EP0680411B2 - Document with doped optical safety mark, stratified composite paper for producing the same and device for checking the authenticity of the document - Google Patents

Document with doped optical safety mark, stratified composite paper for producing the same and device for checking the authenticity of the document Download PDFInfo

- Publication number

- EP0680411B2 EP0680411B2 EP93924429A EP93924429A EP0680411B2 EP 0680411 B2 EP0680411 B2 EP 0680411B2 EP 93924429 A EP93924429 A EP 93924429A EP 93924429 A EP93924429 A EP 93924429A EP 0680411 B2 EP0680411 B2 EP 0680411B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- layer

- document

- substances

- adhesive layer

- film structure

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B42—BOOKBINDING; ALBUMS; FILES; SPECIAL PRINTED MATTER

- B42D—BOOKS; BOOK COVERS; LOOSE LEAVES; PRINTED MATTER CHARACTERISED BY IDENTIFICATION OR SECURITY FEATURES; PRINTED MATTER OF SPECIAL FORMAT OR STYLE NOT OTHERWISE PROVIDED FOR; DEVICES FOR USE THEREWITH AND NOT OTHERWISE PROVIDED FOR; MOVABLE-STRIP WRITING OR READING APPARATUS

- B42D25/00—Information-bearing cards or sheet-like structures characterised by identification or security features; Manufacture thereof

- B42D25/20—Information-bearing cards or sheet-like structures characterised by identification or security features; Manufacture thereof characterised by a particular use or purpose

- B42D25/29—Securities; Bank notes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B42—BOOKBINDING; ALBUMS; FILES; SPECIAL PRINTED MATTER

- B42D—BOOKS; BOOK COVERS; LOOSE LEAVES; PRINTED MATTER CHARACTERISED BY IDENTIFICATION OR SECURITY FEATURES; PRINTED MATTER OF SPECIAL FORMAT OR STYLE NOT OTHERWISE PROVIDED FOR; DEVICES FOR USE THEREWITH AND NOT OTHERWISE PROVIDED FOR; MOVABLE-STRIP WRITING OR READING APPARATUS

- B42D25/00—Information-bearing cards or sheet-like structures characterised by identification or security features; Manufacture thereof

- B42D25/30—Identification or security features, e.g. for preventing forgery

- B42D25/328—Diffraction gratings; Holograms

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B42—BOOKBINDING; ALBUMS; FILES; SPECIAL PRINTED MATTER

- B42D—BOOKS; BOOK COVERS; LOOSE LEAVES; PRINTED MATTER CHARACTERISED BY IDENTIFICATION OR SECURITY FEATURES; PRINTED MATTER OF SPECIAL FORMAT OR STYLE NOT OTHERWISE PROVIDED FOR; DEVICES FOR USE THEREWITH AND NOT OTHERWISE PROVIDED FOR; MOVABLE-STRIP WRITING OR READING APPARATUS

- B42D25/00—Information-bearing cards or sheet-like structures characterised by identification or security features; Manufacture thereof

- B42D25/30—Identification or security features, e.g. for preventing forgery

- B42D25/36—Identification or security features, e.g. for preventing forgery comprising special materials

- B42D25/373—Metallic materials

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B42—BOOKBINDING; ALBUMS; FILES; SPECIAL PRINTED MATTER

- B42D—BOOKS; BOOK COVERS; LOOSE LEAVES; PRINTED MATTER CHARACTERISED BY IDENTIFICATION OR SECURITY FEATURES; PRINTED MATTER OF SPECIAL FORMAT OR STYLE NOT OTHERWISE PROVIDED FOR; DEVICES FOR USE THEREWITH AND NOT OTHERWISE PROVIDED FOR; MOVABLE-STRIP WRITING OR READING APPARATUS

- B42D25/00—Information-bearing cards or sheet-like structures characterised by identification or security features; Manufacture thereof

- B42D25/40—Manufacture

- B42D25/45—Associating two or more layers

- B42D25/465—Associating two or more layers using chemicals or adhesives

- B42D25/47—Associating two or more layers using chemicals or adhesives using adhesives

-

- B42D2033/04—

-

- B42D2033/10—

-

- B42D2033/18—

-

- B42D2033/20—

-

- B42D2035/20—

-

- B42D2035/24—

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S428/00—Stock material or miscellaneous articles

- Y10S428/916—Fraud or tamper detecting

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/14—Layer or component removable to expose adhesive

- Y10T428/1476—Release layer

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/24—Structurally defined web or sheet [e.g., overall dimension, etc.]

- Y10T428/24802—Discontinuous or differential coating, impregnation or bond [e.g., artwork, printing, retouched photograph, etc.]

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/24—Structurally defined web or sheet [e.g., overall dimension, etc.]

- Y10T428/24802—Discontinuous or differential coating, impregnation or bond [e.g., artwork, printing, retouched photograph, etc.]

- Y10T428/24843—Discontinuous or differential coating, impregnation or bond [e.g., artwork, printing, retouched photograph, etc.] with heat sealable or heat releasable adhesive layer

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/24—Structurally defined web or sheet [e.g., overall dimension, etc.]

- Y10T428/24802—Discontinuous or differential coating, impregnation or bond [e.g., artwork, printing, retouched photograph, etc.]

- Y10T428/24893—Discontinuous or differential coating, impregnation or bond [e.g., artwork, printing, retouched photograph, etc.] including particulate material

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/24—Structurally defined web or sheet [e.g., overall dimension, etc.]

- Y10T428/24802—Discontinuous or differential coating, impregnation or bond [e.g., artwork, printing, retouched photograph, etc.]

- Y10T428/24917—Discontinuous or differential coating, impregnation or bond [e.g., artwork, printing, retouched photograph, etc.] including metal layer

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/28—Web or sheet containing structurally defined element or component and having an adhesive outermost layer

- Y10T428/2804—Next to metal

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/28—Web or sheet containing structurally defined element or component and having an adhesive outermost layer

- Y10T428/2839—Web or sheet containing structurally defined element or component and having an adhesive outermost layer with release or antistick coating

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/31504—Composite [nonstructural laminate]

- Y10T428/31678—Of metal

Definitions

- the invention relates to a document, e.g. Banknote, check, credit card, ID card or ticket, which is an optical Security feature in the form of a light reflecting and diffractive provided at least in some areas and / or refractive layer, e.g. a hologram, an interference layer, a (computer-generated) Diffraction structure or the like has, wherein the optical security feature is provided with doping material and in a film structure is present, which is attached to the document by means of an adhesive layer and, if appropriate has at least one transparent layer in the film structure.

- a document e.g. Banknote, check, credit card, ID card or ticket

- an optical Security feature in the form of a light reflecting and diffractive provided at least in some areas and / or refractive layer, e.g. a hologram, an interference layer, a (computer-generated) Diffraction structure or the like has, wherein the optical security feature is provided with doping material and in a film structure is present, which is attached to the document by

- the invention is concerned with a film structure, for the production of such documents, with a carrier film and a transfer layer which can be detached therefrom and which is at least the embossed optical security feature forming, light reflecting as well as diffractive and / or refractive layer, in particular as an embossing film, is preferably formed as a hot stamping film, and on the side of the reflective side facing away from the carrier film Layer has an adhesive layer, at least one transparent layer being arranged in the film structure can.

- the known documents or embossing foils have an optical diffraction effect as a security feature all against color copy structure, such diffraction optically effective, i.e.

- Light reflecting, Diffractive and / or refractive structures have the basic advantage that they are with the unarmed eye recognized, but can also be read by machine.

- Typical structures applied in particular to banknotes include Kinegrams and pixelgrams. The falsification of such structures is very difficult, but is still in preparation all feasible if it is possible to expose the correspondingly structured surface and galvanically to take impressions or to copy phototechnically.

- DE-OS 37 41 179 discloses the use of two security features, namely firstly, a relief embossed in paper and thus already palpable, and secondly a luminescent relief as a second security feature Substances on the peaks or in the valleys of the relief.

- a transfer belt can be used, the layers of which are applied to the document by means of an adhesive layer can be, the transfer ribbon, however, a color layer of a luminescent substance in addition to this luminescent layer can contain a color pigment layer.

- DE-OS 39 06 695 shows the embedding of a tape serving as a security element in a document.

- the Band consists of a translucent plastic film, which with characters or patterns in the form of recesses is provided, with additionally luminescent substances in areas that are identical to the recesses are arranged.

- the known state of the art can thus be summarized in that it is known luminescent substances on the one hand in the area of application of the non-optical features by (partial) printing, To apply coating, embossing or also with transfer ribbon transfer and on the other hand in the area of application optical characteristics (e.g. reflective grid structure with a number of lines of about 1000 / mm and line depth of about 100 nm) to be used to secure documents with protective coatings that cover the surface.

- optical characteristics e.g. reflective grid structure with a number of lines of about 1000 / mm and line depth of about 100 nm

- the object of the invention is now the authenticity detection of the optical feature applied to a document by verifying the authenticity independent of an existing (forged) hologram lattice structure, for example to be able to perform and thereby design the optical feature so that a reliable machine detection guaranteed in the high-speed range (10 m / sec) without incorrect readings and resulting rejections can be.

- Documents should therefore only be rejected as suspicious if an imitation of the optical feature is present or this is missing entirely.

- documents with damaged optical Features in the sorting process are controlled in a storage compartment for unusable documents and therefore none considerable effort in the form of manual processing, like this for Rejection is necessary.

- the adhesive layer at least one luminescent substance is doped. It is also possible that different luminescent substances are contained in the adhesive layer.

- the inventive design of the document on the one hand enables a simple and therefore extremely inexpensive authenticity measurement arrangement and on the other hand a completely negligible rejection rate at the machine processing of the documents achieved.

- a high-quality professional made with the intention of deception Falsification of the structure of the optical feature is nevertheless machine-recognizable and in the case of counterfeiting, this during the sorting process or by one trained cashier can be eliminated or recognized.

- the incorporation of the luminescent substances into the adhesive layer has the advantage that in the case of a Attempted manipulation of the optical security feature, e.g. trying one Lifting or peeling, still parts of the adhesive layer and thus the Doping material stuck to the document.

- the adhesive layer with its thickness of about 6 ⁇ m, it is the thickest layer in the film structure.

- Many Luminescent materials, such as rare earths, are more inorganic Natural and must be milled, with their particle sizes below 5 ⁇ m Significantly lose or lose lighting properties.

- Many of the for circulating Banknotes suitable luminescent pigments with sufficient aging, UV and Chemical resistance can only be produced with particle sizes above about 5 ⁇ m.

- luminescent substances in the adhesive layer has an opposite for example, structures which have a purely optical diffraction effect have the advantage that Security feature can still be determined when the document or Foil structure, e.g. mechanical, badly damaged. Unless it's a forger the diffractive optical structure should succeed on a fake one To transfer the document of value would still be the forgery because of the missing luminescent properties on the fake, but with the original diffractive structure provided document.

- the admixture of luminescent substances provided according to the invention to the adhesive layer in the film structure can practically without additional effort in the usual production of the documents or the film structure can be realized and thus offers a very significant increase in the security effect without noticeable additional costs. If necessary, from security or production engineering considerations the application of the doped adhesive layer also either retrospectively on the prefabricated optical present on carrier film Security feature or in advance on the carrier material, especially paper, at Paper or document manufacturers take place.

- the luminescent Substances only partially in the adhesive layer preferably in one certain, preferably machine-readable patterns are provided additional securing options, because then not just a general admixture of the luminescent substances to the adhesive layer is sufficient, but additionally that luminescent substances have to be introduced in a very specific way, which is only possible using special machines.

- Luminescent substances are expediently fluorescent or phosphorescent, the decision to use fluorescent or phosphorescent substances of the respective purpose depends, but possibly there is also the possibility of fluorescent and use phosphorescent substances together, optionally each of the To provide substances in a certain pattern.

- Substances have narrow-band fluorescent substances, e.g. from the Group of rare earths proven. Also fluorescent substances are very closely adjacent emission compared to the excitation wavelength and those with same emission wavelength can be used advantageously. The presence or The absence of substances of this type can be known from those known per se Determine measuring devices with great accuracy, already using luminescent substances that differ in terms of their luminescent properties Deviate slightly from original fabrics, can be safely determined, above all because the radiation devices used in checking the value documents etc. can be adapted exactly to the substances to be tested.

- the Adhesive layer is formed by a hot melt adhesive, which is then the usual Application method for hot stamping foils easily a reliable adhesion generated.

- the transparent layer in the film structure consists of a film structure expediently according to the invention from one of the known Transparent coatings.

- the reflective layer of one, preferably by Evaporating in a thin metal layer, e.g. one Aluminum layer is formed.

- a release layer e.g. a Wax layer

- the Value document 1 has banknote paper as the carrier 1, however

- the carrier can also use a synthetic one Paper, a plastic film or, in the case of a credit card, a plastic card his.

- a plastic card can be embossed on its front, for example Letters bear the name of the owner and an identification number.

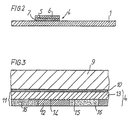

- the Value document 1 has a local security feature, which in a film structure, which can be a layer composite 4 is present, which is shown in FIGS. 3 and 4 is shown where it is formed as an embossing film.

- the layer composite 4 There is an optical security feature in the layer composite 4, namely a light reflective and diffractive and / or refractive structure present, the For example, is formed by a thin metal layer 5, which in the Embodiment of FIGS. 1 and 2 between one drawn as the top one transparent layer 6 embedded in the layer composite 4 and an adhesive layer 7 is.

- the adhesive layer 7 serves to fix the layer composite 4 on the Surface of the document 1.

- the transparent layer 6 in the layer composite 4 the is drawn as the top layer in the exemplary embodiment (FIG. 2), which covers that of the Metal layer 5 formed, diffraction-optical structure and difficult thus a decrease in the structure attempted forgery.

- luminescent substances are present in the adhesive layer 7. Such substances can also be known in the transparent layer 6 be provided. You can, as in the embodiment of FIG. 1, only in areas, namely in area 8, where in the exemplary embodiment Head representation is located. A preparation can be used as a substance narrow band fluorescent rare earths are used.

- the security feature in the document of value according to FIG. 1 thus exists not only from the diffraction optically effective, possibly specially shaped structure in the metal layer 5, but additionally in the layer composite 4 of the Areas with luminescent properties are present, these properties are also determined mechanically by readers and can be checked.

- the attachment of the optical security feature with luminescent properties according to the invention on documents of value in take place in any way, for example also in that the layers of Layer composite 4 are applied in succession.

- the layer composite 4 as in Fig. 3 schematically shown, is applied to a carrier film 9 and as Stamping foil, advantageously as a hot stamping foil, is used.

- Stamping foils can, for example, as described in DE 34 22 910 C1, be constructed. They have a carrier film 9 on which with the interposition a release layer 10 made of wax which is designated as a whole by 11 Transfer position is arranged.

- a release layer 10 made of wax which is designated as a whole by 11 Transfer position is arranged.

- the transfer layer 11 consists of an adhesive layer 12 and a transparent layer 13, in the layer composite.

- a reflective layer between the adhesive layer and the transparent layer Layer 15 made of metal arranged, at least in some areas, an optical diffraction effective, i.e. Has light refractive or diffractive structure 14.

- the layer composite 4 (the embossing foils) is in turn according to DE 34 22 910 C1, first the release layer 10 on the carrier film 9 0 and then the transparent layer 13 applied in the layer composite.

- the ones from Backing film 9 facing surface of the transparent layer 13 is with the desired refractive or diffractive structure 14 introduced.

- the structured surface of the transparent layer then becomes Generation of the reflective layer 15 metallized, for example by Evaporation of aluminum in a vacuum.

- the layer composite 4 is then through Application of the adhesive layer 12 completed.

- the adhesive layer is in areas 16 12 luminescent substances available.

- the reflective layer 15 made of metal may be interrupted in these areas.

- the carrier 1 is transparent in order to test for Presence of the luminescent substances from the underside of the carrier to be able to make, especially if the carrier 1 is a plastic card.

- the luminescent ones Regions 16 may also be present outside the metal layer 5.

- the luminescent substances can also be used in the entire adhesive layer 12 may be present, which is for certain security purposes is quite sufficient. It should also be noted that as a luminescent Substances a wide variety of substances, for example fluorescent and phosphorescent substances, also used in different mixtures can be.

- the group of organic luminous pigments includes an almost colorless, typical at 545 nm fluorescent benzoxazine derivative from the company Riedel-de Haen is sold under the name Lumilux CD 304.

- the range of fluorescent substances in the form of solutions is one of them heterocyclic thioxanthene dye available from Bayer under the Trade name Macrolexfluorescence Red GG is sold.

- Rare earths are phosphorescent and have very typical absorption and Emission spectra with narrow-band emission lines.

- Scandium, yttrium and the lanthanides to call the europium are Scandium, yttrium and the lanthanides to call the europium.

- luminescent materials in the form of organic semiconductors

- conjugated polymers carbon chains in which double and Alternate single bonds

- poly-p-phenylene-vinylene conjugated polymers (carbon chains in which double and Alternate single bonds) known as poly-p-phenylene-vinylene, whereby by Applying an electrical voltage stimulating electroluminescence which is used especially for static or quasi-static tests can be.

Abstract

Description

Die Erfindung betrifft ein Dokument, z.B. Banknote, Scheck, Kreditkarte, Ausweis oder Ticket, welches ein optisches Sicherheitsmerkmal in Form einer wenigstens bereichsweise vorgesehenen, Licht reflektierenden sowie beugenden und/oder brechenden Schicht, z.B. ein Hologramm, eine Interferenzschicht, eine (computer-generierte) Beugungsstruktur od.dgl. aufweist, wobei das optische Sicherheitsmerkmal mit Dotierungsmaterial versehen ist und in einem Folienaufbau vorhanden ist, der an dem Dokument mittels einer Kleberschicht festgelegt ist und gegebenenfalls mindestens eine transparente Schicht im Folienaufbau aufweist.The invention relates to a document, e.g. Banknote, check, credit card, ID card or ticket, which is an optical Security feature in the form of a light reflecting and diffractive provided at least in some areas and / or refractive layer, e.g. a hologram, an interference layer, a (computer-generated) Diffraction structure or the like has, wherein the optical security feature is provided with doping material and in a film structure is present, which is attached to the document by means of an adhesive layer and, if appropriate has at least one transparent layer in the film structure.

Weiterhin befaßt sich die Erfindung mit einem Folienaufbau, zur Herstellung derartiger Dokumente, mit einem Trägerfilm und einer von diesem ablösbaren Übertragungslage, welche wenigstens die das geprägte optische Sicherheitsmerkmal bildende, Licht reflektierende sowie beugende und/oder brechende Schicht, die insbesondere als Prägefolie, bevorzugt als Heißprägefolie, ausgebildet ist, sowie auf der dem Trägerfilm abgekehrten Seite der reflektierenden Schicht eine Kleberschicht aufweist, wobei im Folienaufbau mindestens eine transparente Schicht angeordnet sein kann.Furthermore, the invention is concerned with a film structure, for the production of such documents, with a carrier film and a transfer layer which can be detached therefrom and which is at least the embossed optical security feature forming, light reflecting as well as diffractive and / or refractive layer, in particular as an embossing film, is preferably formed as a hot stamping film, and on the side of the reflective side facing away from the carrier film Layer has an adhesive layer, at least one transparent layer being arranged in the film structure can.

Dokumente der eingangs erwähnten Art sind beispielsweise aus der CH-PS 661 602 bekannt. Zur Herstellung solcher Wertdokumente dienende Prägefolien, insbesondere Heißprägefolien, sind z.B. in der DE 34 22 910 C1 beschrieben.Documents of the type mentioned are known for example from CH-PS 661 602. To make such Embossing foils serving as documents of value, in particular hot embossing foils, are e.g. described in DE 34 22 910 C1.

Die bekannten Dokumente bzw. Prägefolien weisen eine beugungsoptisch wirksame, als Sicherheitsmerkmal vor allem gegen Farbkopiatur dienende Struktur auf, wobei derartige beugungsoptisch wirksame, d.h. Licht reflektierende, beugende und/oder brechende Strukturen den grundsätzlichen Vorteil haben, daß sie mit dem unbewaffneten Auge erkannt, aber auch maschinell gelesen werden können. Typische insbes. auf Banknoten applizierte Strukturen sind u.a. Kinegramme und Pixelgramme. Die Fälschung derartiger Strukturen bereitet zwar große Mühe, ist jedoch trotzdem vor allem dann durchführbar, wenn es möglich ist, die entsprechend strukturierte Oberfläche freizulegen und galvanisch abzuformen oder fototechnisch zu kopieren.The known documents or embossing foils have an optical diffraction effect as a security feature all against color copy structure, such diffraction optically effective, i.e. Light reflecting, Diffractive and / or refractive structures have the basic advantage that they are with the unarmed eye recognized, but can also be read by machine. Typical structures applied in particular to banknotes include Kinegrams and pixelgrams. The falsification of such structures is very difficult, but is still in preparation all feasible if it is possible to expose the correspondingly structured surface and galvanically to take impressions or to copy phototechnically.

Um Dokumente fälschungssicher zu machen, wurde die Anwendung lumineszierender Schichten in den Dokumenten vorgeschlagen. So offenbart etwa die DE-OS 37 41 179 die Verwendung von zwei Sicherheitsmerkmalen, nämlich einmal eines in Papier geprägten und somit bereits tastbaren Reliefs und weiters als zweites Sicherheitsmerkmal lumineszierende Substanzen auf den Gipfeln oder in den Tälern des Reliefs. Beim Gegenstand der DE-OS 37 41 179 kann von einem Transferband Gebrauch gemacht werden, dessen Schichten durch eine Klebeschicht auf das Dokument aufgebracht werden können, wobei das Transferband eine Farbschicht aus einem lumineszierenden Stoff, jedoch auch zusätzlich zu dieser lumineszierenden Schicht eine Farbpigmentschicht enthalten kann.In order to make documents tamper-proof, the use of luminescent layers in the documents proposed. For example, DE-OS 37 41 179 discloses the use of two security features, namely firstly, a relief embossed in paper and thus already palpable, and secondly a luminescent relief as a second security feature Substances on the peaks or in the valleys of the relief. In the subject of DE-OS 37 41 179 can a transfer belt can be used, the layers of which are applied to the document by means of an adhesive layer can be, the transfer ribbon, however, a color layer of a luminescent substance in addition to this luminescent layer can contain a color pigment layer.

Die DE-OS 39 06 695 zeigt die Einbettung eines als Sicherheitselement dienenden Bandes in ein Dokument. Das Band besteht dabei aus einer lichtdurchlässigen Kunststoffolie, welche mit Zeichen oder Mustern in Form von Aussparungen versehen ist, wobei zusätzlich noch lumineszierende Substanzen in Bereichen, die mit den Aussparungen dekkungsgleich sind, angeordnet werden. Es sind somit auch hier zwei Sicherheitselemente vorhanden, nämlich einmal die Zeichen und Muster und weiters noch die lumineszierenden Substanzen.DE-OS 39 06 695 shows the embedding of a tape serving as a security element in a document. The Band consists of a translucent plastic film, which with characters or patterns in the form of recesses is provided, with additionally luminescent substances in areas that are identical to the recesses are arranged. There are therefore two security elements here too, namely one the signs and patterns and also the luminescent substances.

Schließlich sind auch gemäß der DE-PS 27 54 267 bei Dokumenten zwei Sicherheitsmerkmale vorhanden, von welchen eines Lumineszenzeigenschaften aufweist. Im Gegensatz zu den brillanten oberflächigen optischen Merkmalen handelt es sich jedoch um in das Papier eingearbeitete Fäden, Blättchen und Fasern.Finally, according to DE-PS 27 54 267 two security features are available for documents, from which has a luminescent properties. In contrast to the brilliant, superficial optical features however, threads, sheets and fibers are incorporated into the paper.

Der bekanntgewordene Stand der Technik kann somit dahingehend zusammengefaßt werden, daß es bekannt ist, lumineszierende Stoffe einerseits im Anwendungsbereich der nicht optischen Merkmale durch (partielles) Aufdrucken, Beschichten, Prägen oder auch mit Transferbandübertragung anzuwenden und anderseits im Anwendungsbereich der optischen Merkmale (z.B. reflektierende Gitterstruktur mit Linienanzahl von etwa 1000/mm und Linientiefe von etwa 100 nm) solche zur Sicherung von Dokumenten mit oberflächig überziehenden Schutzschichten aufzubringen.The known state of the art can thus be summarized in that it is known luminescent substances on the one hand in the area of application of the non-optical features by (partial) printing, To apply coating, embossing or also with transfer ribbon transfer and on the other hand in the area of application optical characteristics (e.g. reflective grid structure with a number of lines of about 1000 / mm and line depth of about 100 nm) to be used to secure documents with protective coatings that cover the surface.

In den bisherigen Denkansätzen zur maschinellen Detektion von optischen Merkmalen hat man sich auf die an sich naheliegende optische Lesung der Gitterstrukturen bzw. Informations- oder Bildinhalte konzentriert, womit allerdings nicht nur ein ganz erheblicher technischer Aufwand für die Lesung der mehrdimensionalen Information verbunden ist, sondern auch die Auswirkungen von Beschädigungen, wie sie beispielsweise im Banknotenumlauf auftreten und zur Zerstörung der Strukturen und damit zur nachteiligen Unlesbarkeit der Merkmalsechtheit führen, in Kauf genommen. Auch würden entsprechende Eindrucksfälschungen des optischen Merkmales mit derartiger Detektion nicht erkannt werden können.In previous approaches to machine detection of optical features, the focus was on the itself obvious optical reading of the lattice structures or information or image content concentrated, but with that not only is there a considerable amount of technical effort involved in reading the multidimensional information, but also the effects of damage, such as occurs in banknotes in circulation and Destruction of the structures and thus lead to the disadvantageous illegibility of the feature authenticity, accepted. Corresponding falsifications of the impression of the optical feature would not be recognized with such a detection can be.

Aufgabe der Erfindung ist nun, die Echtheitserkennung des auf ein Dokument applizierten optischen Merkmales durch Nachweis der Echtheit unabhängig von einer vorhan- denen (gefälschten) beispielsweise Hologrammgitterstruktur durchführen zu können und dabei das optische Merkmal so zu gestalten, daß eine sichere maschinelle Detektierung im Hochgeschwindigkeitsbereich (10 m/sek) ohne Fehllesungen und daraus resultierende Rückweisungen gewährleistet werden kann. Dokumente sollten demnach nur dann als verdächtig rückgewiesen werden, wenn eine Imitation des optischen Merkmales vorliegt oder dieses gänzlich fehlt. Hingegen sollen Dokumente mit beschädigten optischen Merkmalen beim Sortierprozeß in ein Ablagefach für unbrauchbare Dokumente gesteuert werden und demnach keinen erheblichen Aufwand in Form der händischen Weiterbearbeitung, wie dies für Rückweisungen notwendig ist, verursachen.The object of the invention is now the authenticity detection of the optical feature applied to a document by verifying the authenticity independent of an existing (forged) hologram lattice structure, for example to be able to perform and thereby design the optical feature so that a reliable machine detection guaranteed in the high-speed range (10 m / sec) without incorrect readings and resulting rejections can be. Documents should therefore only be rejected as suspicious if an imitation of the optical feature is present or this is missing entirely. In contrast, documents with damaged optical Features in the sorting process are controlled in a storage compartment for unusable documents and therefore none considerable effort in the form of manual processing, like this for Rejection is necessary.

Gelöst wird diese Aufgabe bei einem Dokument der eingangs erwähnten Art in überraschend einfacher Weise, wenn gemäß der Erfindung die Kleberschicht mit mindestens einer lumineszierenden Substanz dotiert ist. Es ist dabei auch möglich, daß in der Kleberschicht unterschiedliche lumineszierende Substanzen enthalten sind.This problem is solved with a document of the type mentioned in Surprisingly simple way if, according to the invention, the adhesive layer at least one luminescent substance is doped. It is also possible that different luminescent substances are contained in the adhesive layer.

Durch die erfindungsgemäße Ausgestaltung des Dokumentes wird zum einen eine einfache und somit äußerst kostengünstige Echtheitsmeßanordnung ermöglicht und zum anderen eine völlig vernachlässigbare Rückweisungsrate bei der maschinellen Bearbeitung der Dokumente erreicht. Darüberhinaus besteht der Vorteil, daß eine in Täuschungsabsicht hergestellte hochqualitative fachmännische Fälschung der Struktur des optischen Merkmales trotzdem maschinell erkennbar ist und im Falle einer Banknotenfälschung, diese beim Sortierprozeß oder von einem geschulten Kassier ausgeschieden bzw. erkannt werden kann.The inventive design of the document, on the one hand enables a simple and therefore extremely inexpensive authenticity measurement arrangement and on the other hand a completely negligible rejection rate at the machine processing of the documents achieved. In addition, there is Advantage that a high-quality professional made with the intention of deception Falsification of the structure of the optical feature is nevertheless machine-recognizable and in the case of counterfeiting, this during the sorting process or by one trained cashier can be eliminated or recognized.

Die Einarbeitung der lumineszierenden Substanzen in die Kleberschicht (Dotierung der Kleberschicht) bringt den Vorteil, daß im Falle eines Manipulationsversuches am optischen Sicherheitsmerkmal, z.B. der Versuch eines Abhebens oder Ablösens, immer noch Teile der Kleberschicht und somit des Dotierungsmaterials am Dokument haften bleiben. Weiters stellt die Kleberschicht. mit ihrer Stärke von etwa 6 µm die dickste Schicht im Folienaufbau dar. Viele lumineszierende Materialien, wie beispielsweise Seltene Erden, sind anorganischer Natur und müssen gemahlen werden, wobei sie bei Teilchengrößen unter 5 µm ihre Leuchteigenschaft signifikant einbüßen bzw. verlieren. Viele der für umlaufende Banknoten geeigneten Leuchtpigmente mit ausreichender Alterungs-, UV- und chemischer Beständigkeit sind nur mit Teilchengrößen über etwa 5 µm herstellbar. Würde man nun derartige Materialien in eine (nachträglich aufzubringende) am Dokument oberflächige Schutzschicht einarbeiten, würde dies neben anderen Nachteilen auch zu einer Reduzierung der Brillanz und zu einer produktionstechnisch nachteiligen punktuellen Verdickung des Dokumentes bzw. des Papierstapels Anlaß geben. Durch die technologisch bedingte aufwendige Prozeßsteuerung der Kleberbeschichtung kann gewährleistet werden, daß das lumineszierende Material in konstanter Schichtdicke bzw. Konzentration im optischen Merkmal eingearbeitet ist. Das Dotierungsmaterial ist unter der metallischen Reflexionsschicht gegen UV-Strahlung geschützt. Bevorzugt werden lumineszierende Substanzen, die mit normalem Tageslicht nicht, unter Verwendung einer UV-Lampe oder einer sonstigen elektromagnetischen Strahlenquelle entsprechender Energie jedoch feststellbar sind. Die Zugabe lumineszierender Substanzen in die Kleberschicht, hat dabei gegenüber beispielsweise rein beugungsoptisch wirksamen Strukturen den Vorteil, daß das Sicherheitsmerkmal auch dann noch feststellbar ist, wenn das Dokument bzw. der Folienaufbau, z.B. mechanisch, stark beschädigt ist. Sofern es einem Fälscher gelingen sollte, die beugungsoptisch wirksame Struktur auf ein gefälschtes Wertdokument zu übertragen, wäre die Fälschung trotzdem wegen der fehlenden lumineszierenden Eigenschaften auf dem gefälschten, jedoch mit der originalen beugungswirksamen Struktur versehenen Dokument feststellbar.The incorporation of the luminescent substances into the adhesive layer (Doping of the adhesive layer) has the advantage that in the case of a Attempted manipulation of the optical security feature, e.g. trying one Lifting or peeling, still parts of the adhesive layer and thus the Doping material stuck to the document. Furthermore, the adhesive layer. with its thickness of about 6 µm, it is the thickest layer in the film structure. Many Luminescent materials, such as rare earths, are more inorganic Natural and must be milled, with their particle sizes below 5 µm Significantly lose or lose lighting properties. Many of the for circulating Banknotes suitable luminescent pigments with sufficient aging, UV and Chemical resistance can only be produced with particle sizes above about 5 µm. Would you now such materials in a (retrofitted) on Include document surface protective layer, this would be among others Disadvantages also to reduce the brilliance and to a production technology disadvantageous selective thickening of the document or the stack of paper occasion give. Due to the technologically related process control of the Adhesive coating can ensure that the luminescent material in constant layer thickness or concentration is incorporated in the optical feature. The doping material is underneath the metallic reflection layer Protected against UV radiation. Luminescent substances which are preferred normal daylight, not using a UV lamp or other electromagnetic radiation corresponding energy can be determined. The addition of luminescent substances in the adhesive layer has an opposite for example, structures which have a purely optical diffraction effect have the advantage that Security feature can still be determined when the document or Foil structure, e.g. mechanical, badly damaged. Unless it's a forger the diffractive optical structure should succeed on a fake one To transfer the document of value would still be the forgery because of the missing luminescent properties on the fake, but with the original diffractive structure provided document.

Die erfindungsgemäß vorgesehene Beimischung lumineszierender Substanzen zur Kleberschicht im Folienaufbau kann praktisch ohne zusätzlichen Aufwand bei der üblichen Fertigung der Dokumente bzw. des Folienaufbaues verwirklicht werden und bietet somit eine ganz erhebliche Steigerung der Sicherheitswirkung ohne merkliche zusätzliche Kosten. Gegebenenfalls kann aus sicherheitstechnischen oder produktionstechnischen Überlegungen die Aufbringung der dotierten Kleberschicht auch entweder nachträglich auf das vorgefertigte auf Trägerfilm vorliegende optische Sicherheitsmerkmal oder vorweg auf das Trägermaterial, insbesondere Papier, beim Papier- oder Dokumentenhersteller erfolgen.The admixture of luminescent substances provided according to the invention to the adhesive layer in the film structure can practically without additional effort in the usual production of the documents or the film structure can be realized and thus offers a very significant increase in the security effect without noticeable additional costs. If necessary, from security or production engineering considerations the application of the doped adhesive layer also either retrospectively on the prefabricated optical present on carrier film Security feature or in advance on the carrier material, especially paper, at Paper or document manufacturers take place.

Wenn, wie nach der Erfindung weiter möglich, die lumineszierenden Substanzen in der Kleberschicht nur bereichsweise, vorzugsweise in einem bestimmten, bevorzugt maschinell lesbaren Muster vorgesehen sind, bieten sich zusätzliche Sicherungsmöglichkeiten, weil dann nicht nur eine generelle Beimischung der lumineszierenden Substanzen zur Kleberschicht genügt, sondern zusätzlich die lumineszierenden Substanzen in ganz bestimmter Weise eingebracht werden müssen, was nur unter Verwendung spezieller Maschinen möglich ist.If, as is possible according to the invention, the luminescent Substances only partially in the adhesive layer, preferably in one certain, preferably machine-readable patterns are provided additional securing options, because then not just a general admixture of the luminescent substances to the adhesive layer is sufficient, but additionally that luminescent substances have to be introduced in a very specific way, which is only possible using special machines.

Zweckmäßig sind lumineszierende Substanzen fluoreszierend oder phosphoreszierend, wobei die Entscheidung für die Verwendung fluoreszierender oder phosphoreszierender Substanzen von dem jeweiligen Verwendungszweck abhängt, gegebenenfalls aber auch die Möglichkeit besteht, fluoreszierende und phosphoreszierende Substanzen gemeinsam einzusetzen, gegebenenfalls jede der Substanzen in einem bestimmten Muster vorzusehen.Luminescent substances are expediently fluorescent or phosphorescent, the decision to use fluorescent or phosphorescent substances of the respective purpose depends, but possibly there is also the possibility of fluorescent and use phosphorescent substances together, optionally each of the To provide substances in a certain pattern.

Als für die Zwecke der Erfindung besonders geeignete lumineszierende Substanzen haben sich schmalbandig fluoreszierende Substanzen, z.B. aus der Gruppe der Seltenen Erden erwiesen. Auch sind fluoreszierende Substanzen mit sehr eng benachbarter Emission gegenüber der Anregungswellenlänge und solche mit gleicher Emissionswellenlänge vorteilhaft einsetzbar. Das Vorhandensein oder Nicht-Vorhandensein derartiger Substanzen läßt sich mit an sich bekannten Meßgeräten mit großer Exaktheit feststellen, wobei bereits die Verwendung von lumineszierenden Stoffen, die hinsichtlich ihrer Lumineszenzeigenschaften von den Originalstoffen geringfügig abweichen, sicher festgestellt werden kann, vor allem weil die bei der Prüfung der Wertdokumente etc. verwendeten Bestrahlungsgeräte ganz genau an die zu prüfenden Substanzen anpaßbar sind.As a particularly suitable luminescent for the purposes of the invention Substances have narrow-band fluorescent substances, e.g. from the Group of rare earths proven. Also fluorescent substances are very closely adjacent emission compared to the excitation wavelength and those with same emission wavelength can be used advantageously. The presence or The absence of substances of this type can be known from those known per se Determine measuring devices with great accuracy, already using luminescent substances that differ in terms of their luminescent properties Deviate slightly from original fabrics, can be safely determined, above all because the radiation devices used in checking the value documents etc. can be adapted exactly to the substances to be tested.

Bei einem Folienaufbau nach der Erfindung ist es günstig, wenn die Kleberschicht von einem Schmelzkleber gebildet ist, die dann bei den üblichen Aufbringungsverfahren für Heißprägefolien ohne weiteres eine zuverlässige Haftung erzeugt.In a film structure according to the invention, it is advantageous if the Adhesive layer is formed by a hot melt adhesive, which is then the usual Application method for hot stamping foils easily a reliable adhesion generated.

Die transparente Schicht im Folienaufbau besteht bei einem Folienaufbau gemäß der Erfindung zweckmäßig aus einem der an sich bekannten Transparentlacke.The transparent layer in the film structure consists of a film structure expediently according to the invention from one of the known Transparent coatings.

Um sicherzustellen, daß die das optische Sicherheitsmerkmal bildende, Licht reflektierende Schicht auch zuverlässig das Licht reflektiert, ist erfindungsgemäß vorgesehen, daß die reflektierende Schicht von einer, vorzugsweise durch Aufdampfen im Vakuum gebildeten, dünnen Metallschicht, z.B. einer Aluminiumschicht, gebildet ist.To ensure that the light forming the optical security feature reflective layer also reliably reflects the light, is according to the invention provided that the reflective layer of one, preferably by Evaporating in a thin metal layer, e.g. one Aluminum layer is formed.

Bei einem Folienaufbau nach der Erfindung ist schließlich vorgesehen, daß zwischen dem Trägerfilm und der Übertragungslage eine Ablöseschicht, z.B. eine Wachsschicht, angeordnet ist.In a film structure according to the invention it is finally provided that between the carrier film and the transfer layer, a release layer, e.g. a Wax layer, is arranged.

Weitere Merkmale, Einzelheiten und Vorteile der Erfindung ergeben sich aus der folgenden Beschreibung bevorzugter Ausführungsbeispiele anhand der Zeichnung.Further features, details and advantages of the invention result from the following description of preferred exemplary embodiments with reference to the Drawing.

Es zeigen:

Das Wertdokument gemäß Fig. 1 besitzt als Träger 1 Banknotenpapier, jedoch

kann bei anders ausgebildeten Wertdokumenten der Träger auch ein synthetisches

Papier, eine Kunststoffolie oder im Falle einer Kreditkarte auch eine Kunststoffkarte

sein. Eine Kunststoffkarte kann auf ihrer Vorderseite beispielsweise in geprägten

Buchstaben den Namen des Inhabers sowie eine Kennziffer tragen. Das

Wertdokument 1 besitzt ein lokales Sicherheitsmerkmal, das in einem Folienaufbau,

der ein Schichtverbund 4 sein kann, vorhanden ist, der in den Fig. 3 und 4

dargestellt ist, wo er als Prägefolie ausgebildet ist.1 has banknote paper as the

Im Schichtverbund 4 ist ein optisches Sicherheitsmerkmal, nämlich eine Licht

reflektierende sowie beugende und/oder brechende Struktur vorhanden, die

beispielsweise von einer dünnen Metallschicht 5 gebildet ist, die bei dem

Ausführungsbeispiel der Fig. 1 und 2 zwischen einer als oberste gezeichnete

transparenten Schicht 6 im Schichtverbund 4 und einer Kleberschicht 7 eingebettet

ist. Die Kleberschicht 7 dient zur Festlegung des Schichtverbundes 4 auf der

Oberfläche des Dokuments 1. Die transparente Schicht 6 im Schichtverbund 4, die

im Ausführungsbeispiel (Fig. 2) als oberste Schicht gezeichnet ist, deckt die von der

Metallschicht 5 gebildete, beugungsoptisch wirksame Struktur ab und erschwert

damit erheblich eine in Fälschungsabsicht versuchte Abnahme der Struktur.There is an optical security feature in the layer composite 4, namely a light

reflective and diffractive and / or refractive structure present, the

For example, is formed by a

Die Besonderheit des Wertdokumentes nach der Erfindung ist nun darin zu

sehen, daß lumineszierende Substanzen in der Kleberschicht 7 vorhanden sind.

Solche Substanzen können auch wie bekannt in der transparenten Schicht 6

vorgesehen sein. Sie können dabei, wie bei der Ausführungsform der Fig. 1, nur

bereichsweise, nämlich im Bereich 8, wo sich im Ausführungsbeispiel eine

Kopfdarstellung befindet, vorgesehen werden. Als Substanz kann ein Präparat aus

schmalbandig fluoreszierenden Seltenen Erden Verwendung finden.The peculiarity of the document of value according to the invention is now too

see that luminescent substances are present in the adhesive layer 7.

Such substances can also be known in the transparent layer 6

be provided. You can, as in the embodiment of FIG. 1, only

in areas, namely in

Das Sicherheitsmerkmal bei dem Wertdokument gemäß Fig. 1 besteht somit

nicht nur aus der beugungsoptisch wirksamen, eventuell speziell geformten Struktur

in der Metallschicht 5, sondern zusätzlich sind im Schichtverbund 4 des

Wertdokumentes lumineszierende Eigenschaften aufweisende Bereiche vorhanden,

wobei diese Eigenschaften durch Lesegeräte auch maschinell festgestellt und

überprüft werden können.The security feature in the document of value according to FIG. 1 thus exists

not only from the diffraction optically effective, possibly specially shaped structure

in the

Grundsätzlich kann die Anbringung des optischen Sicherheitsmerkmals mit lumineszierenden Eigenschaften nach der Erfindung auf Wertdokumenten in beliebiger Weise erfolgen, etwa auch dadurch, daß die Schichten des Schichtverbundes 4 nacheinander aufgebracht werden.Basically, the attachment of the optical security feature with luminescent properties according to the invention on documents of value in take place in any way, for example also in that the layers of Layer composite 4 are applied in succession.

Wesentlich zweckmäßiger ist es jedoch, wenn der Schichtverbund 4, wie in

Fig. 3 schematisch dargestellt, auf einen Trägerfilm 9 aufgebracht wird und als

Prägefolie, vorteilhafterweise als eine Heißprägefolie, verwendet wird. Solche

Heißprägefolien können beispielsweise, wie in der DE 34 22 910 C1 beschrieben,

aufgebaut sein. Sie weisen einen Trägerfilm 9 auf, an dem unter Zwischenschaltung

einer Ablöseschicht 10 aus Wachs die als Ganzes mit 11 bezeichnete

Übertragungslage angeordnet ist. Beim Aufbringen des Schichtverbundes 4 auf das

Dokument 1 wird die Übertragungslage 11 mit ihrer vom Trägerfilm 9 abgekehrten

Oberfläche auf das Dokument 1, unter Wärmeeinwirkung angedrückt, auf dem sie

dann mittels der Kleberschicht 12 haftet. Der Trägerfilm 9 wird unmittelbar

anschließend abgezogen, was durch die Wachs-Ablöseschicht 10 erleichtert wird.However, it is much more expedient if the layer composite 4, as in

Fig. 3 schematically shown, is applied to a

Bei der in Fig. 3 gezeigten Prägefolien besteht die Übertragungslage 11 aus

einer Kleberschicht 12 und aus einer transparenten Schicht 13, im Schichtverbund.

Zwischen der Kleberschicht und der transparenten Schicht ist eine reflektierende

Schicht 15 aus Metall angeordnet, die zumindest bereichsweise eine beugungsoptisch

wirksame, d.h. Licht brechende oder beugende Struktur 14 aufweist. Bei der

Herstellung des Schichtverbundes 4 (der Prägefolien) wird dabei wiederum

entsprechend der DE 34 22 910 C1 auf den Trägerfilm 9 zuerst die Ablöseschicht 10

0 und dann die transparente Schicht 13 im Schichtverbund aufgebracht. Die vom

Trägerfilm 9 abgekehrte Oberfläche der transparenten Schicht 13 wird mit der

gewünschten lichtbrechenden oder beugenden Struktur 14 eingebracht. Hieran

anschließend wird dann die strukturierte Oberfläche der transparenten Schicht zur

Erzeugung der reflektierenden Schicht 15 metallisiert, beispielsweise durch

Aufdampfen von Aluminium im Vakuum. Der Schichtverbund 4 wird dann durch

Aufbringung der Kleberschicht 12 fertiggestellt.In the stamping foils shown in FIG. 3, the

Denkbar wäre auch eine vereinfachte Ausführungsform für untergeordnete

Anwendungen, bei der die Übertragungslage 11 aus nur einer Schicht besteht,

welche zugleich die optische als auch die Klebefunktion erfüllt.A simplified embodiment for subordinate ones would also be conceivable

Applications in which the

Bei dem Schichtverbund 4 gemäß Fig. 3 sind in Bereichen 16 der Kleberschicht

12 lumineszierende Substanzen vorhanden. Die reflektierende Schicht 15 aus Metall

kann in diesen Bereichen unterbrochen sein. Es sind jedoch auch Ausführungsformen

möglich, bei welchen der Träger 1 transparent ist, um eine Prüfung auf das

Vorhandensein der lumineszierenden Substanzen von der Träger-Unterseite her

vornehmen zu können, insbes. wenn der Träger 1 eine Kunststoffkarte ist.

Beispielsweise könnten bei der Ausführungform der Fig. 1 die lumineszierenden

Bereiche 16 auch außerhalb der Metallschicht 5 vorhanden sein.3, the adhesive layer is in

Selbstverständlich können die lumineszierenden Substanzen auch in der gesamten Kleberschicht 12 vorhanden sein, was für bestimmte Sicherheitszwecke durchaus ausreichend ist. Weiterhin ist darauf hinzuweisen, daß als lumineszierende Substanzen die unterschiedlichsten Substanzen, beispielsweise fluoreszierende und phosphoreszierende Substanzen, auch in unterschiedlichen Gemischen, eingesetzt werden können.Of course, the luminescent substances can also be used in the entire adhesive layer 12 may be present, which is for certain security purposes is quite sufficient. It should also be noted that as a luminescent Substances a wide variety of substances, for example fluorescent and phosphorescent substances, also used in different mixtures can be.

Der Gruppe der organischen Leuchtpigmente gehört ein nahezu farbloses, typisch bei 545 nm fluoreszierendes Benzoxazinderivat an, das von der Fa. Riedel-de Haen unter der Bezeichnung Lumilux CD 304 vertrieben wird.The group of organic luminous pigments includes an almost colorless, typical at 545 nm fluorescent benzoxazine derivative from the company Riedel-de Haen is sold under the name Lumilux CD 304.

Der Reihe der Fluoreszenzstoffe in Form von Lösungen gehört ein heterocyclischer Thioxanthen-Farbstoff an, der von der Fa. Bayer unter dem Handelsnamen Macrolexfluoreszenzrot GG vertrieben wird.The range of fluorescent substances in the form of solutions is one of them heterocyclic thioxanthene dye available from Bayer under the Trade name Macrolexfluorescence Red GG is sold.

Seltene Erden sind phosphoreszierend und weisen sehr typische Absorptionsund Emissionsspektren mit schmalbandigen Emissionslinien auf. Als Beispiele sind Scandium, Yttrium und von den Lanthaniden das Europium zu nennen.Rare earths are phosphorescent and have very typical absorption and Emission spectra with narrow-band emission lines. As examples are Scandium, yttrium and the lanthanides to call the europium.

Durch entsprechende Mischung lumineszierender Substanzen bzw. Mischung mit absorbierenden Stoffen sind Dotierungsmaterialien erhältlich, die im sichtbaren Bereich nicht lumineszieren. Dazu werden unterschiedliche Stoffe verwendet, bei denen sich Absorptionslinien der einen mit den Emissionslinien der anderen im sichtbaren Bereich überdecken.By appropriate mixture of luminescent substances or mixture With absorbent materials, doping materials are available that are visible Do not luminesce the area. Different fabrics are used for this absorption lines of one with the emission lines of the other in the cover visible area.

Auch sind fluoreszierende Substanzen mit sehr eng benachbarter Emission gegenüber der Anregungswellenlänge bekannt. Einen Sonderfall stellt die Resonanzfluoreszenz dar, bei der die Absorptions- gleich der Emissionslinie ist.Also fluorescent substances with very closely adjacent emission known to the excitation wavelength. The represents a special case Resonance fluorescence, in which the absorption is equal to the emission line.

Weiters sind lumineszierende Materialien in Form organischer Halbleiter auf Basis konjugierter Polymere (Kohlenstoffketten, in denen sich Doppel- und Einfachbindungen abwechseln) als Poly-p-phenylen-vinylen bekannt, wobei durch Anlegen einer elektrischen Spannung die Stimulierung der Elektrolumineszenz erfolgt, welche insbes. für statische oder quasistatische Prüfungen angewendet werden kann.There are also luminescent materials in the form of organic semiconductors The basis of conjugated polymers (carbon chains in which double and Alternate single bonds) known as poly-p-phenylene-vinylene, whereby by Applying an electrical voltage stimulating electroluminescence which is used especially for static or quasi-static tests can be.

Kleber, die lumineszierende Stoffe enthalten, können beispielsweise folgende

Formulierungen aufweisen:

Claims (17)

- A document, e.g. bank note, cheque, credit card, identity card or ticket, which has an optical security feature in the form of a layer, e.g. a hologram, an interference layer, a (computer generated) diffraction structure or the like, which deflects and diffracts and/or splits light and which is provided at least in certain regions , the optical security feature being present in a film structure which is secured to the document by means of an adhesive layer and optionally has one or more transparent layers in the film structure, characterised in that the adhesive layer (7, 12) is endowed with at least one luminescent substance.

- The document according to Claim 1, characterised in that different luminescent substances are contained in the adhesive layer (7, 12).

- The document according to Claim 1 or 2, characterised in that the luminescent substances are provided only in certain regions in the adhesive layer (7, 12).

- The document according to Claim 3, characterised in that the luminescent substances are provided in the adhesive layer (7, 12) in a predetermined, preferable machine-readable pattern (8, 16').

- The document according to one of the preceding claims, characterised in that the luminescent substances are fluorescent or phosphorescent substances or mixtures of such substances, the fluorescent substances being optionally arranged in a pattern which is different to the pattern in which the phosphorescent substances are arranged.

- The document according to Claim 5, characterised in that narrow-band fluorescent rare earths are used as luminescent substances.

- A film structure for manufacturing a valuable document as claimed in one of Claims 1 to 6, including a carrier film and a transfer film which may be separated therefrom and which at least has the layer which constitutes the optical security feature and reflects and refracts and/or splits light and which is constructed in particular as an embossed film, preferably a hot embossed film, and an adhesive layer on the side of the reflective layer directed away from the carrier film, whereby a transparent layer can be arranged in the film structure, preferably between the reflective layer and carrier film, characterised in that luminescent substances are contained in the adhesive layer (12).

- The film structure according to Claim 7, characterised in that different luminescent substances are contained in the adhesive layer (12).

- The film structure according to Claim 7 or 8, characterised in that the luminescent substances are provided only in certain regions in the adhesive layer (12).

- The film structure according to Claim 9, characterised in that the luminescent substances are provided in the adhesive layer (12) in a predetermined, preferably machine-readable pattern.

- The film structure according to one of Claims 7 to 10, characterised in that the luminescent substances in the adhesive layer (12) are fluorescent or phosphorescent substances or mixtures of such substances, the fluorescent substances optionally being arranged in a pattern which is different to the pattern in which the phosphorescent substances are arranged.

- The film structure according to Claim 11, characterised in that narrow-band fluorescent rare earths are used as luminescent substances.

- The film structure according to one of Claims 7 to 12, characterised in that the adhesive layer (12) is constituted by a melt adhesive.

- The film structure according to one of Claims 7 to 13, characterised in that the transparent layer (13) is a layer of transparent lacquer.

- The film structure according to one of Claims 7 to 14, characterised in that the reflective layer (15) is constituted by a thin metal layer, preferably formed by vacuum coating.

- The film structure according to one of Claims 7 to 15, characterised in that a release layer (10), e.g. a wax layer, is arranged between the carrier film (9) and the transfer film (11).

- A method of checking a document in accordance with one of Claims 1 to 6, characterised in that the luminescent substances present on the document are excited from at least one source and the emission of the excited luminescent substances is measured in at least one receiver, whereby, for instance, photodiodes, photomultipliers, CCD arrays are used as the receiver and, for instance, a laser tube, laser diodes, light-emitting diodes, fluorescent tubes, halogen lamps, X-ray tubes, electron radiation tubes and radioactive emitters are used as the source.

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT229892 | 1992-11-18 | ||

| AT2298/92 | 1992-11-18 | ||

| AT0229892A AT403967B (en) | 1992-11-18 | 1992-11-18 | DOCUMENT AND FILM STRUCTURE FOR PRODUCING A DOCUMENT |

| PCT/AT1993/000176 WO1994011203A1 (en) | 1992-11-18 | 1993-11-17 | Document with doped optical safety mark, stratified composite paper for producing the same and device for checking the authenticity of the document |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0680411A1 EP0680411A1 (en) | 1995-11-08 |

| EP0680411B1 EP0680411B1 (en) | 1998-02-11 |

| EP0680411B2 true EP0680411B2 (en) | 2002-10-02 |

Family

ID=3531764

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP93924429A Expired - Lifetime EP0680411B2 (en) | 1992-11-18 | 1993-11-17 | Document with doped optical safety mark, stratified composite paper for producing the same and device for checking the authenticity of the document |

Country Status (12)

| Country | Link |

|---|---|

| US (1) | US6165592A (en) |

| EP (1) | EP0680411B2 (en) |

| JP (1) | JPH08506772A (en) |

| AT (2) | AT403967B (en) |

| AU (1) | AU691475B2 (en) |

| CA (1) | CA2149550C (en) |

| DE (1) | DE59308150D1 (en) |

| DK (1) | DK0680411T4 (en) |

| ES (1) | ES2115081T5 (en) |

| MX (1) | MX9307182A (en) |

| RU (1) | RU95112499A (en) |

| WO (1) | WO1994011203A1 (en) |

Families Citing this family (71)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH694636A5 (en) * | 1995-10-12 | 2005-05-13 | Kba Giori Sa | A process for the production of documents with a security feature in the form of a film element and document having such a security feature. |

| DE19611383A1 (en) * | 1996-03-22 | 1997-09-25 | Giesecke & Devrient Gmbh | Data carrier with optically variable element |

| US7129709B2 (en) | 1997-04-25 | 2006-10-31 | Whd Electronische Prueftechnik | Method of testing documents provided with optico-diffractively effective markings |

| RU2101188C1 (en) * | 1997-05-14 | 1998-01-10 | Павел Евстафиевич Трушко | Information distribution method |

| DE19735293C2 (en) † | 1997-08-14 | 2003-06-12 | Bundesdruckerei Gmbh | Value and security product with luminescent element |

| EP0996116B1 (en) * | 1998-04-13 | 2007-06-20 | Seiko Epson Corporation | Information recording method and an information recording device |

| US6269169B1 (en) * | 1998-07-17 | 2001-07-31 | Imaging Automation, Inc. | Secure document reader and method therefor |

| DE19901107C1 (en) * | 1999-01-14 | 2000-11-16 | Bosch Gmbh Robert | Luminescent, electrically conductive adhesive |

| DE19923959A1 (en) * | 1999-05-25 | 2000-11-30 | Giesecke & Devrient Gmbh | Value document |

| GB9917442D0 (en) * | 1999-07-23 | 1999-09-29 | Rue De Int Ltd | Security device |

| GB0015873D0 (en) | 2000-06-28 | 2000-08-23 | Rue De Int Ltd | Optically variable security device |

| JP4891472B2 (en) * | 2000-07-10 | 2012-03-07 | エルピーダメモリ株式会社 | Semiconductor integrated circuit device |

| AU2002357597B2 (en) * | 2001-12-20 | 2008-04-10 | Seiko Epson Corporation | Recorded Article with Anti-Counterfeit Measures |

| US20040202829A1 (en) * | 2002-05-03 | 2004-10-14 | Zercher John Michael | Identification media having a security image |

| US7923260B2 (en) | 2002-08-20 | 2011-04-12 | Illumina, Inc. | Method of reading encoded particles |

| US7508608B2 (en) | 2004-11-17 | 2009-03-24 | Illumina, Inc. | Lithographically fabricated holographic optical identification element |

| US7901630B2 (en) | 2002-08-20 | 2011-03-08 | Illumina, Inc. | Diffraction grating-based encoded microparticle assay stick |

| US7164533B2 (en) | 2003-01-22 | 2007-01-16 | Cyvera Corporation | Hybrid random bead/chip based microarray |

| US7872804B2 (en) | 2002-08-20 | 2011-01-18 | Illumina, Inc. | Encoded particle having a grating with variations in the refractive index |

| US7900836B2 (en) | 2002-08-20 | 2011-03-08 | Illumina, Inc. | Optical reader system for substrates having an optically readable code |

| US20100255603A9 (en) | 2002-09-12 | 2010-10-07 | Putnam Martin A | Method and apparatus for aligning microbeads in order to interrogate the same |

| US7092160B2 (en) | 2002-09-12 | 2006-08-15 | Illumina, Inc. | Method of manufacturing of diffraction grating-based optical identification element |

| US8081792B2 (en) | 2003-08-20 | 2011-12-20 | Illumina, Inc. | Fourier scattering methods for encoding microbeads and methods and apparatus for reading the same |

| US7148493B2 (en) * | 2003-01-27 | 2006-12-12 | Hewlett-Packard Development Company, L.P. | Method, apparatus, and system for imaging a fluorescent object |

| DE10326644A1 (en) | 2003-06-11 | 2005-01-13 | Bundesdruckerei Gmbh | Value document with a security element and method for producing the value document |

| AT501356A1 (en) * | 2003-06-18 | 2006-08-15 | Hueck Folien Gmbh | SAFETY ELEMENTS AND SAFETY FEATURES WITH COLOR EFFECTS |

| US20060219961A1 (en) * | 2003-06-26 | 2006-10-05 | Ross Gary A | Security markers for controlling access to a secure area |

| US7488954B2 (en) * | 2003-06-26 | 2009-02-10 | Ncr Corporation | Security markers for marking a person or property |

| US20060180792A1 (en) * | 2003-06-26 | 2006-08-17 | Prime Technology Llc | Security marker having overt and covert security features |

| US7800088B2 (en) * | 2003-06-26 | 2010-09-21 | Ncr Corporation | Security markers for identifying a source of a substance |

| US20060131517A1 (en) * | 2003-06-26 | 2006-06-22 | Ross Gary A | Security markers for controlling operation of an item |

| US20060118739A1 (en) * | 2003-06-26 | 2006-06-08 | Ncr Corporation | Security markers for marking pharmaceuticals |

| US7378675B2 (en) * | 2003-06-26 | 2008-05-27 | Ncr Corporation | Security markers for indicating condition of an item |

| US7501646B2 (en) * | 2003-06-26 | 2009-03-10 | Ncr Corporation | Security markers for reducing receipt fraud |

| US7256398B2 (en) * | 2003-06-26 | 2007-08-14 | Prime Technology Llc | Security markers for determining composition of a medium |

| GB0314883D0 (en) * | 2003-06-26 | 2003-07-30 | Ncr Int Inc | Security labelling |

| DE10344384B4 (en) * | 2003-09-23 | 2008-07-10 | Bundesdruckerei Gmbh | Method for checking an authentication feature of a rotating optical data carrier and digital data carrier |

| DE10346631A1 (en) * | 2003-10-08 | 2005-05-19 | Giesecke & Devrient Gmbh | value document |

| DE10346630A1 (en) * | 2003-10-08 | 2005-05-04 | Giesecke & Devrient Gmbh | value document |

| DE10360699A1 (en) * | 2003-12-19 | 2005-07-14 | Giesecke & Devrient Gmbh | Security element and method for its production |

| US7433123B2 (en) | 2004-02-19 | 2008-10-07 | Illumina, Inc. | Optical identification element having non-waveguide photosensitive substrate with diffraction grating therein |

| DE102004021396B4 (en) * | 2004-04-30 | 2018-02-15 | Bundesdruckerei Gmbh | Authentication system and marking of value or security documents |

| US7597961B2 (en) * | 2004-07-13 | 2009-10-06 | Sabic Innovative Plastics Ip B.V. | Authenticatable article and method of authenticating |

| WO2006020363A2 (en) | 2004-07-21 | 2006-02-23 | Illumina, Inc. | Method and apparatus for drug product tracking using encoded optical identification elements |

| TWI268013B (en) * | 2004-08-13 | 2006-12-01 | King House Technology Co Ltd | Contact type illuminable card and storage cassette thereof |

| WO2006024530A1 (en) * | 2004-09-02 | 2006-03-09 | Giesecke & Devrient Gmbh | Value document with luminescent properties |

| US20060234014A1 (en) * | 2005-04-14 | 2006-10-19 | Liu Yaoqi J | Patterned adhesives for tamper evident feature |

| US20060234040A1 (en) * | 2005-04-14 | 2006-10-19 | Liu Yaoqi J | Patterned adhesives for color shifting effect |

| US7830575B2 (en) | 2006-04-10 | 2010-11-09 | Illumina, Inc. | Optical scanner with improved scan time |

| US20080129037A1 (en) * | 2006-12-01 | 2008-06-05 | Prime Technology Llc | Tagging items with a security feature |

| US9734442B2 (en) * | 2007-10-31 | 2017-08-15 | Ncr Corporation | LumID barcode format |

| DE102008049631A1 (en) | 2008-09-30 | 2010-04-01 | Giesecke & Devrient Gmbh | Card with embedded security feature |

| FR2941713B1 (en) * | 2009-02-03 | 2011-04-01 | Arjowiggins Security | METHOD FOR SECURING A COLORED OPAQUE OBJECT |

| CA2656506A1 (en) * | 2009-02-27 | 2010-08-27 | Bank Of Canada | Security device |

| US8400509B2 (en) * | 2009-09-22 | 2013-03-19 | Honeywell International Inc. | Authentication apparatus for value documents |

| DE102010050031A1 (en) * | 2010-11-02 | 2012-05-03 | Ovd Kinegram Ag | Security element and method for producing a security element |

| DE102010051087A1 (en) * | 2010-11-12 | 2012-05-16 | Beb Industrie-Elektronik Ag | Method and device for checking the authenticity of banknotes with security windows |

| FR2973392A1 (en) * | 2011-03-31 | 2012-10-05 | Crime Scene Technology | FLUORESCENT POLYMER COMPOSITION, FILMS COMPRISING THE SAME, PROCESS FOR THEIR PREPARATION AND THEIR APPLICATIONS |

| CN104272139B (en) * | 2012-03-09 | 2018-01-12 | 美国邮政署 | For item authentication and the method and system of customization |

| US10275969B2 (en) | 2012-03-09 | 2019-04-30 | United States Postal Service | Method and system for item authentication and customization |

| CN102760379B (en) * | 2012-07-10 | 2014-12-10 | 深圳职业技术学院 | Anti-fake label and manufacture method thereof |

| FR3004471B1 (en) | 2013-04-11 | 2015-10-23 | Arjowiggins Security | SECURITY ELEMENT COMPRISING A MASKING STRUCTURE CONTAINING A MIXTURE OF NANOMETER CHARGES. |

| FR3004470B1 (en) * | 2013-04-11 | 2015-05-22 | Arjowiggins Security | SECURITY ELEMENT COMPRISING AN INTERFERENTIAL PIGMENT AND A NANOMETRIC LOAD. |

| US8950855B1 (en) | 2013-11-22 | 2015-02-10 | Xerox Corporation | System and method for highlighting printed material on a document |

| DE102014010175A1 (en) | 2014-07-09 | 2016-01-14 | Hydac Filtertechnik Gmbh | filter element |

| US10036125B2 (en) | 2015-05-11 | 2018-07-31 | Nanotech Security Corp. | Security device |

| DE102016009024A1 (en) † | 2016-07-25 | 2018-01-25 | Giesecke+Devrient Currency Technology Gmbh | Security paper, security element and value document |

| SI3305541T1 (en) * | 2016-10-04 | 2020-07-31 | Hueck Folien Gesellschaft M.B.H. | Security element and valuable document with this security element |

| US10699610B2 (en) * | 2018-09-07 | 2020-06-30 | Royal Consumer Products Llc | Framed poster board that reflects and refracts light as color hues |

| WO2020263744A1 (en) * | 2019-06-26 | 2020-12-30 | Microtrace, Llc | Standardization of taggant signatures using transfer images |

| US20220281259A1 (en) * | 2019-08-29 | 2022-09-08 | Microtrace, Llc | Standardization of taggant signatures using transfer images |

Citations (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3473027A (en) † | 1965-03-08 | 1969-10-14 | American Cyanamid Co | Process for recording and retrieving information employing photoluminescent inks which luminesce under ultraviolet illumination |

| DE3239995C2 (en) † | 1982-10-28 | 1985-07-25 | COPYTEX GmbH Sicherheitssysteme, 7730 Villingen-Schwenningen | Device for recognizing documents |

| DE3422910C1 (en) † | 1984-06-20 | 1985-09-05 | Leonhard Kurz GmbH & Co, 8510 Fürth | Embossing foil, in particular hot stamping foil with a magnetic layer |

| CH661602A5 (en) † | 1981-02-19 | 1987-07-31 | Rca Corp | IDENTIFICATION DEVICE FOR A LEAF-SHAPED OBJECT. |

| DE3514852C2 (en) † | 1985-04-24 | 1987-10-29 | Gao Gesellschaft Fuer Automation Und Organisation Mbh, 8000 Muenchen, De | |

| DE3321657C2 (en) † | 1982-06-16 | 1988-05-19 | Kabushiki Kaisha Toshiba, Kawasaki, Kanagawa, Jp | |

| EP0420261A2 (en) † | 1989-09-28 | 1991-04-03 | GAO Gesellschaft für Automation und Organisation mbH | Record carrier with an optical variable element and method of producing it |

| WO1991006925A1 (en) † | 1989-10-26 | 1991-05-16 | Amblehurst Limited | Optical device |

| EP0461475A1 (en) † | 1990-06-06 | 1991-12-18 | Leonhard Kurz Gmbh & Co. | Method for transferring a pattern onto a substrate and use of a film |

| WO1992016378A1 (en) † | 1991-03-22 | 1992-10-01 | De La Rue Holographics Limited | Article |

Family Cites Families (23)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| NL7515010A (en) * | 1975-01-16 | 1976-07-20 | Siemens Ag | PROTECTED AGAINST COUNTERFEIT CARD. |

| GB1585533A (en) * | 1976-12-07 | 1981-03-04 | Portals Ltd | Security papers |

| US4151667A (en) * | 1976-12-30 | 1979-05-01 | Polaroid Corporation | Novel I.D. cards |

| GB2016370B (en) * | 1978-01-18 | 1982-02-17 | Post Office | Credit cards security documents and the like |

| FR2467089A1 (en) * | 1979-10-15 | 1981-04-17 | Bartoli Bernard | Forge proof documents - coated with liq. UV curable epoxy! acrylate! varnish contg. monomolecular layer of luminescent pigment, covered with heat sealed film |

| JPS58200275A (en) * | 1982-05-18 | 1983-11-21 | Dainippon Printing Co Ltd | Production for patterned fresnel hologram |

| GB8311795D0 (en) * | 1983-04-29 | 1983-06-02 | De La Rue Syst | Detecting luminescent security features |

| US4758296A (en) * | 1983-06-20 | 1988-07-19 | Mcgrew Stephen P | Method of fabricating surface relief holograms |

| US4705300A (en) * | 1984-07-13 | 1987-11-10 | Optical Coating Laboratory, Inc. | Thin film optically variable article and method having gold to green color shift for currency authentication |

| FR2570101B1 (en) * | 1984-09-07 | 1987-09-25 | Sotimag | ANTI-FRAUD PROCESS FOR VALUE DOCUMENTS |

| US4881268A (en) * | 1986-06-17 | 1989-11-14 | Laurel Bank Machines Co., Ltd. | Paper money discriminator |

| FR2605123B1 (en) * | 1986-10-10 | 1989-07-07 | Bric | TRUST OR SECURITY OBJECT ALLOWING VISUAL OR OPTICAL AUTHENTICATION |

| DE3741179A1 (en) * | 1987-12-04 | 1989-06-15 | Gao Ges Automation Org | DOCUMENT WITH FALSE-PROOF SURFACE RELIEF AND METHOD FOR PRODUCING THE SAME |

| DE3906695A1 (en) * | 1988-03-04 | 1989-09-14 | Gao Ges Automation Org | Security element in the form of a thread or strip for embedding in securities and method for its production |