CN1638683A - 抹布 - Google Patents

抹布 Download PDFInfo

- Publication number

- CN1638683A CN1638683A CNA038053993A CN03805399A CN1638683A CN 1638683 A CN1638683 A CN 1638683A CN A038053993 A CNA038053993 A CN A038053993A CN 03805399 A CN03805399 A CN 03805399A CN 1638683 A CN1638683 A CN 1638683A

- Authority

- CN

- China

- Prior art keywords

- adhesive

- rag

- cleaning

- backing spare

- rag structure

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B37/00—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding

- B32B37/12—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding characterised by using adhesives

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L13/00—Implements for cleaning floors, carpets, furniture, walls, or wall coverings

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L13/00—Implements for cleaning floors, carpets, furniture, walls, or wall coverings

- A47L13/10—Scrubbing; Scouring; Cleaning; Polishing

- A47L13/16—Cloths; Pads; Sponges

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L25/00—Domestic cleaning devices not provided for in other groups of this subclass

- A47L25/005—Domestic cleaning devices not provided for in other groups of this subclass using adhesive or tacky surfaces to remove dirt, e.g. lint removers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/12—Layered products comprising a layer of synthetic resin next to a fibrous or filamentary layer

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B3/00—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar form; Layered products having particular features of form

- B32B3/26—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar form; Layered products having particular features of form characterised by a particular shape of the outline of the cross-section of a continuous layer; characterised by a layer with cavities or internal voids ; characterised by an apertured layer

- B32B3/28—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar form; Layered products having particular features of form characterised by a particular shape of the outline of the cross-section of a continuous layer; characterised by a layer with cavities or internal voids ; characterised by an apertured layer characterised by a layer comprising a deformed thin sheet, i.e. the layer having its entire thickness deformed out of the plane, e.g. corrugated, crumpled

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2305/00—Condition, form or state of the layers or laminate

- B32B2305/10—Fibres of continuous length

- B32B2305/20—Fibres of continuous length in the form of a non-woven mat

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B37/00—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding

- B32B37/0076—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding characterised in that the layers are not bonded on the totality of their surfaces

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/24—Structurally defined web or sheet [e.g., overall dimension, etc.]

- Y10T428/24033—Structurally defined web or sheet [e.g., overall dimension, etc.] including stitching and discrete fastener[s], coating or bond

- Y10T428/24041—Discontinuous or differential coating, impregnation, or bond

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/24—Structurally defined web or sheet [e.g., overall dimension, etc.]

- Y10T428/24479—Structurally defined web or sheet [e.g., overall dimension, etc.] including variation in thickness

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/24—Structurally defined web or sheet [e.g., overall dimension, etc.]

- Y10T428/24479—Structurally defined web or sheet [e.g., overall dimension, etc.] including variation in thickness

- Y10T428/24521—Structurally defined web or sheet [e.g., overall dimension, etc.] including variation in thickness with component conforming to contour of nonplanar surface

- Y10T428/24537—Parallel ribs and/or grooves

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/24—Structurally defined web or sheet [e.g., overall dimension, etc.]

- Y10T428/24802—Discontinuous or differential coating, impregnation or bond [e.g., artwork, printing, retouched photograph, etc.]

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/28—Web or sheet containing structurally defined element or component and having an adhesive outermost layer

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T442/00—Fabric [woven, knitted, or nonwoven textile or cloth, etc.]

- Y10T442/20—Coated or impregnated woven, knit, or nonwoven fabric which is not [a] associated with another preformed layer or fiber layer or, [b] with respect to woven and knit, characterized, respectively, by a particular or differential weave or knit, wherein the coating or impregnation is neither a foamed material nor a free metal or alloy layer

- Y10T442/2738—Coating or impregnation intended to function as an adhesive to solid surfaces subsequently associated therewith

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T442/00—Fabric [woven, knitted, or nonwoven textile or cloth, etc.]

- Y10T442/20—Coated or impregnated woven, knit, or nonwoven fabric which is not [a] associated with another preformed layer or fiber layer or, [b] with respect to woven and knit, characterized, respectively, by a particular or differential weave or knit, wherein the coating or impregnation is neither a foamed material nor a free metal or alloy layer

- Y10T442/2738—Coating or impregnation intended to function as an adhesive to solid surfaces subsequently associated therewith

- Y10T442/2754—Pressure-sensitive adhesive

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T442/00—Fabric [woven, knitted, or nonwoven textile or cloth, etc.]

- Y10T442/60—Nonwoven fabric [i.e., nonwoven strand or fiber material]

Abstract

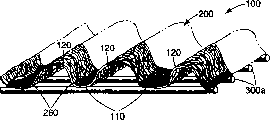

本发明提供了一种用于捕集普通灰尘和较重颗粒如沙子的抹布(100),它包含沿低谷部分(110)粘合在背衬件(300)上的第一揩拭件(200),其中揩拭件(200)包含许多分立峰(120)。在一种实施方式中,粘合剂(250)施涂在低谷部分(110),而不是施涂在峰(120)上。

Description

发明领域

本发明涉及一种清扫用品,它特别适用于捕集普通灰尘或污垢,也特别适用于捕集重的颗粒如沙子。

发明背景

擦布和其他清扫用品已经存在很长时间了,但对这些用品的显著改进却非常鲜见。多数清扫用品或抹布要么用织造片制作,要么用非织造片制作。人们都用手直接地或握住拖把柄末端沿所需方向清扫灰尘或污垢。灰尘或污垢收拢后,使用者一般使抹布卷曲,将拢好的灰尘或污垢收集起来,然后抖落到垃圾筒里。这个简单的过程每天都重复着成千上万次。使用者为拾起较大的颗粒如沙子,往往要将该过程重复数次才能将收拢的所有沙子或较重颗粒捡起来。

PCT专利公开WO 01/41622,即题为“具有无规宏观三维特征的无孔清洁板材(Non-apertured Cleaning Sheets Having Non-Random Macroscopic Three-Dimensional Character)”的专利介绍了具有凹凸区域的片。片中可以加入某些添加剂,以提高性能。这些添加剂可以是石蜡、病虫害防治组分、杀菌剂和其他组分,它们宜大致均匀地嵌入片中至少一个独立的连续区域。但是,据信此专利所介绍的清洁片因以突起部分收集灰尘和颗粒,当使用者连续擦拭表面时容易刮损表面。例如,据信粘在突起部分的沙粒会刮伤木质表面,显然这不是所希望的。

另外,日本特许公开公报专利申请昭9-164110总体上介绍了一种包含粘合剂的清洁布。在至少一个实施方式中,如图3(A)-3(B)所示,清洁布的两个可压缩层之间含有一层粘合剂层。在图3(A)中,清洁布借助工具清洁表面,粘合层不与表面接触。在图3(B)中,用力压工具,粘合层就与表面接触,由此拾起颗粒,如沙和灰尘。撤去压力后,可以预见清洁布会回复到图3(A)所示位置。尽管这种类型的清洁布具有某些用途,但使用者似乎要完成一种特定的动作才能使粘合剂发挥作用。在通常的地板清扫过程中,粘合剂似乎也难以从地板上清除较大颗粒,而且需要施加额外的力,粘合剂才能与灰尘和碎屑接触。至于清洁布的组成或压力强度、粘合剂与清洁布工作表面之间的高度差,或者粘合剂的类型,该专利没有提供详情。

PCT专利公开WO 01/80705也介绍了一种含有颗粒容留穴的清洁片。该清洁片的制备方法是,在非织造底层上涂敷粘合剂,然后在粘合层上层压多孔非织造布。颗粒容留孔的横截面积为1-10mm2,所述清洁片常包含0.1-5%粘合剂(以清洁片总重计)。在另一实施方式中,所述清洁片可由一个稍厚的织物材料单层形成,这种材料的至少一个主表面上含有孔穴。据信,由于粘合剂量太少,此专利所介绍的清洁片层在突起部位收集灰尘和颗粒,因此使用者连续擦拭表面时会刮伤表面。此外,由于凹陷穴是不连续的,因而抹布前部漏掉的灰尘没有回到抹布的路径,抹布后部无法收集它。

另一日本审定公报专利申请3231993介绍了一种清洁布,它包含非织造布做成的基材、两面涂有压敏粘合剂的中间片和由多孔网丝构成的表面片。多孔表面片通过双面涂有粘合剂的中间片粘着到基材上。清洁片具有第一和第二区域,其中第二区域具有捕集灰尘的粘性表面,第一区域的表面要么没有粘性,要么粘性比第二区域小。第一区域沿厚度方向的弹性比第二区域的弹性高。清洁片不具有尘粒与粘合剂接触的连续路径,因此,清洁片前部漏掉的灰尘没有回到清洁片的通道,无法为清洁片后部收集。另一种实施方式介绍的是,冲压出非织造布盘或条,以指定间隔将它们粘着到中间粘性片上,而不需要用表面卷材片。尽管此实施方式能更有效地利用清洁片的粘性区,但据信此清洁片难以生产,而且不会很牢固。至于该清洁片各组分的组成、第一和第二区域的弹性、清洁布的粘性面与工作面之间的高度差、粘合剂类型或清洁片的性能特征,该专利没有提供详情。

上述及其他已知抹布都有一个或多个缺点,因此提供一种能克服这些缺点的新抹布将是十分有益的。

附图简介

下面将结合附图介绍本发明,其中:

图1-6是本发明抹布结构的高位倾角侧视图。

图7和8是本发明实施方式中抹布结构的高位倾角侧视图,所述抹布结构没有衬底。

图9-11是制造本发明抹布结构的过程示意图。

图12是本发明实施方式中抹布结构的放大顶视照片(约2倍放大)。

图13是本发明实施方式中的抹布结构用来清扫颗粒后的放大顶视图(约2倍放大)。

发明详述

本发明总体上涉及能用来清扫大大小小的尘粒、沙粒和其他污染物的抹布。该抹布具有三维结构,包含交替出现的峰谷,并且至少在一个实施方式中,谷里涂有粘合剂。与已知抹布不同,所述粘合剂通常与要擦拭的表面接触,因而能收集大大小小的尘粒、沙粒等。通过这种方式,使用者无须在擦拭或清洁过程结束时增加一步操作,使粘合剂与灰尘和沙子接触。通过适当设计抹布,可使粘合剂与表面充分接触,从而拾起沙子和其他重颗粒,但粘着强度不会强到抹布与表面间的摩擦系数过高,以至于使擦拭变得困难。本发明抹布的上述及其他优点,还有制造和使用这种抹布的方法,将在下面更加详细地讨论。

A.抹布的物理性质

本发明抹布的一个实例示于图1。该抹布具有三维形貌,揩拭面包含许多被低谷分隔的峰或突起区域。在低谷部分涂有粘合剂,或者至少有某些粘性的物质如软蜡或粘胶,但峰上没有涂。或者,如果粘合剂开始涂敷在整个抹布表面上,则可以峰上的粘合剂失去粘性,方法如在抹布表面的峰上,也许还有低谷的一部分上施涂诸如二氧化钛或碳酸钙。

峰谷宜以规则方式排列。例如,峰或突起区域可按成排地平行连续排列,以低谷将其分隔,如图1-8所示。或者,峰或突起区域可以直线栅格形式排列,使突起区域呈矩形或方形或其他图案和形状,包括(但不限于)菱形(图12和13)、圆形、椭圆形、三角形、泪珠形、六角形和八角形。峰和谷也可以形成不规则图案,但由于峰一般是通过辊或其他工具形成的,这种不规则图案将周期性重复出现,所以最后的排列方式实际上是重复的不规则图案,或者说半无规图案。峰高一般是一致的,在约0.25-5mm范围内,宜在约1.5-3.9mm范围内。对于峰或突起区域被低谷分隔成直线栅格的情况,如图12和13所示实施方式,单个峰或突起区域的表面积在约9-250mm2范围内。对于峰或突起区域被低谷分隔成平行连续行的波纹样品,如图1-8所示样品,峰或突起区域的表面积在约150-450mm2范围内(测定表面积约为645mm2的一段抹布获得的数据)。

峰间谷宽约1-40mm。例如,图1所示距离A和图12所示距离B约为1-15mm。图12所示距离C约为0.9-4mm。图12所示距离D约为4-40mm。这些样品的尺寸通过光学显微镜测定,然后通过对所得显微照片进行成像分析。

许多抹布结构适用于本发明情境。在第一种实施方式中,如图1所示,抹布结构100包含揩拭件200和背衬件300,它们中间是粘合层250,在谷底区110将揩拭件200与背衬件300粘合在一起。在抹布上施加压力(在加热或不加热情况下)至少形成谷110,或许同时形成120(例如用阴/阳式滚筒时)的区域,粘合层250中的粘合剂将渗透到第一揩拭件200的谷110上,并充分露出来,使它能够粘住颗粒,如沙子和灰尘。因此在这些谷中,抹布截面包含第一揩拭件200、背衬件300和粘合层250。

抹布件200可以是针织、织造纤维材料,宜为非织造纤维材料。背衬件300可以针织或织造纤维、非织造卷材、热塑性膜或它们的层合物。当背衬件300为非织造或针织或织造织物时,它也可以作为第二揩拭件。揩拭件200和背衬件300宜连续,即揩拭件和背衬件都不包含比这些构件的纤维在形成这些构件时随机形成的空隙更大的孔、缝隙或沿着Z方向(即厚度或高度方向)延伸的沟道。此外,揩拭件和背衬件各自宣单独形成整体卷材或膜结构。在图1所示实施方式中,当背衬件300是密度较大的非织造或针织或织造织物或膜时,揩起来的颗粒可进入并保留在峰120与背衬件300之间形成的腔室130中。发生这种情况是因为粘在粘性区的颗粒受推进入相邻腔室,或者因为颗粒在揩起来的过程中钻入揩拭件。即使背衬件是密度较小的非织造布,但由于粘合层250的原因,也会在某种程度上发生这种情况。不管是哪种情况,我们相信本实施方式中的抹布能将颗粒收集在开口腔室中是一个显著的优点。

在第二种实施方式中,如图2和3所示,揩拭件200和背衬件300和300a都粘合在谷110上,粘合剂260局部施涂在这些低谷中。在此实施方式中,揩拭件200和背衬件300可通过粘合层粘合在一起,如图1实施例所述。或者,热塑性膜或许多间距很小的丝300a(示于图3)可直接粘合在揩拭件200上,形成背衬件300。另一种方式是通过热粘合或超声粘合方法将背衬件300粘合在揩拭件200上。尽管此结构可能需要更昂贵的工具(例如以与低谷相匹配的特定方式施涂粘合剂的特殊模具),所得结构将有更多的粘合剂粘着尘粒、沙粒、碎屑等,因此效果可能特别好。

在第三种实施方式中,如图4所示,揩拭件200和背衬件300通过谷110粘合在一起,粘合剂260施涂在揩拭件的几乎所有暴露面上。但是,整个表面上都有粘合剂的抹布将难以在表面上移动,因为粘合剂容易使整个抹布粘结在表面上。因此,宜通过至少在抹布的部分区域去粘来对抹布进行改性,特别是在峰120上,使得基本上只有谷的粘合剂保持粘性,从而能够粘着沙、灰尘和其他颗粒。本实施方式的一个潜在优点是,粘合剂260除施涂在谷底之外,还有可能存在于峰120的侧面125上,因此有更多的粘性表面粘着尘粒、沙粒、碎屑等。合适的去粘剂包括无机颗粒,如二氧化钛、碳酸钙、氧化硅、粘土和滑石。使用去粘剂的方法可以是简单地将抹布搁在去粘剂上,使峰上暴露的粘合剂与去粘剂接触。

有选择地去除峰上的粘性的其他试剂包括非粘性有机材料,如矿物油、结晶蜡、低粘性底胶涂料和聚烯烃聚合物及共聚物,如乙烯-乙烯乙酸酯。这些材料可通过挂胶方法,以流体如溶液、分散液、乳液、可辐射固化单体和低聚物,以及热熔体的形式施涂。对峰进行选择涂覆也可以通过低角喷涂完成,使谷留在峰的影子中。有选择地脱去整个揩拭件表面都涂有粘合剂的抹布峰上的粘性的另一种方法是,选择活化施涂在谷中的粘合剂。可活化粘合剂的例子包括热活化粘合剂(例如,可参见PCT专利公开WO02/04548)和增塑剂活化粘合剂(例如,可参见PCT专利公开WO00/56830)非粘性聚合物。这些非粘性聚合物可施涂在抹布整个表面上,然后通过在谷中加热或施用增塑流体来有选择地使谷带上粘性。这些材料也可以粉末形式滴在谷中,一旦固定后,就通过加热或施用增塑流体来加以活化。或者,可将粘性聚合物施涂在整个抹布表面上,然后通过粘合剂的辐射诱导交联有选择地使峰失去粘性。

在第四种实施方式中,如图5所示,抹布结构100包含揩拭件200和背衬件300,中间夹着粘合层250,在谷区110将抹布件200与背衬件300粘合在一起。此实施方式与图1-4所示实施方式不同的是,峰120底下的腔室130包含松散堆积的纤维,而在前面的实施方式中这里只是空腔。如图1所示实施方式所述,在此实施方式中,粘合剂渗过第一揩拭件200,充分进入谷110,使之能粘住颗粒如沙子和灰尘。本实施方式的一个优点是,由于腔室130包含纤维,峰120在外加压力下不那么容易坍塌。这种压力可以是,例如,将抹布卷成一卷或堆在箱子中时加在抹布材料上的压力,或者就是使用者擦拭待清洁表面时下推引起的压力。如果峰坍塌,则粘合剂可能无法从揩拭件表面充分凹进去,清洁布会粘在待清洁表面上,从而对揩拭造成一定程度的牵拉或阻力,这是不希望发生的。

在第五种实施方式中,如图6所示,揩拭件200和背衬件300通过谷110粘结在一起,粘合剂260局部施涂在这些谷中。类似于图5所示实施方式,在此实施方式中,峰120下面的腔室130包含松散堆积的纤维,因此同样具有上述优点。在此实施方式中,揩拭件200和背衬件300通过图5所示实施方式中所述粘合层粘合在一起。或者,热塑性膜或许多间距很小的丝(未示出)可直接粘合在揩拭件上,形成背衬件。另一种方式是通过热粘合或超声粘合方法将背衬件粘合在揩拭件上。类似于图2和3所示实施方式,图6所示抹布结构也将有更多的粘合剂粘着尘粒、沙粒、碎屑等,因此效果可能特别好。

图7所示为本发明的第六种实施方式,它类似于图4所示实施方式,不同之处在于揩拭件200上没有粘合背衬件。成型揩拭件具有足以保持其形状的整体性,而不需要额外的背衬件。揩拭件可由纤维形成,所述纤维包含足够量的粘合剂纤维(如套-芯型双组分粘合剂纤维),得到具有足够结构刚性的非织造卷材,因而不需要额外的背衬件。或者,抹布也可以这样成型,在足够的热量和压力下,在非织造揩拭件的谷或凹陷区熔化一部分纤维,将揩拭件(例如聚丙烯纤维非织造卷材)粘合到结构背衬件上,然后再从揩拭件上清除背衬,其中所述结构背衬件由对揩拭件粘性不好的材料制成。在此实施方式中,粘合剂260局部施涂在谷110中。除了成本可能较低外,本特定抹布实例的另一个优点是它具有开放腔室130,里面可方便地充填添加剂如油、香粉、肥皂、洗涤剂等。然后可将背衬件粘合到揩拭件上,以便将添加剂保留在腔室130中。

图8所示为本发明的第七种实施方式,它类似于图6所示实施方式,不同之处在于揩拭件200上没有粘合背衬件。类似于图7所示揩拭件,本实施方式中的成型揩拭件具有足以维持其形状的结构整体性,而不需要额外的背衬件。

本发明揩拭结构中的揩拭件可以是针织或织造织物,也可以是非织造卷材。所述揩拭件宜为非织造卷材。非织造卷材可用任何合适的熔融成型或机械成型工艺制备。例如,非织造卷材可以通过梳纺、纺粘、水刺、熔吹、空气铺网、起皱形成,或通过本领域已知其他工艺制备。本发明揩拭件的优选组分包括非织造卷材,它由常用来形成纤维的一种或多种热塑性聚合物制备。合适的热塑性聚合物可选自聚烯烃(如聚乙烯、聚丙烯和聚丁烯)、聚酰胺(如尼龙6、尼龙6/6和尼龙10)、聚酯(如聚对二苯甲酸乙二酯)、含丙烯酸单体的共聚物,和它们的混合物及共聚物。半合成纤维(如乙酸纤维)、天然纤维(如棉花)、再生纤维(如人造丝),其他非热塑性纤维也可与热塑性纤维混合。纤维的但尼尔一般约为2-32,更宣约为5-15。揩拭件的基重宜为约10-90g/m2,更宜约为15-60g/m2。

本发明抹布结构的背衬件可以是针织或织造纤维、非织造卷材、纸、塑料膜或她们的层合物。所述背衬件可以永久性或临时性粘合到揩拭件上。当背衬件是非织造卷材,或针织或织造织物时,它可以作为第二揩拭件。背衬件宜为类似于上述用于揩拭件的非织造卷材。非织造背衬件的基重可以在上面介绍非织造揩拭件时所提到的范围内,但基重较轻的非织造布可使更多的粘合剂渗透背衬件,到达揩拭件相反的面,这减少了揩拭件谷中粘着灰尘和沙子的粘合剂的量。因此,用于背衬件的非织造布宜具有超过15-20g/m2的基重。

如果用塑料膜作背衬件,则可以采用聚烯烃(如聚丙烯或聚乙烯)、聚酰胺、聚酯或其他膜。膜厚约为0.012mm(0.5mil)-0.075mm(3mil)。如果膜通过挤压粘合到非织造揩拭件上,则非织造揩拭件与膜背衬件由相容材料组成非常重要,这样才能使二者充分粘合。

适用于本发明的粘合剂包括在室温下呈粘性的任何粘合剂,既包括原本就有粘性的粘合剂,也包括原本没有粘性,但受到激发后变得有粘性的粘合剂。合适的粘合剂包括压敏粘合剂,包括基于丙烯酸酯、聚硅氧烷、聚α烯烃、聚异丁烯、橡胶嵌段共聚物(如苯乙烯/异戊烯/苯乙烯和苯乙烯/丁二烯/苯乙烯嵌段共聚物)、苯乙烯-丁二烯橡胶、合成异戊烯、天然橡胶的材料,以及它们的混合物。压敏粘合剂可从溶剂、水中施涂,可在辐射下聚合,或进行热熔处理。这些压敏粘合剂可以交联,也可以不交联。交联可通过很成熟的方法进行,包括化学法、离子法、物理法或辐射诱导法。如果将粘合剂推过揩拭件,则宜用低粘性材料。为提高粘合剂沉积到揩拭件谷之后的粘着强度,可以进行一定的交联。为了既获得利于处理的低粘性,又具有较好的粘着强度,宜采用物理交联、离子交联或某种形式的后交联。粘合剂的后交联可在辐射下进行,如电子束辐射或高强度紫外线(UV)辐射。对于UV交联,宜在聚合物主链上加入吸光基团,以利于交联反应的进行。美国专利4737559(Kellen等)介绍了这种UV交联粘合剂的例子。物理或离子交联法的优点是该过程热可逆,因而特别适用于热熔过程。物理交联粘合剂包括基于橡胶嵌段共聚物的粘合剂。合成橡胶嵌段共聚物的例子包括Kration聚合物公司(Houston,Texas)生产的KratonTM和Exxon-Mobil(Houston,Texas)公司生产的VectorTM。这些嵌段共聚物一般与增粘剂和/或油混合,形成压敏粘合剂。有关这些类型的粘合剂的详细配方见《压敏粘合剂技术手册》,第2版,第13章(D.Satas编,Van Nostrand Reinhold出版社,N.Y.)。其他物理交联粘合剂包括接枝到聚合物上的大分子单体,见美国专利5057366(Husman等)。

适用于本发明的粘合剂在干湿条件下均可具有粘性。在湿润条件下具有高粘性的粘合剂见述于PCT专利公开WO 00/56828。压敏粘合剂也可以从水中以乳胶或分散液的形式施涂。如《压敏粘合剂技术手册(Pressure-Sensitive AdhesiveTechnology)》第2版(D.Satas编,Van Nostrand Reinhold出版社,N.Y.,1989)所述,这些粘合剂可以基于聚合物,如天然橡胶、丙烯酸酯类、苯乙烯-丁二烯类和乙烯基醚类。特别是当直接施涂在多孔、织造或非织造基底上时,纯乳胶粘合剂的粘性不一定要强到防止它过多地渗到基底上。尽管乳胶粘合剂的粘性和流动性可以通过材料中固体的含量来控制,但用增稠剂配制乳胶也许更有利。增稠剂通常归为水溶性聚合物或相关的增稠物质。它们的性质和作用机理见《乳化聚合反应和乳化聚合物(Emulsion Polymerization and EmulsionPolymers)》,第13章,第455页(P.Lovell和M.El-Aasser编,John Wiley & Sons,NY,1997)。如《压敏粘合剂技术手册》第2版(D.Satas编,Van Nostrand Reinhold出版杜,N.Y.,1989),第16章,第473页所述,对于压敏粘合剂,选择增稠剂时要特别谨慎,不能让它影响粘合剂的性质。

粘合剂的用量取决于若干因素,包括粘合剂的粘性、粘合剂必须挤到揩拭件上的程度、揩拭件和背衬件的特点(特别是粘合剂能推过每个组件的量)、粘合剂粘着到表面上的强度(太强则使揩拭困难)和其他因素。粘合剂的用量要足以使抹布能够捕集各种形状、密度和大小的颗粒,如棉绒、灰尘、毛发、沙子、食物碎粒、沙砾、小树枝、叶子等,但又不能太多,以免产生牵拉阻力,使揩拭变得困难,或者转移到正在清洁的表面上。粘合剂可以涂成连续层,也可以涂成非连续层,并且可以用本领域已知的各种方法施涂,如条纹涂布、花样涂布、喷涂、网印涂布等。抹布结构通常包含约10-200重量%的粘合剂,更宜包含约30-130重量%的粘合剂,含量以输入非织造揩拭件重量计(或者,如果存在背衬件,以输入非织造揩拭件和背衬件总重计)。此外,有粘合剂与没有粘合剂或有去粘粘合剂的区域面积比约为75∶25-20∶80。

在揩拭件的整个尺寸上分布谷(和粘合剂)是有好处的。例如,如果采用直线凹槽形式,则凹槽可以分布在整个揩拭件上。对于突起菱形或其他形状也是如此,其中低谷(虽然不一定是直线形)分布在整个揩拭件上。这为粘合剂接触污物颗粒提供了连续通道,因此待清洁表面在抹布的整个表面上与粘合剂接触,它保证了更加均匀的揩拭效果。

B.制造抹布的方法

有许多合适的途径可以用来制造本发明的抹布。例如,美国专利5256231、5616394、5643397和欧洲专利EP 341993B1(全为Gorman等发明)介绍的通用系统可用来同时输送揩拭件和背衬件,在它们之间形成粘合层,然后将它们制成所述类型的三维抹布。图9为形成图1所示类型的抹布用到的方法和设备的示意图。图9所示方法一般包括:形成具有突起区域或峰120和低谷部分110的非织造揩拭件200,在揩拭件和背衬件300之间挤涂一层粘合剂250,它将揩拭件200低谷部分110与背衬件300粘合在一起,形成三维抹布100。此方法是这样实施的,提供第一和第二成皱部件或辊26和27,它们各含一个轴,通常包含许多沿周径间隔分布、沿轴向延伸的脊28,脊28之间的间隔刚好可以容纳另一个成皱部件26或27的脊28,在啮合的脊28之间的非织造布200与它形成啮合关系。安装成皱部件26和27时,要使它们的脊28部分成轴向平行关系,一般像轮齿那样捏合;成皱部件26或27中至少有一个旋转;在成皱部件26和27的脊28的啮合部分送入非织造布200,使它皱化。皱纹非织造布200离开脊28后,依然保留在第二个成皱部件27的周缘。粘合层250从模具24上挤出后,进入第二成皱部件27与冷却辊25之间形成的啮合缝隙中,同时使背衬件300进入第二个成皱部件27与冷却辊25之间沿辊25表面形成的啮合缝隙中。这样做的结果是挤出粘合层250沉积在背衬件300与非织造布200之间,背衬件300与非织造布200沿低谷部分110粘合。背衬件表面的一些粘合剂在热和压力存在下,在啮合点上借助啮合压力进到并穿过非织造卷材200的纤维。然后将非织造抹布层合物100部分送到冷却辊25上,借此完成冷却。

用于形成图2和3所示类型的抹布的方法类似于图9所示方法,并采用相同的设备,不同之处在于背衬件300或众多相间丝300a是这样形成并粘着到非织造卷材200上的,即将熔融态热塑性背衬件300或300a从模具24挤出或共挤出到第二成皱件27与冷却辊25之间形成的夹缝中,而不是通过挤涂粘合层将背衬件300粘着到非织造卷材200上。这种方法将非织造卷材的纤维包埋到膜背衬件或丝背衬件中。然后在谷110中局部施涂粘合剂260,形成抹布100。

图2所示类型的抹布也可以这样形成,通过加热方法或超声波方法将背衬件300粘合到揩拭件200上,然后在抹布100的谷110中局部施涂粘合剂260。

图10是形成图5所示类型的抹布的方法和设备示意图。此方法类似于图9所示方法,并采用相同的设备,不同之处在于背衬件300或众多相间丝300a是这样形成并粘着到非织造卷材200上的,即将熔融态热塑性背衬件300或300a从模具24挤出或共挤出到第二成皱件27与冷却辊25之间形成的夹缝中,而不是通过挤涂粘合层将背衬件300粘着到非织造卷材200上。这种方法将非织造卷材的纤维包埋到膜背衬件或丝背衬件中。然后在谷110中局部施涂粘合剂260,形成抹布100。

图5所示类型的抹布也可以通过图11所示方法和设备制备,该图示出了双辊过程,而不是上述三辊过程。在图11中,此方法是借助第一和第二成皱件或辊26和27a实施的,它们的轴一般在同一平面内,并具有相同的直径。成皱件27a的表面一般是平整的。成皱件26是齿形件或辊,一般由成皱件27a传动或驱动,这样它们就以相同的圆周速度沿相反的方向转动。第一成皱件26的温度一般与第二成皱件27a相同,通常对二者同时加热,以利于褶皱的形成和粘合剂的流动。非织造揩拭件200由成皱辊26的表面送进第一和第二成皱辊之间的夹缝中。粘合剂250自模具24挤入夹缝,同时沿第二成皱辊27a将背衬件300送入夹缝。这样就在背衬件300和非织造揩拭件200之间沉积了挤出粘合层250,它通过低谷部分110将背衬件300和非织造揩拭件200粘合在一起。由于存在热和压力,有些粘合剂自背衬层表面渗入非织造卷材200的纤维当中。然后将非织造抹布层合物100部分送到成皱辊27a上,借此完成冷却。

图6所示类型的抹布也可用类似于图11所示方法和设备制备,不同之处在于,抹布的形成过程是借助加热方法或超声波方法将背衬件300粘合到揩拭件200上,然后在抹布100的低谷110中局部施涂粘合剂260。

还应当指出,在制备图1和5所示类型的抹布时,也可以用预涂粘合剂的背衬件代替在线挤涂热熔粘合剂层。接着可将此涂有粘合剂的非织造背衬件送入第二印花辊和冷却辊之间,使粘合剂在压力下(可以加热,也可以不加热)流经非织造揩拭件,进入抹布低谷部分。如果背衬件非永久性粘合到揩拭件上,终端用户可去掉背衬件,将抹布固定在清洁辅助工具上,如绑拖把头上。

形成图7和8所示抹布结构的方法类似于图9-11所示方法,并采用相同设备。如果非织造揩拭件由纤维制成,所述纤维包含足够量的粘合剂纤维(如套-芯型双组分粘合剂纤维),形成具有足够结构刚性的非织造卷材,则不必单独提供背衬件。揩拭件也可以通过将非织造揩拭件(例如聚丙烯纤维非织造卷材)粘合到结构背衬件上成型,形成结构背衬件的材料在足够的热和压力下不能牢固地粘着到揩拭件上(例如聚酯非织造纤维),非织造揩拭件的低谷或凹进区域中的部分纤维在此热和压力下可发生熔化。如果以后要从揩拭件上拿掉背衬件,则非织造卷材可以形成足够的结构刚性。对于这些抹布实例,粘合剂260可在揩拭件形成后局部施涂在低谷部分110中。

应当指出,双面抹布结构(即具有上下揩拭表面的抹布结构,揩拭表面含有为低谷所分隔的峰或突起区域)也可以利用图1-7所示任何一种实施方式制备。可以用本领域已知的各种层压方法将两个抹布结构层压在一起。这一步也可以通过在图9-11所示设备中增加成皱件来完成(例如,见美国专利5681302中图4和5及相关描述)。

C.使用抹布的方法

表征本发明抹布的另一个途径是看它性能如何。在介绍测定性能的实施例之前,需要说明一些重要的性能指标。第一,该抹布能捡起简单的抹布通常无法捡起的沙子、污垢和其他较大的颗粒。第二,该抹布在揩过表面时应当具有适当的牵拉力。本发明抹布的牵拉力是抹布非粘性部分与表面之间的摩擦力和抹布粘性部分与表面之间的粘合力的综合表现。如果暴露出来的粘合剂太多,或者暴露出来的粘合剂太粘,则抹布将套在表面上,马上就会让使用者不舒服。如果暴露出来的粘合剂太少,或者暴露出来的粘合剂粘性不够,则抹布拾起的污垢、沙子等将不如期望的多。如果峰高太高或者对挤压的抵抗力太高,则与灰尘接触的粘合剂将较少,因而抹布效率降低。

D.本发明的其他特点

在本发明抹布中可以加入添加剂,以获得其他所需性质。例如,在揩拭件的上面或者下面可以添加洗涤剂、研磨剂、消毒剂、化学清洁剂、抛光剂、油或石蜡,这些添加剂可以作用于抹布移动的表面。揩拭件纤维可以是亲水性的,也可以进行亲水改性(例如用表面活性剂),使干揩和湿揩都可以进行。

也可以对抹布上色,甚至可以上荧光色,这可以通过在制备揩拭件、背衬件的材料或同时在制备二者的材料中加入着色剂完成。它也可以在生产完成之后进行,例如用染料给抹布上色,但应当注意确保染料不能对粘合剂的性能和外观造成不利影响,也不能将颜色转移到要揩拭的表面上。

本发明抹布可以单独用作除尘布,也可以借助清洁辅助工具如拖把、手套、掸子或滚筒等。抹布也可以包装成卷的形式,或者以片层形式堆叠起来,以便于取用。

测试方法

除沙试验A

在60cm×243cm的乙烯基地板表面上撒2g(记作W1)沙子(平均直径90-175μm),然后测定抹布的除沙能力。将抹布样品安装在明尼苏达采矿和制造公司(3M公司)(St.Paul,Minnesota)生产的ScotchBriteTM高性能清扫拖把的头上。去掉样品外面的套管,将其附着在一片纺粘聚丙烯(20g/m2,位于以色列Holon的Avgol有限公司生产)上,然后进行测试。称量安装了抹布的拖把头的重量,记作W2。将拖把头安装在拖把柄上,将试验样品一次性拖过整个撒有沙子的地板区(即通过撒有沙子的地板的每一个区域),拖动时使施加在拖把柄上的压力最小。再次将拖把头从柄上取下,称其重量(W3)。抹布从表面上清除的沙子的重量百分数按下式计算:

%(清除的沙子)=[(W3-W2)/W1]×100

除沙试验B

按照除沙试验A所述方法测定抹布的除沙能力,不同之处在于抹布样品安装在10cm×25cm Pledge Grab-ItTM拖把(威斯康辛Racine的S.C.Johnson有限公司生产)的头上。

除沙试验C

按照除沙试验A所述方法测定抹布的除沙能力,不同之处在于试验所用沙子具有较大的平均直径:175-250μm。

除沙试验D

按照除沙试验B所述方法测定抹布的除沙能力,不同之处在于将1.54g沙子(W1),而不是2g沙子撒在46cm×243cm的乙烯基地板表面上,试验所用沙子具有较大的平均直径:175-250μm。

对于所有除沙试验,表中所列数据是至少两个试验结果的平均值。

牵拉测定

在225-1型摩擦/剥离测定仪(Thwing-Albert仪器公司(费城,PA)生产)上装配力变换器(MB-2KG-171型,Thwing-Albert生产)。摩擦测定仪的速度设定为110英寸(279.4cm)/分钟,时间设定为5秒。将一片黑色剥离切割成66.5cm×21.5cm,安装在摩擦测定仪上。用3M公司生产的WindexTM和ScotchBriteTM微纤维清洁布清洁玻璃。将清洁布样品切割成4英寸×6英寸(10.2cm×15.2cm),沿着6英寸边安装到测定装置上。去掉样品外面的套管,将其附着在一片基重为31克/平方米的热粘梳纺聚丙烯卷材样品上(FPN336D,购于BBA非织造制品公司,Simpsonville,南卡罗莱纳州),然后进行测定。在抹布上放一块500克重物(7.6cm×12.7cm),测定摩擦力,记录动摩擦因数(KI)。表中所列数据是至少两个试验结果的平均值。

非织造材料

非织造N1是基重为20g/m2的平纺粘聚丙烯非织造卷材,购于以色列Holon的Avgol公司。

非织造N2是基重为31g/m2的平梳纺热粘聚丙烯非织造卷材,FPN336D,购于BBA非织造制品公司,Simpsonville,南卡罗莱纳州。

非织造N3是基重为56g/m2、由9旦聚丙烯纤维制备的平无粘粗梳非织造卷材,购于佐治亚州Covington的Fiber Visions公司。

非织造N4是基重为90g/m2、由32旦聚丙烯纤维制备的平无粘粗梳非织造卷材,购于南卡罗莱纳州Charlotte的Kosa公司。

非织造N5是基重为31g/m2的spunlace聚酯非织造卷材,购于缅因州Walpole的Veratec公司。

非织造N6是基重为30g/m2、由9旦聚丙烯纤维制备的平无粘粗梳非织造卷材,购于佐治亚州Covington的Fiber Visions公司。

非织造N7是基重为30g/m2、由9旦聚丙烯纤维(购于佐治亚州Covington的Fiber Visions公司)和1.5旦人造丝纤维(购于Lowland TN的Lenzing Fibers公司)按80/20制备的平无粘粗梳非织造卷材。

非织造N8是基重为25g/m2的spunlace人造丝非织造卷材,以商品名S7125购于日本Shinwa公司。

非织造N9是基重为50g/m2、由9旦聚丙烯纤维制备的平无粘粗梳非织造卷材,购于佐治亚州Covington的Fiber Visions公司。

非织造N10是基重为45g/m2的聚酯水刺非织造卷材,购于特拉华州Wilmington的杜邦公司。

实施例

实施例1

用图9所示方法和设备制备抹布材料,不同之处在于所用互相咬合的第一和第二印花辊(分别为成皱件26和27)加工成菱形图样。将揩拭件(非织造N1)送入带菱形图案的第一和第二咬合印花辊之间的夹缝中,使印花密度约为9个菱形/平方英寸(6.45cm2),每个菱形图案之间有一定空隙。将每个菱形突起的顶部加工平整,宽8mm。形成非织造印花片,既有突起区或峰,又有沿着非织造卷材形成谷的连接部,每个突起区或峰高约3mm,每个连接部宽约4mm。将第一个印花辊加热到93℃,第二个印花辊加热到149℃。利用2英寸(5.1cm)Davis单螺杆挤出机将商品名为HM-1902的热熔粘合剂(购于明尼苏达州St.Paul的H.B.Fuller公司)挤出到背衬件上(非织造N2)。在夹缝前沿着冷却辊周缘挤出粘合剂,模具温度为135℃,基重为60g/m2。将成型揩拭件和涂有粘合剂的背衬件送入第二印花辊27和冷却辊25(38℃)之间的夹缝中,压力约为300磅/英寸。所得抹布材料上的粘性区与非粘性区之比为52∶48。

实施例2

按照实施例1所述过程制备实施例2,但有如下变化。用非织造N3作为揩拭件,送入第一和第二咬合印花辊之间的夹缝中,用光滑的钢辊代替印花辊作为第一辊。用预涂粘合剂的背衬件代替挤涂热熔粘合层,并用如下方法制备。在40克甲苯中溶解60克干KratonTM聚合物HM-1902样品(购于HB Fuller,St.Paul,MN),制备手涂粘合剂。溶液搅拌过夜,得到非常均匀的混合物。然后用刮涂器将溶液涂敷到聚硅氧烷隔离衬垫上,在70℃烘箱中干燥10分钟,产生3mil(0.076mm)厚的干燥粘合剂涂层。将样品放置过夜,然后在室温下用4.5磅橡皮辊层压到聚丙烯背衬件(非织造N2)上。然后取下隔离衬垫,将此涂有粘合剂的非织造背衬件送入第二印花辊与冷却辊之间,压力为300磅/英寸。

实施例3

用图10所示方法和设备制备实施例3,制备过程类似于上述实施例1,不同之处在于用非织造N3作为揩拭件,用光滑钢辊代替印花辊作为第一辊,在113℃挤出HM-1902粘合剂,基重为29g/m2。

实施例4

按照实施例3所述过程制备实施例4,不同之处在于在该过程中送入的是非织造N4,用光滑钢辊代替印花辊作为第一辊,在113℃挤出HM-1902粘合剂,基重为40g/m2。

实施例5

按照实施例1所述过程制备实施例5,不同之处在于用非织造N5作为揩拭件,将第二印花辊加热到190℃,冷却辊在10℃工作。采用预涂粘合剂的背衬件,并用如下方法制备。在40克甲苯中溶解60克聚合物样品,制备手涂粘合剂。所述聚合物包含100份Zeon Rubber 3620(购于日本Nippon Zeon的苯乙烯-异戊二烯-苯乙烯嵌段共聚物)、85份Wingtack(购于OH,Akron的Goodyear公司的增粘剂)、1.5份Irganox1076(购于NY,Tarrytown的汽巴特种化学品公司(Ciba Specialty Chemicals)的抗氧化剂)和1.5份CyanoxLTDP(购于NJ,West Paterson的Cytec工业公司)。溶液搅拌过夜,得到非常均匀的混合物。然后用刮涂器将溶液涂敷到聚硅氧烷隔离衬垫上,在70℃烘箱中干燥10分钟,产生3mil(0.076mm)厚的干燥粘合剂涂层。将样品放置过夜,然后在室温下用4.5磅橡皮辊层压到聚丙烯背衬件(非织造N5)上。然后取下隔离衬垫,将此涂有粘合剂的非织造背衬件送入第二印花辊与冷却辊之间,压力为250磅/英寸。

实施例6

按照实施例2所述过程制备实施例6,不同之处在于,将100份含55%丙烯酸2-乙基己酯和45%丙烯酸的热熔丙烯酸酯类共聚物与70份增塑剂UCON50HB400(购于MI,Midland的陶氏化学公司(Dow Chemical Company))混合,将此混合物作为粘合剂预涂在背衬件上。

实施例7

用图11所示方法和设备制备实施例7。将揩拭件(非织造N6)送入第一成皱辊26(149℃)和第二成皱辊27a(21℃)之间的夹缝中。在190℃将基重为60g/m2的粘合剂HM-1902挤涂到1mil(0.025mm)聚酯膜背衬件上(购于MN,St.Paul的3M公司)。揩拭件和涂有粘合剂的背衬件通过第一成皱辊和第二成皱辊之间的夹缝,压力为370磅/英寸。

实施例8

按照实施例3所述过程制备实施例8,不同之处在于采用非织造N7,粘合剂在190℃挤出,基重为60g/m2,第二印花辊和冷却辊(21℃)在370磅/英寸工作。

对比例C1

对比例C1是购于3M公司的ScotchBriteTM高性能一次性清洁布。

比较C2

对比例C2是购于威斯康辛Racine的S.C.Johnson公司生产的Pledge Grab-ItTM静电布。

对比例C3

对比例C3根据PCT专利公开01/80705制备。在非织造N2上喷涂Super 77粘合剂(购于MN,St.Paul的3M公司),然后层压到布上钻有孔洞的对比例C2样品上。喷涂粘合剂后,干粘合剂占非织造卷材总重约1.8%。使粘合剂干燥过夜。用抹布剪出直径为7.5mm的圆块,作为对比例C2,每平方英寸抹布剪出4个圆块。粘性区与非粘性区的面积比为27∶73。

对比例C4

根据实施例1制备对比例C4,不同之处在于不施涂粘合剂。

用前述除沙试验A、B、C和D,以及牵拉力测定试验对实施例1-8和对比例C1-C4进行评定,结果列于表I。

表I

| 实施例 | %(除沙)(试验A) | %(除沙)(试验B) | %(除沙)(试验C) | 牵拉测定(KI) |

| 实施例1 | 70 | - | 88 | 0.41 |

| 实施例2 | 57 | - | - | 0.49 |

| 实施例3 | 53 | - | 68 | - |

| 实施例4 | 65 | - | - | 0.27 |

| 实施例5 | 71 | - | - | - |

| 实施例6 | - | - | 72 | - |

| 实施例7 | - | - | 87 | - |

| 实施例8 | - | - | 73 | - |

| C1 | 50 | - | 62 | 0.05 |

| C2 | - | 30 | - | 0.18 |

| C3 | - | 38 | - | - |

| C4 | 13 | - | - | - |

实施例5与对比例C4的性能值表明粘合剂的存在具有重要影响。还要注意到,对比例C3中存在粘合剂与没有粘合剂的对比例C2相比在性能上没有显著不同。

实施例9

按类似于实施例1所述方法制备实施例9。将非织造卷材N10送入第一和第二咬合印花辊之间的夹缝中,印花辊加工成菱形图案,每平方英寸上约有38个菱形,每个菱形之间留有间隙。将每个菱形突起的顶部加工平整,宽4.5mm。形成非织造印花片,既有突起区或峰,又有沿着非织造卷材形成谷的连接部,每个突起区或峰高约1.8mm,每个连接部宽约1.2mm。将第一个印花辊加热到66℃,第二个印花辊加热到149℃。将隔离衬垫上的5mil(0.13mm)聚辛烯膜(购于3M公司)送入第二印花辊和冷却辊之间的夹缝中,压力为450磅/英寸。粘性区与非粘性区之比为43∶57。

实施例10

按照实施例9制备实施例10,不同之处在于第一和第二咬合印花辊开放运行(彼此不接触)。每个突起区或峰约0.25mm高。

实施例11

用印压机制备实施例11,制备时将印花平板加热到149℃。将非织造N9放置在覆有一层隔离衬垫的受热印花板顶部,关闭印压机15秒,压强为15磅/平方英寸。在样品织构边上喷涂Super 77粘合剂,干重非织造卷材总重60%,将其置于66℃烘箱中15分钟。用印花板遮蔽样品,并在样品的峰上撒滑石粉,以此使样品的峰不具有粘性。真空除去多余的滑石粉。这样形成的样品具有圆形突起,每平方英寸约1.8个突起部分,峰宽15mm,峰高3.9mm,相邻峰之间的距离为9mm。粘性区与非粘性区面积之比为50∶50。

实施例12

用印花平板和约150℃的熨斗制备实施例12。采用非织造N8,将其层压到2.5mil(0.064mm)聚丙烯膜上(购于MN,St.Paul的3M公司)。褶皱图样是在100mm×100mm区域内有16个条纹。用聚硅氧烷橡皮图章通过转移涂布法将基于溶剂的压敏粘合剂(异辛基丙烯酸酯/丙烯酰胺96/4)施涂到褶皱图样的凹陷部位。粘合剂的施涂重量为0.6g/(100mm×300mm)。峰高2.1mm,谷宽1.0mm,粘性区与非粘性区面积之比为20∶80。

对比例C6

按照实施例11制备对比例C6,不同之处在于不在非织造卷材上施涂粘合剂。

用前述除沙试验B和D,以及牵拉测定试验对实施例9-12和对比例C6进行评定,结果列于表II。

表II

| 实施例 | %(除沙)(试验B) | %(除沙)(试验D) | 牵拉测定(KI) |

| 实施例9 | - | - | 0.13 |

| 实施例10 | - | - | 0.71 |

| 实施例11 | - | 65 | 0.84 |

| 实施例12 | 69 | - | - |

| 对比例C6 | - | 20 | 0.37 |

比较实施例11和对比例C6的性能可以看出,粘合剂的存在具有较大影响。

本领域技术人员不难理解,只要不背离本发明的范围和原则,可以对本发明进行各种改进和变通。应当认识到,本发明不受上述示例性实施方式的限制。

Claims (34)

1.一种抹布结构,它包含基本上沿低谷粘合在背衬件上的连续揩拭件,其中揩拭件包含许多分立的峰,粘合剂施涂在低谷部分。

2.权利要求1所述的抹布结构,其特征在于,所述低谷按规则图样排布。

3.权利要求1所述的抹布结构,其特征在于,至少有一个低谷基本上横穿整个揩拭件。

4.权利要求1所述的抹布结构,其特征在于,所述揩拭件是整体非织造卷材。

5.权利要求4所述的抹布结构,其特征在于,所述背衬件是非织造的。

6.权利要求4所述的抹布结构,其特征在于,所述背衬件是连续膜。

7.权利要求1所述的抹布结构,其特征在于,所述粘合剂是压敏粘合剂。

8.权利要求1所述的抹布结构,其特征在于,所述峰谷是线性峰和线性谷组成的褶皱图样的一部分。

9.权利要求1所述的抹布结构,其特征在于,所述谷以直线栅格形式排布。

10.权利要求1所述的抹布结构,其特征在于,所述背衬件也是基本上连续的。

11.权利要求1所述的抹布结构,其特征在于它还包含存在于至少一些峰与背衬件之间的腔室。

12.权利要求11所述的抹布结构,其特征在于,所述腔室可收集从表面上扫下来的颗粒。

13.权利要求1所述的抹布结构,其特征在于,基本上所有揩拭件暴露表面覆盖着粘合剂,去粘剂覆盖在粘性峰顶上。

14.一种抹布结构,它基本上由具有峰谷的连续揩拭件和施涂在谷中的粘合剂组成。

15.权利要求14所述的抹布结构,其特征在于,所述低谷排列成规则图样。

16.权利要求14所述的抹布结构,其特征在于,至少有一个低谷基本上横穿整个揩拭件。

17.权利要求14所述的抹布结构,其特征在于,所述背衬件是非织造的。

18.权利要求14所述的抹布结构,其特征在于,所述粘合剂是压敏粘合剂。

19.权利要求14所述的抹布结构,其特征在于所述峰和谷是线性峰和线性谷。

20.权利要求14所述的抹布结构,其特征在于,所述谷以直线栅格形式排布。

21.权利要求14所述的抹布结构,其特征在于,基本上所有揩拭件暴露表面覆盖着粘合剂,去粘剂覆盖在粘性峰顶上。

22.一种抹布结构,它包含沿低谷粘合在背衬件上且基本上连续的揩拭件,其中揩拭件包含许多分立的峰,粘合剂施涂在低谷部分,经牵拉测定,抹布结构的牵拉动摩擦因数(KI)小于1.4。

23.一种抹布结构,它包含沿低谷粘合在背衬件上且基本上连续的揩拭件,其中揩拭件包含许多分立的峰,粘合剂施涂在低谷部分,背衬件是连续膜,峰与膜之间形成腔室,可捕集颗粒。

24.制备抹布结构的方法,它包含如下步骤:

(a)提供基本上连续的揩拭件;

(b)提供背衬件;

(c)在揩拭件和背衬件之间涂敷粘合剂;

(d)沿低谷将揩拭件与背衬件压合在一起,使得至少部分粘合剂存在于至少部分低谷中,当揩拭件揩拭表面时,抹布能粘附颗粒。

25.权利要求24所述的方法,其特征在于,步骤(d)包含用辊将揩拭件和背衬件压合在一起。

26.权利要求24所述的方法,其特征在于,步骤(d)在受热情况下完成。

27.权利要求25所述的方法,其特征在于,至少有一个辊具有平滑表面,至少有一个辊具有印花表面,用以形成抹布结构上的峰谷。

28.制备抹布结构的方法,它包含如下步骤:

(a)提供基本上连续的揩拭件和背衬件,它们沿着低谷部分粘合在一起,所述揩拭件具有分立的峰;

(b)将粘合剂施涂在揩拭件的几乎整个外露面上;

(c)有选择地使峰上的粘合剂失去粘性,而将粘合剂留在低谷部分。

29.权利要求28所述的方法,其特征在于,所述粘合剂用无机微粒进行有选择地去粘。

30.权利要求28所述的方法,其特征在于,用去粘剂有选择地对粘合剂进行去粘,所述去粘剂选自二氧化钛、碳酸钙、氧化硅、粘土和滑石。

31.权利要求28所述的方法,其特征在于,用非粘性有机材料对粘合剂进行有选择地去粘。

32.权利要求28所述的方法,其特征在于,用去粘剂有选择地对粘合剂进行去粘,所述去粘剂选自矿物油、结晶腊、低粘性底胶涂料和乙烯聚合物。

33.制备抹布结构的方法,它包含如下步骤:

(a)提供基本上连续的揩拭件和背衬件,它们沿着低谷部分粘合在一起,所述揩拭件含有分立峰;

(b)将可活化粘合剂施涂在揩拭件的几乎整个外露面上;

(c)有选择地使谷中的粘合剂活化。

34.权利要求33所述的方法,其特征在于,所述粘合剂选自热活化粘合剂和增塑剂活化粘合剂。

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US10/093,792 US20030171051A1 (en) | 2002-03-08 | 2002-03-08 | Wipe |

| US10/093,792 | 2002-03-08 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN1638683A true CN1638683A (zh) | 2005-07-13 |

Family

ID=27804228

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CNA038053993A Pending CN1638683A (zh) | 2002-03-08 | 2003-02-14 | 抹布 |

Country Status (13)

| Country | Link |

|---|---|

| US (3) | US20030171051A1 (zh) |

| EP (2) | EP1482828B1 (zh) |

| JP (1) | JP2005526548A (zh) |

| KR (1) | KR20050048540A (zh) |

| CN (1) | CN1638683A (zh) |

| AT (1) | ATE444013T1 (zh) |

| AU (1) | AU2003211044A1 (zh) |

| BR (1) | BR0308264A (zh) |

| CA (1) | CA2477154A1 (zh) |

| DE (1) | DE60329472D1 (zh) |

| ES (1) | ES2333954T3 (zh) |

| MX (1) | MXPA04008482A (zh) |

| WO (1) | WO2003075735A1 (zh) |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102825849A (zh) * | 2012-08-09 | 2012-12-19 | 濮阳市虹霞新型防水材料有限公司 | 皱褶型防水卷材生产工艺 |

| CN101969832B (zh) * | 2008-03-14 | 2013-08-21 | 尼托母斯股份有限公司 | 清扫用胶粘带辊和胶粘带的制造装置及其制造方法 |

| CN104367280A (zh) * | 2014-11-25 | 2015-02-25 | 苏州新纶超净技术有限公司 | 一种可有效去除微尘的机织无尘布及其制造方法 |

| CN104688140A (zh) * | 2015-04-05 | 2015-06-10 | 高尚义 | 一种书本式抹布 |

| CN106388737A (zh) * | 2016-11-05 | 2017-02-15 | 北海益生源农贸有限责任公司 | 一种高容污性能的集成拖把 |

| CN109070554A (zh) * | 2015-12-01 | 2018-12-21 | 金伯利-克拉克环球有限公司 | 吸油擦拭产品 |

Families Citing this family (86)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2001527454A (ja) | 1997-05-23 | 2001-12-25 | ザ、プロクター、エンド、ギャンブル、カンパニー | 掃除シートとして有用な三次元構造体 |

| US20020042962A1 (en) * | 2000-02-24 | 2002-04-18 | Willman Kenneth William | Cleaning sheets comprising a polymeric additive to improve particulate pick-up and minimize residue left on surfaces and cleaning implements for use with cleaning sheets |

| US20030003831A1 (en) * | 2001-06-29 | 2003-01-02 | Childs Stephen Lee | Cleaning sheets comprising multi-denier fibers |

| US20030003832A1 (en) * | 2001-06-29 | 2003-01-02 | The Procter & Gamble Company | Cleaning sheets comprising a fibrous web of carded staple fibers hydroentangled with a reinforcing fibrous web |

| US20030171051A1 (en) | 2002-03-08 | 2003-09-11 | 3M Innovative Properties Company | Wipe |

| US7431975B2 (en) * | 2002-11-29 | 2008-10-07 | Dzs, L.L.C. | Textured composite material |

| AU2003277527A1 (en) † | 2002-12-27 | 2004-07-29 | Kao Corporation | Cleaning sheet |

| WO2004073480A2 (en) * | 2003-02-19 | 2004-09-02 | The Procter & Gamble Company | Cleaning substrate with additive |

| US7560398B2 (en) | 2003-07-18 | 2009-07-14 | 3M Innovative Properties Company | Cleaning wipe and method of manufacture |

| US20050148260A1 (en) * | 2003-12-24 | 2005-07-07 | Kopacz Thomas J. | Highly textured non-woven composite wipe |

| US7393371B2 (en) * | 2004-04-13 | 2008-07-01 | 3M Innovative Properties Company | Nonwoven abrasive articles and methods |

| US7291359B2 (en) * | 2004-08-18 | 2007-11-06 | 3M Innovative Properties Company | Method and apparatus for making an adhesive cleaning sheet |

| US20060138693A1 (en) * | 2004-12-29 | 2006-06-29 | Tuman Scott J | Method and apparatus for making a cleaning sheet |

| US20070212398A1 (en) * | 2005-01-21 | 2007-09-13 | Tiffany Aceto | Powdered wipe |

| US20060169301A1 (en) * | 2005-01-28 | 2006-08-03 | Haskett Thomas E | Cleaning wipe with variable loft working surface |

| CN1303935C (zh) * | 2005-03-22 | 2007-03-14 | 东华大学 | 具有导湿耐用涤/锦复合超细纤维毛圈织物洁净布的制造方法 |

| US7329839B2 (en) * | 2005-04-25 | 2008-02-12 | Palmer Jeffery W | Cover for a candle warmer |

| EP1749470A1 (en) | 2005-08-05 | 2007-02-07 | The Procter and Gamble Company | Hard surface cleaning article comprising an adhesive |

| US20070079462A1 (en) * | 2005-10-06 | 2007-04-12 | Haskett Thomas E | Scouring web and method of making |

| US20070079919A1 (en) * | 2005-10-06 | 2007-04-12 | Haskett Thomas E | Scouring web and method of making |

| US20070136967A1 (en) * | 2005-12-20 | 2007-06-21 | 3M Innovative Properties Company | Adhesive wipe |

| US7700178B2 (en) | 2006-02-24 | 2010-04-20 | 3M Innovative Properties Company | Cleaning wipe with variable loft working surface |

| US8540846B2 (en) | 2009-01-28 | 2013-09-24 | Georgia-Pacific Consumer Products Lp | Belt-creped, variable local basis weight multi-ply sheet with cellulose microfiber prepared with perforated polymeric belt |

| US7718036B2 (en) | 2006-03-21 | 2010-05-18 | Georgia Pacific Consumer Products Lp | Absorbent sheet having regenerated cellulose microfiber network |

| US8187422B2 (en) | 2006-03-21 | 2012-05-29 | Georgia-Pacific Consumer Products Lp | Disposable cellulosic wiper |

| US8187421B2 (en) | 2006-03-21 | 2012-05-29 | Georgia-Pacific Consumer Products Lp | Absorbent sheet incorporating regenerated cellulose microfiber |

| US7843637B2 (en) * | 2006-06-22 | 2010-11-30 | 3M Innovative Properties Company | Birefringent structured film for LED color mixing in a backlight |

| US7856690B2 (en) * | 2006-11-22 | 2010-12-28 | 3M Innovative Properties Company | Brushing assembly |

| US7951264B2 (en) | 2007-01-19 | 2011-05-31 | Georgia-Pacific Consumer Products Lp | Absorbent cellulosic products with regenerated cellulose formed in-situ |

| US20080311363A1 (en) * | 2007-06-12 | 2008-12-18 | 3M Innovative Properties Company | Metal fiber coated substrate and method of making |

| US7836540B2 (en) * | 2007-08-02 | 2010-11-23 | 3M Innovative Properties Company | Broom with particle capture sheet |

| WO2009151612A2 (en) | 2008-06-11 | 2009-12-17 | Georgia-Pacific Consumer Products Lp | Absorbent sheet prepared with papermaking fiber and synthetic fiber exhibiting improved wet strength |

| MX2011000103A (es) | 2008-06-30 | 2011-02-22 | 3M Innovative Properties Co | Herramienta de limpieza de piso con una lamina de captura circundante. |

| US20100044909A1 (en) * | 2008-08-20 | 2010-02-25 | 3M Innovative Properties Company | Lofty, tackified nonwoven sheet and method of making |

| WO2010033536A2 (en) | 2008-09-16 | 2010-03-25 | Dixie Consumer Products Llc | Food wrap basesheet with regenerated cellulose microfiber |

| US20100144257A1 (en) * | 2008-12-05 | 2010-06-10 | Bart Donald Beaumont | Abrasive pad releasably attachable to cleaning devices |

| US9682512B2 (en) | 2009-02-06 | 2017-06-20 | Nike, Inc. | Methods of joining textiles and other elements incorporating a thermoplastic polymer material |

| US20100199406A1 (en) | 2009-02-06 | 2010-08-12 | Nike, Inc. | Thermoplastic Non-Woven Textile Elements |

| US20100199520A1 (en) * | 2009-02-06 | 2010-08-12 | Nike, Inc. | Textured Thermoplastic Non-Woven Elements |

| US8906275B2 (en) | 2012-05-29 | 2014-12-09 | Nike, Inc. | Textured elements incorporating non-woven textile materials and methods for manufacturing the textured elements |

| US8850719B2 (en) | 2009-02-06 | 2014-10-07 | Nike, Inc. | Layered thermoplastic non-woven textile elements |

| US20100218326A1 (en) * | 2009-02-27 | 2010-09-02 | Yamaguchi Vickie L | Multi-use cleaning glove |

| US8347447B2 (en) * | 2009-11-10 | 2013-01-08 | 3M Innovative Properties Company | Mop body having recessed side surfaces |

| US9260808B2 (en) | 2009-12-21 | 2016-02-16 | Kimberly-Clark Worldwide, Inc. | Flexible coform nonwoven web |

| US20110152808A1 (en) * | 2009-12-21 | 2011-06-23 | Jackson David M | Resilient absorbent coform nonwoven web |

| JP5520117B2 (ja) * | 2010-03-31 | 2014-06-11 | ユニ・チャーム株式会社 | 弾性不織布およびその製造方法 |

| US20120066855A1 (en) * | 2010-09-17 | 2012-03-22 | Schmidt Michael A | Coform nonwoven web having multiple textures |

| US8703267B2 (en) | 2010-11-03 | 2014-04-22 | Kimberly-Clark Worldwide, Inc. | Synthetic gecko adhesive attachments |

| US20120315473A1 (en) * | 2011-06-10 | 2012-12-13 | Chin Guey N | Self-adhesive cloth |

| WO2012176825A1 (ja) * | 2011-06-23 | 2012-12-27 | 花王株式会社 | 複合シート及びその製造方法 |

| MX2014005639A (es) | 2011-11-11 | 2014-07-11 | 3M Innovative Properties Co | Superficie de limpieza con adhesivo reactivable. |

| US20130255103A1 (en) | 2012-04-03 | 2013-10-03 | Nike, Inc. | Apparel And Other Products Incorporating A Thermoplastic Polymer Material |

| US20130309439A1 (en) | 2012-05-21 | 2013-11-21 | Kimberly-Clark Worldwide, Inc. | Fibrous Nonwoven Web with Uniform, Directionally-Oriented Projections and a Process and Apparatus for Making the Same |

| JP6704729B2 (ja) * | 2013-06-25 | 2020-06-03 | 株式会社ニトムズ | 有機質汚れ除去用粘着クリーナー |

| US9174159B2 (en) | 2013-08-16 | 2015-11-03 | 3M Innovative Properties Company | Framed pleated air filter with upstream bridging filaments |

| US9278301B2 (en) | 2013-08-16 | 2016-03-08 | 3M Innovative Properties Company | Nestable framed pleated air filter and method of making |

| US9649792B2 (en) | 2013-10-15 | 2017-05-16 | Velcro BVBA | Forming longitudinally pleated products |

| USD738536S1 (en) * | 2013-12-17 | 2015-09-08 | Gage 78, Inc. | Wall panel |

| USD738537S1 (en) * | 2013-12-17 | 2015-09-08 | Gage 78, Inc. | Wall panel |

| CN105828684B (zh) | 2013-12-18 | 2019-04-19 | 3M创新有限公司 | 清洁制品 |

| USD748932S1 (en) * | 2014-03-03 | 2016-02-09 | Elaine Snider Puricelli | Two-layer towel having a corrugated design |

| MX2016013042A (es) * | 2014-04-04 | 2017-02-28 | 3M Innovative Properties Co | Adhesivos para superficie húmeda y seca. |

| US10264937B2 (en) | 2014-10-08 | 2019-04-23 | Emerson Electric Co. | Swivel assembly for a vacuum accessory |

| US10258213B2 (en) | 2014-10-08 | 2019-04-16 | Emerson Electric Co. | Balanced airflow for a vacuum accessory |

| US9241603B1 (en) | 2014-10-08 | 2016-01-26 | Emerson Electric Co. | Swivel assembly for connecting a wand to a vacuum accessory and associated accessory tool for use on hard surface |

| JP2016116795A (ja) * | 2014-12-22 | 2016-06-30 | 株式会社ニトムズ | 抗菌処理用粘着クリーナー |

| WO2017096048A1 (en) | 2015-12-01 | 2017-06-08 | Kimberly-Clark Worldwide, Inc. | Absorbent and protective composition containing an elastomeric copolymer |

| CN108778708A (zh) | 2016-01-12 | 2018-11-09 | 佐治亚-太平洋无纺布有限责任公司 | 非织造清洁基材 |

| US11172803B2 (en) | 2016-08-12 | 2021-11-16 | The Procter & Gamble Company | Cleaning sheets having coating thereon |

| US20190387956A1 (en) * | 2017-01-25 | 2019-12-26 | 3M Innovative Properties Company | Dusting articles consisting of easytrap and interior scrim |

| US11253128B2 (en) | 2017-09-11 | 2022-02-22 | The Procter & Gamble Company | Cleaning article with differential pitch tow tufts |

| US11950737B2 (en) * | 2017-09-11 | 2024-04-09 | The Procter & Gamble Company | Cleaning article with irregularly spaced tow tufts |

| US10722091B2 (en) | 2017-10-06 | 2020-07-28 | The Procter & Gamble Company | Cleaning article with preferentially coated tow fibers |

| US10653286B2 (en) | 2017-10-06 | 2020-05-19 | The Procter & Gamble Company | Cleaning article with preferential coating |

| US11839845B2 (en) | 2018-08-03 | 2023-12-12 | 3M Innovative Properties Company | Air-filter media comprising a relofted spunbonded web, and methods of making and using |

| WO2020033946A1 (en) * | 2018-08-10 | 2020-02-13 | Avery Dennison Retail Information Services, Llc | Intelligent advertising insert method, system, and apparatus |

| JP1643789S (zh) * | 2018-11-09 | 2019-10-21 | ||

| CN113165311A (zh) | 2018-12-20 | 2021-07-23 | 宝洁公司 | 包括成形的非织造基底的粘结层合体 |

| DE102019104225A1 (de) * | 2019-02-20 | 2020-08-20 | Rkw Se | Dehnbares Windelelement |

| US11812909B2 (en) | 2020-04-10 | 2023-11-14 | The Procter & Gamble Company | Cleaning implement with a rheological solid composition |

| US20210315434A1 (en) | 2020-04-10 | 2021-10-14 | The Procter & Gamble Company | Cleaning article with preferential rheological solid composition |

| US11638473B2 (en) * | 2020-04-29 | 2023-05-02 | L'oreal | Pleated cosmetic tool |

| EP4229161A1 (en) | 2020-10-16 | 2023-08-23 | The Procter & Gamble Company | Cleaning article with preferential coating |

| KR102280533B1 (ko) * | 2021-01-04 | 2021-07-26 | 주식회사 라온티알엠 | 고성능 테이프 클리너 |

| US11833237B2 (en) | 2021-03-09 | 2023-12-05 | The Procter & Gamble Company | Method for enhancing scalp active deposition |

| US11965298B2 (en) | 2021-12-01 | 2024-04-23 | Saudi Arabian Oil Company | System, apparatus, and method for detecting and removing accumulated sand in an enclosure |

Family Cites Families (182)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US429589A (en) * | 1890-06-03 | rowland | ||

| US341944A (en) * | 1886-05-18 | George w | ||

| US172703A (en) * | 1876-01-25 | Improvement in neck-ties | ||

| US301088A (en) * | 1884-07-01 | Thomas | ||

| US161221A (en) * | 1875-03-23 | Improvement in excavators | ||

| US370127A (en) * | 1887-09-20 | Electrical transmission of power | ||

| US2325903A (en) * | 1941-09-20 | 1943-08-03 | Mishawaka Rubber & Woolen Mfg | Method of making sponge rubber material |

| BE534424A (zh) * | 1953-12-24 | |||

| US2862251A (en) * | 1955-04-12 | 1958-12-02 | Chicopee Mfg Corp | Method of and apparatus for producing nonwoven product |

| US3047444A (en) * | 1955-07-15 | 1962-07-31 | Kimberly Clark Co | Non-woven fabric and method of making the same |

| US3025199A (en) * | 1956-06-13 | 1962-03-13 | Kimberly Clark Co | Puffed cellulosic product and method of manufacture |

| US3208093A (en) * | 1960-05-31 | 1965-09-28 | Fred M Greider | Tack cloth coated with plasticized synthetic resin and method for preparing same |

| DE1428365A1 (de) | 1962-02-23 | 1968-11-28 | Colgate Palmolive Co | Scheuerflecken,sowie Verfahren zur Herstellung derselben |

| US3424643A (en) * | 1965-11-08 | 1969-01-28 | Kimberly Clark Co | Sheet material creped tissue product |

| US3494821A (en) * | 1967-01-06 | 1970-02-10 | Du Pont | Patterned nonwoven fabric of hydraulically entangled textile fibers and reinforcing fibers |

| US3485706A (en) | 1968-01-18 | 1969-12-23 | Du Pont | Textile-like patterned nonwoven fabrics and their production |

| US3597299A (en) * | 1968-07-03 | 1971-08-03 | Kimberly Clark Co | Disposable washcloth |

| US3687754A (en) * | 1968-10-23 | 1972-08-29 | Kimberly Clark Co | Method of manufacturing an elastic nonwoven fabric |

| US3775231A (en) | 1968-12-20 | 1973-11-27 | Kimberly Clark Co | Multiple embossed flexible web |

| US3575764A (en) * | 1969-03-03 | 1971-04-20 | Hercules Inc | Bonding fabrics |

| US3619251A (en) | 1969-05-22 | 1971-11-09 | Norman S Stiles Sr | Cleaning and polishing cloth and method of making it |

| US3616157A (en) * | 1969-08-08 | 1971-10-26 | Johnson & Johnson | Embossed nonwoven wiping and cleaning materials |

| US3673060A (en) * | 1970-01-12 | 1972-06-27 | Int Paper Co | Adhesively laminated creped dinner napkin |

| CA956873A (en) | 1970-01-26 | 1974-10-29 | Philip Surowitz | Crumpled laminated fabrics and methods of making the same |

| US3629047A (en) | 1970-02-02 | 1971-12-21 | Hercules Inc | Nonwoven fabric |

| US4207367A (en) * | 1970-03-30 | 1980-06-10 | Scott Paper Company | Nonwoven fabric |

| US3658578A (en) * | 1970-07-22 | 1972-04-25 | Phillips Petroleum Co | Dust-retentive article |

| US3695985A (en) * | 1970-07-29 | 1972-10-03 | Kimberly Clark Co | High bulk laminates |

| US3687797A (en) * | 1970-09-28 | 1972-08-29 | Kimberly Clark Co | Resilient cellulosic wadding product |

| US3708361A (en) * | 1970-11-16 | 1973-01-02 | Kimberly Clark Co | Method of making elastic high-loft non-woven fabric with improved cross directional strength |

| US3780392A (en) | 1971-07-09 | 1973-12-25 | Quatek Inc | Micro-organism control composition and dust cloth therewith |

| US3755062A (en) * | 1971-07-21 | 1973-08-28 | Grace W R & Co | Fabric formed by heat sealing, shrinking and foaming backing |

| US4001472A (en) * | 1971-09-03 | 1977-01-04 | Kimberly-Clark Corporation | Nonwoven reinforced cellulosic material and method of preparation |

| US3794537A (en) * | 1972-03-21 | 1974-02-26 | Georgia Pacific Corp | Method of making absorbent pads |

| GB1445981A (en) * | 1972-08-11 | 1976-08-11 | Beghin Say Sa | Net and method of producing same |

| GB1454403A (en) | 1972-11-13 | 1976-11-03 | Strickman R L | Polyurethane sponges |

| US3953638A (en) * | 1973-11-26 | 1976-04-27 | The Procter & Gamble Company | Multi-ply absorbent wiping product having relatively inextensible center ply bonded to highly extensible outer plies |

| US3965518A (en) * | 1974-07-08 | 1976-06-29 | S. C. Johnson & Son, Inc. | Impregnated wiper |

| US3965519A (en) * | 1974-07-08 | 1976-06-29 | S. C. Johnson & Son, Inc. | Disposable floor polishing wipe |

| GB1550955A (en) * | 1975-12-29 | 1979-08-22 | Johnson & Johnson | Textile fabric and method of manufacturing the same |

| DE2632545C2 (de) * | 1976-07-20 | 1984-04-26 | Collo Gmbh, 5303 Bornheim | Reinigungskörper für die Körperpflege, für Haushaltszwecke und dgl. |

| US4097638A (en) * | 1976-12-20 | 1978-06-27 | Conwed Corporation | Selectively sorptive reinforced sheet |

| US4064061A (en) | 1977-01-04 | 1977-12-20 | Magi-Cloth, Inc. | Cleaning cloth composition |

| CA1109654A (en) * | 1978-08-21 | 1981-09-29 | Minnesota Mining And Manufacturing Company | Embossed dust mop having embossed, nonwoven fabric cleaning element |

| US4418123A (en) | 1978-12-06 | 1983-11-29 | H. B. Fuller Company | Extrudable self-adhering elastic and method of employing same |

| US4543099A (en) * | 1978-12-06 | 1985-09-24 | H. B. Fuller Company | Method for imparting elastic properties to a flexible substrate |

| US4239792A (en) | 1979-02-05 | 1980-12-16 | The Procter & Gamble Company | Surface wiping device |

| US4342314A (en) * | 1979-03-05 | 1982-08-03 | The Procter & Gamble Company | Resilient plastic web exhibiting fiber-like properties |

| DE3166379D1 (en) | 1980-01-16 | 1984-11-08 | Procter & Gamble | Cleansing article |

| US4355425A (en) * | 1980-02-01 | 1982-10-26 | The Procter & Gamble Company | Panty with a built-in elastic system to minimize gathering and provide a comfortable, conforming fit and method to assemble a panty |

| US4612231A (en) * | 1981-10-05 | 1986-09-16 | James River-Dixie Northern, Inc. | Patterned dry laid fibrous web products of enhanced absorbency |

| US4412879A (en) | 1981-11-02 | 1983-11-01 | Ranpak Corp. | Cushioning dunnage apparatus and method |

| IN157924B (zh) | 1982-01-22 | 1986-07-26 | Chicopee | |

| NZ205183A (en) * | 1982-08-13 | 1987-01-23 | Unilever Plc | Wiping cloth includes a liquid"active material" |

| US4436780A (en) * | 1982-09-02 | 1984-03-13 | Kimberly-Clark Corporation | Nonwoven wiper laminate |

| US5057366A (en) | 1982-09-16 | 1991-10-15 | Minnesota Mining And Manufacturing Company | Acrylate copolymer pressure-sensitive adhesive coated sheet material |

| US4769265A (en) * | 1983-01-10 | 1988-09-06 | Coburn Jr Joseph W | Laminated decorative film and methods of making same |

| US4426417A (en) * | 1983-03-28 | 1984-01-17 | Kimberly-Clark Corporation | Nonwoven wiper |

| CA1252604A (en) * | 1984-05-11 | 1989-04-18 | Gavin B. Rowe | Wiping article |

| US4634621A (en) * | 1984-05-17 | 1987-01-06 | The James River Corporation | Scrim reinforced, cloth-like composite laminate and a method of making |

| US4522863A (en) * | 1984-06-21 | 1985-06-11 | Kimberly-Clark Corporation | Soft nonwoven laminate bonded by adhesive on reinforcing scrim |

| US4637949A (en) * | 1984-07-03 | 1987-01-20 | James River Corporation | Scrim reinforced, flat cloth-like composite laminate and a method of making |

| US4731276A (en) * | 1984-07-03 | 1988-03-15 | The James River Corporation | Scrim reinforced, quilted cloth-like composite laminate and a method of making |

| ATE59811T1 (de) * | 1984-10-19 | 1991-01-15 | Biflex Dev Partners Ltd | Verfahren zum verbinden von schichten ohne klebemittel. |

| USD287433S (en) | 1985-01-08 | 1986-12-30 | Dry Forming Processes In Europe Ab | Embossed pattern for paper tissue |

| US4609518A (en) * | 1985-05-31 | 1986-09-02 | The Procter & Gamble Company | Multi-phase process for debossing and perforating a polymeric web to coincide with the image of one or more three-dimensional forming structures |

| US4683001A (en) * | 1985-08-23 | 1987-07-28 | Kimberly-Clark Corporation | One step dry-and-shine polishing cloth |

| US4606964A (en) * | 1985-11-22 | 1986-08-19 | Kimberly-Clark Corporation | Bulked web composite and method of making the same |

| US4636429A (en) * | 1986-01-13 | 1987-01-13 | Kimberly-Clark Corporation | Dusting cloth |

| US4666621A (en) * | 1986-04-02 | 1987-05-19 | Sterling Drug Inc. | Pre-moistened, streak-free, lint-free hard surface wiping article |

| US5292582A (en) * | 1986-04-04 | 1994-03-08 | Kimberly-Clark Corporation | Elastic dust cloth |

| US4737559A (en) | 1986-05-19 | 1988-04-12 | Minnesota Mining And Manufacturing Co. | Pressure-sensitive adhesive crosslinked by copolymerizable aromatic ketone monomers |

| USD301088S (en) | 1986-05-27 | 1989-05-16 | Patty Madden Inc. | Synthetic resin cloth |

| US4741944A (en) * | 1986-07-30 | 1988-05-03 | Kimberly-Clark Corporation | Wet wipe and wipe dispensing arrangement |

| US4781966A (en) | 1986-10-15 | 1988-11-01 | Kimberly-Clark Corporation | Spunlaced polyester-meltblown polyetherester laminate |

| US4704321A (en) | 1986-11-05 | 1987-11-03 | E. I. Du Pont De Nemours And Company | Stitched polyethylene plexifilamentary sheet |

| US4772501A (en) * | 1987-02-27 | 1988-09-20 | James River Corporation | Wet wiper natural acid preservation system |

| US5277761A (en) * | 1991-06-28 | 1994-01-11 | The Procter & Gamble Company | Cellulosic fibrous structures having at least three regions distinguished by intensive properties |

| US4773238A (en) * | 1987-08-14 | 1988-09-27 | E. I. Du Pont De Nemours And Company | Stitched nonwoven dust-cloth |

| US4778644A (en) * | 1987-08-24 | 1988-10-18 | The Procter & Gamble Company | Method and apparatus for making substantially fluid-impervious microbubbled polymeric web using high pressure liquid stream |

| US4808467A (en) * | 1987-09-15 | 1989-02-28 | James River Corporation Of Virginia | High strength hydroentangled nonwoven fabric |

| US4891258A (en) * | 1987-12-22 | 1990-01-02 | Kimberly-Clark Corporation | Stretchable absorbent composite |

| US4880682A (en) | 1988-03-22 | 1989-11-14 | Exxon Chemical Patents Inc. | Low gloss film and process of manufacture (FP 1323) |

| US5227228A (en) * | 1988-05-02 | 1993-07-13 | Newell Robert D | Sorptive article comprising elements having capacitive spaces for fluid and/or particulate solids |

| US5616394A (en) | 1988-05-13 | 1997-04-01 | Minnesota Mining And Manufacturing Company | Sheet of loop material, and garments having such loop material incorporated therein |

| US5643397A (en) | 1988-05-13 | 1997-07-01 | Minnesota Mining And Manufacturing Company | Equipment for forming a sheet of loop material |

| AU622171B2 (en) | 1988-05-13 | 1992-04-02 | Minnesota Mining And Manufacturing Company | Sheet material for forming the loop portion for hook and loop fasteners |

| US5256231A (en) | 1988-05-13 | 1993-10-26 | Minnesota Mining And Manufacturing Company | Method for making a sheet of loop material |

| US4820579A (en) * | 1988-06-07 | 1989-04-11 | Colgate-Palmolive Company | Scrubber pad |

| US5198293A (en) * | 1988-06-15 | 1993-03-30 | International Paper Company | Non-woven cleaning cloth |

| US5198292A (en) * | 1988-06-15 | 1993-03-30 | International Paper Company | Tack cloth for removing solid particles from solid surfaces and method for its manufacture |

| US4941995A (en) * | 1988-07-05 | 1990-07-17 | Scott Paper Company | Natural preservative composition for wet wipes |

| DE3826318A1 (de) * | 1988-08-03 | 1990-02-15 | Hoechst Ag | Hochfester plattenfoermiger koerper mit oberflaechenstruktur |

| US4931201A (en) | 1988-09-02 | 1990-06-05 | Colgate-Palmolive Company | Wiping cloth for cleaning non-abrasive surfaces |

| US4904524A (en) * | 1988-10-18 | 1990-02-27 | Scott Paper Company | Wet wipes |

| US4946617A (en) * | 1988-11-15 | 1990-08-07 | Nordico, Inc. | Substantially dry cleaning wipe capable of rendering a cleaned surface static free |

| US4945617A (en) * | 1989-03-20 | 1990-08-07 | General Motors Corporation | Seat belt buckle |

| US4904521A (en) | 1989-05-26 | 1990-02-27 | Kimberly-Clark Corporation | Melt-blown nonwoven wiper |

| EP0418493A1 (en) | 1989-07-28 | 1991-03-27 | Fiberweb North America, Inc. | A nonwoven composite fabric combined by hydroentangling and a method of manufacturing the same |

| US5203186A (en) * | 1989-09-13 | 1993-04-20 | E. I. Du Pont De Nemours And Company | Stitch-stabilized nonwoven fabric |

| US5144729A (en) * | 1989-10-13 | 1992-09-08 | Fiberweb North America, Inc. | Wiping fabric and method of manufacture |

| DE3937720A1 (de) | 1989-11-13 | 1991-05-16 | Henkel Kgaa | Verfahren zur reinigung von mikrowellengeraeten |

| US5599550A (en) * | 1989-11-18 | 1997-02-04 | Kohlruss; Gregor | Disposable, biodegradable, wax-impregnated dust-cloth |

| US5065887A (en) | 1990-02-20 | 1991-11-19 | Scott Paper Company | Container with hinged cover |

| US5098764A (en) * | 1990-03-12 | 1992-03-24 | Chicopee | Non-woven fabric and method and apparatus for making the same |

| US5142752A (en) * | 1990-03-16 | 1992-09-01 | International Paper Company | Method for producing textured nonwoven fabric |

| US5185856A (en) | 1990-03-16 | 1993-02-09 | Hewlett-Packard Company | Arithmetic and logic processing unit for computer graphics system |

| CA2029491C (en) | 1990-03-30 | 2001-12-18 | David C. Strack | Flat laminations of textiles and nonwoven elastomeric webs |

| US5165979A (en) | 1990-05-04 | 1992-11-24 | Kimberly-Clark Corporation | Three-dimensional polymer webs with improved physical properties |

| US5275700A (en) * | 1990-06-29 | 1994-01-04 | The Procter & Gamble Company | Papermaking belt and method of making the same using a deformable casting surface |

| USD341944S (en) | 1990-09-11 | 1993-12-07 | Merfin Hygienic Products Ltd. | Embossed tissue or similar article |

| US5093190A (en) * | 1990-10-22 | 1992-03-03 | E. I. Du Pont De Nemours And Company | Spunlaced acrylic/polyester fabrics |

| JP3139713B2 (ja) | 1990-12-20 | 2001-03-05 | ソリユテイア・インコーポレイテッド | 積層グレージングのためのプラスチックシート及び接着の調節並びにそれのブロッキング化の低減化方法 |

| US5334446A (en) | 1992-01-24 | 1994-08-02 | Fiberweb North America, Inc. | Composite elastic nonwoven fabric |

| WO1993015245A1 (en) | 1992-02-03 | 1993-08-05 | Minnesota Mining And Manufacturing Company | Nonwoven sheet materials, tapes and methods |

| EP0556749B1 (en) | 1992-02-13 | 1997-05-07 | Japan Absorbent Technology Institute | A sheet elastic complex used in sanitary products, its manufacturing process, and its usages |

| DE9202836U1 (zh) * | 1992-03-04 | 1992-06-04 | Grundmann, Ernst H., 4005 Meerbusch, De | |

| US5280664A (en) * | 1992-03-20 | 1994-01-25 | Lin Mary D | Disposable household cleaning devices |

| US5464096A (en) | 1992-08-25 | 1995-11-07 | Hurwitz; Robert | Kit for cleaning radiological cassettes |

| DE4238541C2 (de) * | 1992-11-14 | 1999-01-28 | Amoco Fabrics Zweigniederlassu | Verfahren und Vorrichtung zur Herstellung einer elastischen, mehrschichtigen Materialbahn |

| DE4243012C2 (de) | 1992-12-18 | 1997-09-11 | Corovin Gmbh | Mehrschichtiges elastisches Flächengebilde sowie Verfahren zur Herstellung eines mehrschichtigen elastischen Flächengebildes |

| CA2092581C (en) * | 1992-12-22 | 2003-10-14 | Judith K. Faass | Self-adhesive nonwoven elastic compressible composite material |

| US5310590A (en) * | 1993-02-04 | 1994-05-10 | Minnesota Mining And Manufacturing Company | Stitchbonded articles |

| US5342436A (en) * | 1993-03-11 | 1994-08-30 | Thrasher John K | Composition for protecting and sealing articles |

| CA2136675C (en) * | 1993-12-17 | 2005-02-15 | Kimberly-Clark Worldwide, Inc. | Liquid permeable, quilted film laminates |

| CA2123330C (en) * | 1993-12-23 | 2004-08-31 | Ruth Lisa Levy | Ribbed clothlike nonwoven fabric and process for making same |

| JP2765690B2 (ja) * | 1993-12-27 | 1998-06-18 | 花王株式会社 | 清掃用シート |

| US5470648A (en) | 1994-06-10 | 1995-11-28 | E. I. Du Pont De Nemours And Company | Composite fabrics of nonwoven nylon layers and fiberglass scrim |

| US5681302A (en) | 1994-06-14 | 1997-10-28 | Minnesota Mining And Manufacturing Company | Elastic sheet-like composite |

| US5595567A (en) * | 1994-08-09 | 1997-01-21 | The Procter & Gamble Company | Nonwoven female component for refastenable fastening device |

| JP2986689B2 (ja) * | 1994-08-29 | 1999-12-06 | ユニ・チャーム株式会社 | 不織布ワイパーの製造方法 |

| US5591239A (en) * | 1994-08-30 | 1997-01-07 | Minnesota Mining And Manufacturing Company | Nonwoven abrasive article and method of making same |

| US5674591A (en) * | 1994-09-16 | 1997-10-07 | James; William A. | Nonwoven fabrics having raised portions |

| MX9703158A (es) * | 1994-11-02 | 1997-07-31 | Procter & Gamble | Metodo para producir generos no tejidos. |

| USD370127S (en) | 1994-11-30 | 1996-05-28 | Foamex L.P. | Diamond surface pattern for synthetic foam sheeting |

| HUP9801443A3 (en) * | 1995-04-27 | 2001-11-28 | Procter & Gamble | Carrier substrate treated with high internal water phase inverse emulsion made with an organopolysiloxane-polyoxyalkylene emulsifier |

| DE19518975C1 (de) * | 1995-05-23 | 1996-06-13 | Freudenberg Carl Fa | Wischtuch |

| JP3208306B2 (ja) | 1995-11-17 | 2001-09-10 | ユニ・チャーム株式会社 | 使い捨て拭き取り用具 |

| JP3124478B2 (ja) | 1995-12-01 | 2001-01-15 | ユニ・チャーム株式会社 | 使い捨て拭き取り用具の製造方法 |

| JP3515261B2 (ja) | 1995-12-15 | 2004-04-05 | 株式会社ニトムズ | 清掃布 |

| US5662758A (en) * | 1996-01-10 | 1997-09-02 | The Procter & Gamble Company | Composite material releasably sealable to a target surface when pressed thereagainst and method of making |

| ATE228925T1 (de) * | 1996-01-10 | 2002-12-15 | Procter & Gamble | Verfahren zum herstellen eines materials mit einer substanz, die mit verformbaren vorsprüngen geschützt wird |

| JP3231993B2 (ja) * | 1996-02-28 | 2001-11-26 | ユニ・チャーム株式会社 | 掃除用シート |

| US5874159A (en) * | 1996-05-03 | 1999-02-23 | E. I. Du Pont De Nemours And Company | Durable spunlaced fabric structures |

| KR100304217B1 (ko) | 1996-05-23 | 2001-11-22 | 데이비드 엠 모이어 | 연속망영역을갖는다겹티슈페이퍼 |

| US5840403A (en) * | 1996-06-14 | 1998-11-24 | The Procter & Gamble Company | Multi-elevational tissue paper containing selectively disposed chemical papermaking additive |

| US5958555A (en) * | 1996-07-03 | 1999-09-28 | Uni-Charm Corporation | Disposable wiper sheet |

| US6074505A (en) | 1996-07-15 | 2000-06-13 | The Procter & Gamble Company | Structure and method of forming a laminate structure |

| US5843057A (en) | 1996-07-15 | 1998-12-01 | Kimberly-Clark Worldwide, Inc. | Film-nonwoven laminate containing an adhesively-reinforced stretch-thinned film |

| US5904793A (en) | 1996-08-14 | 1999-05-18 | Minnesota Mining And Manufacturing Company | Method and equipment for rapid manufacture of loop material |

| US5965235A (en) * | 1996-11-08 | 1999-10-12 | The Procter & Gamble Co. | Three-dimensional, amorphous-patterned, nesting-resistant sheet materials and method and apparatus for making same |

| TW307179U (en) * | 1996-11-22 | 1997-06-01 | Xing-Yuan Xu | Multi-directional mop structure improvement |

| US5960508A (en) | 1996-11-26 | 1999-10-05 | The Proctor & Gamble Company | Cleaning implement having controlled fluid absorbency |

| US5918342A (en) * | 1996-12-06 | 1999-07-06 | Smith; Sidney D. | Method of and apparatus for sanitizing MRI machines |

| DE19710032B4 (de) * | 1997-03-12 | 2004-01-29 | Carl Freudenberg Kg | Textiles Flächenmaterial für Reinigungszwecke |

| SG65749A1 (en) | 1997-04-17 | 1999-06-22 | Kao Corp | Cleaning sheet |

| JP2001527454A (ja) | 1997-05-23 | 2001-12-25 | ザ、プロクター、エンド、ギャンブル、カンパニー | 掃除シートとして有用な三次元構造体 |

| TR200000379T2 (tr) | 1997-08-12 | 2000-09-21 | The Procter & Gamble Company | Gevşek dokuma katmanı ve üç boyutlu temizleme yüzeyine sahip temizleme maddesi. |

| US6197404B1 (en) | 1997-10-31 | 2001-03-06 | Kimberly-Clark Worldwide, Inc. | Creped nonwoven materials |

| US6305046B1 (en) | 1998-06-02 | 2001-10-23 | The Procter & Gamble Company | Cleaning implements having structures for retaining a sheet |

| US6314627B1 (en) | 1998-06-30 | 2001-11-13 | Polymer Group, Inc. | Hydroentangled fabric having structured surfaces |

| US20020050016A1 (en) * | 2000-02-24 | 2002-05-02 | Willman Kenneth William | Cleaning sheets comprising a polymeric additive to improve particulate pick-up and minimize residue left on surfaces and cleaning implements for use with cleaning sheets |

| JP2000210238A (ja) | 1999-01-21 | 2000-08-02 | Kao Corp | 清掃用シ―ト |

| USD429589S (en) | 1999-02-19 | 2000-08-22 | Foamex Lp | Carpet cushion |

| WO2000056828A1 (en) | 1999-03-19 | 2000-09-28 | Minnesota Mining And Manufacturing Company | Wet surface adhesives |

| EP1163308B1 (en) * | 1999-03-19 | 2004-10-06 | Minnesota Mining And Manufacturing Company | Plasticized pressure sensitive adhesive |

| JP3988387B2 (ja) * | 1999-03-26 | 2007-10-10 | 王子製紙株式会社 | クリーニングシート |

| US6193918B1 (en) * | 1999-04-09 | 2001-02-27 | The Procter & Gamble Company | High speed embossing and adhesive printing process and apparatus |

| ATE322874T1 (de) * | 1999-07-02 | 2006-04-15 | Fintex And Partners Italia S P | Bahnmaterial mit einem kunststoffilm und einer faserbahn, verfahren und vorrichtung zu dessen herstellung sowie dessen verwendungen |

| AU6900500A (en) | 1999-08-11 | 2001-03-05 | Procter & Gamble Company, The | Cleaning sheets to minimize residue left on surfaces |

| US20010029966A1 (en) | 1999-12-10 | 2001-10-18 | Arthur Wong | Non-apertured cleaning sheets having non-random macroscopic three-dimensional character |

| USD454433S1 (en) | 2000-03-17 | 2002-03-19 | Concert Industries Ltd. | Embossed non-woven fabric |

| WO2001071081A1 (en) | 2000-03-24 | 2001-09-27 | Kao Corporation | Bulky sheet and process for producing the same |

| US6550092B1 (en) * | 2000-04-26 | 2003-04-22 | S. C. Johnson & Son, Inc. | Cleaning sheet with particle retaining cavities |

| WO2002004548A1 (en) | 2000-07-07 | 2002-01-17 | 3M Innovative Properties Company | Polymer compositions with energetically degradable crosslinker |

| US20020150609A1 (en) | 2001-02-09 | 2002-10-17 | Yasuhiro Kono | Cosmetic sheet product |

| WO2002083834A1 (en) | 2001-04-12 | 2002-10-24 | The Procter & Gamble Company | Cleaning sheets having long-lasting perfume odor |

| US20030003832A1 (en) * | 2001-06-29 | 2003-01-02 | The Procter & Gamble Company | Cleaning sheets comprising a fibrous web of carded staple fibers hydroentangled with a reinforcing fibrous web |

| US20030003831A1 (en) * | 2001-06-29 | 2003-01-02 | Childs Stephen Lee | Cleaning sheets comprising multi-denier fibers |

| US20030171051A1 (en) * | 2002-03-08 | 2003-09-11 | 3M Innovative Properties Company | Wipe |

| USD478494S1 (en) | 2002-09-20 | 2003-08-19 | Kevin D. Arnold | Replaceable, trimmable grip with pressure sensitive adhesive for tool handle |

| AU2003277527A1 (en) | 2002-12-27 | 2004-07-29 | Kao Corporation | Cleaning sheet |

-

2002

- 2002-03-08 US US10/093,792 patent/US20030171051A1/en not_active Abandoned

-

2003

- 2003-02-14 EP EP03744109A patent/EP1482828B1/en not_active Expired - Lifetime

- 2003-02-14 ES ES03744109T patent/ES2333954T3/es not_active Expired - Lifetime

- 2003-02-14 KR KR1020047014003A patent/KR20050048540A/ko not_active Application Discontinuation

- 2003-02-14 EP EP20090168461 patent/EP2113186B1/en not_active Expired - Lifetime

- 2003-02-14 CA CA 2477154 patent/CA2477154A1/en not_active Abandoned

- 2003-02-14 BR BRPI0308264-4A patent/BR0308264A/pt not_active IP Right Cessation

- 2003-02-14 AT AT03744109T patent/ATE444013T1/de not_active IP Right Cessation

- 2003-02-14 JP JP2003574017A patent/JP2005526548A/ja active Pending

- 2003-02-14 CN CNA038053993A patent/CN1638683A/zh active Pending

- 2003-02-14 DE DE60329472T patent/DE60329472D1/de not_active Expired - Lifetime

- 2003-02-14 MX MXPA04008482A patent/MXPA04008482A/es unknown

- 2003-02-14 WO PCT/US2003/004420 patent/WO2003075735A1/en active Application Filing

- 2003-02-14 AU AU2003211044A patent/AU2003211044A1/en not_active Abandoned

-

2006

- 2006-02-24 US US11/361,875 patent/US7691760B2/en not_active Expired - Fee Related

-

2010

- 2010-02-19 US US12/708,931 patent/US20100139021A1/en not_active Abandoned

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101969832B (zh) * | 2008-03-14 | 2013-08-21 | 尼托母斯股份有限公司 | 清扫用胶粘带辊和胶粘带的制造装置及其制造方法 |

| CN102825849A (zh) * | 2012-08-09 | 2012-12-19 | 濮阳市虹霞新型防水材料有限公司 | 皱褶型防水卷材生产工艺 |

| CN102825849B (zh) * | 2012-08-09 | 2015-10-21 | 濮阳市虹霞新型防水材料有限公司 | 皱褶型防水卷材生产工艺 |

| CN104367280A (zh) * | 2014-11-25 | 2015-02-25 | 苏州新纶超净技术有限公司 | 一种可有效去除微尘的机织无尘布及其制造方法 |

| CN104688140A (zh) * | 2015-04-05 | 2015-06-10 | 高尚义 | 一种书本式抹布 |

| CN109070554A (zh) * | 2015-12-01 | 2018-12-21 | 金伯利-克拉克环球有限公司 | 吸油擦拭产品 |

| CN109070554B (zh) * | 2015-12-01 | 2021-06-04 | 金伯利-克拉克环球有限公司 | 吸油擦拭产品 |

| CN106388737A (zh) * | 2016-11-05 | 2017-02-15 | 北海益生源农贸有限责任公司 | 一种高容污性能的集成拖把 |

Also Published As

| Publication number | Publication date |

|---|---|

| US7691760B2 (en) | 2010-04-06 |

| CA2477154A1 (en) | 2003-09-18 |

| US20030171051A1 (en) | 2003-09-11 |

| DE60329472D1 (de) | 2009-11-12 |

| EP1482828A1 (en) | 2004-12-08 |

| EP2113186A1 (en) | 2009-11-04 |

| BR0308264A (pt) | 2007-01-09 |

| JP2005526548A (ja) | 2005-09-08 |

| AU2003211044A1 (en) | 2003-09-22 |

| EP2113186B1 (en) | 2013-04-24 |

| WO2003075735A1 (en) | 2003-09-18 |

| US20100139021A1 (en) | 2010-06-10 |

| EP1482828B1 (en) | 2009-09-30 |

| MXPA04008482A (es) | 2004-12-06 |

| KR20050048540A (ko) | 2005-05-24 |

| ATE444013T1 (de) | 2009-10-15 |

| ES2333954T3 (es) | 2010-03-03 |

| US20060141881A1 (en) | 2006-06-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN1638683A (zh) | 抹布 | |

| US7700178B2 (en) | Cleaning wipe with variable loft working surface | |

| CA2590830A1 (en) | Method and apparatus for making a cleaning sheet | |

| KR101102727B1 (ko) | 클리닝 와이프 및 이의 제조 방법 | |

| JP2008510058A (ja) | 接着クリーニングシートを製造するための方法および装置 | |

| US20160183742A1 (en) | Textured cotton wipes | |

| US20070136967A1 (en) | Adhesive wipe | |

| US20060240223A1 (en) | Cleaning sheet and method of making | |

| WO2006023278A1 (en) | Method and apparatus for making an adhesive cleaning sheet | |

| CN103533877A (zh) | 包括纺粘片状件的清洁擦拭物 | |

| JP7358176B2 (ja) | 清掃用シートおよび清掃具 | |

| JPH10216060A (ja) | 掃除用積層シート |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C02 | Deemed withdrawal of patent application after publication (patent law 2001) | ||

| WD01 | Invention patent application deemed withdrawn after publication |