US20060148271A1 - Silicon source reagent compositions, and method of making and using same for microelectronic device structure - Google Patents

Silicon source reagent compositions, and method of making and using same for microelectronic device structure Download PDFInfo

- Publication number

- US20060148271A1 US20060148271A1 US11/363,904 US36390406A US2006148271A1 US 20060148271 A1 US20060148271 A1 US 20060148271A1 US 36390406 A US36390406 A US 36390406A US 2006148271 A1 US2006148271 A1 US 2006148271A1

- Authority

- US

- United States

- Prior art keywords

- source reagent

- aminosilane

- precursor

- composition

- compound

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Abandoned

Links

- 239000003153 chemical reaction reagent Substances 0.000 title claims abstract description 247

- 239000000203 mixture Substances 0.000 title claims abstract description 232

- 229910052710 silicon Inorganic materials 0.000 title claims abstract description 88

- 239000010703 silicon Substances 0.000 title claims abstract description 83

- 238000004519 manufacturing process Methods 0.000 title claims description 13

- 238000004377 microelectronic Methods 0.000 title claims description 7

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 title description 73

- 239000002243 precursor Substances 0.000 claims abstract description 226

- FZHAPNGMFPVSLP-UHFFFAOYSA-N silanamine Chemical compound [SiH3]N FZHAPNGMFPVSLP-UHFFFAOYSA-N 0.000 claims abstract description 158

- 238000005229 chemical vapour deposition Methods 0.000 claims abstract description 154

- 239000010409 thin film Substances 0.000 claims abstract description 147

- 150000001875 compounds Chemical class 0.000 claims abstract description 133

- 239000000758 substrate Substances 0.000 claims abstract description 113

- 238000000034 method Methods 0.000 claims abstract description 111

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 claims abstract description 74

- 239000002904 solvent Substances 0.000 claims abstract description 66

- -1 perfluoroaryl Chemical group 0.000 claims abstract description 49

- 229910052739 hydrogen Inorganic materials 0.000 claims abstract description 47

- 150000001412 amines Chemical class 0.000 claims abstract description 46

- 229910052757 nitrogen Inorganic materials 0.000 claims abstract description 46

- 229910052751 metal Inorganic materials 0.000 claims abstract description 30

- 239000002184 metal Substances 0.000 claims abstract description 30

- 125000003118 aryl group Chemical group 0.000 claims abstract description 27

- 229910052735 hafnium Inorganic materials 0.000 claims abstract description 27

- 125000004209 (C1-C8) alkyl group Chemical group 0.000 claims abstract description 26

- 125000005010 perfluoroalkyl group Chemical group 0.000 claims abstract description 26

- 150000004820 halides Chemical class 0.000 claims abstract description 20

- 229910052736 halogen Inorganic materials 0.000 claims abstract description 19

- 150000002367 halogens Chemical class 0.000 claims abstract description 19

- 239000001257 hydrogen Substances 0.000 claims abstract description 18

- 229910052746 lanthanum Inorganic materials 0.000 claims abstract description 16

- 229910052715 tantalum Inorganic materials 0.000 claims abstract description 16

- 230000003213 activating effect Effects 0.000 claims abstract description 15

- 229910052727 yttrium Inorganic materials 0.000 claims abstract description 15

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 claims abstract description 10

- 125000005103 alkyl silyl group Chemical group 0.000 claims abstract description 10

- 230000003647 oxidation Effects 0.000 claims abstract description 10

- 238000007254 oxidation reaction Methods 0.000 claims abstract description 10

- 230000002194 synthesizing effect Effects 0.000 claims abstract description 8

- 239000007788 liquid Substances 0.000 claims description 48

- 238000000151 deposition Methods 0.000 claims description 33

- 230000008016 vaporization Effects 0.000 claims description 28

- 230000008021 deposition Effects 0.000 claims description 23

- 239000007789 gas Substances 0.000 claims description 23

- 239000011541 reaction mixture Substances 0.000 claims description 21

- 239000012159 carrier gas Substances 0.000 claims description 20

- 238000006243 chemical reaction Methods 0.000 claims description 20

- 239000003446 ligand Substances 0.000 claims description 17

- SSCVMVQLICADPI-UHFFFAOYSA-N n-methyl-n-[tris(dimethylamino)silyl]methanamine Chemical compound CN(C)[Si](N(C)C)(N(C)C)N(C)C SSCVMVQLICADPI-UHFFFAOYSA-N 0.000 claims description 14

- 239000012454 non-polar solvent Substances 0.000 claims description 11

- 239000007800 oxidant agent Substances 0.000 claims description 8

- 238000006467 substitution reaction Methods 0.000 claims description 8

- 150000004945 aromatic hydrocarbons Chemical class 0.000 claims description 6

- 229910052801 chlorine Inorganic materials 0.000 claims description 6

- 150000002170 ethers Chemical class 0.000 claims description 6

- 230000001590 oxidative effect Effects 0.000 claims description 6

- 150000001338 aliphatic hydrocarbons Chemical class 0.000 claims description 5

- 239000006227 byproduct Substances 0.000 claims description 5

- 150000004292 cyclic ethers Chemical class 0.000 claims description 5

- 239000003960 organic solvent Substances 0.000 claims description 5

- 229920000768 polyamine Polymers 0.000 claims description 5

- 238000004821 distillation Methods 0.000 claims description 4

- BLRPTPMANUNPDV-UHFFFAOYSA-N Silane Chemical compound [SiH4] BLRPTPMANUNPDV-UHFFFAOYSA-N 0.000 claims description 2

- BOTDANWDWHJENH-UHFFFAOYSA-N Tetraethyl orthosilicate Chemical compound CCO[Si](OCC)(OCC)OCC BOTDANWDWHJENH-UHFFFAOYSA-N 0.000 claims description 2

- 229910052744 lithium Inorganic materials 0.000 claims description 2

- 229910052700 potassium Inorganic materials 0.000 claims description 2

- 229910000077 silane Inorganic materials 0.000 claims description 2

- 229910052708 sodium Inorganic materials 0.000 claims description 2

- CZDYPVPMEAXLPK-UHFFFAOYSA-N tetramethylsilane Chemical compound C[Si](C)(C)C CZDYPVPMEAXLPK-UHFFFAOYSA-N 0.000 claims description 2

- PQDJYEQOELDLCP-UHFFFAOYSA-N trimethylsilane Chemical compound C[SiH](C)C PQDJYEQOELDLCP-UHFFFAOYSA-N 0.000 claims description 2

- 229910052725 zinc Inorganic materials 0.000 claims description 2

- 239000012453 solvate Substances 0.000 claims 3

- 125000002924 primary amino group Chemical group [H]N([H])* 0.000 claims 1

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 abstract description 75

- 239000000377 silicon dioxide Substances 0.000 abstract description 37

- 229910052726 zirconium Inorganic materials 0.000 abstract description 22

- 239000003989 dielectric material Substances 0.000 abstract description 18

- 229910052747 lanthanoid Inorganic materials 0.000 abstract description 15

- 150000002602 lanthanoids Chemical class 0.000 abstract description 15

- 229910052719 titanium Inorganic materials 0.000 abstract description 15

- 229910052782 aluminium Inorganic materials 0.000 abstract description 13

- 229910052799 carbon Inorganic materials 0.000 abstract description 10

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 abstract description 9

- 239000012535 impurity Substances 0.000 abstract description 8

- 229910052681 coesite Inorganic materials 0.000 abstract 1

- 229910052906 cristobalite Inorganic materials 0.000 abstract 1

- 229910052682 stishovite Inorganic materials 0.000 abstract 1

- 229910052905 tridymite Inorganic materials 0.000 abstract 1

- 239000010408 film Substances 0.000 description 62

- 230000008569 process Effects 0.000 description 39

- VLKZOEOYAKHREP-UHFFFAOYSA-N n-Hexane Chemical class CCCCCC VLKZOEOYAKHREP-UHFFFAOYSA-N 0.000 description 36

- 239000000243 solution Substances 0.000 description 30

- 239000010410 layer Substances 0.000 description 29

- 229910052914 metal silicate Inorganic materials 0.000 description 24

- 239000012686 silicon precursor Substances 0.000 description 24

- 239000000460 chlorine Substances 0.000 description 22

- 230000015572 biosynthetic process Effects 0.000 description 21

- 125000004432 carbon atom Chemical group C* 0.000 description 20

- BPQQTUXANYXVAA-UHFFFAOYSA-N Orthosilicate Chemical compound [O-][Si]([O-])([O-])[O-] BPQQTUXANYXVAA-UHFFFAOYSA-N 0.000 description 19

- 125000001495 ethyl group Chemical group [H]C([H])([H])C([H])([H])* 0.000 description 15

- 125000002496 methyl group Chemical group [H]C([H])([H])* 0.000 description 15

- 239000000376 reactant Substances 0.000 description 15

- 239000010936 titanium Substances 0.000 description 15

- 239000000047 product Substances 0.000 description 14

- 239000004065 semiconductor Substances 0.000 description 14

- 238000009834 vaporization Methods 0.000 description 14

- 238000000277 atomic layer chemical vapour deposition Methods 0.000 description 13

- WYURNTSHIVDZCO-UHFFFAOYSA-N Tetrahydrofuran Chemical compound C1CCOC1 WYURNTSHIVDZCO-UHFFFAOYSA-N 0.000 description 12

- 125000000623 heterocyclic group Chemical group 0.000 description 12

- 239000000463 material Substances 0.000 description 12

- 229910044991 metal oxide Inorganic materials 0.000 description 12

- 150000004706 metal oxides Chemical class 0.000 description 12

- 229910052581 Si3N4 Inorganic materials 0.000 description 11

- HQVNEWCFYHHQES-UHFFFAOYSA-N silicon nitride Chemical compound N12[Si]34N5[Si]62N3[Si]51N64 HQVNEWCFYHHQES-UHFFFAOYSA-N 0.000 description 11

- XKRFYHLGVUSROY-UHFFFAOYSA-N Argon Chemical compound [Ar] XKRFYHLGVUSROY-UHFFFAOYSA-N 0.000 description 10

- 239000002019 doping agent Substances 0.000 description 10

- 230000000694 effects Effects 0.000 description 10

- 230000005669 field effect Effects 0.000 description 10

- 238000000354 decomposition reaction Methods 0.000 description 9

- 235000012239 silicon dioxide Nutrition 0.000 description 9

- 241000894007 species Species 0.000 description 9

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Chemical compound O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 9

- 125000000229 (C1-C4)alkoxy group Chemical group 0.000 description 8

- 229910003910 SiCl4 Inorganic materials 0.000 description 8

- UHOVQNZJYSORNB-MZWXYZOWSA-N benzene-d6 Chemical compound [2H]C1=C([2H])C([2H])=C([2H])C([2H])=C1[2H] UHOVQNZJYSORNB-MZWXYZOWSA-N 0.000 description 8

- 150000002431 hydrogen Chemical group 0.000 description 8

- 125000004433 nitrogen atom Chemical group N* 0.000 description 8

- FDNAPBUWERUEDA-UHFFFAOYSA-N silicon tetrachloride Chemical compound Cl[Si](Cl)(Cl)Cl FDNAPBUWERUEDA-UHFFFAOYSA-N 0.000 description 8

- 125000004178 (C1-C4) alkyl group Chemical group 0.000 description 7

- 238000002474 experimental method Methods 0.000 description 7

- 238000010438 heat treatment Methods 0.000 description 7

- 229910052786 argon Inorganic materials 0.000 description 6

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 6

- CJNBYAVZURUTKZ-UHFFFAOYSA-N hafnium(IV) oxide Inorganic materials O=[Hf]=O CJNBYAVZURUTKZ-UHFFFAOYSA-N 0.000 description 6

- 238000010348 incorporation Methods 0.000 description 6

- 239000001301 oxygen Substances 0.000 description 6

- 229910052760 oxygen Inorganic materials 0.000 description 6

- 238000012545 processing Methods 0.000 description 6

- 238000010926 purge Methods 0.000 description 6

- 238000003786 synthesis reaction Methods 0.000 description 6

- YLQBMQCUIZJEEH-UHFFFAOYSA-N tetrahydrofuran Natural products C=1C=COC=1 YLQBMQCUIZJEEH-UHFFFAOYSA-N 0.000 description 6

- 239000006200 vaporizer Substances 0.000 description 6

- ZMANZCXQSJIPKH-UHFFFAOYSA-N Triethylamine Chemical compound CCN(CC)CC ZMANZCXQSJIPKH-UHFFFAOYSA-N 0.000 description 5

- 238000013459 approach Methods 0.000 description 5

- 230000004888 barrier function Effects 0.000 description 5

- 230000002939 deleterious effect Effects 0.000 description 5

- DWCMDRNGBIZOQL-UHFFFAOYSA-N dimethylazanide;zirconium(4+) Chemical compound [Zr+4].C[N-]C.C[N-]C.C[N-]C.C[N-]C DWCMDRNGBIZOQL-UHFFFAOYSA-N 0.000 description 5

- 239000000126 substance Substances 0.000 description 5

- QGZKDVFQNNGYKY-UHFFFAOYSA-N Ammonia Chemical compound N QGZKDVFQNNGYKY-UHFFFAOYSA-N 0.000 description 4

- MCMNRKCIXSYSNV-UHFFFAOYSA-N Zirconium dioxide Chemical compound O=[Zr]=O MCMNRKCIXSYSNV-UHFFFAOYSA-N 0.000 description 4

- 125000004429 atom Chemical group 0.000 description 4

- 239000004020 conductor Substances 0.000 description 4

- 229910052734 helium Inorganic materials 0.000 description 4

- 239000011229 interlayer Substances 0.000 description 4

- 125000001449 isopropyl group Chemical group [H]C([H])([H])C([H])(*)C([H])([H])[H] 0.000 description 4

- SJHDWSADDRUNNE-UHFFFAOYSA-N n-[dichloro(diethylamino)silyl]-n-ethylethanamine Chemical compound CCN(CC)[Si](Cl)(Cl)N(CC)CC SJHDWSADDRUNNE-UHFFFAOYSA-N 0.000 description 4

- TVMXDCGIABBOFY-UHFFFAOYSA-N octane Chemical compound CCCCCCCC TVMXDCGIABBOFY-UHFFFAOYSA-N 0.000 description 4

- 230000036961 partial effect Effects 0.000 description 4

- 239000002245 particle Substances 0.000 description 4

- 239000012071 phase Substances 0.000 description 4

- 125000003386 piperidinyl group Chemical group 0.000 description 4

- 239000002798 polar solvent Substances 0.000 description 4

- 230000002829 reductive effect Effects 0.000 description 4

- 150000004760 silicates Chemical class 0.000 description 4

- 239000007787 solid Substances 0.000 description 4

- ZUHZGEOKBKGPSW-UHFFFAOYSA-N tetraglyme Chemical compound COCCOCCOCCOCCOC ZUHZGEOKBKGPSW-UHFFFAOYSA-N 0.000 description 4

- 239000003039 volatile agent Substances 0.000 description 4

- 238000005160 1H NMR spectroscopy Methods 0.000 description 3

- RTZKZFJDLAIYFH-UHFFFAOYSA-N Diethyl ether Chemical compound CCOCC RTZKZFJDLAIYFH-UHFFFAOYSA-N 0.000 description 3

- XTHFKEDIFFGKHM-UHFFFAOYSA-N Dimethoxyethane Chemical compound COCCOC XTHFKEDIFFGKHM-UHFFFAOYSA-N 0.000 description 3

- YXFVVABEGXRONW-UHFFFAOYSA-N Toluene Chemical compound CC1=CC=CC=C1 YXFVVABEGXRONW-UHFFFAOYSA-N 0.000 description 3

- 230000008901 benefit Effects 0.000 description 3

- 238000001816 cooling Methods 0.000 description 3

- 125000004663 dialkyl amino group Chemical group 0.000 description 3

- 125000002147 dimethylamino group Chemical group [H]C([H])([H])N(*)C([H])([H])[H] 0.000 description 3

- VSLPMIMVDUOYFW-UHFFFAOYSA-N dimethylazanide;tantalum(5+) Chemical compound [Ta+5].C[N-]C.C[N-]C.C[N-]C.C[N-]C.C[N-]C VSLPMIMVDUOYFW-UHFFFAOYSA-N 0.000 description 3

- 229910000167 hafnon Inorganic materials 0.000 description 3

- 239000001307 helium Substances 0.000 description 3

- SWQJXJOGLNCZEY-UHFFFAOYSA-N helium atom Chemical compound [He] SWQJXJOGLNCZEY-UHFFFAOYSA-N 0.000 description 3

- 238000011065 in-situ storage Methods 0.000 description 3

- 238000002347 injection Methods 0.000 description 3

- 239000007924 injection Substances 0.000 description 3

- 230000000670 limiting effect Effects 0.000 description 3

- 239000007791 liquid phase Substances 0.000 description 3

- 238000003760 magnetic stirring Methods 0.000 description 3

- 239000011159 matrix material Substances 0.000 description 3

- 238000002156 mixing Methods 0.000 description 3

- YLZCZVGQEADVNK-UHFFFAOYSA-N n-[chloro-bis(dimethylamino)silyl]-n-methylmethanamine Chemical compound CN(C)[Si](Cl)(N(C)C)N(C)C YLZCZVGQEADVNK-UHFFFAOYSA-N 0.000 description 3

- 239000002244 precipitate Substances 0.000 description 3

- 230000002028 premature Effects 0.000 description 3

- 230000005641 tunneling Effects 0.000 description 3

- XQQZRZQVBFHBHL-UHFFFAOYSA-N 12-crown-4 Chemical compound C1COCCOCCOCCO1 XQQZRZQVBFHBHL-UHFFFAOYSA-N 0.000 description 2

- VFTFKUDGYRBSAL-UHFFFAOYSA-N 15-crown-5 Chemical compound C1COCCOCCOCCOCCO1 VFTFKUDGYRBSAL-UHFFFAOYSA-N 0.000 description 2

- XEZNGIUYQVAUSS-UHFFFAOYSA-N 18-crown-6 Chemical compound C1COCCOCCOCCOCCOCCO1 XEZNGIUYQVAUSS-UHFFFAOYSA-N 0.000 description 2

- WADSJYLPJPTMLN-UHFFFAOYSA-N 3-(cycloundecen-1-yl)-1,2-diazacycloundec-2-ene Chemical compound C1CCCCCCCCC=C1C1=NNCCCCCCCC1 WADSJYLPJPTMLN-UHFFFAOYSA-N 0.000 description 2

- UTNHCPDKZQGQGC-UHFFFAOYSA-N B.C1CNC1 Chemical compound B.C1CNC1 UTNHCPDKZQGQGC-UHFFFAOYSA-N 0.000 description 2

- DWCGWFJCFCRCDF-UHFFFAOYSA-N C.C1CNC1 Chemical compound C.C1CNC1 DWCGWFJCFCRCDF-UHFFFAOYSA-N 0.000 description 2

- VEXZGXHMUGYJMC-UHFFFAOYSA-M Chloride anion Chemical compound [Cl-] VEXZGXHMUGYJMC-UHFFFAOYSA-M 0.000 description 2

- 229910004721 HSiCl3 Inorganic materials 0.000 description 2

- KWYHDKDOAIKMQN-UHFFFAOYSA-N N,N,N',N'-tetramethylethylenediamine Chemical compound CN(C)CCN(C)C KWYHDKDOAIKMQN-UHFFFAOYSA-N 0.000 description 2

- CBENFWSGALASAD-UHFFFAOYSA-N Ozone Chemical compound [O-][O+]=O CBENFWSGALASAD-UHFFFAOYSA-N 0.000 description 2

- GWEVSGVZZGPLCZ-UHFFFAOYSA-N Titan oxide Chemical compound O=[Ti]=O GWEVSGVZZGPLCZ-UHFFFAOYSA-N 0.000 description 2

- QCWXUUIWCKQGHC-UHFFFAOYSA-N Zirconium Chemical compound [Zr] QCWXUUIWCKQGHC-UHFFFAOYSA-N 0.000 description 2

- 230000002411 adverse Effects 0.000 description 2

- 150000001298 alcohols Chemical class 0.000 description 2

- 125000000217 alkyl group Chemical group 0.000 description 2

- 239000003990 capacitor Substances 0.000 description 2

- 230000008859 change Effects 0.000 description 2

- 238000002425 crystallisation Methods 0.000 description 2

- 230000008025 crystallization Effects 0.000 description 2

- 230000003247 decreasing effect Effects 0.000 description 2

- 230000007547 defect Effects 0.000 description 2

- VBCSQFQVDXIOJL-UHFFFAOYSA-N diethylazanide;hafnium(4+) Chemical compound [Hf+4].CC[N-]CC.CC[N-]CC.CC[N-]CC.CC[N-]CC VBCSQFQVDXIOJL-UHFFFAOYSA-N 0.000 description 2

- VJDVOZLYDLHLSM-UHFFFAOYSA-N diethylazanide;titanium(4+) Chemical compound [Ti+4].CC[N-]CC.CC[N-]CC.CC[N-]CC.CC[N-]CC VJDVOZLYDLHLSM-UHFFFAOYSA-N 0.000 description 2

- 238000009792 diffusion process Methods 0.000 description 2

- SBZXBUIDTXKZTM-UHFFFAOYSA-N diglyme Chemical compound COCCOCCOC SBZXBUIDTXKZTM-UHFFFAOYSA-N 0.000 description 2

- 238000005516 engineering process Methods 0.000 description 2

- 238000009472 formulation Methods 0.000 description 2

- VBJZVLUMGGDVMO-UHFFFAOYSA-N hafnium atom Chemical compound [Hf] VBJZVLUMGGDVMO-UHFFFAOYSA-N 0.000 description 2

- 239000011261 inert gas Substances 0.000 description 2

- DLEDOFVPSDKWEF-UHFFFAOYSA-N lithium butane Chemical compound [Li+].CCC[CH2-] DLEDOFVPSDKWEF-UHFFFAOYSA-N 0.000 description 2

- YDGSUPBDGKOGQT-UHFFFAOYSA-N lithium;dimethylazanide Chemical compound [Li+].C[N-]C YDGSUPBDGKOGQT-UHFFFAOYSA-N 0.000 description 2

- 238000004518 low pressure chemical vapour deposition Methods 0.000 description 2

- 238000001819 mass spectrum Methods 0.000 description 2

- DIHKMUNUGQVFES-UHFFFAOYSA-N n,n,n',n'-tetraethylethane-1,2-diamine Chemical compound CCN(CC)CCN(CC)CC DIHKMUNUGQVFES-UHFFFAOYSA-N 0.000 description 2

- MZRVEZGGRBJDDB-UHFFFAOYSA-N n-Butyllithium Substances [Li]CCCC MZRVEZGGRBJDDB-UHFFFAOYSA-N 0.000 description 2

- 229910000069 nitrogen hydride Inorganic materials 0.000 description 2

- 150000002902 organometallic compounds Chemical class 0.000 description 2

- 125000001997 phenyl group Chemical group [H]C1=C([H])C([H])=C(*)C([H])=C1[H] 0.000 description 2

- 125000001436 propyl group Chemical group [H]C([*])([H])C([H])([H])C([H])([H])[H] 0.000 description 2

- 238000007086 side reaction Methods 0.000 description 2

- 150000004756 silanes Chemical class 0.000 description 2

- 239000000725 suspension Substances 0.000 description 2

- 238000010189 synthetic method Methods 0.000 description 2

- PBCFLUZVCVVTBY-UHFFFAOYSA-N tantalum pentoxide Inorganic materials O=[Ta](=O)O[Ta](=O)=O PBCFLUZVCVVTBY-UHFFFAOYSA-N 0.000 description 2

- MNWRORMXBIWXCI-UHFFFAOYSA-N tetrakis(dimethylamido)titanium Chemical compound CN(C)[Ti](N(C)C)(N(C)C)N(C)C MNWRORMXBIWXCI-UHFFFAOYSA-N 0.000 description 2

- IMFACGCPASFAPR-UHFFFAOYSA-N tributylamine Chemical compound CCCCN(CCCC)CCCC IMFACGCPASFAPR-UHFFFAOYSA-N 0.000 description 2

- ZDHXKXAHOVTTAH-UHFFFAOYSA-N trichlorosilane Chemical compound Cl[SiH](Cl)Cl ZDHXKXAHOVTTAH-UHFFFAOYSA-N 0.000 description 2

- 238000002604 ultrasonography Methods 0.000 description 2

- 238000005292 vacuum distillation Methods 0.000 description 2

- 238000007738 vacuum evaporation Methods 0.000 description 2

- 239000012808 vapor phase Substances 0.000 description 2

- RYHBNJHYFVUHQT-UHFFFAOYSA-N 1,4-Dioxane Chemical compound C1COCCO1 RYHBNJHYFVUHQT-UHFFFAOYSA-N 0.000 description 1

- PXMNMQRDXWABCY-UHFFFAOYSA-N 1-(4-chlorophenyl)-4,4-dimethyl-3-(1H-1,2,4-triazol-1-ylmethyl)pentan-3-ol Chemical compound C1=NC=NN1CC(O)(C(C)(C)C)CCC1=CC=C(Cl)C=C1 PXMNMQRDXWABCY-UHFFFAOYSA-N 0.000 description 1

- 238000001644 13C nuclear magnetic resonance spectroscopy Methods 0.000 description 1

- 229910016909 AlxOy Inorganic materials 0.000 description 1

- ZOXJGFHDIHLPTG-UHFFFAOYSA-N Boron Chemical compound [B] ZOXJGFHDIHLPTG-UHFFFAOYSA-N 0.000 description 1

- 229910052684 Cerium Inorganic materials 0.000 description 1

- ZAMOUSCENKQFHK-UHFFFAOYSA-N Chlorine atom Chemical compound [Cl] ZAMOUSCENKQFHK-UHFFFAOYSA-N 0.000 description 1

- ROSDSFDQCJNGOL-UHFFFAOYSA-N Dimethylamine Chemical compound CNC ROSDSFDQCJNGOL-UHFFFAOYSA-N 0.000 description 1

- 229910052692 Dysprosium Inorganic materials 0.000 description 1

- 229910052691 Erbium Inorganic materials 0.000 description 1

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 1

- 229910052693 Europium Inorganic materials 0.000 description 1

- 229910052688 Gadolinium Inorganic materials 0.000 description 1

- 241000588731 Hafnia Species 0.000 description 1

- 229910052689 Holmium Inorganic materials 0.000 description 1

- VEXZGXHMUGYJMC-UHFFFAOYSA-N Hydrochloric acid Chemical compound Cl VEXZGXHMUGYJMC-UHFFFAOYSA-N 0.000 description 1

- 239000002879 Lewis base Substances 0.000 description 1

- 229910052765 Lutetium Inorganic materials 0.000 description 1

- 238000005481 NMR spectroscopy Methods 0.000 description 1

- 229910052779 Neodymium Inorganic materials 0.000 description 1

- 229910052777 Praseodymium Inorganic materials 0.000 description 1

- 229910052773 Promethium Inorganic materials 0.000 description 1

- 229910052772 Samarium Inorganic materials 0.000 description 1

- 229910020781 SixOy Inorganic materials 0.000 description 1

- 229910052771 Terbium Inorganic materials 0.000 description 1

- 229910052775 Thulium Inorganic materials 0.000 description 1

- 229910052769 Ytterbium Inorganic materials 0.000 description 1

- 229910006498 ZrxSi1-x Inorganic materials 0.000 description 1

- 238000009825 accumulation Methods 0.000 description 1

- 150000001335 aliphatic alkanes Chemical class 0.000 description 1

- 150000001336 alkenes Chemical class 0.000 description 1

- 150000001345 alkine derivatives Chemical class 0.000 description 1

- 150000004703 alkoxides Chemical class 0.000 description 1

- 125000003545 alkoxy group Chemical group 0.000 description 1

- 150000001343 alkyl silanes Chemical class 0.000 description 1

- 229910021529 ammonia Inorganic materials 0.000 description 1

- 238000004458 analytical method Methods 0.000 description 1

- 229910052454 barium strontium titanate Inorganic materials 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 229910052796 boron Inorganic materials 0.000 description 1

- 244000309464 bull Species 0.000 description 1

- 150000007942 carboxylates Chemical class 0.000 description 1

- 230000003197 catalytic effect Effects 0.000 description 1

- ZMIGMASIKSOYAM-UHFFFAOYSA-N cerium Chemical compound [Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce] ZMIGMASIKSOYAM-UHFFFAOYSA-N 0.000 description 1

- 239000012043 crude product Substances 0.000 description 1

- 239000013078 crystal Substances 0.000 description 1

- 238000010908 decantation Methods 0.000 description 1

- 230000002950 deficient Effects 0.000 description 1

- 238000001514 detection method Methods 0.000 description 1

- ZYLGGWPMIDHSEZ-UHFFFAOYSA-N dimethylazanide;hafnium(4+) Chemical compound [Hf+4].C[N-]C.C[N-]C.C[N-]C.C[N-]C ZYLGGWPMIDHSEZ-UHFFFAOYSA-N 0.000 description 1

- KBQHZAAAGSGFKK-UHFFFAOYSA-N dysprosium atom Chemical compound [Dy] KBQHZAAAGSGFKK-UHFFFAOYSA-N 0.000 description 1

- 230000005684 electric field Effects 0.000 description 1

- 230000002708 enhancing effect Effects 0.000 description 1

- UYAHIZSMUZPPFV-UHFFFAOYSA-N erbium Chemical compound [Er] UYAHIZSMUZPPFV-UHFFFAOYSA-N 0.000 description 1

- OGPBJKLSAFTDLK-UHFFFAOYSA-N europium atom Chemical compound [Eu] OGPBJKLSAFTDLK-UHFFFAOYSA-N 0.000 description 1

- 238000000605 extraction Methods 0.000 description 1

- 239000000706 filtrate Substances 0.000 description 1

- 238000001914 filtration Methods 0.000 description 1

- 239000012530 fluid Substances 0.000 description 1

- UIWYJDYFSGRHKR-UHFFFAOYSA-N gadolinium atom Chemical compound [Gd] UIWYJDYFSGRHKR-UHFFFAOYSA-N 0.000 description 1

- KJZYNXUDTRRSPN-UHFFFAOYSA-N holmium atom Chemical compound [Ho] KJZYNXUDTRRSPN-UHFFFAOYSA-N 0.000 description 1

- IXCSERBJSXMMFS-UHFFFAOYSA-N hydrogen chloride Substances Cl.Cl IXCSERBJSXMMFS-UHFFFAOYSA-N 0.000 description 1

- 229910000041 hydrogen chloride Inorganic materials 0.000 description 1

- 238000013383 initial experiment Methods 0.000 description 1

- 239000011810 insulating material Substances 0.000 description 1

- 238000002955 isolation Methods 0.000 description 1

- 229910052743 krypton Inorganic materials 0.000 description 1

- DNNSSWSSYDEUBZ-UHFFFAOYSA-N krypton atom Chemical compound [Kr] DNNSSWSSYDEUBZ-UHFFFAOYSA-N 0.000 description 1

- FZLIPJUXYLNCLC-UHFFFAOYSA-N lanthanum atom Chemical compound [La] FZLIPJUXYLNCLC-UHFFFAOYSA-N 0.000 description 1

- 239000012705 liquid precursor Substances 0.000 description 1

- OHSVLFRHMCKCQY-UHFFFAOYSA-N lutetium atom Chemical compound [Lu] OHSVLFRHMCKCQY-UHFFFAOYSA-N 0.000 description 1

- 230000007246 mechanism Effects 0.000 description 1

- 230000008018 melting Effects 0.000 description 1

- 238000002844 melting Methods 0.000 description 1

- 238000001465 metallisation Methods 0.000 description 1

- 239000000178 monomer Substances 0.000 description 1

- MJBZMPMVOIEPQI-UHFFFAOYSA-N n-methyl-n-tris[ethyl(methyl)amino]silylethanamine Chemical compound CCN(C)[Si](N(C)CC)(N(C)CC)N(C)CC MJBZMPMVOIEPQI-UHFFFAOYSA-N 0.000 description 1

- 238000002663 nebulization Methods 0.000 description 1

- QEFYFXOXNSNQGX-UHFFFAOYSA-N neodymium atom Chemical compound [Nd] QEFYFXOXNSNQGX-UHFFFAOYSA-N 0.000 description 1

- 150000002926 oxygen Chemical class 0.000 description 1

- BPUBBGLMJRNUCC-UHFFFAOYSA-N oxygen(2-);tantalum(5+) Chemical compound [O-2].[O-2].[O-2].[O-2].[O-2].[Ta+5].[Ta+5] BPUBBGLMJRNUCC-UHFFFAOYSA-N 0.000 description 1

- NFHFRUOZVGFOOS-UHFFFAOYSA-N palladium;triphenylphosphane Chemical compound [Pd].C1=CC=CC=C1P(C=1C=CC=CC=1)C1=CC=CC=C1.C1=CC=CC=C1P(C=1C=CC=CC=1)C1=CC=CC=C1.C1=CC=CC=C1P(C=1C=CC=CC=1)C1=CC=CC=C1.C1=CC=CC=C1P(C=1C=CC=CC=1)C1=CC=CC=C1 NFHFRUOZVGFOOS-UHFFFAOYSA-N 0.000 description 1

- 230000000737 periodic effect Effects 0.000 description 1

- 238000000623 plasma-assisted chemical vapour deposition Methods 0.000 description 1

- PUDIUYLPXJFUGB-UHFFFAOYSA-N praseodymium atom Chemical compound [Pr] PUDIUYLPXJFUGB-UHFFFAOYSA-N 0.000 description 1

- 238000004886 process control Methods 0.000 description 1

- VQMWBBYLQSCNPO-UHFFFAOYSA-N promethium atom Chemical compound [Pm] VQMWBBYLQSCNPO-UHFFFAOYSA-N 0.000 description 1

- 238000000746 purification Methods 0.000 description 1

- 150000003839 salts Chemical class 0.000 description 1

- KZUNJOHGWZRPMI-UHFFFAOYSA-N samarium atom Chemical compound [Sm] KZUNJOHGWZRPMI-UHFFFAOYSA-N 0.000 description 1

- 229920006395 saturated elastomer Polymers 0.000 description 1

- 229910052814 silicon oxide Inorganic materials 0.000 description 1

- 239000002356 single layer Substances 0.000 description 1

- 238000000096 single-wavelength ellipsometry Methods 0.000 description 1

- 239000002002 slurry Substances 0.000 description 1

- 239000011877 solvent mixture Substances 0.000 description 1

- 125000006850 spacer group Chemical group 0.000 description 1

- 238000001228 spectrum Methods 0.000 description 1

- GUVRBAGPIYLISA-UHFFFAOYSA-N tantalum atom Chemical compound [Ta] GUVRBAGPIYLISA-UHFFFAOYSA-N 0.000 description 1

- GZCRRIHWUXGPOV-UHFFFAOYSA-N terbium atom Chemical compound [Tb] GZCRRIHWUXGPOV-UHFFFAOYSA-N 0.000 description 1

- 150000003512 tertiary amines Chemical class 0.000 description 1

- 238000007736 thin film deposition technique Methods 0.000 description 1

- 239000004408 titanium dioxide Substances 0.000 description 1

- 229910000314 transition metal oxide Inorganic materials 0.000 description 1

- 229910000326 transition metal silicate Inorganic materials 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

- NAWDYIZEMPQZHO-UHFFFAOYSA-N ytterbium Chemical compound [Yb] NAWDYIZEMPQZHO-UHFFFAOYSA-N 0.000 description 1

- 229910052845 zircon Inorganic materials 0.000 description 1

- 150000003754 zirconium Chemical class 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having at least one potential-jump barrier or surface barrier, e.g. PN junction, depletion layer or carrier concentration layer

- H01L21/18—Manufacture or treatment of semiconductor devices or of parts thereof the devices having at least one potential-jump barrier or surface barrier, e.g. PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising elements of Group IV of the Periodic System or AIIIBV compounds with or without impurities, e.g. doping materials

- H01L21/28—Manufacture of electrodes on semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/268

- H01L21/28008—Making conductor-insulator-semiconductor electrodes

- H01L21/28017—Making conductor-insulator-semiconductor electrodes the insulator being formed after the semiconductor body, the semiconductor being silicon

- H01L21/28158—Making the insulator

- H01L21/28167—Making the insulator on single crystalline silicon, e.g. using a liquid, i.e. chemical oxidation

- H01L21/28185—Making the insulator on single crystalline silicon, e.g. using a liquid, i.e. chemical oxidation with a treatment, e.g. annealing, after the formation of the gate insulator and before the formation of the definitive gate conductor

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07F—ACYCLIC, CARBOCYCLIC OR HETEROCYCLIC COMPOUNDS CONTAINING ELEMENTS OTHER THAN CARBON, HYDROGEN, HALOGEN, OXYGEN, NITROGEN, SULFUR, SELENIUM OR TELLURIUM

- C07F7/00—Compounds containing elements of Groups 4 or 14 of the Periodic System

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07F—ACYCLIC, CARBOCYCLIC OR HETEROCYCLIC COMPOUNDS CONTAINING ELEMENTS OTHER THAN CARBON, HYDROGEN, HALOGEN, OXYGEN, NITROGEN, SULFUR, SELENIUM OR TELLURIUM

- C07F7/00—Compounds containing elements of Groups 4 or 14 of the Periodic System

- C07F7/003—Compounds containing elements of Groups 4 or 14 of the Periodic System without C-Metal linkages

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07F—ACYCLIC, CARBOCYCLIC OR HETEROCYCLIC COMPOUNDS CONTAINING ELEMENTS OTHER THAN CARBON, HYDROGEN, HALOGEN, OXYGEN, NITROGEN, SULFUR, SELENIUM OR TELLURIUM

- C07F7/00—Compounds containing elements of Groups 4 or 14 of the Periodic System

- C07F7/02—Silicon compounds

- C07F7/025—Silicon compounds without C-silicon linkages

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07F—ACYCLIC, CARBOCYCLIC OR HETEROCYCLIC COMPOUNDS CONTAINING ELEMENTS OTHER THAN CARBON, HYDROGEN, HALOGEN, OXYGEN, NITROGEN, SULFUR, SELENIUM OR TELLURIUM

- C07F7/00—Compounds containing elements of Groups 4 or 14 of the Periodic System

- C07F7/02—Silicon compounds

- C07F7/08—Compounds having one or more C—Si linkages

- C07F7/10—Compounds having one or more C—Si linkages containing nitrogen having a Si-N linkage

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/06—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material characterised by the coating material

- C23C14/08—Oxides

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/06—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material characterised by the coating material

- C23C14/08—Oxides

- C23C14/083—Oxides of refractory metals or yttrium

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/22—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the deposition of inorganic material, other than metallic material

- C23C16/30—Deposition of compounds, mixtures or solid solutions, e.g. borides, carbides, nitrides

- C23C16/40—Oxides

- C23C16/401—Oxides containing silicon

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/22—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the deposition of inorganic material, other than metallic material

- C23C16/30—Deposition of compounds, mixtures or solid solutions, e.g. borides, carbides, nitrides

- C23C16/40—Oxides

- C23C16/405—Oxides of refractory metals or yttrium

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02104—Forming layers

- H01L21/02107—Forming insulating materials on a substrate

- H01L21/02109—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates

- H01L21/02112—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer

- H01L21/02123—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer the material containing silicon

- H01L21/02142—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer the material containing silicon the material containing silicon and at least one metal element, e.g. metal silicate based insulators or metal silicon oxynitrides

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02104—Forming layers

- H01L21/02107—Forming insulating materials on a substrate

- H01L21/02109—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates

- H01L21/02112—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer

- H01L21/02123—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer the material containing silicon

- H01L21/02142—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer the material containing silicon the material containing silicon and at least one metal element, e.g. metal silicate based insulators or metal silicon oxynitrides

- H01L21/02148—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer the material containing silicon the material containing silicon and at least one metal element, e.g. metal silicate based insulators or metal silicon oxynitrides the material containing hafnium, e.g. HfSiOx or HfSiON

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02104—Forming layers

- H01L21/02107—Forming insulating materials on a substrate

- H01L21/02109—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates

- H01L21/02112—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer

- H01L21/02123—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer the material containing silicon

- H01L21/02164—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer the material containing silicon the material being a silicon oxide, e.g. SiO2

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02104—Forming layers

- H01L21/02107—Forming insulating materials on a substrate

- H01L21/02109—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates

- H01L21/02112—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer

- H01L21/02172—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer the material containing at least one metal element, e.g. metal oxides, metal nitrides, metal oxynitrides or metal carbides

- H01L21/02175—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer the material containing at least one metal element, e.g. metal oxides, metal nitrides, metal oxynitrides or metal carbides characterised by the metal

- H01L21/02181—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer the material containing at least one metal element, e.g. metal oxides, metal nitrides, metal oxynitrides or metal carbides characterised by the metal the material containing hafnium, e.g. HfO2

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02104—Forming layers

- H01L21/02107—Forming insulating materials on a substrate

- H01L21/02109—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates

- H01L21/02205—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates the layer being characterised by the precursor material for deposition

- H01L21/02208—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates the layer being characterised by the precursor material for deposition the precursor containing a compound comprising Si

- H01L21/02219—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates the layer being characterised by the precursor material for deposition the precursor containing a compound comprising Si the compound comprising silicon and nitrogen

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02104—Forming layers

- H01L21/02107—Forming insulating materials on a substrate

- H01L21/02109—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates

- H01L21/02205—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates the layer being characterised by the precursor material for deposition

- H01L21/02208—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates the layer being characterised by the precursor material for deposition the precursor containing a compound comprising Si

- H01L21/02219—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates the layer being characterised by the precursor material for deposition the precursor containing a compound comprising Si the compound comprising silicon and nitrogen

- H01L21/02222—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates the layer being characterised by the precursor material for deposition the precursor containing a compound comprising Si the compound comprising silicon and nitrogen the compound being a silazane

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02104—Forming layers

- H01L21/02107—Forming insulating materials on a substrate

- H01L21/02225—Forming insulating materials on a substrate characterised by the process for the formation of the insulating layer

- H01L21/0226—Forming insulating materials on a substrate characterised by the process for the formation of the insulating layer formation by a deposition process

- H01L21/02263—Forming insulating materials on a substrate characterised by the process for the formation of the insulating layer formation by a deposition process deposition from the gas or vapour phase

- H01L21/02271—Forming insulating materials on a substrate characterised by the process for the formation of the insulating layer formation by a deposition process deposition from the gas or vapour phase deposition by decomposition or reaction of gaseous or vapour phase compounds, i.e. chemical vapour deposition

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having at least one potential-jump barrier or surface barrier, e.g. PN junction, depletion layer or carrier concentration layer

- H01L21/18—Manufacture or treatment of semiconductor devices or of parts thereof the devices having at least one potential-jump barrier or surface barrier, e.g. PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising elements of Group IV of the Periodic System or AIIIBV compounds with or without impurities, e.g. doping materials

- H01L21/28—Manufacture of electrodes on semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/268

- H01L21/28008—Making conductor-insulator-semiconductor electrodes

- H01L21/28017—Making conductor-insulator-semiconductor electrodes the insulator being formed after the semiconductor body, the semiconductor being silicon

- H01L21/28158—Making the insulator

- H01L21/28167—Making the insulator on single crystalline silicon, e.g. using a liquid, i.e. chemical oxidation

- H01L21/28194—Making the insulator on single crystalline silicon, e.g. using a liquid, i.e. chemical oxidation by deposition, e.g. evaporation, ALD, CVD, sputtering, laser deposition

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having at least one potential-jump barrier or surface barrier, e.g. PN junction, depletion layer or carrier concentration layer

- H01L21/18—Manufacture or treatment of semiconductor devices or of parts thereof the devices having at least one potential-jump barrier or surface barrier, e.g. PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising elements of Group IV of the Periodic System or AIIIBV compounds with or without impurities, e.g. doping materials

- H01L21/30—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26

- H01L21/31—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26 to form insulating layers thereon, e.g. for masking or by using photolithographic techniques; After treatment of these layers; Selection of materials for these layers

- H01L21/312—Organic layers, e.g. photoresist

- H01L21/3121—Layers comprising organo-silicon compounds

- H01L21/3125—Layers comprising organo-silicon compounds layers comprising silazane compounds

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having at least one potential-jump barrier or surface barrier, e.g. PN junction, depletion layer or carrier concentration layer

- H01L21/18—Manufacture or treatment of semiconductor devices or of parts thereof the devices having at least one potential-jump barrier or surface barrier, e.g. PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising elements of Group IV of the Periodic System or AIIIBV compounds with or without impurities, e.g. doping materials

- H01L21/30—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26

- H01L21/31—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26 to form insulating layers thereon, e.g. for masking or by using photolithographic techniques; After treatment of these layers; Selection of materials for these layers

- H01L21/314—Inorganic layers

- H01L21/316—Inorganic layers composed of oxides or glassy oxides or oxide based glass

- H01L21/31604—Deposition from a gas or vapour

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having at least one potential-jump barrier or surface barrier, e.g. PN junction, depletion layer or carrier concentration layer

- H01L21/18—Manufacture or treatment of semiconductor devices or of parts thereof the devices having at least one potential-jump barrier or surface barrier, e.g. PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising elements of Group IV of the Periodic System or AIIIBV compounds with or without impurities, e.g. doping materials

- H01L21/30—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26

- H01L21/31—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26 to form insulating layers thereon, e.g. for masking or by using photolithographic techniques; After treatment of these layers; Selection of materials for these layers

- H01L21/314—Inorganic layers

- H01L21/318—Inorganic layers composed of nitrides

- H01L21/3185—Inorganic layers composed of nitrides of siliconnitrides

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having at least one potential-jump barrier or surface barrier, e.g. PN junction, depletion layer or carrier concentration layer

- H01L21/18—Manufacture or treatment of semiconductor devices or of parts thereof the devices having at least one potential-jump barrier or surface barrier, e.g. PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising elements of Group IV of the Periodic System or AIIIBV compounds with or without impurities, e.g. doping materials

- H01L21/28—Manufacture of electrodes on semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/268

- H01L21/28008—Making conductor-insulator-semiconductor electrodes

- H01L21/28017—Making conductor-insulator-semiconductor electrodes the insulator being formed after the semiconductor body, the semiconductor being silicon

- H01L21/28158—Making the insulator

- H01L21/28167—Making the insulator on single crystalline silicon, e.g. using a liquid, i.e. chemical oxidation

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L29/00—Semiconductor devices adapted for rectifying, amplifying, oscillating or switching, or capacitors or resistors with at least one potential-jump barrier or surface barrier, e.g. PN junction depletion layer or carrier concentration layer; Details of semiconductor bodies or of electrodes thereof ; Multistep manufacturing processes therefor

- H01L29/40—Electrodes ; Multistep manufacturing processes therefor

- H01L29/43—Electrodes ; Multistep manufacturing processes therefor characterised by the materials of which they are formed

- H01L29/49—Metal-insulator-semiconductor electrodes, e.g. gates of MOSFET

- H01L29/51—Insulating materials associated therewith

- H01L29/517—Insulating materials associated therewith the insulating material comprising a metallic compound, e.g. metal oxide, metal silicate

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L29/00—Semiconductor devices adapted for rectifying, amplifying, oscillating or switching, or capacitors or resistors with at least one potential-jump barrier or surface barrier, e.g. PN junction depletion layer or carrier concentration layer; Details of semiconductor bodies or of electrodes thereof ; Multistep manufacturing processes therefor

- H01L29/40—Electrodes ; Multistep manufacturing processes therefor

- H01L29/43—Electrodes ; Multistep manufacturing processes therefor characterised by the materials of which they are formed

- H01L29/49—Metal-insulator-semiconductor electrodes, e.g. gates of MOSFET

- H01L29/51—Insulating materials associated therewith

- H01L29/518—Insulating materials associated therewith the insulating material containing nitrogen, e.g. nitride, oxynitride, nitrogen-doped material

Definitions

- metal oxide and metal oxy-nitride thin films comprising Zr, Hf, Y, La, Lanthanide series elements, Ta, Ti and/or Al and silicates of these metal oxides and metal oxy-nitrides are regarded as potential material replacements of the SiO 2 gate oxides, (i.e., U.S. Pat. Nos. 6,159,855 and 6,013,553).

- these films must be deposited at relatively low temperatures.

- the source reagents must be thermally stable to avoid premature decomposition of such source reagents before they reach the CVD reaction chamber during the CVD process. Premature decomposition of source reagents not only results in undesirable accumulation of side products that will clog fluid flow conduits of the CVD apparatus, but also causes undesirable variations in composition of the deposited gate dielectric thin film. Further, particle formation can result in deleterious yields in device fabrication.

- the present invention relates to a CVD precursor composition for forming a thin film dielectric on a substrate, such precursor composition including a vapor source reagent of the formula: M(NR 1 R 2 ) x wherein M is selected from the group consisting of: Zr, Hf, Y, La, Lanthanide series elements, Ta, Ti, Al; N is nitrogen; each of R1 and R2 is same or different and is independently selected from the group consisting of H, aryl, perfluoroaryl, C 1 -C 8 alkyl, C 1 -C 8 perfluoroalkyl, alkylsilyl; and x is the oxidation state on metal M.

- the nitrogen atom of the metalloamide is bonded to two carbon atoms, those two carbon atoms may be bonded to one another to form a heterocyclic ring.

- FIGS. 2A and 2B show a limited pressure-temperature matrix for Si(N(C 2 H 5 ) 2 ) 2 Cl 2 (bis(diethyl-amino)dichlorosilane), and Si(N(CH 3 ) 2 ) 3 Cl(tris(dimethyl-amino)chlorosilane in N 2 O.

- step (3) adding an activating polar solvent to the partially substituted aminosilane component and the unreacted amine component of the reaction mixture of step (1) to at least partially activate the unreacted amine component;

- step (3) (4) continuing the reaction of step (3) for a period of time sufficient to provide for essentially stoichiometric substitution of at least one halide on the aminosilane precursor compound by an amine component.

- the present invention relates to a method of synthesizing an aminosilane source reagent composition, by reacting an aminosilane precursor compound with an amine source reagent compound in a solvent system comprising at least one activating solvent component in an amount equal to at least one equivalent of the amine source reagent compound, to yield an aminosilane precursor having reduced halide content as compared to existing commercial precursors.

- aminosilane source reagent compositions of the present invention when utilized in a CVD process to deposit silicon containing thin films on a substrate, result in silicon containing thin films having very little or no halide impurity.

- the metalloamide CVD precursor composition is used to deposit a silicate gate dielectric thin film wherein the metalloamide precursor is suitably used in combination with a silicon precursor(s) source to yield the product metal silicate film.

- the silicon precursor may advantageously comprise an aminosilane source reagent compound as described herein or may alternatively comprise an alternative silicon source reagent compound as known to those skilled in the art, to deposit silicate thin films, (i.e. silane, trimethylsilane, tetramethylsilane and tetraethylorthosilicate).

- the present invention relates to a method for forming a dielectric thin film on a substrate by chemical vapor deposition.

- the present invention relates to a method for forming a dielectric silicate thin film on a substrate by chemical vapor deposition.

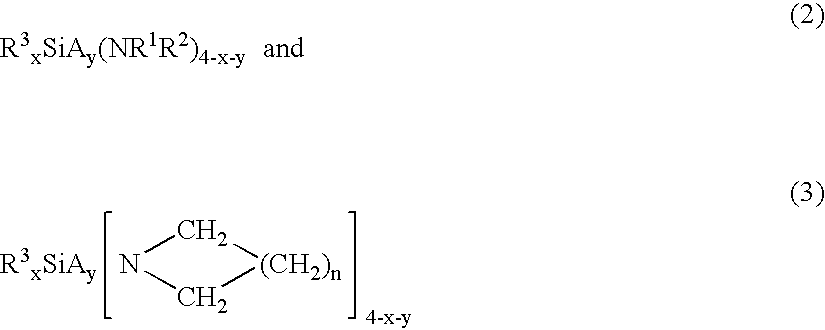

- At least one metalloamide source reagent composition selected from the group consisting of: wherein M is selected from the group consisting of: Zr, Hf, Y, La, Lanthanide series elements, Ta, Ti, Al; N is nitrogen; each of R 1 and R 2 is same or different and is independently selected from the group consisting of H, aryl, perfluoroaryl, C 1 -C 8 alkyl, C 1 -C 8 perfluoroalkyl, alkylsilyl; x is the oxidation state on metal M; and n is from 1-6.

- R 1 and R 2 of the aminosilane and metalloamide source reagent compositions are methyl and/or ethyl.

- composition or method may contain or involve additional aminosilane and/or other compounds.

Abstract

A CVD Method of forming gate dielectric thin films on a substrate using metalloamide compounds of the formula M(NR1R2)x, wherein M is selected from the group consisting of: Zr, Hf, Y, La, Lanthanide series elements, Ta, Ti, Al; N is nitrogen; each of R1 and R2 is same or different and is independently selected from the group consisting of H, aryl, perfluoroaryl, C1-C8 alkyl, C1-C8 perfluoroalkyl, alkylsilyl and x is the oxidation state on metal M; and an aminosilane compound of the formula HxSi(NR1R2)4−x, wherein H is hydrogen; x is from 0 to 3; Si is silicon; N is nitrogen; each of R1 and R2 is same or different and is independently selected from the group consisting of H, aryl, perfluoroaryl, C1-C8 alkyl, and C1-C8 perfluoroalkyl. By comparison with the standard SiO2 gate dielectric materials, these gate dielectric materials provide low levels of carbon and halide impurity. Also described is a method of synthesizing an aminosilane source reagent composition, by reacting an aminosilane precursor compound with an amine source reagent compound in a solvent medium comprising at least one activating solvent component, to yield an aminosilane source reagent composition having less than 1000 ppm halogen.

Description

- This is a continuation of U.S. patent application Ser. No. 10/112,517 filed on Mar. 29, 2002 in the name of Alexander S. Borovik et al., which is a continuation-in-part of U.S. patent application Ser. No.09/954,831 filed on Sep. 18, 2001 in the name of Thomas H. Baum et al., which is a continuation-in-part of U.S. patent application Ser. No. 09/823,196 filed on Mar. 30, 2001 in the name of Thomas H. Baum et al. This is also a continuation of U.S. patent application Ser. No. 09/823,196 filed Mar. 30, 2001 in the names of Thomas H. Baum, Chongying Xu, Bryan C. Hendrix and Jeffrey F. Roeder. The disclosures of all of the foregoing applications are hereby incorporated herein in their respective entireties, for all purposes, and the priority of all such applications is hereby claimed under the provisions of 35 USC 120.

- The present invention relates to silicon precursor compositions and their synthesis, and to the use of such silicon precursor compositions for the fabrication of microelectronic device structures, e.g., in the formation of gate dielectrics and silicon nitride barrier layers, in the manufacture of semiconductor integrated circuits, or in otherwise forming silicon-containing films on a substrate by chemical vapor deposition (CVD) utilizing such precursor compositions.

- The process of fabricating semiconductor integrated circuits generally includes the formation of such components as, gate oxides, high k dielectrics, low k dielectrics, barrier layers, etch stop layers and gate spacers. Such components often include silicon or silicon oxide in their compositions. For example, conventional gate dielectric materials may be formed from silicon dioxide, silicon oxy-nitride, silicon nitride or metal silicates.

- Semiconductor devices such as field effect transistors (FET) and metal oxide semiconductor capacitors (MOS-caps), which are common in the electronics industry, include many of the components identified above. Such devices may be formed with dimensions that enable thousands or even millions of devices to be formed on a single-crystal substrate and interconnected to perform useful functions in an integrated circuit such as a microprocessor.

- The general structure and operation of a field effect transistor is as follows. With reference to

FIG. 1 , a simplified field effect transistor is shown in cross-section. In a field effect transistor a portion of the substrate (or epi-layer) 100 near the surface is designated as thechannel 120 during processing.Channel 120 is electrically connected tosource 140 and drain 160, such that when a voltage difference exists betweensource 140 anddrain 160, current will tend to flow throughchannel 120. The semiconducting characteristics ofchannel 120 are altered such that its resistivity may be controlled by the voltage applied togate 200, a conductivelayer overlying channel 120. Thus by changing the voltage ongate 200, more or less current can be made to flow throughchannel 120.Gate 200 andchannel 120 are separated by gate dielectric 180; the gate dielectric is insulating, such that betweengate 200 andchannel 120 the current flow during operation is small compared to the source to drain current (although “tunneling” current is observed with thin dielectrics.) However, the gate dielectric allows the gate voltage to induce an electric field inchannel 120, giving rise to the name “field effect transistor.” The general structure of a MOS-cap can be visualized aslayers FIG. 1 without the source and drain. The MOS-cap functions as a capacitor. - SiO2 represents the highest quality gate

dielectric material 180 so far developed in silicon technology with low defects and low surface state density. One important advantage of SiO2 is that it may be grown from the silicon substrate at elevated temperatures in an oxidizing environment. It is well known in the art, that thermally grown oxides tend to have fewer defects, (i.e. pinholes), than deposited materials. Thus, SiO2 has persisted as the dielectric material in most silicon device structures. - Generally, integrated circuit performance and density may be enhanced by decreasing the size of the individual semiconductor devices on a chip. Unfortunately, field effect semiconductor devices produce an output signal that is proportional to the length of the channel, such that scaling reduces their output. This effect has generally been compensated for by decreasing the thickness of gate dielectric 180, thus bringing the gate in closer proximity to the channel and enhancing the field effect.

- As devices have scaled to smaller and smaller dimensions, the gate dielectric thickness has continued to shrink. Although further scaling of devices is still possible, scaling of the gate dielectric thickness has almost reached its practical limit with the conventional gate dielectric materials: silicon dioxide, silicon oxy-nitride and silicon nitride. Further scaling of silicon dioxide gate dielectric thickness will involve problems such as: extremely thin layers allowing for large leakage currents due to direct tunneling through the oxide. Because such layers are formed literally from a few atomic layers, exact process control is required to repeatably produce such layers. Uniformity of coverage is also critical because device parameters may change dramatically based on the presence or absence of even a single monolayer of dielectric material. Finally, such thin layers form poor diffusion barriers to impurities and dopants.

- Consequently, there is a need in the art for alternative dielectric materials, which can be formed in a thicker layer than silicon dioxide and yet still produce the same field effect performance. This performance is often expressed as “equivalent oxide thickness” (EOT). Although the alternative material layer may be thick, it has the equivalent effect of a much thinner layer of silicon dioxide (commonly called simply “oxide”). In order to have a physically thick layer with a low EOT, the dielectric constant of the insulating material must be increased. Many, if not most, of the attractive alternatives for achieving low equivalent oxide thicknesses are metal oxides, such as tantalum pentoxide, titanium dioxide, barium strontium titanate and other suitable thin films.

- However, the formation of such metal oxides as gate dielectrics has been found to be problematic. At typical metal oxide deposition temperatures, the oxygen co-reactant or oxygen-containing precursor tends to oxidize the silicon substrate, producing a lower dielectric constant oxide layer at the interface between the substrate and the higher dielectric constant, gate dielectric material. It could be that the transition metal oxide acts as a catalytic source of activated oxygen, that the precursor molecules increase the oxygen activity or that oxygen from the precursor is incorporated in the growing oxide film. Whatever the cause, the presence of this interfacial oxide layer increases the effective oxide thickness, reducing the effectiveness of the alternative gate dielectric material. The existence of the interfacial oxide layer places a severe constraint on the performance of an alternative dielectric field effect device and therefore, is unacceptable.

- The use of metal oxide and metal oxy-nitride thin films comprising Zr, Hf, Y, La, Lanthanide series elements, Ta, Ti and/or Al and silicates of these metal oxides and metal oxy-nitrides are regarded as potential material replacements of the SiO2 gate oxides, (i.e., U.S. Pat. Nos. 6,159,855 and 6,013,553). However, to ensure a high integrity interface between the silicon and the gate dielectric film these films must be deposited at relatively low temperatures.

- The source reagents and methodology employed to form such gate dielectric thin films are extremely critical for the provision of a gate structure having satisfactory electrical performance characteristics in the product device. Specifically, the source reagents and methodology must permit the gate dielectric thin film to form on a clean silicon surface, without the occurrence of side reactions producing predominantly silicon dioxide (SiO2), locally doped SiO2 and/or other impurities, that lower the dielectric constant and compromise the performance of the product microelectronic device. Accordingly, the absence of impurities is highly desirable.

- Chemical vapor deposition (CVD) is the thin film deposition method of choice for high-density, large-scale fabrication of microelectronic device structures, and the semiconductor manufacturing industry has extensive expertise in its use. Metalorganic CVD (MOCVD) and more particularly atomic layer CVD (ALCVD) are particularly advantageous processes because they allow for lower deposition temperatures and stricter control of the stoichiometry and thickness of the formed layer.

- In the formation of gate dielectrics and other semiconductor manufacturing applications it is essential to control the composition of the deposited thin film. The molar ratio(s) of the different elements in the thin film typically corresponds very closely to a predetermined value. Therefore, it is very important to select a precursor delivery system that allows for strict control of the precursors delivered into the CVD chamber. Precursor delivery systems are well known in the art of CVD, (i.e., U.S. Pat. No. 5,820,678, entitled “Solid Source MOCVD System” describes the bubbler delivery approach and U.S. Pat. No. 5,204,314, entitled “Method for Delivering an Involatile Reagent in Vapor Form to a CVD Reactor,” and U.S. Pat. No. 5,536,323, entitled “Apparatus for Flash Vaporization Delivery of Reagents,” describe the liquid delivery, flash vaporization approach).

- Chemical vapor deposition (CVD) of silicon-containing films provides uniform coverage. Liquid CVD precursors enable direct delivery or liquid injection of the precursors into a CVD vaporizer unit. The accurate and precise delivery rate can be obtained through volumetric metering to achieve reproducible CVD metallization during VLSI device manufacturing.

- Impurities that are known to lower the dielectric constant and/or increase leakage include among others, carbon and halides. Carbon and/or halide incorporation into the dielectric thin film would degrade leakage, dielectric constant, and overall electrical performance of the thin film. In contrast, nitrogen incorporation may exhibit some beneficial properties on the dielectric thin film.

- Excess halide may adversely affect a gate dieletric thin film in either of two ways. Halide incorporation into a gate dielectric thin film, may directly affect the electronic nature of the film, thereby reducing device lifetime. Secondly, halide, such as chloride, leads to formation of hydrogen chloride during the decomposition of the precursor, which potentially affects the CVD chamber making the treatment of the effluent from the chamber more challenging.

- Zr, Hf, Y, La, Lanthanide series elements, Ta, Ti, Al and/or silicon source reagents, specifically Zr and Hf-containing silicates such as ZrxSi1−xO2, and HfxSi1−xO2 are of great interest for use as next generation gate dielectrics. These materials possess dielectric constant (k) values in the range of 10 to 20, depending on x, and allow the use of a physical thickness to prevent leakage by electron tunneling. Given the feature sizes of the VLSI devices, CVD is becoming a unique technique for depositing these materials.

- In such applications, the choice of the zirconium or hafnium CVD source reagents and a compatible silicon source reagent is of critical importance for the successful deposition of high quality Zr or Hf silicate gate dielectric. Low temperature CVD silicon precursors are required to minimize the formation of interfacial silicon dioxide. Ideally, the precursors are compatible in solution and in vapor phase and decompose below 600° C. on substrate surfaces, forming Hf or Zr silicates in high purity and high density with no interfacial layer.

- The source reagents must be thermally stable to avoid premature decomposition of such source reagents before they reach the CVD reaction chamber during the CVD process. Premature decomposition of source reagents not only results in undesirable accumulation of side products that will clog fluid flow conduits of the CVD apparatus, but also causes undesirable variations in composition of the deposited gate dielectric thin film. Further, particle formation can result in deleterious yields in device fabrication.

- Further, Zr, Hf, Y, La, Lanthanide series elements, Ta, Ti, Al and/or silicon source reagents have to be chemically compatible with other source reagents used in the CVD process. “Chemically compatible” means that the source reagents will not undergo, undesirable side reactions with other co-deposited source reagents, and/or deleterious ligand exchange reactions that may alter the precursor properties, such as transport behavior, incorporation rates and film stoichiometries.