1956-10-09 | Pfizer & Co C | Machine for assembling hypodermic syringes |

| US3245194A (en) * | 1962-07-31 | 1966-04-12 | B D Lab Inc | Method and apparatus for filling hypodermic syringes, ampules, etc. |

| US3503113A (en) * | 1968-01-11 | 1970-03-31 | American Cyanamid Co | Automatic machine for applying handles to filled hypodermic syringes |

-

1971

- 1971-01-06 US US00104257A patent/US3708945A/en not_active Expired - Lifetime

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2765606A (en) * | 1954-09-13 | 1956-10-09 | Pfizer & Co C | Machine for assembling hypodermic syringes |

| US3245194A (en) * | 1962-07-31 | 1966-04-12 | B D Lab Inc | Method and apparatus for filling hypodermic syringes, ampules, etc. |

| US3503113A (en) * | 1968-01-11 | 1970-03-31 | American Cyanamid Co | Automatic machine for applying handles to filled hypodermic syringes |

Cited By (59)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3807119A (en) * | 1972-06-21 | 1974-04-30 | W Shields | Method of assembling a multiple compartment hypodermic syringe |

| US4355495A (en) * | 1979-01-17 | 1982-10-26 | Norden Packaging Machinery Aktiebolag | Method and apparatus for handling packaging containers |

| US6065270A (en) * | 1996-12-18 | 2000-05-23 | Schott Glaswerke | Method of producing a filled plastic syringe body for medical purposes |

| US5884457A (en) * | 1997-02-05 | 1999-03-23 | Smithkline Beecham Corporation | Method and apparatus for automatically producing a plurality of sterile liquid filled delivery devices |

| US6910313B2 (en) * | 1999-09-13 | 2005-06-28 | Gilbert L. De Cardenas | System and apparatus for an automated container filling production line |

| US20040020163A1 (en) * | 1999-09-13 | 2004-02-05 | De Cardenas Gilbert L. | System and apparatus for an automated container filling production line |

| US20060260275A1 (en) * | 2000-08-10 | 2006-11-23 | Baldwin Brian E | Method For Handling And Labeling Syringes |

| US7392638B2 (en) | 2000-08-10 | 2008-07-01 | Baxa Corporation | Method, system, and apparatus for handling, labeling, filling, and capping syringes with improved cap |

| US6813868B2 (en) | 2000-08-10 | 2004-11-09 | Baxa Corporation | Method, system, and apparatus for handling, labeling, filling and capping syringes |

| US20040221548A1 (en) * | 2000-08-10 | 2004-11-11 | Baldwin Brian Eugene | Method, system, and apparatus for handling, labeling, filling, and capping syringes |

| US20040088951A1 (en) * | 2000-08-10 | 2004-05-13 | Baldwin Brian Eugene | Method, system, and apparatus for handling, labeling, filling, and capping syringes |

| US7631475B2 (en) | 2000-08-10 | 2009-12-15 | Baxa Corporation | Method for filling and capping syringes |

| US7478513B2 (en) | 2000-08-10 | 2009-01-20 | Baxa Corporation | Method for handling and labeling syringes |

| US6976349B2 (en) | 2000-08-10 | 2005-12-20 | Baxa Corporation | Method for filling and capping syringes |

| US20060219317A1 (en) * | 2000-08-10 | 2006-10-05 | Baldwin Brian E | Method, system, and apparatus for handling, labeling, filling, and capping syringes with improved cap |

| US20060225381A1 (en) * | 2000-08-10 | 2006-10-12 | Baldwin Brian E | Method, system, and apparatus for handling, labeling, filling and capping syringes |

| US7469518B2 (en) | 2000-08-10 | 2008-12-30 | Baxa Corporation | Method for handling and labeling syringes |

| US20060260276A1 (en) * | 2000-08-10 | 2006-11-23 | Baldwin Brian E | Method for handling and labeling syringes |

| US7207152B2 (en) | 2000-08-10 | 2007-04-24 | Baxa Corporation | Method for handling, labeling and filling syringes |

| US6957522B2 (en) | 2001-08-10 | 2005-10-25 | Baxa Corporation | Method and system for labeling syringe bodies |

| US6915619B2 (en) | 2001-08-10 | 2005-07-12 | Baxa Corporation | Method for handling syringe bodies |

| US20030135978A1 (en) * | 2002-01-23 | 2003-07-24 | Safety Syringes, Inc. | Systems and methods for assembling injection device |

| US6742246B2 (en) * | 2002-01-23 | 2004-06-01 | Safety Syringes, Inc. | Systems for assembling injection devices |

| US8234769B2 (en) * | 2006-09-28 | 2012-08-07 | Robert Bosch Gmbh | Device and method for mounting a needle guard on a syringe body |

| US20100162548A1 (en) * | 2006-09-28 | 2010-07-01 | Juergen Leidig | Device and method for mounting a needle guard on a syringe body |

| US11504481B2 (en) | 2007-10-02 | 2022-11-22 | West Pharma. Services IL, Ltd. | Anti-rotation feature for infusion pump cartridge |

| US11590291B2 (en) | 2007-10-02 | 2023-02-28 | West Pharma. Services IL, Ltd. | External drug pump |

| US10420880B2 (en) | 2007-10-02 | 2019-09-24 | West Pharma. Services IL, Ltd. | Key for securing components of a drug delivery system during assembly and/or transport and methods of using same |

| US10960131B2 (en) | 2007-10-02 | 2021-03-30 | West Pharma. Services IL, Ltd. | Apparatuses for securing components of a drug delivery system during transport and methods of using same |

| US20170112998A1 (en) * | 2007-10-02 | 2017-04-27 | Medimop Medical Projects Ltd. | Method of using a key to secure components of a drug delivery system during assembly |

| US10716890B2 (en) * | 2007-10-02 | 2020-07-21 | West Pharma. Services IL, Ltd. | Method of using a key to secure components of a drug delivery system during assembly |

| US20100139215A1 (en) * | 2008-12-09 | 2010-06-10 | Pierre Jacques Van Roy | Device and Method for Packing Syringes in Nests |

| US20100299904A1 (en) * | 2009-05-26 | 2010-12-02 | Angelo Ansaloni | Method and apparatus for screwing pistons of syringes |

| US20140109518A1 (en) * | 2010-10-19 | 2014-04-24 | Vince Benetti | System and Method for Packaging Dental Ingots |

| US9579179B2 (en) * | 2010-10-19 | 2017-02-28 | Vince Benetti | System and method for packaging dental ingots |

| US8499531B2 (en) * | 2010-10-19 | 2013-08-06 | Aalba Dent Inc. | System and method for packaging dental ingots |

| US20130219710A1 (en) * | 2010-11-19 | 2013-08-29 | Michael Jugl | Assembly Device for Injection Needles |

| US10758679B2 (en) | 2015-05-29 | 2020-09-01 | West Pharma. Services IL, Ltd. | Linear rotation stabilizer for a telescoping syringe stopper driverdriving assembly |

| US10912891B2 (en) | 2015-09-22 | 2021-02-09 | West Pharma. Services IL, Ltd. | Rotation resistant friction adapter for plunger driver of drug delivery device |

| US11318254B2 (en) | 2015-10-09 | 2022-05-03 | West Pharma. Services IL, Ltd. | Injector needle cap remover |

| US11759573B2 (en) | 2015-10-09 | 2023-09-19 | West Pharma. Services, IL, Ltd. | Bent fluid path add on to a prefilled reservoir |

| US11724034B2 (en) | 2015-10-09 | 2023-08-15 | West Pharma. Services, IL, Ltd. | Injector system |

| US11547802B2 (en) | 2015-10-09 | 2023-01-10 | West Pharma. Services IL, Ltd. | Angled syringe patch injector |

| US11672904B2 (en) | 2016-01-21 | 2023-06-13 | West Pharma. Services IL, Ltd. | Needle insertion and retraction mechanism |

| US11311674B2 (en) | 2016-01-21 | 2022-04-26 | West Pharma. Services IL, Ltd. | Medicament delivery device comprising a visual indicator |

| US11364337B2 (en) | 2016-01-21 | 2022-06-21 | West Pharma. Services IL, Ltd. | Force containment in an automatic injector |

| US11389597B2 (en) | 2016-03-16 | 2022-07-19 | West Pharma. Services IL, Ltd. | Staged telescopic screw assembly having different visual indicators |

| US11338090B2 (en) | 2016-08-01 | 2022-05-24 | West Pharma. Services IL, Ltd. | Anti-rotation cartridge pin |

| WO2018183039A1 (en) * | 2017-03-28 | 2018-10-04 | Amgen Inc. | Plunger rod and syringe assembly system and method |

| JP7118993B2 (en) | 2017-03-28 | 2022-08-16 | アムジエン・インコーポレーテツド | Plunger rod and syringe assembly system and method |

| EA037969B1 (en) * | 2017-03-28 | 2021-06-17 | Эмджен Инк. | Plunger rod and syringe assembly system and method |

| CN110446512A (en) * | 2017-03-28 | 2019-11-12 | 美国安进公司 | Plunger rod and injector assembly system and method |

| CN114588404A (en) * | 2017-03-28 | 2022-06-07 | 美国安进公司 | Plunger rod and syringe assembly systems and methods |

| JP2020512111A (en) * | 2017-03-28 | 2020-04-23 | アムジエン・インコーポレーテツド | Plunger rod and syringe assembly system and method |

| EP4241807A3 (en) * | 2017-03-28 | 2023-10-11 | Amgen Inc. | Plunger rod and syringe assembly system and method |

| US11957883B2 (en) | 2017-03-28 | 2024-04-16 | Amgen Inc. | Plunger rod and syringe assembly system and method |

| US11819666B2 (en) | 2017-05-30 | 2023-11-21 | West Pharma. Services IL, Ltd. | Modular drive train for wearable injector |

| WO2021126677A1 (en) * | 2019-12-16 | 2021-06-24 | Merck Sharp & Dohme Corp. | Torque-limiting device for manual insertion of syringe plunger rods and methods of using same |

| EP4076600A4 (en) * | 2019-12-16 | 2024-04-24 | Merck Sharp & Dohme Llc | Torque-limiting device for manual insertion of syringe plunger rods and methods of using same |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US3708945A (en) | Syringe assembling method and machine | |

| US3245194A (en) | Method and apparatus for filling hypodermic syringes, ampules, etc. | |

| US3789575A (en) | Article packaging machine | |

| US3589103A (en) | Machines for unscrewing caps or stoppers from containers | |

| US2668550A (en) | Apparatus for automatically opening cans, dispensing their contents, and flushing the cans | |

| CN112722351A (en) | Online full-automatic screw rod powder liquid filling machine with rectify and exempt from to examine function | |

| US4118914A (en) | Vial assembler | |

| CN112456420A (en) | Aseptic liquid filling machine of plant extract | |

| US2336415A (en) | Can filling machine | |

| US3788035A (en) | Caulking cartridge filling and seaming machine | |

| KR102024848B1 (en) | Spout poutch packing machine | |

| CN111646402A (en) | Glass medicine bottle seals rubber plug device | |

| US3204387A (en) | Container sealing machine | |

| CN115144516A (en) | Gas chromatograph capable of automatically feeding sample | |

| US1545777A (en) | Capsule-decapping machine | |

| US2823500A (en) | Machine for assembling hypodermic syringes | |

| JPS59164957A (en) | Method and device for sampling sample | |

| US4735238A (en) | Drum filling method and apparatus | |

| DE2410529A1 (en) | SAMPLE INJECTION SYSTEM | |

| US2897643A (en) | Apparatus for applying closures to flexible containers | |

| SE415875B (en) | DEVICE FOR FILLING WITH THE SLIDABLE BOTTOM PROVIDED PACKAGING CONTAINER | |

| DE3106074A1 (en) | Method and apparatus for producing sausage skin sections which are ready for filling and are to be processed on combined filling and sealing machines | |

| US3391518A (en) | Process and apparatus for breechfilling cartridge syringe units | |

| EP0798263A1 (en) | Container capping and filling apparatus | |

| US3470671A (en) | Process and apparatus for the breech-filling and stoppering of cartridge syringe units |