EP0158464A1 - Low-temperature-effective detergent compositions and delivery systems therefor - Google Patents

Low-temperature-effective detergent compositions and delivery systems therefor Download PDFInfo

- Publication number

- EP0158464A1 EP0158464A1 EP85301979A EP85301979A EP0158464A1 EP 0158464 A1 EP0158464 A1 EP 0158464A1 EP 85301979 A EP85301979 A EP 85301979A EP 85301979 A EP85301979 A EP 85301979A EP 0158464 A1 EP0158464 A1 EP 0158464A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- mull

- composition

- detergent

- water

- pour point

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Classifications

-

- C—CHEMISTRY; METALLURGY

- C11—ANIMAL OR VEGETABLE OILS, FATS, FATTY SUBSTANCES OR WAXES; FATTY ACIDS THEREFROM; DETERGENTS; CANDLES

- C11D—DETERGENT COMPOSITIONS; USE OF SINGLE SUBSTANCES AS DETERGENTS; SOAP OR SOAP-MAKING; RESIN SOAPS; RECOVERY OF GLYCEROL

- C11D1/00—Detergent compositions based essentially on surface-active compounds; Use of these compounds as a detergent

- C11D1/66—Non-ionic compounds

- C11D1/825—Mixtures of compounds all of which are non-ionic

-

- C—CHEMISTRY; METALLURGY

- C11—ANIMAL OR VEGETABLE OILS, FATS, FATTY SUBSTANCES OR WAXES; FATTY ACIDS THEREFROM; DETERGENTS; CANDLES

- C11D—DETERGENT COMPOSITIONS; USE OF SINGLE SUBSTANCES AS DETERGENTS; SOAP OR SOAP-MAKING; RESIN SOAPS; RECOVERY OF GLYCEROL

- C11D1/00—Detergent compositions based essentially on surface-active compounds; Use of these compounds as a detergent

- C11D1/66—Non-ionic compounds

- C11D1/72—Ethers of polyoxyalkylene glycols

-

- C—CHEMISTRY; METALLURGY

- C11—ANIMAL OR VEGETABLE OILS, FATS, FATTY SUBSTANCES OR WAXES; FATTY ACIDS THEREFROM; DETERGENTS; CANDLES

- C11D—DETERGENT COMPOSITIONS; USE OF SINGLE SUBSTANCES AS DETERGENTS; SOAP OR SOAP-MAKING; RESIN SOAPS; RECOVERY OF GLYCEROL

- C11D17/00—Detergent materials or soaps characterised by their shape or physical properties

-

- C—CHEMISTRY; METALLURGY

- C11—ANIMAL OR VEGETABLE OILS, FATS, FATTY SUBSTANCES OR WAXES; FATTY ACIDS THEREFROM; DETERGENTS; CANDLES

- C11D—DETERGENT COMPOSITIONS; USE OF SINGLE SUBSTANCES AS DETERGENTS; SOAP OR SOAP-MAKING; RESIN SOAPS; RECOVERY OF GLYCEROL

- C11D17/00—Detergent materials or soaps characterised by their shape or physical properties

- C11D17/0004—Non aqueous liquid compositions comprising insoluble particles

-

- C—CHEMISTRY; METALLURGY

- C11—ANIMAL OR VEGETABLE OILS, FATS, FATTY SUBSTANCES OR WAXES; FATTY ACIDS THEREFROM; DETERGENTS; CANDLES

- C11D—DETERGENT COMPOSITIONS; USE OF SINGLE SUBSTANCES AS DETERGENTS; SOAP OR SOAP-MAKING; RESIN SOAPS; RECOVERY OF GLYCEROL

- C11D17/00—Detergent materials or soaps characterised by their shape or physical properties

- C11D17/04—Detergent materials or soaps characterised by their shape or physical properties combined with or containing other objects

- C11D17/041—Compositions releasably affixed on a substrate or incorporated into a dispensing means

- C11D17/042—Water soluble or water disintegrable containers or substrates containing cleaning compositions or additives for cleaning compositions

- C11D17/043—Liquid or thixotropic (gel) compositions

-

- C—CHEMISTRY; METALLURGY

- C11—ANIMAL OR VEGETABLE OILS, FATS, FATTY SUBSTANCES OR WAXES; FATTY ACIDS THEREFROM; DETERGENTS; CANDLES

- C11D—DETERGENT COMPOSITIONS; USE OF SINGLE SUBSTANCES AS DETERGENTS; SOAP OR SOAP-MAKING; RESIN SOAPS; RECOVERY OF GLYCEROL

- C11D17/00—Detergent materials or soaps characterised by their shape or physical properties

- C11D17/04—Detergent materials or soaps characterised by their shape or physical properties combined with or containing other objects

- C11D17/041—Compositions releasably affixed on a substrate or incorporated into a dispensing means

- C11D17/042—Water soluble or water disintegrable containers or substrates containing cleaning compositions or additives for cleaning compositions

- C11D17/044—Solid compositions

Definitions

- the within disclosed invention relates to detergent mull compositions and delivery means therefor.

- nonionic surfactants are useful in formulating laundry detergents for use in low water temperature washes. It is further known that nonionic surfactants are particularly efficient at removing oily soils from synthetic fabrics but that they are not as efficient at removing particulate soils as anionic surfactants. As a result it is desirable to include detergent builders in detergent formulations containing nonionic surfactants to improve performance on particulate soils and provide good overall cleaning performance. However, the amount of nonionic surfactant that can be included in powder detergents is limited by the amount that can be absorbed into or adsorbed onto the solid components.

- Agglomeration techniques usually produce dense particles that have little capacity for absorbing nonionic surfactants and the final compositions usually have poor solubility rates and flowability.

- Spray-drying techniques produce more porous particules that can sorb more nonionic surfactant.

- the temperatures involved in spray-drying can cause oxidation of the nonionic surfactant and it is desirable to add the nonionic surfactant in a second step if a high concentration is desired. Since the spray-drying process is energy and capital intensive, this approach results in high manufacturing costs.

- the spray-drying process itself can lead to the formation of insoluble particles that deposit on clothes during the washing process.

- pouches constructed of water soluble films to deliver unit dosages of laundry additives is well documented.

- US-A-4115292 issued to Richardson et al, shows compositions with low amounts of very high pour point nonionic surfactants and relatively high amounts of water in water-soluble polyvinyl alcohol pouches.

- This invention seeks to provide detergent mull compositions containing high amounts of nonionic surfactants which are not produced by such energy consumptive processes.

- This invention seeks to provide detergent compositions in the form of.mulls which have excellent solubility or dispersibility in cool and cold water and which efficiently remove both particulate and oily soils.

- This invention can provide detergent compositions in the form of mulls which have excellent rates of dispersion/dissolution in cool and cold water and which have good phase stability without the addition of clays or other costly phase-stabilizing ingredients and without the requirement of an extremely small average particle size for the solid components of the mulls.

- this invention seeks to provide a method for conveniently packing, storing and delivering these detergent compositions to washing machines.

- the invention provides novel low-temperature-effective detergent mull compositions comprising:

- novel detergent mull compositions are rapidly soluble/dispersible in cold water and yet surprisingly provide good removal of oily and particulate soils from both natural and synthetic fibres, even though the HLB values of the surfactant systems of these compositions may be lower than is considered optimum for good detergency.

- novel low-temperature-effective detergent mull compositions comprising:

- compositions of this embodiment have an average viscosity of about 20,000 - 60,000 cps and most preferably 30,000 - 50,000 cps under the same rheological test conditions.

- the invention provides a means for eliminating phase separation in these detergent mull compositions.

- This comprises adding water to the above-mentioned detergent mull compositions in an amount which is about 0.1 to 5.0% by weight of the composition (unless otherwise specified, all further measures herein are by percent by weight of the composition). This eliminates the need for the addition of more expensive materials, such as clays, and reduces the phase separation without significantly reducing the cold water solubility of the composition.

- the invention provides a premeasured, low-temperature-effective delivery system comprising:

- any of the inventive detergent mull compositions or into the low temperature effective detergent delivery system described above there may be added further surfactants which do not render detergent solubility/dispersibility unacceptable, fluorescent whitening agents, bleaches, corrosion inhibiting agents (i.e. anti-corrosion agents), anti-redeposition agents, enzymes, dyes, pigments, fabric softeners, fragrances and other adjuncts.

- further surfactants which do not render detergent solubility/dispersibility unacceptable, fluorescent whitening agents, bleaches, corrosion inhibiting agents (i.e. anti-corrosion agents), anti-redeposition agents, enzymes, dyes, pigments, fabric softeners, fragrances and other adjuncts.

- the invention further provides a method of laundering fabrics by contacting the fabrics with the foregoing detergent mull compositions or with water into which the composition has been dissolved or dispersed, or by contacting the fabric with water to which the low temperature delivery system has been added.

- HLB hydrophile-lipophile balance

- a further potential problem with mulls containing surfactants with low pour points is that the surfactants are too fluid at room temperature, and as a result, have more tendency to separate from the solids in the mulls. This leads to phase separation upon storage of the detergent composition. It has been surprisingly found that the addition of very small amounts of water to the surfactant system will essentially eliminate phase separation in the final detergent mull composition. Water added in the range of about 0.1 to 5.0%. based on the weight of composition, will adequately control phase separation without significantly reducing detergent solubility or dispersibility. Although not wishing to be bound to any one particular theory, applicants speculate that this effect results from flocculation of the solids in the mull which further increases their capacity to adsorb and absorb the surfactant.

- the amounts of builders and surfactants that can be included in the formulations disclosed herein can vary considerably depending on the nature of the builders, the final desired viscosity and the amount of water added to the surfactant system.

- other additives commonly found in detergent compositions can also be included in the formulations described herein. These include but are not limited to further surfactants which do not render detergent dissolution/dispersion rates unacceptable, fluorescent whitening agents, bleaches, corrosion-inhibiting agents, anti-redeposition agents, enzymes, fabric softeners, perfumes, dyes and pigments.

- the amount of builder should desirably be in the range of about 30 to 90% by weight of the total composition, with the surfactant system comprising about 10 to 70% by weight of the composition and the additional optional ingredients comprising about 0 to 60% by weight of the composition.

- the ratio of these ingredients should be further adjusted along with the level of water, which increases the viscosity when added to the formulation, to provide a mull composition with a viscosity preferably in the range of about 10,000 to 100,000 centipoise (cps) at 25 0 C and 6.25 revolutions per minute as measured on a Haake Rotoviscometer with an MVII sensor, and more preferably in the range of about 20,000 to 60,000 cps and still more preferably in the range of about 30,000 to 50,000 cps.

- cps centipoise

- the invention disclosed herein provides for mull detergent compositions that can be manufactured economically, will dissolve or disperse at acceptable rates in cool and cold water, have good overall cleaning performance and have controllable phase separation.

- Suitable, and preferred, materials for the individual constituents of the novel compositions of this invention are described as follows:

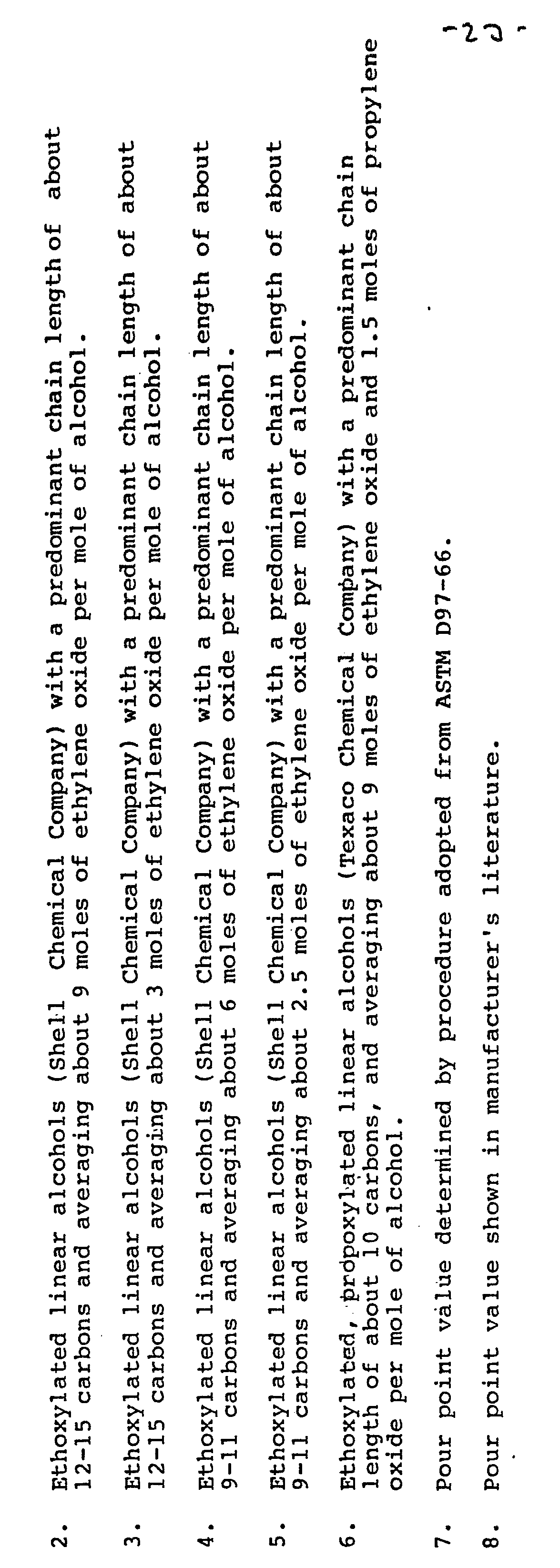

- the surfactants of choice in the nonionic surfactant system have been selected from the nonionic surfactants including linear and branched, primary and secondary ethoxylated alcohols with an average chain length of 6 to 16 carbon atoms and averaging about 2 to 10 moles of ethylene oxide per mole of alcohol; linear and branched, primary and secondary ethoxylated, propoxylated alcohols with an average chain length of about 6 to 16 carbon atoms and averaging about 0 to 10 moles of ethylene oxide and about 1 to 10 moles of propylene oxide per mole of alcohol; linear and branched alkylphenoxy (polyethoxy) alcohols, otherwise known as ethoxylated alkyl phenols, with an average chain length of 8 to 16 carbon atoms and averaging 1.5 to 30 moles of ethylene oxide per mole of alcohol; and mixtures thereof.

- nonionic surfactants are those containing about 6 to 10 moles of ethylene oxide per mole of alcohol. While the invention encompasses branched chain nonionic surfactants, it is well known that for commercial purposes, linear nonionics are preferred due to their better biodegradability. Exemplary of such surfactants are the Neodol (trade name of Shell Chemical Company) ethoxylate series.

- preferred surfactants include alcohol ethoxylates such as Neodol 91-6, which is a linear ethoxylated alcohol with a predominant chain length of about 9 to 11 carbons and average 6 moles of ethylene oxide per mole of alcohol, with a pour point of 7°C (45°F); Neodol 91-8, having the same predominant carbon chain length as Neodol 91-6 averaging 8.4 moles of ethylene oxide per mole of alcohol, with a pour point of 15 .5 o C (60°F); Neodol 23-6.5, which is a linear ethoxylated alcohol with a predominant chain length of about 12 to 13 carbons averaging 6.5 moles of ethylene oxide per mole of alcohol, with a pour point of 15.5°C (60°F); Neodol 25-7, which is a linear ethoxylated alcohol with a predominant chain length of about 12 to 15 carbons averaging 7.2 moles of ethylene oxide per mole of alcohol, with a pour point of

- Neodol ethoxylate series containing 1-5 moles of ethylene oxide per mole of alcohol.

- exemplary of these particular surfactants are Neodol 91-2.5, which is a linear ethoxylated alcohol with a predominant chain length of about 9 to 11 carbons, averaging 2.5 moles of ethylene oxide per mole of alcohol, with a pour point of -15°C (5°F), and an HLB value of about 8.1; and Neodol 25-3, which is a linear ethoxylated alcohol with a predominant chain length of 12 to 15 carbons, averaging 3 moles of ethylene oxide per mole of alcohol, with a pour point of 4.5°C (40 0 F), and an HLB value of about 7.9.

- Surfonic JL-80X is an ethoxylated, propoxylated alcohol with an average chain length of 10 carbon atoms and averaging 9 moles of ethylene oxide and 1.5 moles of propylene oxide per mole of alcohol, with a pour point of -9.5°C (15 0 F), and an HLB value of about 13, available from Texaco Chemical Company.

- Suitable alkylphenoxy (polyethoxy) alcohols include nonyl- and octylphenoxypoly (ethyleneoxy) alcohols, such as the Igepal series manufactured by GAF Corporation, e.g., Igepal CO-210, a nonylphenol average 1.5 moles of ethylene oxide per mole of alcohol, and the Triton series, manufactured by Rohm and Haas Company, e.g. Triton N-57, an ethoxylated nonylphenol averaging 5 moles of ethylene oxide per mole of alcohol.

- nonyl- and octylphenoxypoly (ethyleneoxy) alcohols such as the Igepal series manufactured by GAF Corporation, e.g., Igepal CO-210, a nonylphenol average 1.5 moles of ethylene oxide per mole of alcohol, and the Triton series, manufactured by Rohm and Haas Company, e.g. Triton N-57, an ethoxylated nonylphenol averaging 5

- the mulls of this invention have nonionic surfactant systems with pour points below about 24 0 C (75 0 F), more preferably below 19°C (65 0 F), and most preferably below about 5°C (40 0 F).

- Combinations of these surfactants may be used in the detergent mulls of this invention.

- Preferred combinations include those which combine a surfactant with a pour point of at least about 15.5°C (60°F) with a surfactant with a much lower pour point such that the pour point of the combination is less than 24°C (75 0 F), more preferably less than 19°C (65 0 F), and most preferably less than 5 C (40°F).

- the pour point of combinations of these surfactants is usually between the pour points of each individual surfactant, but is not necessarily a weighted average of the pour points of each individual surfactant.

- the predominant criterion for choosing the surfactants with particular pour points is the temperature of the cold water wash into which the mulls of this invention will be placed.

- Cold water wash temperatures in the United States vary greatly depending on both location and time of the year. As mentioned above, the average cold water wash has been determined to be about 18-19°C (65°F). However, the cold water wash temperatures can actually range from about 32 0 C (90 0 F) to about 4-5 0 C (40°F).

- the mulls of this invention are intended to be soluble in such wash temperatures.

- the.pour points of the nonionic surfactant systems within the mulls should be at least lower, more preferably about 2.7 Celsius degrees (5 Fahrenheit degrees) lower, most preferably about 5.5 Celsius degrees (10 Fahrenheit degrees) lower than the temperature of the wash water into which they are placed.

- Suitable builders can be selected in this invention from the inorganic builders such as polyphosphates, orthophosphates, metaphosphates, tetraphosphates, tripolyphosphates, phosphates, pyrophosphates, carbonates, bicarbonates, borates, metasilicates, silicates, polysilicates, aluminosilicates (zeolites) and the alkali metal and ammonium salts of any of the foregoing.

- the inorganic builders such as polyphosphates, orthophosphates, metaphosphates, tetraphosphates, tripolyphosphates, phosphates, pyrophosphates, carbonates, bicarbonates, borates, metasilicates, silicates, polysilicates, aluminosilicates (zeolites) and the alkali metal and ammonium salts of any of the foregoing.

- Further builders can be selected from such organic builders as nitrolotriacetic acid (NTA), polycarboxylates, polyhydroxysulfonates, citrates, succinates, oxydisuccinates, polyacrylic acid, ethylenediaminetetraacetic acid (EDTA) and the alkali metal and ammonium salts of the foregoing. Mixtures of any of the builders can be used. Two particularly preferred builders are sodium carbonate and sodium tripolyphosphate. An additional preferred builder is sodium polysilicate manufactured by PQ Corporation of Valley Forge, Pennsylvania, under the trademark Britesil ®

- the combination of at least one builder and the nonionic surfactant system should be readily soluble and/or dispersible in the wash water to which it is added.

- the concept of dispersibility includes solubility.

- satisfactory dispersibility is obtained when an observer is unable to visually discern any localised blue residue on fabrics washed with a mull composition containing a blue dye or pigment, or in the washing machine in which these fabrics were washed.

- an additional concept which is relevant to the invention is rate of dissolution/dispersion. Over time, many solid particulates will disperse in water. However, to be acceptable for use in this invention, the mulls should dissolve/disperse in the water at about 18-19°C (65 0 F) within at least about 25 minutes with gentle agitation, more preferably within about 15 minutes, and most preferably within about 10 minutes.

- the particle size of the builders is not critical if the viscosity of the composition is adjusted to be in the range of about 10,000 to 100,000 centipoise.

- the builder used in this composition can thus be generally used as received from the supplier without an extra processing step to mill the particles to a desired size as required in US-A-4316812.

- the average particle size of the solid components of the mull compositions of this invention is preferably between 10 to 500 microns, more preferably about 50 to 250 microns, and most preferably about 50 to 175 microns.

- the average particle size of one of the preferred builders, sodium tripolyphosphate (STPP) -- which, in the Examples following, constitutes a major portion of the solids in the mull compositions -- was determined by screening and is set forth in Table I:

- the viscosity is in the range of preferably about 10,000 to 100,000 centipoise (cps) at 25 0 C and at 6.25 revolutions per minute (rpm) as measured with a Haake Rotoviscometer with an MVII sensor, more preferably about 20,000 to 60,000 cps.

- the inventive mull compositions comprise preferably about 30 to 90% by weight of at least one builder, about 10 to 70% by weight surfactant system, and about 0 to 60% by weight adjuncts (as described below); more preferably about 40 to 80% by weight of at least one builder, about 20 to 60% by weight surfactant system, and about 0 to 40% by weight adjuncts; and most preferably about 50 to 75% by weight of at least one builder, about 25 to 50% by weight surfactant system, and about 0 to 25% by weight adjuncts.

- Water has been used in Examples 12-14 below as a phase stabiliser and for viscosity control. In fact, in these particular uses, a clay or other thickener is not utilized. While it is not entirely understood why water may act as a thickener in this invention, it is believed that it may cause flocculation of the solids in the compositions of this invention which leads to further adsorption or absorption of the surfactants.

- the amount of water required to produce the desired viscosity and adequate phase stability appears to show a critical range. This amount ranges from about 0.1% to about 5%, more preferably 0.4% to about 2% by weight of the composition.

- deionized water is especially preferred for use, although from a commercial standpoint, tap water appears acceptable.

- fluorescent whitening agents are preferably added to improve whitening of fabrics.

- fluorescent brighteners can be selected from stilbene brighteners, and their derivatives; styrylnaphthalene brighteners and their derivatives; and styrene brighteners and their derivatives.

- Exemplary of the derivatives used is the preferred brightener Tinopal ® 5BM-XC, produced by Ciba-Geigy A.G., Switzerland.

- Other brighteners include those disclosed in UK patents 1298577, 2076011, 2026054, 2026566, 1393042; and US patents 3951960, 4298290, 3993659, 3980713 and 3627758, whose disclosures are incorporated herein by reference.

- nonionic, anionic, cationic and amphoteric surfactants may be combined with the detergent mulls of this invention in a manner to impart greater cleaning where desired, with the proviso that such added surfactants do not render detergent solubility or dispersibility unacceptable, especially in cool or cold water up to 24 0 C ( 75 0 F ) .

- anionic surfactants may be added to increase cleaning of particulate soils.

- anionic surfactants include the ammonium, substituted ammonium (e.g., mono-, di- and triethanolammonium), alkali metal, and alkaline earth metal salts of C 6 -C 20 fatty acids and rosin acids, linear and branched alkylbenzenesulfonates, alkyl sulfates, alkyl ether sulfates, alkanesulfonates, olefin sulfonates, hydroxyalkanesulfonates, fatty acid monoglyceride sulfates, alkyl glyceryl ether sulfates, acyl sarcosinates, and acyl N-methyl taurides.

- nonionic surfactants include polyoxyethylene carboxylic acid esters, fatty acid glycerol esters, fatty acid and ethoxylated fatty acid alkanolamides, certain block copolymers of propylene oxide and ethylene oxide, and block polymers of propylene oxide and ethylene oxide with propoxylated ethylenediamine. Also included are such semi-polar nonionic surfactants like amine oxides, phosphine oxides, sulfoxides, and their ethoxylated derivatives.

- Suitable cationic surfactants include the quaternary ammonium compounds in which typically one of the groups linked to the nitrogen atom is a C 12 -C 18 alkyl group and the other three groups are short-chain alkyl groups which may bear inert substituents such as phenyl groups.

- suitable amphoteric and zwitterionic surfactants which contain an anionic water-solubilizing group, a cationic group, and a hydrophobic organic group include aminocarboxylic acids and their salts, iminodicarboxylic acids and their salts, alkylbetaines, alkylamidopropylbetaines, sulfobetaines, alkylimidazolinium derivatives, certain quaternary ammonium compounds, certain quaternary phosphonium compounds and certain tertiary sulfonium compounds.

- suitable zwitterionic surfactants can be found described in US-A-4005029, issued to Jones, at Columns 11-15, which are incorporated herein by reference.

- anionic, nonionic, cationic and amphoteric surfactants which may be suitable for use in this invention are depicted in Kirk-Othmer, Encyclopedia of Chemical Technology, Third Edition, Vol. 22, pages 347-387, and McCutcheon's Detergents and Emulsifiers, North American Edition, 1983, which are incorporated herein by reference.

- Further cleaning adjuncts can include enzymes. Particularly preferred are amylases and proteases. Particularly preferred are proteases such as alkaline proteases, also denoted as subtilisins. Suitable examples include Savinase® , Alcalase®, and Esperase all from Novo Industri A/S, Denmark, and Maxacal and Maxatase ® from Gist Brocades, N.V., Netherlands.

- Bleaches can also be added to the compositions of this invention, preferably peroxygen bleaches such as percarbonate, perborate, and the salts thereof, e.g. sodium perborate monohydrate, and organic and inorganic peroxy compounds, such as peracids, e.g. perlauric acid, and potassium peroxymonosulfate (available from E.I.-du Pont de Nemours, Delaware, under the trade mark Oxone ® ).

- bleach activators can be incorporated, such as tetraacetylethylenediamine (TAED), ketones or aldehydes.

- TAED tetraacetylethylenediamine

- preferred forms of this invention comprise a delivery system comprising (a) a water-soluble delivery pouch, which comprises a film prepared from at least one film-forming polymer and (b) an effective amount of a low temperature detergent mull which comprises a nonionic surfactant system and a builder.

- Particularly preferred films are castable, water-soluble films comprised of polyvinyl alcohols which have number average molecular weights from about 5,000 to 250,000.

- the polyvinyl alcohols generally have about 1 to 25% residual acetate groups, more preferably 5 to 20% residual acetate groups, and most preferably about 10 to 15% residual acetate groups.

- polymers as polyvinyl pyrrolidone, methyl cellulose, polyethylene oxide, gelatin and other film formers can be utilized.

- Plasticizers such as trimethylolpropane, glycerol, polyethylene glycol and others known to those skilled in the art can be included in the film to provide the film strength and flexibility required for producing, filling, shipping and storing the pouches prepared from these films.

- other ingredients such as wetting agents, defoamers, and anti-blocking agents can be included in these films to aid in their manufacture and in the preparation of pouches made from these films

- the films employed can have a thickness of from 25 to 127 microns (1.0-5.0 mils), with the thickness and film material being selected to provide the optimum balance of film strength and cold water solubility. It has been found that films with a thickness of 38 to 89 microns (1.5-3.5 mils) produced from polyvinyl alcohol with about 12% residual acetate groups are preferred.

- a further embodiment of this invention comprises a delivery system comprising (a) a water-soluble delivery pouch, and (b) an effective amount of a low-temperature-effective detergent mull which comprises a builder, a nonionic surfactant system and 30% or less, based on the weight of the surfactant system, of at least one ingredient that is suitable for use as a film plasticizer for the film used to form the water-soluble pouch.

- a low-temperature-effective detergent mull which comprises a builder, a nonionic surfactant system and 30% or less, based on the weight of the surfactant system, of at least one ingredient that is suitable for use as a film plasticizer for the film used to form the water-soluble pouch.

- each of the 10 exemplified compositions in TABLE II were prepared by premixing the nonionic surfactants together and then mixing the surfactant system together with the remainder of the ingredients in a Hobart mixer. Relatively low shear mixing was used and a total mixing time of 15-30 minutes was sufficient to provide uniform distribution of the ingredients in the resulting mulls. The pour point of each surfactant mixture was measured using the basic procedure found in ASTM D97-66.

- the resulting pouches were then placed at 4.5° C (40°F) for 24-48 hours (to simulate storage by the consumer, such as in a garage), removed and their solubility in 4.5°C (40 0 F) water was evaluated.

- This procedure involved placing the pouches in a washing machine containing 68 litres of water at 4.5°C (40 0 F) and initiating a wash cycle using the "delicate" setting to control agitation. After ten minutes, the agitation was terminated, and the machine was drained and inspected for residual detergent. Residual detergent is determined by whether any residue remains which is visually discernible in the washing machine. This is a measure of the dissolution/dispersion rates of the mull compositions. The results are shown in TABLE II, below.

- Example 1 which contains two surfactants, Neodol 23-6.5 and Neodol 25-9, which are considered to be water soluble by their manufacturer, failed to completely dissolve at 4.5 Q C (40°F) under the test conditions.

- this composition was stored at 21°C (70 0 F) and added to wash water at 17°C (63 0 F), it again failed to completely dissolve under the test conditions described previously.

- Example 4 by comparison, which contains Neodol 91-2.5, dissolved/dispersed completely in the cold, i.e. 4.5 0 C (40°F) water even after storage at 4.5 0 C (40°F).

- compositions of this invention provide good cleaning as well as good solubility/dispersibility characteristics.

- the cleaning performance was evaluated by washing swatches treated with these soils in water at 38°C (100°F) containing 100 ppm water hardness (as CaC0 3 ) with a molar ratio of Ca 2+ :Mg 2+ of 3:1 and a concentration of 0.08% of the appropriate detergent mull composition in a commercial washing machine.

- the reflectance values of the swatches were measured before and after washing, and the Kubelka-Munk equation was used to calculate % soil removal.

- Example 10 is a ternary system containing mixture of three nonionic surfactants, two of which have very low pour points (Neodol 91-2.5 and Surfonic JL-80X). On two fabrics, cotton and polyester, this ternary system had significantly better particulate (clay) soil removal, than the composition of Example 1, which was unexpected based on the HLB's of the surfactant systems.

- Example 12 50 kilogram quantities of mull detergent compositions were prepared using a ribbon blender and the formulas are summarized below. In Example 12, the water was added to the surfactant system before this system was mixed with the rest of the composition.

- Example 11 The composition of Example 11 was observed to have phase separation after storage at room temperature. The separation was quantified by placing 1000 grams of the composition in a one-litre graduated cylinder for one week at room temperature and then removing and weighing the separated liquid phase that appeared on top of the remainder of the composition. It was found that weight of the liquid totaled 4.8% of the total composition. When the detergent of composition 12 was evaluated under the same conditions, 0.1% or less liquid phase separation was observed.

- Example 12 Furthermore, 2 kilogram quantities of the detergent composition in Example 12 were prepared and tested for solubility as were Examples 1-10.

- the composition of Example 12 dissolved/dispersed completely in less than ten minutes in 4.5°C (40 0 F) water.

- mull detergent compositions 2 kilogram quantities were prepared using a Hobart mixer and their formulas are summarized below. Approximately 25 grams of each composition were placed in a 2 x 3 inch water-soluble pouch constructed from a 63 micron (2.5 mil) thick film comprised predominately of polyvinyl alcohol (number average molecular weight of about 10,000 and about 12% residual acetate groups) with 5% glycerol and 4% trimethylolpropane as plasticizers. The pouches were stored for nine weeks at 21°C/50% relative humidity (70°F/50%).

Abstract

Description

- The within disclosed invention relates to detergent mull compositions and delivery means therefor.

- It is well known to those skilled in the art that nonionic surfactants are useful in formulating laundry detergents for use in low water temperature washes. It is further known that nonionic surfactants are particularly efficient at removing oily soils from synthetic fabrics but that they are not as efficient at removing particulate soils as anionic surfactants. As a result it is desirable to include detergent builders in detergent formulations containing nonionic surfactants to improve performance on particulate soils and provide good overall cleaning performance. However, the amount of nonionic surfactant that can be included in powder detergents is limited by the amount that can be absorbed into or adsorbed onto the solid components. Agglomeration techniques usually produce dense particles that have little capacity for absorbing nonionic surfactants and the final compositions usually have poor solubility rates and flowability. Spray-drying techniques produce more porous particules that can sorb more nonionic surfactant. However, the temperatures involved in spray-drying can cause oxidation of the nonionic surfactant and it is desirable to add the nonionic surfactant in a second step if a high concentration is desired. Since the spray-drying process is energy and capital intensive, this approach results in high manufacturing costs. In addition, if certain builders are present, the spray-drying process itself can lead to the formation of insoluble particles that deposit on clothes during the washing process.

- High levels of nonionic surfactants can be readily incorporated into liquid laundry detergents. However, these formulations are normally severely limited in the type and amount of builder that can be incorporated therein since the builder must be soluble or dispersible in the formulation to prevent phase separation. As a result, the overall particulate soil removal performance of liquid laundry detergents is generally poorer than that of powder detergents.

- US-A-4316812, issued to Hancock et al, appears to disclose liquid detergent compositions containing builders, a bleach, and nonionic surfactant system, in which the solids have an average particle diameter of less than 10 microns and the nonionic surfactant system has a pour point of less than 10°C. However, it is expensive and inconvenient to use most conventional builders and most other solids at such a small particle size and a potential for the development of health and safety problems related to dusting with these builders and solids exists. Post milling the composition to reduce the particle size of the solids may eliminate the health and safety problems, but it requires an extra processing step that is energy intensive, and it generates significant heat which may affect temperature- sensitive compounds of the composition. Furthermore, it may have a deleterious effect on encapsulated materials within the composition. Furthermore, no mention is made of the solubility characteristics of these formulations in cold water.

- There have been attempts to combine high levels of nonionic surfactants and builders in laundry detergent formulations which have the physical form of mulls or pastes. US-A-4264466, issued to Carleton et al, describes detergent mulls which contain chain structure clays to prevent phase separation of the liquid and solid components. US-A-4409146 issued to Cheng, discloses a paste detergent composition containing a specific nonionic surfactant along with a relatively high amount of water.

- Because of the viscous nature of these paste formulations, it is difficult to deliver them into the washing machine from a conventional, liquid laundry detergent bottle, even one equipped with a pump dispenser. The use of a squeezable tube, similar to those used to dispense toothpaste, to dispense a liquid detergent in the form of a paste may be feasible from a technical consideration, but the size of the tube required to contain a reasonable amount of detergent for multiple wash loads would make it difficult for the consumer to use conveniently.

- The use of pouches constructed of water soluble films to deliver unit dosages of laundry additives is well documented. However, there has been no demonstration in the prior art of the use of such pouches to contain and deliver a composition containing a high level of nonionic surfactant. For example, US-A-4115292, issued to Richardson et al, shows compositions with low amounts of very high pour point nonionic surfactants and relatively high amounts of water in water-soluble polyvinyl alcohol pouches.

- The steady rise in energy costs has made energy intensive manufacturing processes much less attractive. This invention seeks to provide detergent mull compositions containing high amounts of nonionic surfactants which are not produced by such energy consumptive processes.

- There has been a trend in domestic laundry towards lowered wash temperatures. This invention seeks to provide detergent compositions in the form of.mulls which have excellent solubility or dispersibility in cool and cold water and which efficiently remove both particulate and oily soils.

- This invention can provide detergent compositions in the form of mulls which have excellent rates of dispersion/dissolution in cool and cold water and which have good phase stability without the addition of clays or other costly phase-stabilizing ingredients and without the requirement of an extremely small average particle size for the solid components of the mulls.

- In some aspects this invention seeks to provide a method for conveniently packing, storing and delivering these detergent compositions to washing machines.

- In one aspect, the invention provides novel low-temperature-effective detergent mull compositions comprising:

- (a) a builder; and

- (b) a nonionic surfactant system, wherein the pour point of the system is preferably less than 24°C (750F), more preferably less than 19°C (65°F) and most preferably less than 5 C (40°F); and wherein the average particle size of the solid components of the compositions is greater than 10 microns.

- As will be more specifically discussed herein, the novel detergent mull compositions are rapidly soluble/dispersible in cold water and yet surprisingly provide good removal of oily and particulate soils from both natural and synthetic fibres, even though the HLB values of the surfactant systems of these compositions may be lower than is considered optimum for good detergency.

- In a further aspect, the invention provides novel low-temperature-effective detergent mull compositions comprising:

- (a) a builder; and

- (b) a mixture of nonionic surfactants having pour points preferably less than 24°C (750F), more preferably less than 19°C (650F), and most preferably less than 5°C (400F);

- More preferably, the compositions of this embodiment have an average viscosity of about 20,000 - 60,000 cps and most preferably 30,000 - 50,000 cps under the same rheological test conditions.

- In further embodiments, the invention provides a means for eliminating phase separation in these detergent mull compositions. This comprises adding water to the above-mentioned detergent mull compositions in an amount which is about 0.1 to 5.0% by weight of the composition (unless otherwise specified, all further measures herein are by percent by weight of the composition). This eliminates the need for the addition of more expensive materials, such as clays, and reduces the phase separation without significantly reducing the cold water solubility of the composition.

- In yet another aspect, the invention provides a premeasured, low-temperature-effective delivery system comprising:

- a water soluble delivery pouch which contains a low-temperature-effective detergent mull composition as any set forth above.

- Furthermore, into any of the inventive detergent mull compositions or into the low temperature effective detergent delivery system described above, there may be added further surfactants which do not render detergent solubility/dispersibility unacceptable, fluorescent whitening agents, bleaches, corrosion inhibiting agents (i.e. anti-corrosion agents), anti-redeposition agents, enzymes, dyes, pigments, fabric softeners, fragrances and other adjuncts.

- The invention further provides a method of laundering fabrics by contacting the fabrics with the foregoing detergent mull compositions or with water into which the composition has been dissolved or dispersed, or by contacting the fabric with water to which the low temperature delivery system has been added.

- Recent studies have indicated that the average wash temperature of cold water washes in the United States is approximately 18-19°C (650F) but the temperature range of cold water washes is from about 32°C (90°F) to about 4-50C (40°F), and a significant number of wash loads is done in water with a temperature of less than 10°C (500F). Surprisingly, many mull detergent compositions consisting predominantly of builders and cold water soluble nonionic surfactants will not dissolve/disperse at an adequate rate in cold water washes. It has been further surprisingly discovered that if the pour point of the nonionic surfactant system in these mulls is lower than the water temperature into which the mull is placed, the mull will dissolve/disperse at a rate sufficient to be acceptable for use as a consumer product. It is desirable to formulate these mulls with surfactant systems with pour points of less than about 24°C (75°F) more preferably less than about 19 C (65°F), and most preferably less than about 5°C (40°F) to make them adequately soluble in most cold water washes.

- However, generally, as the pour point of the surfactant decreases, so does its hydrophile-lipophile balance (HLB) value, and thus the pour points of the systems disclosed herein approach values much lower than is generally considered optimum for good overall detergency. As disclosed in Schick, Nonionic Surfactants, Vol. 2, p. 607 (1962), optimal detergency was thought present at HLB values of around 13-15. HLB values are calculated from the number of ethylene oxide or other solubilizing groups contained in the particular nonionic surfactant. Surprisingly, the compositions disclosed in this invention nonetheless provide good detergency on both particulate and oily type soils even though the HLB values of these surfactant systems are quite low. In fact, some of the systems disclosed in this invention with the lowest HLB values provide the best overall detergency. There is no disclosure or recognition in the prior art that the dispersion/dissolution rates of these forms of detergents in cold water are highly dependent upon the pour points of the nonionic surfactant used in the formulations. Furthermore, no suggestion has been made in the prior art for conveniently delivering viscous detergent compositions containing high levels of nonionic surfactant into the washing machine.

- A further potential problem with mulls containing surfactants with low pour points is that the surfactants are too fluid at room temperature, and as a result, have more tendency to separate from the solids in the mulls. This leads to phase separation upon storage of the detergent composition. It has been surprisingly found that the addition of very small amounts of water to the surfactant system will essentially eliminate phase separation in the final detergent mull composition. Water added in the range of about 0.1 to 5.0%. based on the weight of composition, will adequately control phase separation without significantly reducing detergent solubility or dispersibility. Although not wishing to be bound to any one particular theory, applicants speculate that this effect results from flocculation of the solids in the mull which further increases their capacity to adsorb and absorb the surfactant. This is in contrast to the disclosure in US-A-4264466, which teaches the use of chain structure clays to prevent phase separation. These clays are more expensive to use than water and the formation of the chain structure in the mull will most probably reduce the rate of dissolution/dispersion of the resultant detergent composition in cool water.

- The amounts of builders and surfactants that can be included in the formulations disclosed herein can vary considerably depending on the nature of the builders, the final desired viscosity and the amount of water added to the surfactant system. In addition, other additives commonly found in detergent compositions can also be included in the formulations described herein. These include but are not limited to further surfactants which do not render detergent dissolution/dispersion rates unacceptable, fluorescent whitening agents, bleaches, corrosion-inhibiting agents, anti-redeposition agents, enzymes, fabric softeners, perfumes, dyes and pigments.

- The amount of builder should desirably be in the range of about 30 to 90% by weight of the total composition, with the surfactant system comprising about 10 to 70% by weight of the composition and the additional optional ingredients comprising about 0 to 60% by weight of the composition. The ratio of these ingredients should be further adjusted along with the level of water, which increases the viscosity when added to the formulation, to provide a mull composition with a viscosity preferably in the range of about 10,000 to 100,000 centipoise (cps) at 250C and 6.25 revolutions per minute as measured on a Haake Rotoviscometer with an MVII sensor, and more preferably in the range of about 20,000 to 60,000 cps and still more preferably in the range of about 30,000 to 50,000 cps.

- Thus, the invention disclosed herein provides for mull detergent compositions that can be manufactured economically, will dissolve or disperse at acceptable rates in cool and cold water, have good overall cleaning performance and have controllable phase separation. Suitable, and preferred, materials for the individual constituents of the novel compositions of this invention are described as follows:

- The surfactants of choice in the nonionic surfactant system have been selected from the nonionic surfactants including linear and branched, primary and secondary ethoxylated alcohols with an average chain length of 6 to 16 carbon atoms and averaging about 2 to 10 moles of ethylene oxide per mole of alcohol; linear and branched, primary and secondary ethoxylated, propoxylated alcohols with an average chain length of about 6 to 16 carbon atoms and averaging about 0 to 10 moles of ethylene oxide and about 1 to 10 moles of propylene oxide per mole of alcohol; linear and branched alkylphenoxy (polyethoxy) alcohols, otherwise known as ethoxylated alkyl phenols, with an average chain length of 8 to 16 carbon atoms and averaging 1.5 to 30 moles of ethylene oxide per mole of alcohol; and mixtures thereof.

- Particularly preferred examples of these nonionic surfactants are those containing about 6 to 10 moles of ethylene oxide per mole of alcohol. While the invention encompasses branched chain nonionic surfactants, it is well known that for commercial purposes, linear nonionics are preferred due to their better biodegradability. Exemplary of such surfactants are the Neodol (trade name of Shell Chemical Company) ethoxylate series. In particular, preferred surfactants include alcohol ethoxylates such as Neodol 91-6, which is a linear ethoxylated alcohol with a predominant chain length of about 9 to 11 carbons and average 6 moles of ethylene oxide per mole of alcohol, with a pour point of 7°C (45°F); Neodol 91-8, having the same predominant carbon chain length as Neodol 91-6 averaging 8.4 moles of ethylene oxide per mole of alcohol, with a pour point of 15.5oC (60°F); Neodol 23-6.5, which is a linear ethoxylated alcohol with a predominant chain length of about 12 to 13 carbons averaging 6.5 moles of ethylene oxide per mole of alcohol, with a pour point of 15.5°C (60°F); Neodol 25-7, which is a linear ethoxylated alcohol with a predominant chain length of about 12 to 15 carbons averaging 7.2 moles of ethylene oxide per mole of alcohol, with a pour point of 210C (700F); Neodol 25-9, having the same predominant chain length as Neodol 25-7, averaging 9 moles of ethylene oxide per mole of alcohol, with a pour point of 240C (750F); and Neodol 45-7, which is a linear ethoxylated alcohol with a predominant chain length of about 14 to 15 carbons, averaging 7 moles of ethylene oxide per mole of alcohol, with a pour point of 210 C (70°F). These particular alcohol ethoxylates are characterised by having HLB values ranging from 12.0 to about 14.0 and with hydroxyl numbers (measured in milligrams of potassium hydroxide per gram) ranging from about 132-92.

- Other nonionic surfactants may be selected from the Neodol ethoxylate series containing 1-5 moles of ethylene oxide per mole of alcohol. Exemplary of these particular surfactants are Neodol 91-2.5, which is a linear ethoxylated alcohol with a predominant chain length of about 9 to 11 carbons, averaging 2.5 moles of ethylene oxide per mole of alcohol, with a pour point of -15°C (5°F), and an HLB value of about 8.1; and Neodol 25-3, which is a linear ethoxylated alcohol with a predominant chain length of 12 to 15 carbons, averaging 3 moles of ethylene oxide per mole of alcohol, with a pour point of 4.5°C (400F), and an HLB value of about 7.9.

- Yet another particularly preferred surfactant is Surfonic JL-80X, which is an ethoxylated, propoxylated alcohol with an average chain length of 10 carbon atoms and averaging 9 moles of ethylene oxide and 1.5 moles of propylene oxide per mole of alcohol, with a pour point of -9.5°C (150F), and an HLB value of about 13, available from Texaco Chemical Company.

- Suitable alkylphenoxy (polyethoxy) alcohols, otherwise known as ethoxylated alkylphenols, include nonyl- and octylphenoxypoly (ethyleneoxy) alcohols, such as the Igepal series manufactured by GAF Corporation, e.g., Igepal CO-210, a nonylphenol average 1.5 moles of ethylene oxide per mole of alcohol, and the Triton series, manufactured by Rohm and Haas Company, e.g. Triton N-57, an ethoxylated nonylphenol averaging 5 moles of ethylene oxide per mole of alcohol.

- In general, the mulls of this invention have nonionic surfactant systems with pour points below about 240C (750F), more preferably below 19°C (650F), and most preferably below about 5°C (400F). Combinations of these surfactants may be used in the detergent mulls of this invention. Preferred combinations include those which combine a surfactant with a pour point of at least about 15.5°C (60°F) with a surfactant with a much lower pour point such that the pour point of the combination is less than 24°C (750F), more preferably less than 19°C (650F), and most preferably less than 5 C (40°F). In practice, the pour point of combinations of these surfactants is usually between the pour points of each individual surfactant, but is not necessarily a weighted average of the pour points of each individual surfactant.

- The predominant criterion for choosing the surfactants with particular pour points is the temperature of the cold water wash into which the mulls of this invention will be placed. Cold water wash temperatures in the United States vary greatly depending on both location and time of the year. As mentioned above, the average cold water wash has been determined to be about 18-19°C (65°F). However, the cold water wash temperatures can actually range from about 320C (900F) to about 4-50C (40°F). The mulls of this invention are intended to be soluble in such wash temperatures. Therefore, the.pour points of the nonionic surfactant systems within the mulls should be at least lower, more preferably about 2.7 Celsius degrees (5 Fahrenheit degrees) lower, most preferably about 5.5 Celsius degrees (10 Fahrenheit degrees) lower than the temperature of the wash water into which they are placed.

- Suitable builders can be selected in this invention from the inorganic builders such as polyphosphates, orthophosphates, metaphosphates, tetraphosphates, tripolyphosphates, phosphates, pyrophosphates, carbonates, bicarbonates, borates, metasilicates, silicates, polysilicates, aluminosilicates (zeolites) and the alkali metal and ammonium salts of any of the foregoing. Further builders can be selected from such organic builders as nitrolotriacetic acid (NTA), polycarboxylates, polyhydroxysulfonates, citrates, succinates, oxydisuccinates, polyacrylic acid, ethylenediaminetetraacetic acid (EDTA) and the alkali metal and ammonium salts of the foregoing. Mixtures of any of the builders can be used. Two particularly preferred builders are sodium carbonate and sodium tripolyphosphate. An additional preferred builder is sodium polysilicate manufactured by PQ Corporation of Valley Forge, Pennsylvania, under the trademark Britesil ®

- As previously mentioned, the combination of at least one builder and the nonionic surfactant system should be readily soluble and/or dispersible in the wash water to which it is added. For the purposes of this invention, the concept of dispersibility includes solubility. For purposes of this invention, satisfactory dispersibility is obtained when an observer is unable to visually discern any localised blue residue on fabrics washed with a mull composition containing a blue dye or pigment, or in the washing machine in which these fabrics were washed.

- An additional concept which is relevant to the invention is rate of dissolution/dispersion. Over time, many solid particulates will disperse in water. However, to be acceptable for use in this invention, the mulls should dissolve/disperse in the water at about 18-19°C (650F) within at least about 25 minutes with gentle agitation, more preferably within about 15 minutes, and most preferably within about 10 minutes.

- The particle size of the builders is not critical if the viscosity of the composition is adjusted to be in the range of about 10,000 to 100,000 centipoise. As a result, the builder used in this composition can thus be generally used as received from the supplier without an extra processing step to mill the particles to a desired size as required in US-A-4316812.

- Further, if the viscosity of the composition is maintained in the appropriate range, no dispersant is required to prevent the builders from separating from the balance of the compositions of this invention. Although US-A-4316812 contends no dispersant is needed for its liquid detergent, in fact, all of its examples include finely divided silica ("Aerosil")-, polyethylene glycol, or a combination of the two as dispersants (cf. Column 4, lines 3-7 and Example 5, column 5, line 54, showing use of polyethylene glycol).

- The average particle size of the solid components of the mull compositions of this invention is preferably between 10 to 500 microns, more preferably about 50 to 250 microns, and most preferably about 50 to 175 microns. The average particle size of one of the preferred builders, sodium tripolyphosphate (STPP) -- which, in the Examples following, constitutes a major portion of the solids in the mull compositions -- was determined by screening and is set forth in Table I:

- As noted above, particle size, however, is not critical, but the amounts of builder, surfactants and water must be adjusted to provide satisfactory viscosity. In the invention, the viscosity is in the range of preferably about 10,000 to 100,000 centipoise (cps) at 250C and at 6.25 revolutions per minute (rpm) as measured with a Haake Rotoviscometer with an MVII sensor, more preferably about 20,000 to 60,000 cps.

- In order to meet the desirable criteria outlined above, the inventive mull compositions comprise preferably about 30 to 90% by weight of at least one builder, about 10 to 70% by weight surfactant system, and about 0 to 60% by weight adjuncts (as described below); more preferably about 40 to 80% by weight of at least one builder, about 20 to 60% by weight surfactant system, and about 0 to 40% by weight adjuncts; and most preferably about 50 to 75% by weight of at least one builder, about 25 to 50% by weight surfactant system, and about 0 to 25% by weight adjuncts.

- Water has been used in Examples 12-14 below as a phase stabiliser and for viscosity control. In fact, in these particular uses, a clay or other thickener is not utilized. While it is not entirely understood why water may act as a thickener in this invention, it is believed that it may cause flocculation of the solids in the compositions of this invention which leads to further adsorption or absorption of the surfactants. The amount of water required to produce the desired viscosity and adequate phase stability appears to show a critical range. This amount ranges from about 0.1% to about 5%, more preferably 0.4% to about 2% by weight of the composition. Furthermore, deionized water is especially preferred for use, although from a commercial standpoint, tap water appears acceptable.

- In the invention, fluorescent whitening agents, or brighteners, are preferably added to improve whitening of fabrics. Such fluorescent brighteners can be selected from stilbene brighteners, and their derivatives; styrylnaphthalene brighteners and their derivatives; and styrene brighteners and their derivatives. Exemplary of the derivatives used is the preferred brightener Tinopal ® 5BM-XC, produced by Ciba-Geigy A.G., Switzerland. Other brighteners include those disclosed in UK patents 1298577, 2076011, 2026054, 2026566, 1393042; and US patents 3951960, 4298290, 3993659, 3980713 and 3627758, whose disclosures are incorporated herein by reference.

- Further nonionic, anionic, cationic and amphoteric surfactants may be combined with the detergent mulls of this invention in a manner to impart greater cleaning where desired, with the proviso that such added surfactants do not render detergent solubility or dispersibility unacceptable, especially in cool or cold water up to 240 C (75 0 F).

- For example, anionic surfactants may be added to increase cleaning of particulate soils. Suitable examples of such anionic surfactants include the ammonium, substituted ammonium (e.g., mono-, di- and triethanolammonium), alkali metal, and alkaline earth metal salts of C6-C20 fatty acids and rosin acids, linear and branched alkylbenzenesulfonates, alkyl sulfates, alkyl ether sulfates, alkanesulfonates, olefin sulfonates, hydroxyalkanesulfonates, fatty acid monoglyceride sulfates, alkyl glyceryl ether sulfates, acyl sarcosinates, and acyl N-methyl taurides.

- Further, suitable nonionic surfactants include polyoxyethylene carboxylic acid esters, fatty acid glycerol esters, fatty acid and ethoxylated fatty acid alkanolamides, certain block copolymers of propylene oxide and ethylene oxide, and block polymers of propylene oxide and ethylene oxide with propoxylated ethylenediamine. Also included are such semi-polar nonionic surfactants like amine oxides, phosphine oxides, sulfoxides, and their ethoxylated derivatives.

- Suitable cationic surfactants include the quaternary ammonium compounds in which typically one of the groups linked to the nitrogen atom is a C12-C18 alkyl group and the other three groups are short-chain alkyl groups which may bear inert substituents such as phenyl groups.

- Further, suitable amphoteric and zwitterionic surfactants which contain an anionic water-solubilizing group, a cationic group, and a hydrophobic organic group include aminocarboxylic acids and their salts, iminodicarboxylic acids and their salts, alkylbetaines, alkylamidopropylbetaines, sulfobetaines, alkylimidazolinium derivatives, certain quaternary ammonium compounds, certain quaternary phosphonium compounds and certain tertiary sulfonium compounds. Other examples of suitable zwitterionic surfactants can be found described in US-A-4005029, issued to Jones, at Columns 11-15, which are incorporated herein by reference.

- Further examples of anionic, nonionic, cationic and amphoteric surfactants which may be suitable for use in this invention are depicted in Kirk-Othmer, Encyclopedia of Chemical Technology, Third Edition, Vol. 22, pages 347-387, and McCutcheon's Detergents and Emulsifiers, North American Edition, 1983, which are incorporated herein by reference.

- Further cleaning adjuncts can include enzymes. Particularly preferred are amylases and proteases. Particularly preferred are proteases such as alkaline proteases, also denoted as subtilisins. Suitable examples include Savinase® , Alcalase®, and Esperase all from Novo Industri A/S, Denmark, and Maxacal and Maxatase ® from Gist Brocades, N.V., Netherlands.

- Bleaches can also be added to the compositions of this invention, preferably peroxygen bleaches such as percarbonate, perborate, and the salts thereof, e.g. sodium perborate monohydrate, and organic and inorganic peroxy compounds, such as peracids, e.g. perlauric acid, and potassium peroxymonosulfate (available from E.I.-du Pont de Nemours, Delaware, under the trade mark Oxone ® ). Additionally, bleach activators can be incorporated, such as tetraacetylethylenediamine (TAED), ketones or aldehydes.

- Yet other common detergent additives can be included in the formulas of this invention, such as dyes, pigments and colorants, exemplary of which are ultramarine blue (UMB) pigments, anthraquinone dyes, and Monastral dyes, which are manufactured by E.I. du Pont de Nemours, Delaware. Especially preferred is UMB to impart a pleasing color to the mull composition as well as to deliver a bluing effect on fabrics. Fabric softeners may be added to the inventive mulls. These fabric softeners are generally quaternary ammonium compounds and their salts, as disclosed in US-A-4250043, issued to Jones, and US-A-4339335, issued to Wixon, both of whose disclosures are incorporated herein by reference. Use of such fabric softeners is particularly favoured in the mulls of this invention due to the general absence of anionic surfactants in the mulls' formulations. Further, fragrances of various sorts, most of which are ketones or aldehydes containing substituted phenyl rings, can be added to the mulls. Also, corrosion-inhibition agents and anti-redeposition agents may be included in these mulls.

- As noted in the foregoing, because of the physical nature of the mull detergent compositions, packaging and delivery of these compositions into the wash water cannot be implemented efficiently by most current commercial detergent packaging systems. As a result preferred forms of this invention comprise a delivery system comprising (a) a water-soluble delivery pouch, which comprises a film prepared from at least one film-forming polymer and (b) an effective amount of a low temperature detergent mull which comprises a nonionic surfactant system and a builder.

- Particularly preferred films are castable, water-soluble films comprised of polyvinyl alcohols which have number average molecular weights from about 5,000 to 250,000. The polyvinyl alcohols generally have about 1 to 25% residual acetate groups, more preferably 5 to 20% residual acetate groups, and most preferably about 10 to 15% residual acetate groups. Additionally, such polymers as polyvinyl pyrrolidone, methyl cellulose, polyethylene oxide, gelatin and other film formers can be utilized. Plasticizers such as trimethylolpropane, glycerol, polyethylene glycol and others known to those skilled in the art can be included in the film to provide the film strength and flexibility required for producing, filling, shipping and storing the pouches prepared from these films. In addition other ingredients such as wetting agents, defoamers, and anti-blocking agents can be included in these films to aid in their manufacture and in the preparation of pouches made from these films

- The films employed can have a thickness of from 25 to 127 microns (1.0-5.0 mils), with the thickness and film material being selected to provide the optimum balance of film strength and cold water solubility. It has been found that films with a thickness of 38 to 89 microns (1.5-3.5 mils) produced from polyvinyl alcohol with about 12% residual acetate groups are preferred.

- It has been further found that when pouches are produced from these preferred films and stored in contact with the detergent mulls of this invention, significant losses of impact strength can occur. It has been found however, that the incorporation of small amounts of known film plasticizers into the detergent mull composition itself surprisingly minimizes this loss of impact strength of the films after storage in contact with'the detergent compositions. Thus, a further embodiment of this invention comprises a delivery system comprising (a) a water-soluble delivery pouch, and (b) an effective amount of a low-temperature-effective detergent mull which comprises a builder, a nonionic surfactant system and 30% or less, based on the weight of the surfactant system, of at least one ingredient that is suitable for use as a film plasticizer for the film used to form the water-soluble pouch.

- This invention is further exemplified by the examples set forth below which are intended to illustrate but not restrict the scope of the invention.

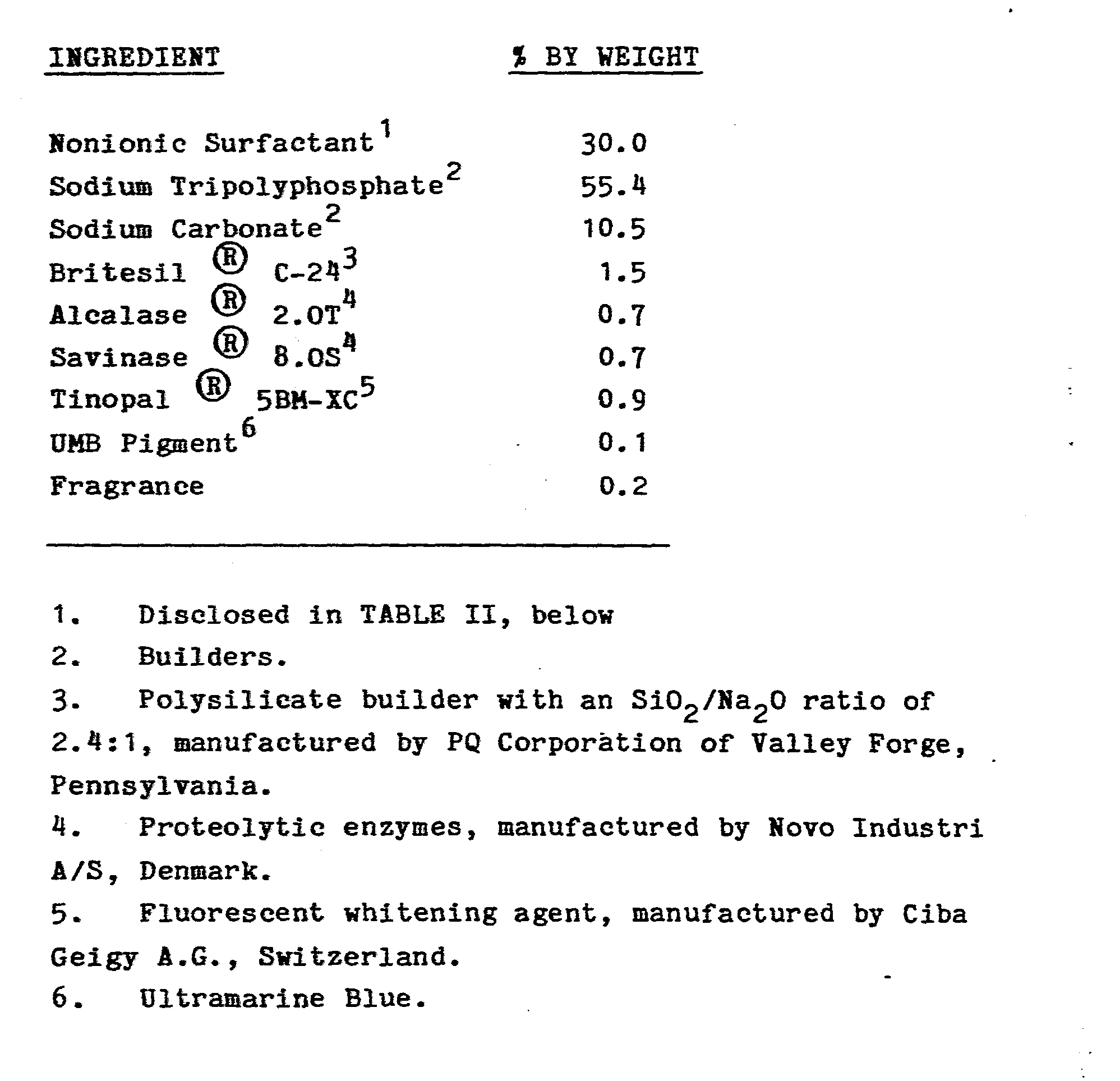

- The following detergent formula was used to prepare the mull detergent compositions in Examples 1-10:

-

- Approximately 2 kilograms of each of the 10 exemplified compositions in TABLE II were prepared by premixing the nonionic surfactants together and then mixing the surfactant system together with the remainder of the ingredients in a Hobart mixer. Relatively low shear mixing was used and a total mixing time of 15-30 minutes was sufficient to provide uniform distribution of the ingredients in the resulting mulls. The pour point of each surfactant mixture was measured using the basic procedure found in ASTM D97-66.

- After each composition was prepared, approximately 30 grams of each were placed in individual pouches prepared from Quiksol A film supplied by Polymer Films Inc. of Rockville, Connecticut, USA. The films were 38 microns (1.5 mils) thick and were composed of polyvinyl alcohol with an average molecular weight of about 96,000 and approximately 12% residual acetate groups. The mulls were enclosed in the films, which were heat sealed.

- The resulting pouches were then placed at 4.5°C (40°F) for 24-48 hours (to simulate storage by the consumer, such as in a garage), removed and their solubility in 4.5°C (400F) water was evaluated. This procedure involved placing the pouches in a washing machine containing 68 litres of water at 4.5°C (400F) and initiating a wash cycle using the "delicate" setting to control agitation. After ten minutes, the agitation was terminated, and the machine was drained and inspected for residual detergent. Residual detergent is determined by whether any residue remains which is visually discernible in the washing machine. This is a measure of the dissolution/dispersion rates of the mull compositions. The results are shown in TABLE II, below.

- Reviewing TABLE II, one can see that the composition of Example 1, which contains two surfactants, Neodol 23-6.5 and Neodol 25-9, which are considered to be water soluble by their manufacturer, failed to completely dissolve at 4.5QC (40°F) under the test conditions. In addition when this composition was stored at 21°C (700F) and added to wash water at 17°C (630F), it again failed to completely dissolve under the test conditions described previously. Example 4, by comparison, which contains Neodol 91-2.5, dissolved/dispersed completely in the cold, i.e. 4.50C (40°F) water even after storage at 4.50C (40°F). This was particularly surprising since this particular surfactant is considered by its manufacturer to be less soluble in water than both of the surfactants used in Example 1. Thus, surprisingly, adding a surfactant system that is apparently less soluble in water to the remaining components of Examples 1-10 improved the dissolution/dispersion rates of the mull compositions in cold water.

- Further examination of TABLE II shows that Examples 4, 6, 9 and 10, with surfactant systems with pour points less than or equal to about 2.2°C (36°F) completely dissolved/dispersed in 4.5°C (40°F) water under the test conditions described above. Thus, the applicants have concluded that the dissolution/dispersion rates of the mulls of this invention are related to the pour points of the surfactant systems in these mulls and that the pour points should be at least lower than the temperature of the water in which the mulls are placed to provide acceptable dissolution/dispersion rates in the water. Apparently, the examples which have the lower pour point surfactant systems maintain more fluidity in cold water, which facilitates their dispersion. It is surprising that these differences in fluidity of already viscous samples are more important than overall water solubility in controlling the rates of dissolution/dispersion of these compositions in cold water.

- Performance studies on cotton, cotton/polyester blends, and polyester fabrics soiled with a synthetic sebum or a synthetic clay soil (Performance Test I) show that reducing the pour point of the surfactant system does not reduce the cleaning efficacy of these compositions even if the HLB value is reduced to a level much lower than that normally prescribed for good detergency. Thus, the compositions of this invention provide good cleaning as well as good solubility/dispersibility characteristics. The cleaning performance was evaluated by washing swatches treated with these soils in water at 38°C (100°F) containing 100 ppm water hardness (as CaC03) with a molar ratio of Ca2+:Mg2+ of 3:1 and a concentration of 0.08% of the appropriate detergent mull composition in a commercial washing machine. The reflectance values of the swatches were measured before and after washing, and the Kubelka-Munk equation was used to calculate % soil removal.

-

- It was particularly surprising that Examples 6 and 10 performed so well, since they each contain a significant amount of Neodol 91-2.5, which is not merely considered insoluble by its manufacturer, but unsuitable for good detergency as well. Further surprising results were obtained with Example 10. Example 10 is a ternary system containing mixture of three nonionic surfactants, two of which have very low pour points (Neodol 91-2.5 and Surfonic JL-80X). On two fabrics, cotton and polyester, this ternary system had significantly better particulate (clay) soil removal, than the composition of Example 1, which was unexpected based on the HLB's of the surfactant systems.

- Selected examples based on the compositions of TABLE II were tested for performance at 4.50C (40°F), under the same conditions as the foregoing, except for temperature and the use of only cotton and polyester fabrics. The results for % soil removal of both sebum (oily) and clay (particulate) soils are shown below:

- The above results show that a combination of nonionic surfactants having a reduced pour point and reduced HLB values surprisingly demonstrated soil removal properties in a low temperature wash as good as or better than a single nonionic surfactant which one would expect to have better solubility and detergency than the combination.

- 50 kilogram quantities of mull detergent compositions were prepared using a ribbon blender and the formulas are summarized below. In Example 12, the water was added to the surfactant system before this system was mixed with the rest of the composition.

-

- The composition of Example 11 was observed to have phase separation after storage at room temperature. The separation was quantified by placing 1000 grams of the composition in a one-litre graduated cylinder for one week at room temperature and then removing and weighing the separated liquid phase that appeared on top of the remainder of the composition. It was found that weight of the liquid totaled 4.8% of the total composition. When the detergent of composition 12 was evaluated under the same conditions, 0.1% or less liquid phase separation was observed.

- Furthermore, 2 kilogram quantities of the detergent composition in Example 12 were prepared and tested for solubility as were Examples 1-10. The composition of Example 12 dissolved/dispersed completely in less than ten minutes in 4.5°C (400F) water.

- 2 kilogram quantities of mull detergent compositions were prepared using a Hobart mixer and their formulas are summarized below. Approximately 25 grams of each composition were placed in a 2 x 3 inch water-soluble pouch constructed from a 63 micron (2.5 mil) thick film comprised predominately of polyvinyl alcohol (number average molecular weight of about 10,000 and about 12% residual acetate groups) with 5% glycerol and 4% trimethylolpropane as plasticizers. The pouches were stored for nine weeks at 21°C/50% relative humidity (70°F/50%).

-

- After nine weeks of storage, the film from the pouches containing the composition of Example 13 was obviously brittle while the film from the pouches containing the composition of Example 14 was much more flexible. Impact strength measurements made on these films using a Rheos Total Energy Impact Strength Tester and testing conditions of 1.7°C/42% relative humidity (350F/42$) indicate that the films used with the composition in Example 14 had about five times more impact strength than the films used with the composition in Example 13. As previously discussed, this shows that the addition of the plasticizer directly to the mull minimises the loss of film impact strength when the film is exposed to the mull. This was unexpected and further shows the unobvious characteristics of the delivery system of this invention.

wherein the compositions have an average viscosity of about 10,000 - 100,000 centipoise (cps) at 25°C and at 6.25 revolutions per minute as measured on a Haake Rotoviscometer with an MVII sensor.

Claims (21)

wherein the average particle size of the solid components of the mull composition exceeds about 10 microns.

wherein the viscosity of the mull composition ranges from about 10,000 to 100,000 centipoise.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US59266084A | 1984-03-23 | 1984-03-23 | |

| US592660 | 1984-03-23 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0158464A1 true EP0158464A1 (en) | 1985-10-16 |

| EP0158464B1 EP0158464B1 (en) | 1989-07-19 |

Family

ID=24371570

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19850301979 Expired EP0158464B1 (en) | 1984-03-23 | 1985-03-21 | Low-temperature-effective detergent compositions and delivery systems therefor |

Country Status (11)

| Country | Link |

|---|---|

| EP (1) | EP0158464B1 (en) |

| JP (1) | JPS60212495A (en) |

| AR (1) | AR241466A1 (en) |

| AU (1) | AU575383B2 (en) |

| BR (1) | BR8501303A (en) |

| CA (1) | CA1284602C (en) |

| DE (1) | DE3571643D1 (en) |

| EG (1) | EG16786A (en) |

| ES (3) | ES8705022A1 (en) |

| MX (1) | MX164019B (en) |

| TR (1) | TR22756A (en) |

Cited By (37)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2603600A1 (en) * | 1986-09-08 | 1988-03-11 | Colgate Palmolive Co | HIGH FOAMING LIQUID DETERGENT COMPOSITIONS BASED ON ETHOXYL FATTY ALCOHOL AND METHODS OF USE THEREOF FOR CLEANING DIRTY TISSUES |

| EP0266199A2 (en) * | 1986-10-30 | 1988-05-04 | Unilever Plc | Liquid cleaning products |

| EP0284334A2 (en) * | 1987-03-24 | 1988-09-28 | The Clorox Company | Rinse soluble polymer film composition for wash additives |

| EP0295525A2 (en) * | 1987-06-15 | 1988-12-21 | Henkel Kommanditgesellschaft auf Aktien | Mechanical washing process |

| FR2619823A1 (en) * | 1987-08-31 | 1989-03-03 | Colgate Palmolive Co | NON-AQUEOUS LIQUID DETERGENT COMPOSITIONS FOR HIGH TEMPERATURE LAUNDRYING, AND APPLICATIONS THEREOF |

| US4874537A (en) * | 1988-09-28 | 1989-10-17 | The Clorox Company | Stable liquid nonaqueous detergent compositions |

| US4919834A (en) * | 1988-09-28 | 1990-04-24 | The Clorox Company | Package for controlling the stability of a liquid nonaqueous detergent |

| US4929380A (en) * | 1986-06-27 | 1990-05-29 | Henkel Kommanditgesellschaft Aug Aktien | Process for the preparation of a storage-stable liquid detergent composition |

| WO1991014765A1 (en) * | 1990-03-28 | 1991-10-03 | Unilever N.V. | Liquid cleaning products |

| US5080226A (en) * | 1990-07-18 | 1992-01-14 | Rhone-Poulenc Ag Company | Containerization system for agrochemicals and the like |

| FR2666348A1 (en) * | 1990-08-28 | 1992-03-06 | Nln Sa | Detergent in a sachet containing a predetermined amount of detergent for cleaning linen (clothes) |

| EP0513902A2 (en) * | 1991-05-17 | 1992-11-19 | Unilever N.V. | Liquid non-ionic surfactant blend and non-aqueous detergent compositions containing it |

| US5222595A (en) * | 1990-07-18 | 1993-06-29 | Rhone-Poulenc Ag Company | Bag in a bag for containerization of toxic or hazardous material |

| US5224601A (en) * | 1990-07-18 | 1993-07-06 | Rhone-Poulenc Ag Company | Water soluble package |

| US5280835A (en) * | 1990-05-02 | 1994-01-25 | Rhone-Poulenc Inc. | Laminated bags for containerization of toxic and hazardous materials |

| US5341932A (en) * | 1991-06-14 | 1994-08-30 | Rhone-Poulenc Ag Company | Aqueous formulations |