EP0069079A2 - Cushion with central passing aperture for cervical arthrosis sufferers, and procedure for construction - Google Patents

Cushion with central passing aperture for cervical arthrosis sufferers, and procedure for construction Download PDFInfo

- Publication number

- EP0069079A2 EP0069079A2 EP82830144A EP82830144A EP0069079A2 EP 0069079 A2 EP0069079 A2 EP 0069079A2 EP 82830144 A EP82830144 A EP 82830144A EP 82830144 A EP82830144 A EP 82830144A EP 0069079 A2 EP0069079 A2 EP 0069079A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- cushion

- internal

- polyurethane

- procedure

- construction

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47G—HOUSEHOLD OR TABLE EQUIPMENT

- A47G9/00—Bed-covers; Counterpanes; Travelling rugs; Sleeping rugs; Sleeping bags; Pillows

- A47G9/10—Pillows

- A47G9/1081—Pillows comprising a neck support, e.g. a neck roll

Definitions

- This invention concerns a cushion that offers relief to those suffering from cerebral arthrosis and also prevents the onset of related conditions.

- the aim of this invention is to supply a cushion coad- juvant in the therapy of cervical arthrosis, low in cost and of enhanced functionality.

- a cushion consisting of an internal structure, preferably made of expanded polyurethane, with internal springs, or of typical known materials, of the traditional shape but equipped with a central passing rectangular, square, circular, oval or any other shape aperture in which the sleeper's head may be inserted. At the same time, it holds the neck with no bending since it is supported by the perimetrical structure, in whatever position is assumed.

- said central aperture of the internal structure of the ucshion may be divided into two or more secondary apertures.

- said central aperture may be filled to a thickness less thah that of said perimetrical swelling.

- the perimetrical structure described may eventually have spacers on the opposite sides of any type.

- said spacers consist of several thread stitches applied, in correspondence with the internal part of the central passing aperture, between the sopposite lengths of the necessary lining containing said cushion.

- each cushion may be inserted in one or more transparent plastic bags (or not), placed beneath a press of known type and emptied of air.

- the open side or sides of the container bags are hot welded, with resulting vacuum or semi-vacuum packaging, as a function of the number of bags used.

Abstract

Cushion consisting of an internal structure, preferably made of expanded polyurethane, with internal springs or of typical known materials, of the traditional shape but equipped with a central passing rectangular, square, circular, oval or any other shape aperture in which the sleeper's head may be inserted. At the same time, it holds the neck with no vending since it is supported by the perimetrical structure, in whatever position is assumed.

Description

- This invention concerns a cushion that offers relief to those suffering from cerebral arthrosis and also prevents the onset of related conditions.

- It is known that the unnatural position of the neck during sleep, in contact with the more or'less swollen and hard cushions currently used leads frequently to the onset of cervical arthrosis, shown to be a wide-spread phenomenon today.

- The aim of this invention is to supply a cushion coad- juvant in the therapy of cervical arthrosis, low in cost and of enhanced functionality.

- This aim is achieved with a cushion consisting of an internal structure, preferably made of expanded polyurethane, with internal springs, or of typical known materials, of the traditional shape but equipped with a central passing rectangular, square, circular, oval or any other shape aperture in which the sleeper's head may be inserted. At the same time, it holds the neck with no bending since it is supported by the perimetrical structure, in whatever position is assumed.

- It is evident that in this way the use of the cushion - is not dependent on a precise position of the head relative to the structure.

- In one variant of the invention, said central aperture of the internal structure of the ucshion may be divided into two or more secondary apertures.

- In a further variant, said central aperture may be filled to a thickness less thah that of said perimetrical swelling.

- Furthermore, in order to prevent any deformation, the perimetrical structure described may eventually have spacers on the opposite sides of any type. In one of their simplest variants, said spacers consist of several thread stitches applied, in correspondence with the internal part of the central passing aperture, between the sopposite lengths of the necessary lining containing said cushion.

- With regard to the procedure for constructing the internal structures of the expanded polyurethane cushions, they are shaped using high frequency welders.

- However, it is known that expanded polyurethane cannot be hot welded because of thedanger of fire and also because of the fumes resulting from the increased temperature, and that the traditional high frequency welders have no weld effect. THerefore, when they are applied directly to the portions of said material, the welding of the internal parts of the cushions and the like is effected according to the present invention by using a counter-punch shaped as required. First there is a layer of 100% cotton (or synthetic fiber blend) material, then the polyurethane to be welded and a second layer of material as above, before the punch to give the welding shape. When the high frequency generators are then powered, equipped with electronic welders, the electromagnetic waves, passing through the two layers of material, easily and perfectly effect the welding of the polyurethane parts.

- Finally, once the cushion has been constructed, including the insertion of the internal polyurethane structures in the respective lining, the invention provides that each cushion may be inserted in one or more transparent plastic bags (or not), placed beneath a press of known type and emptied of air. At the same time the open side or sides of the container bags are hot welded, with resulting vacuum or semi-vacuum packaging, as a function of the number of bags used.

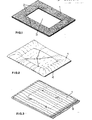

- A preferred embodiment of the invention is shown in the enclosed drawing in figures 1, 2 and 3.

-

- Figure 1 shows an axonometric view of the internal structure, in expanded polyurethane.

- Figure 2 shows the packaging with lining and eventual spacer points.

- Figure 3 shows the cushion in its final preparation, after passage under the press and welding of the plastic containers.

- The details of the drawings show

internal structure 1, in expanded polyurethane, prepared using the high frequency welding procedure, characterized by the perimetrical swellings 2 and thecentral passing aperture 3, saidstructure 1 being inserted inlining 4 and eventually blocked, withpassing spacer points 5 and then placed in single or multiple bag 6 of plastic materials and hot welded to effect an air seal. - Naturally, while the principle of the invention remains the same, the forms of realization and the details of construction may be varied widely from that reported here without going beyond the bounds of the invention.

Claims (7)

1. Cushion consisting of an internal structure, preferably made of expanded polyurethane, with internal springs, or of typical known materials, of'the traditional shape but equipped with a central passing rectangular, square, oval or any other shape aperture in which the sleeper's head may be inserted; at the same time, holding the neck with no bending since it is supported by the perimetrical structure, in whatever position is assumed.

2. Cushion as claimed in claim 1, wherein said central aperture of the internal structure of the cushion may be divided into two or more secondary apertures.

3. Cushion as claimed in the preceding claims, wherein said central aperture may be filled to a thickness less than that of said perimetrical swelling. '

4. Cushion as claimed in the preceding claims, characterized by the presence of spacers on opposite sides of the perimetrical structure to prevent deformations.

5. Cushion as claimed in the preceding claims, wherein said spacers consist of several thread stitches applied, in correspondence with the internal part of the central passing apertures, between the opposite lengths of the necessary lining containing said cushion.

6. Procedure for the construction of cushions shaped as in the preceding claims characterized by the use of high frequency welders, using a counter-punch shaped as required; first there is a layer of 100% cotton (or synthetic fiber blend) material, then the polyurethane to be welded and a second layer of material as above, before thepunc h to give the welding shape; when the high frequency generators are then powered, equipped with electronic welders, the electromagnetic waves, passing through the two layers of material, easily and perfectly effect the welding of the polyurethane parts.

7. Procedure for the construction of cushions shaped as in the preceding claims characterized by the insertion of the internal polyurethane structure in one or more plastic bags, followed by placement beneath a press and hot welding of the open side or sides, to effect a cav- uum or semi-vacuum packaging, as a function of the number of bags used.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| IT48755/81A IT1143204B (en) | 1981-06-25 | 1981-06-25 | CUSHION WITH CENTRAL THROUGH OPENING FOR CERVICAL ARTHROSIS AND CONSTRUCTION PROCEDURE |

| IT4875581 | 1981-06-25 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0069079A2 true EP0069079A2 (en) | 1983-01-05 |

| EP0069079A3 EP0069079A3 (en) | 1984-03-07 |

Family

ID=11268404

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP82830144A Withdrawn EP0069079A3 (en) | 1981-06-25 | 1982-05-27 | Cushion with central passing aperture for cervical arthrosis sufferers, and procedure for construction |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0069079A3 (en) |

| IT (1) | IT1143204B (en) |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0302426A1 (en) * | 1987-08-01 | 1989-02-08 | Auviso Videotechnische Werbe -Und Vertriebsgesellschaft Mit Beschränkter Haftung | Orthopaedic cushion |

| EP0486016A1 (en) * | 1990-11-14 | 1992-05-20 | Auviso Videotechnische Werbe -Und Vertriebsgesellschaft Mit Beschränkter Haftung | Orthopedic cushion |

| GB2269741A (en) * | 1992-07-24 | 1994-02-23 | Helen Katharine Macdiarmid | Safe baby seat |

| US6128797A (en) * | 1997-12-22 | 2000-10-10 | Shaffer; Timothy A. | Face down tanning and massage pad |

| US6931682B2 (en) * | 2003-10-14 | 2005-08-23 | Pacific Coast Feather Company | Pillow with central area having lower fill volume |

| US7346947B2 (en) * | 2003-10-14 | 2008-03-25 | Pacific Coast Feather Company | Pillow with central area having lower fill volume |

Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3400413A (en) * | 1966-12-13 | 1968-09-10 | Grossa Elinor La | Contour pillow |

| CH521740A (en) * | 1970-03-12 | 1972-04-30 | Nishikawa Sangyo Co Ltd | Children's pillow |

| DE2145591A1 (en) * | 1970-10-29 | 1972-05-04 | Ford Werke AG, 5000 Köln | Decoratively designed cover |

| US3848281A (en) * | 1974-01-23 | 1974-11-19 | D Mathews | Apertured article and protective cover therefor |

| US3983587A (en) * | 1975-09-23 | 1976-10-05 | Gorran Jody A | Wheel or geriatrics chair cushion |

| GB2030449A (en) * | 1978-10-03 | 1980-04-10 | Condor | Orthopaedic pillow |

| FR2466406A1 (en) * | 1979-10-02 | 1981-04-10 | Cavicchia Fiorella | Packing bulky articles, e.g. cushions and mattresses, under vacuum - in plastic envelopes, to give smallest possible bulk, to aid transportation |

| JPS5653028A (en) * | 1979-10-09 | 1981-05-12 | Tachikawa Spring Co Ltd | Production of sheet trim cover having ordinary polyurethane welded thereto |

| GB1594111A (en) * | 1978-05-23 | 1981-07-30 | Olivelark Ltd | Floatation cushions |

-

1981

- 1981-06-25 IT IT48755/81A patent/IT1143204B/en active

-

1982

- 1982-05-27 EP EP82830144A patent/EP0069079A3/en not_active Withdrawn

Patent Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3400413A (en) * | 1966-12-13 | 1968-09-10 | Grossa Elinor La | Contour pillow |

| CH521740A (en) * | 1970-03-12 | 1972-04-30 | Nishikawa Sangyo Co Ltd | Children's pillow |

| DE2145591A1 (en) * | 1970-10-29 | 1972-05-04 | Ford Werke AG, 5000 Köln | Decoratively designed cover |

| US3848281A (en) * | 1974-01-23 | 1974-11-19 | D Mathews | Apertured article and protective cover therefor |

| US3983587A (en) * | 1975-09-23 | 1976-10-05 | Gorran Jody A | Wheel or geriatrics chair cushion |

| GB1594111A (en) * | 1978-05-23 | 1981-07-30 | Olivelark Ltd | Floatation cushions |

| GB2030449A (en) * | 1978-10-03 | 1980-04-10 | Condor | Orthopaedic pillow |

| FR2466406A1 (en) * | 1979-10-02 | 1981-04-10 | Cavicchia Fiorella | Packing bulky articles, e.g. cushions and mattresses, under vacuum - in plastic envelopes, to give smallest possible bulk, to aid transportation |

| JPS5653028A (en) * | 1979-10-09 | 1981-05-12 | Tachikawa Spring Co Ltd | Production of sheet trim cover having ordinary polyurethane welded thereto |

Non-Patent Citations (1)

| Title |

|---|

| PATENTS ABSTRACTS OF JAPAN, vol. 5, no. 112 (M-79)[784] 21st July 1981, & JP - A - 56 - 53 028 (TACHIKAWA SPRING K.K.) 12-05-1981 * |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0302426A1 (en) * | 1987-08-01 | 1989-02-08 | Auviso Videotechnische Werbe -Und Vertriebsgesellschaft Mit Beschränkter Haftung | Orthopaedic cushion |

| EP0486016A1 (en) * | 1990-11-14 | 1992-05-20 | Auviso Videotechnische Werbe -Und Vertriebsgesellschaft Mit Beschränkter Haftung | Orthopedic cushion |

| GB2269741A (en) * | 1992-07-24 | 1994-02-23 | Helen Katharine Macdiarmid | Safe baby seat |

| US6128797A (en) * | 1997-12-22 | 2000-10-10 | Shaffer; Timothy A. | Face down tanning and massage pad |

| US6931682B2 (en) * | 2003-10-14 | 2005-08-23 | Pacific Coast Feather Company | Pillow with central area having lower fill volume |

| US7346947B2 (en) * | 2003-10-14 | 2008-03-25 | Pacific Coast Feather Company | Pillow with central area having lower fill volume |

Also Published As

| Publication number | Publication date |

|---|---|

| IT1143204B (en) | 1986-10-22 |

| IT8148755A0 (en) | 1981-06-25 |

| EP0069079A3 (en) | 1984-03-07 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US2962158A (en) | Means and method of packaging articles | |

| AU679410B2 (en) | Mattress border assembly and method of making same | |

| US4184237A (en) | Method of making a cushion construction | |

| GB2048161B (en) | Process for manufacturing a padding for cushions and the like | |

| EP0069079A2 (en) | Cushion with central passing aperture for cervical arthrosis sufferers, and procedure for construction | |

| US4007503A (en) | Pillow and case of physiologically advantageous shape | |

| DE2620160C3 (en) | Packaging for a stack of uniformly shaped units of food | |

| US4430765A (en) | Flame retardant mattress | |

| DE1960496A1 (en) | Chest pad | |

| ZA843610B (en) | A valve arrangement in a bag consisting of two welded sheets | |

| USD259594S (en) | Embossed plastic sheet material | |

| US20080105366A1 (en) | Method for producing plastic products with reinforced heat sealed joints | |

| GB9022036D0 (en) | A pleated box body made of cardboard,corrugated cardboard or other material in sheet form suitably cut and folded,a box incorporated such a box body | |

| US4090908A (en) | Apparatus for making water bed mattresses | |

| EP0574047A3 (en) | ||

| GB2080116A (en) | Drainage bag | |

| EP0152272A3 (en) | Heated waterbed | |

| USD283988S (en) | Fuel gauge for propane tank | |

| IT1238272B (en) | Packaging for cushions and mattresses | |

| USD286622S (en) | Thermal indicator for vacuum sterilizer test packs | |

| JPS607142Y2 (en) | filled panel | |

| GB2248796B (en) | Ultrasonic welding in pouch manufacture | |

| JPH0343358A (en) | Filling and sealing bag and film for use in forming same | |

| GB2235921B (en) | Packaging made of cardboard,corrugated cardboard or other material in sheet form with zigzag folding lines,and the corresponding blank | |

| JP2782807B2 (en) | Manufacturing method of drip absorbing sheet |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR GB LI NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR GB LI NL SE |

|

| 17P | Request for examination filed |

Effective date: 19840831 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 19860826 |