CN101802653B - Sheeting with composite image that floats - Google Patents

Sheeting with composite image that floats Download PDFInfo

- Publication number

- CN101802653B CN101802653B CN2008801066634A CN200880106663A CN101802653B CN 101802653 B CN101802653 B CN 101802653B CN 2008801066634 A CN2008801066634 A CN 2008801066634A CN 200880106663 A CN200880106663 A CN 200880106663A CN 101802653 B CN101802653 B CN 101802653B

- Authority

- CN

- China

- Prior art keywords

- sheet material

- image

- lens

- light

- composograph

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B3/00—Simple or compound lenses

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03B—APPARATUS OR ARRANGEMENTS FOR TAKING PHOTOGRAPHS OR FOR PROJECTING OR VIEWING THEM; APPARATUS OR ARRANGEMENTS EMPLOYING ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ACCESSORIES THEREFOR

- G03B21/00—Projectors or projection-type viewers; Accessories therefor

- G03B21/54—Accessories

- G03B21/56—Projection screens

- G03B21/60—Projection screens characterised by the nature of the surface

- G03B21/62—Translucent screens

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B30/00—Optical systems or apparatus for producing three-dimensional [3D] effects, e.g. stereoscopic images

- G02B30/20—Optical systems or apparatus for producing three-dimensional [3D] effects, e.g. stereoscopic images by providing first and second parallax images to an observer's left and right eyes

- G02B30/26—Optical systems or apparatus for producing three-dimensional [3D] effects, e.g. stereoscopic images by providing first and second parallax images to an observer's left and right eyes of the autostereoscopic type

- G02B30/27—Optical systems or apparatus for producing three-dimensional [3D] effects, e.g. stereoscopic images by providing first and second parallax images to an observer's left and right eyes of the autostereoscopic type involving lenticular arrays

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B30/00—Optical systems or apparatus for producing three-dimensional [3D] effects, e.g. stereoscopic images

- G02B30/50—Optical systems or apparatus for producing three-dimensional [3D] effects, e.g. stereoscopic images the image being built up from image elements distributed over a 3D volume, e.g. voxels

- G02B30/56—Optical systems or apparatus for producing three-dimensional [3D] effects, e.g. stereoscopic images the image being built up from image elements distributed over a 3D volume, e.g. voxels by projecting aerial or floating images

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B5/00—Optical elements other than lenses

- G02B5/12—Reflex reflectors

- G02B5/126—Reflex reflectors including curved refracting surface

- G02B5/128—Reflex reflectors including curved refracting surface transparent spheres being embedded in matrix

Abstract

Techniques are described for forming microlens sheeting having composite images that appear to float with respect to the plane of the sheeting. As one example, a method comprises forming one or more images within a sheeting having a surface of microlenses, wherein at least one of the images is a partially complete image, and wherein each of the images is associated with a different one of the microlenses, wherein the microlenses have refractive surfaces that transmit light to positions within the sheeting to produce a plurality of composite images from the images formed within the sheeting so that each of the composite images appears to float with respect to the plane of the sheeting, and wherein forming the one or more images comprises forming the one or more images such that each of the composite images is associated with a different viewing angle range.

Description

Technical field

The present invention relates to sheet material, this sheet material provides one or more composographs, and the observer feels that composograph is suspended in the air with respect to sheet material, and the observation of synthetic images changes along with the variation at visual angle.

Background technology

Sheet material with graph image or other marks is widely used, in particular for differentiating the label of goods or document.For example, in U.S. Patent No. 3,154,872, No.3,801,183, No.4,082,426 and No.4, those sheet materials described in 099,838 have been used as the safety diaphragm of the checking paster of car plate and driving license, public document, tape, playing card, beverage can etc.Other purposes are included in such as the graphical application that is used as identifying purpose on police car, fire truck or other the urgent purposes vehicles, and show as the characteristic label to strengthen the brand effect in advertisement and sales promotion.

U.S. Patent No. 4,200,875 (Galanos) disclose the imaging sheet material of another kind of form.Galanos discloses the purposes of special " exposing lens-type high-gain retroreflection sheet ", and wherein laser forms image by mask or patterned illumination sheet material.This sheet material comprises and is partially submerged in the adhesive layer and part is exposed to a plurality of clear glass microballoons on the adhesive layer, and is coated with metallic reflector on the embedding surface of each microballoon in a plurality of microballoon.Adhesive layer contains carbon black, it is said that carbon black makes any spurious rays of injecting on it minimize when the sheet material imaging.The lenticular focusing effect that embeds adhesive layer is further concentrated the energy of laser beam.

And if only if when watching sheet material with the equal angular of laser directive sheet material, can see the image that forms in the retroreflection sheet of Galanos.In other words, only this means and in very limited view angle, just can see image.Owing to this reason and other reasons, improve in addition the needs of this some characteristic of based sheet.

As far back as 1908, Gabriel Lippman just invented the method for the true three-dimension image of generating scene in having the lens medium of one or more photographic layers.This method that is called as integral photography is described in Publication about Document to some extent: De Montebello, " Processing andDisplay of Three-Dimensional Data II " in Proceedings of SPIE, SanDiego, 1984 (De Montebello, " processing of three-dimensional data and demonstration II ", U.S. SPIE proceedings, 1984).In the method for Lippman, scioptics (or " lenslet ") array exposes to photographic negative, so that each lenslet in the array will be replicated the photographic layer that the thumbnail image of scene is transmitted through photographic negative, just as viewed from the visual angle of the sheet material point that occupied by this lenslet.Photographic negative watches the observer of the composograph on the egative film can see the 3-d reproduction of captured scene by lenslet array after developing.Image can be black and white or colour, and this depends on used photosensitive material.

Because the image that is formed by lenslet in the egative film exposure process only allows each thumbnail image upset once, so the 3-d reproduction that generates is psudoscopic image.That is to say that the perceived depth of image overturns, therefore so that object appears to " inboard outwardly ".This is a significant drawback, because want remedial frames, must carry out the secondary optics upset.These methods are very complicated, relate to a camera or multi-section camera or multi-lens camera carrying out multiexposure, multiple exposure, in order to recording a plurality of views of same object, and need clock like precision ground to aim at a plurality of images so that the single 3 D image to be provided.In addition, any method that depends on traditional camera all requires to exist before camera in kind.This further shows, the method is not suitable for the generating virtual object 3-D view of (referring to exist and non-existent object in fact in effect).Another shortcoming of integral photography is, in order to form the true picture that can see, and must be from watching side illumination composograph.

Summary of the invention

The invention provides a kind of lenticule sheet material, it has the one or more composographs that seem to be suspended in above or below the sheet material.The composite image of these suspensions to be referred to as the image that floats, and they seem to be positioned at (can be two-dimensional image or three-dimensional image) above or below the sheet material, perhaps can look it is the three-dimensional image that is apparent in sheet material top, the upper and lower side in plane.Floating image also can seem to change continuously to another height or the degree of depth from a height or the degree of depth.Floating image can be black and white or colour, and can seem to move and change with the observer.The observer can with the naked eye watch floating image.Term " floating image " also is used as the synonym of term " virtual image ".

With radiation source (as passing through optical module) irradiation sheet material, can in sheet material, form floating image.The energy that incides the incident light on the lenticule sheet material focuses on zone in the sheet material by each lenticule.The energy that focuses on makes this layer modification so that a plurality of independent images to be provided, and its size, shape and outward appearance depend on the interaction between light and the lenticule.For example, light forms the independent image relevant with each lenticule in the sheet material.Lenticule has refractive surface, and this surface transports light on the interior position of sheet material, to generate one or more composographs by independent image.

The floating image of lenticule sheet material can comprise a plurality of composographs that presented (namely from this image viewing) by the image that forms in the lenticule sheet material.Each composograph can be relevant with the different visual angles scope, so that can observe composograph from the different visual angles of sheet material.In certain embodiments, the image that forms in the sheet material can present different composographs, and these different composographs can have different angulars field of view.In this embodiment, two observers that are positioned at respect to the different visual angles place of sheet material can see different composographs from sheet material.In another embodiment, can be formed on identical composograph in a plurality of angulars field of view.In some cases, angular field of view can be overlapping, to form larger continuous angular field of view.Therefore, can observe composograph from the angular field of view more much bigger than original angular field of view.

Sheet material with above-mentioned composograph of the present invention can be used for multiple application, for example the anti-tamper image of safety in security document, passport, I.D., financial transaction card (for example credit card), car plate or other goods.This sheet material also can be used for commercial the application, uses such as automobile.

In one embodiment, a kind of method comprises with the energy beam irradiation having the sheet material on lenticule surface to form a plurality of images in sheet material, the face normal of the misalignment sheet material of energy beam wherein, at least one image that wherein forms in sheet material is the complete image of part, and wherein this image is relevant from the different lenticules of sheet material, wherein lenticule has refractive surface, this refractive surface is transmitted to position in the sheet material with light, is used in the image that forms in the sheet material and produces and seem one or more composographs of floating with respect to the surface of sheet material.

In another embodiment, sheet material comprises the material layer with lenticule surface, lenticule forms a plurality of images in sheet material, wherein at least one image that forms in sheet material is the complete image of part, and wherein image is relevant from the different lenticules of sheet material, wherein lenticule has refractive surface, and refractive surface is transmitted to position in the sheet material with light, is used in the image that forms in the sheet material and produces and seem one or more composographs of floating with respect to the surface of sheet material.

In yet another embodiment, system comprises six shaft mechanical arm and controllers, and wherein six shaft mechanical arms are equipped with the optical package to the substrate imaging, and the motion of six-freedom degree is provided, controller is used for controlling six shaft mechanical arms, by optical package radiation source is located with respect to substrate.

In yet another embodiment, system comprises galvanometer scanner, optical module and controller, and wherein, galvanometer scanner comprises a plurality of catoptrons by galvanometer control, and galvanometer control radiation source is to produce the energy beam to the substrate imaging; Optical module has the object lens for the focus energy bundle; Controller is used for the control galvanometer, so that energy beam is located with respect to optical module.

In another embodiment, be used for the sheet material imaging is comprised fiber optic cables and a plurality of Liar with the optical package that produces composograph, fiber optic cables are used for the transmission laser beam, Liar is used for laser beam direction is in a plurality of focuses of a plurality of different angles, and wherein a plurality of focuses are positioned at a position.

In accompanying drawing and explanation hereinafter, one or more embodiments of the detail of the present invention have been shown.Other performances of the present invention, purpose and advantage will be from this description and accompanying drawings, and it is more obvious to become from claims.

Description of drawings

The present invention will be described with reference to the drawings herein, wherein:

Fig. 1 is the amplification view of " exposing lens " type lenticule sheet material;

Fig. 2 is the amplification view of " embedding lens " type lenticule sheet material;

Fig. 3 is the amplification view that comprises the lenticule sheet material of plano-convex substrate;

Fig. 4 is the synoptic diagram that incides the dissipate energy on the lenticule sheet material that is made of microsphere;

Fig. 5 is the planimetric map of a lenticule sheet material part, this Figure illustrates the sample image that records in the material layer of adjacent each microsphere, and the image that records further is shown becomes partial replication from copying fully of composograph;

Fig. 6 is that it has been imaged to provide the composograph that seems to appear in one's mind above sheet material according to the optical microscopy map of lenticule sheet material of the invention process, as to have the radiation sensitive material layer of being made by the aluminium film;

Fig. 7 is that it has been imaged to provide the composograph that seems to appear in one's mind below sheet material according to the optical microscopy map of lenticule sheet material of the invention process, as to have the radiation sensitive material layer of being made by the aluminium film;

Fig. 8 is the geometrical optics synoptic diagram of composograph forming process, and it seems to appear in one's mind above the lenticule sheet material;

Fig. 9 is the synoptic diagram of sheet material of the present invention, and when watching under reflected light, it has the composograph that seems to appear in one's mind above sheet material;

Figure 10 is the synoptic diagram of sheet material of the present invention, and when watching under transmitted light, it has the composograph that seems to appear in one's mind above sheet material;

Figure 11 is the geometrical optics synoptic diagram of composograph forming process, and it seems to appear in one's mind below the lenticule sheet material;

Figure 12 is the synoptic diagram of sheet material of the present invention, and when watching under reflected light, it has the composograph figure that seems to appear in one's mind below sheet material;

Figure 13 is the synoptic diagram of sheet material of the present invention, and when watching under transmitted light, it has the composograph figure that seems to appear in one's mind below sheet material;

Figure 14 is the description figure of optical module, and its generation is used to form the dissipate energy of composograph of the present invention;

Figure 15 is the description figure of the second optical module, and its generation is used to form the dissipate energy of composograph of the present invention;

Figure 16 is the description figure of the 3rd optical module, and its generation is used to form the dissipate energy of composograph of the present invention;

Figure 17 A and 17B are frame shape figure, illustrate for the example that floating image is write the optical module of sheet material;

Figure 18 is frame shape figure, and the optical package that laser beam is focused on to write substrate is shown;

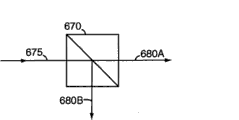

Figure 19 is frame shape figure, and the optical element structure that can form an optical system part is shown;

Figure 20 is frame shape figure, and the system that the six shaft mechanical arms that utilize example write floating image that is shaped as is shown;

Figure 21 A is frame shape figure, and the side view of example objective lens unit is shown, and objective lens unit comprises three object lens, focuses on respectively three laser beam;

Figure 21 B is frame shape figure, and the top view of three lens openings of the objective lens unit of Figure 21 A is shown;

Figure 22 A-22C is frame shape figure, and the exemplary field-of-view cone of the floating image that writes according to technology described herein is shown;

Figure 23 is frame shape figure, illustrates for the beam splitter that incident beam is disperseed stand in channel;

Figure 24 is frame shape figure, and the exemplary divided beam system that comprises grating is shown, and grating is separated into a plurality of light beams with incident beam;

Figure 25 is frame shape figure, illustrates for the exemplary divided beam system that laser beam is divided into a plurality of light beams, and these light beams focus in separately the fiber optic cables;

Figure 26 is the frame shape figure that exemplary divided beam system is shown, and this divided beam system utilizes a pair of galvanometer incoming laser beam to be divided into a plurality of light beams that enter a plurality of passages;

Figure 27 is the frame shape figure that the example divided beam system is shown, and this divided beam system utilizes acousto-optic (AO) modulator that incoming laser beam is divided into a plurality of passages;

Embodiment

Lenticule sheet material of the present invention provides composograph, and it provides by each image relevant with a plurality of lenticules, its seem to suspend or float above sheet material, in the sheet material plane and/or below the sheet material.

For comprehensive description of the present invention is provided, to in the part i lenticule sheet material be described hereinafter, next describe some material layers (being preferably radiation sensitive material layer) of this sheet material in part ii, partly describe radiation source at III, and partly describe imaging process at IV.Provide simultaneously several examples with further explanation a plurality of embodiment of the present invention.

I. lenticule sheet material

The lenticule sheet material that can form therein image of the present invention comprises the lenticule of one or more discrete layers, in adjacent one or more layers lenticular side material layer (being preferably hereinafter described radiation-sensitive materials or coating) is set.For example, Fig. 1 illustrates the lenticule sheet material 10 of " exposing lens " type, and it comprises the single-layer and transparent microsphere 12 that is partially submerged into adhesive layer 14, and this adhesive layer 14 is generally polymeric material.For can be used for the image-forming radiation wavelength of material layer and be used for the light wavelength of watching composograph, microsphere all is transparent.Material layer 16 is arranged on the rear surface of each microsphere, and usually only contacts in the embodiment shown the part on the surface of each microsphere 12.Such sheet material is in U.S. Patent No. 2,326, more detailed description arranged in 634, and can buy from 3M company at present commodity Scotchlite 8910 series reflection fabrics by name.

Fig. 2 illustrates the another kind of lenticule sheet material type that is fit to.This lenticule sheet material 20 is " embedding lens " matrix materials, and wherein microsphere lens 22 are embedded in the transparency protected external coating 24, and this external coating 24 is polymeric material normally.Material layer 26 is arranged on the behind of the transparent spacer layer 28 in microsphere back, and wherein transparent spacer layer 28 also is polymeric material usually.This type sheet material is in U.S. Patent No. 3,801, describes in more detail in 183, and can buy from 3M company at present, and commodity are called Scotchlite 3290 series engineering level retroreflection sheets.The another kind of lenticule sheet material type that is fit to is called the lens sheet of encapsulation, in U.S. Patent No. 5,064, such example has been described in 272, can buy from 3M company at present, commodity are called Scotchlite 3870 series high strength level retroreflection sheets.

Fig. 3 illustrates the another kind of lenticule sheet material type that is fit to.This sheet material comprises that transparent plano-convex or 30, the second 32 of aspheric base sheet with first and second wide are roughly the plane, and first surface has the microlens array 34 that is roughly hemisphere or non-hemisphere.Lenticular shape and substrate thickness approximately focus on second through selecting so that incide the collimated light beam of this array.Material layer 36 is arranged on second.For example, U.S. Patent No. 5,254,390 have described this sheet material, and at present can be available from 3M company, and commodity are called 2600 serial 3M sector card receiver receivers.

The lenticule of sheet material preferably has the imaging refractive surface for imaging, and image is usually by the lenticule Surface forming.To the shaped form surface, lenticule preferably has uniform refractive index.Provide other Available Materials of graded index (GRIN) not need the shaped form surface to come refracted ray.The lenticule surface is real sphere preferably, but non-spherical surface also is acceptable.Lenticule can have any symmetry, and such as post symmetry or Sphere symmetry, precondition is that refractive surface can form picture.Lenticule itself can be multi-form, such as circular plano-convex lenslet, circular biconvex lenslet, rod, microsphere, globule shape or cylindrical lenslet.Can form the combination that lenticular material comprises glass, polymkeric substance, ore, crystal, semiconductor and these materials and other materials.Also can use non-discrete lenticular lens elements.Therefore, also can use the lenticule that is formed by duplication process or embossed technology (wherein the shape of sheet surface can change, and has the repetition profile of imaging characteristic with formation).

The homogeneous refractive index of ultraviolet wavelength, visible wavelength and infrared light wavelength is that the lenticule between 1.5 to 3.0 is the most useful.The microlens material that is fit to is minimum to visible Optical Absorption, and is using energy source to make among the embodiment of radiation-sensitive layer imaging, and material also should show energy source is absorbed minimum.No matter lenticule is discrete or copies, no matter also lenticule by what material is made, refraction will occur and focus on lenticular opposite side in the light that lenticular refractive power is preferably to incide on the refractive surface.More particularly, light will focus on lenticular rear surface or focus on the contiguous lenticular material.Be among radiosensitive embodiment at material layer, lenticule preferably forms the true picture that dwindles in the appropriate position of this layer.About 100 to 800 times image minification is particularly useful for forming the good image of resolution.Described the structure of lenticule sheet material in the United States Patent (USP) that quote previously this part, it provides necessary focused condition, can focus on the material layer so that incide the energy of lenticule sheet material front surface, and this material layer is radiation-sensitive layer preferably.

Although can use the microsphere of other sizes, diameter is that 15 microns microspheres to 275 micrometer ranges are preferred.To being rendered as composograph nearer apart from the microsphere layer on the space, use diameter can obtain good composograph resolution at the microsphere of above-mentioned scope lower limit, and to being rendered as composograph far away apart from microsphere on the space, use larger microsphere can obtain good composograph resolution.Other microspheres (being the size of microsphere appointment suitable convexo-plane, cylindrical, spherical or aspheric microsphere such as lenslet size and those) expection can produce similar optical results.

II. material layer

As mentioned above, provide material layer at contiguous lenticule place.Material layer can be high reflectance, and as the material layer that uses in some above-mentioned lenticule sheet material, or it can have antiradar reflectivity.When material had high reflectance, sheet material can have such as U.S. Patent No. 2,326,634 described retroeflection.When the observer under reflection or transmitted light when observing, each image that in the material relevant with a plurality of lenticules, forms can form seem to suspend or appear in one's mind above sheet material, in the plane and/or below composograph.Although can use additive method, provide the method for optimizing of above-mentioned image to provide radiation-sensitive materials as material layer, and use radiation to make this material sex change so that image to be provided in the mode of expectation.Thereby although the present invention is not limited, all the other problems of contiguous lenticular material layer will mainly be discussed take radiation sensitive material layer as background.

Spendable radiation-sensitive materials comprises coating and the film of the potpourri of metal, polymeric material, semiconductor material and these materials among the present invention.As used in conjunction with the present invention, material is that " radiosensitive " refers to that material appearance can change when the visible light that is exposed to given degree or other radiation, and forms contrast with the material that is not exposed to radiation.Therefore, the image that forms thus may be that the radiation-sensitive coating composition changes, material is removed or the result of ablation, phase transformation or polyreaction.The example of some radiosensitive metal membrane materials comprises the alloy of aluminium, silver, copper, gold, titanium, zinc, tin, chromium, vanadium, tantalum and these metals.Because natural colour and the difference of metal exposed between the color that changes after the radiation of metal, these metals can form contrast usually.As mentioned above, the formation of image can also be adopted and ablate or the radiation heating material, until the optical property of this material changes and forms image.For example, United States Patent (USP) 4,743,526 have described the heating of metal alloy forms change color.

Except metal alloy, metal oxide and metal suboxide also can be used as radiosensitive medium.This class material comprises the oxide that aluminium, iron, copper, tin and chromium form.Nonmetallic materials such as zinc sulphide, zinc selenide, silicon dioxide, tin indium oxide, zinc paste, magnesium fluoride and silicon also can form color or the color contrast useful to the present invention.

Also can provide special radiation-sensitive materials with multilayered film material.These multilayer materials can be constructed to because showing or removing the variation that a kind of color or contrast medium form contrast.Representative configuration comprises optical layers overlapping piece and the tuning cavity that is designed to by the radiation of specific wavelength the imaging variation of color (for example by).A concrete example is in U.S. Patent No. 3,801, describes to some extent in 183, and it discloses use cryolite/zinc sulphide (Na

3AlF

6/ ZnS) as dielectric mirror.Another example is by optical layers overlapping piece that chromium/polymkeric substance (such as the plasma polymerization butadiene)/silicon dioxide/aluminium forms, the thickness of chromium layer is about 4 nanometers, the thickness of polymeric layer is between 20 to 60 nanometers, the thickness of silicon dioxide layer is between 20 to 60 nanometers, the thickness of aluminium lamination is between 80 to 100 nanometers, and each layer thickness of choosing provides the reflectivity to particular color in the visible spectrum.Can use the tuning cavity of the film that contains any single thin film discussed above.For example, to chromium layer with about 4 nanometer thickness and the tuning cavity of the silicon dioxide layer between about 100 nanometer to 300 nanometers, adjust the thickness of silicon dioxide layer, provide colored image with the radiation of response specific wavelength.

The present invention can with radiation-sensitive materials also comprise thermochromic material.The material of color change when " thermochromism " described temperature variation.The example of the thermochromic material that the present invention can use is in U.S. Patent No. 4,424, describes to some extent in 990, and comprises copper carbonate, has the copper nitrate of thiocarbamide and have the copper carbonate of sulfocompound (such as mercaptan, thioether, sulfoxide and sulfone).The example of the thermal discoloration compound that other are fit to is in U.S. Patent No. 4,121, describes to some extent in 011, comprises hydrated sulfate and the nitride of boron, aluminium and bismuth, the oxide of boron, iron and phosphorus and hydrous oxid.

Certainly, if material layer does not prepare to use the radiation source imaging, this material layer can be so, but and need not be radiosensitive.Yet, for ease of making, preferably use radiation-sensitive materials, and thereby also preferably use suitable radiation source.

III. radiation source

As mentioned above, providing the optimal way of picture pattern at contiguous lenticular material layer is to use radiation source so that the radiation-sensitive materials imaging.Any energy source of the radiation of desirable strength and wavelength that provides all can be used for method of the present invention.Can provide wavelength to be considered to especially preferred between the device of the radiation between 200nm and 11 microns.The present invention can with the example of high-peak power radiation source comprise that quasi-molecule flashlamp, passive Q-switched micro-slice laser and Q-switch neodymium-doped yttrium-aluminum garnet (being called for short Nd:YAG) laser instrument, neodymium-doped YLF (being called for short Nd:YLF) laser instrument and titanium-doped sapphire (are called for short Ti: sapphire) laser instrument.These high-peak power radiation sources are to being the most useful by the radiation-sensitive materials of ablating (being removing materials) or form image in the Multiphoton Absorbtion process.Other examples of available radiation source comprise the equipment that low peak power is provided, such as the incandescent light source of laser diode, ion laser, non-Q-switch solid-state laser, metallic vapor laser, gas laser, arc lamp and high power.When radiosensitive medium adopted non-ablative method imaging, these radiation sources were particularly useful.

Concerning all useful radiation sources, from the energy of radiation source directive lenticule sheet material material all, and the controlled energy beam of highly dispersing that sends.To being in the energy source in ultraviolet light, visible light and infrared light district in the electromagnetic spectrum, can be by suitable optical element control light, its example such as Figure 14, Figure 15 and shown in Figure 16 describe hereinafter in more detail.In one embodiment, being optical module to the requirement of this arrangement (being commonly referred to optical module) of optical element disperses or disperses light directive sheet material by suitable, thereby with required angular illumination lenticule, and thereby irradiation material layer.Composograph of the present invention preferably has the light transmission device acquisition of the numerical aperture (being defined as the sine of maximum divergent rays half-angle) more than or equal to 0.3 by use.Light transmission device with bigger numerical aperture produces to have with great visual angle and the composograph of larger image apparent movement scope.

IV. imaging process

Exemplary imaging process according to the present invention comprises the collimated light beam scioptics directive lenticule sheet material from laser instrument.In order to generate the sheet material with floating image, as hereinafter further as described in, light is by having the divergent lens transmission of high-NA (NA), in order to produce the cone-shaped beam of highly dispersing.High NA lens are to have the lens that are equal to or greater than 0.3 NA.The radiation-sensitive coating side of microsphere is set to away from lens, thereby makes light cone axle (optical axial) perpendicular to the plane of lenticule sheet material.

Because in occupation of peculiar position, the light of therefore injecting on each lenticule has distinctive incident angle with respect to the light that incides on each other lenticule to each independent lenticule with respect to optical axial.Like this, light can be transmitted to peculiar position on the material layer by each lenticule, and produces distinctive image.More precisely, single light pulse only produces single imaging point on material layer, therefore in order to provide image at adjacent each lenticule place, uses multiple-pulse light in order to generate this image by a plurality of imaging points.For each pulse, with respect to the optical axial position of a upper recurrence interval, its optical axial is positioned at new position.Optical axis position causes the respective change of the incident angle of light on each lenticule with respect to lenticular continuous variation, correspondingly, and the also corresponding change of position of the imaging point that is generated at material layer by this pulse.Therefore, focus on the incident light at microsphere rear at the image of a selected pattern of radiation sensitive material layer generation.Because with respect to each optical axis, the position of each microsphere is distinctive, so each microsphere will be different at the relevant image of each microsphere of image and other that radiation-sensitive materials forms.

The another kind of method that forms the composograph that floats uses lens to become row to produce the height diverging light, with to micro-transmission material imaging.Lens arra is comprised of a plurality of lenslets, and all lenslets all have high-NA and arrange with plane geometric shape.When this array during by light illumination, this array will generate a plurality of height and disperse light cone, and each independent light cone is in array centered by the lens corresponding with it.Select the physical size of array to adapt to the maximum lateral dimensions of composograph.By the size of array, each energy cone that lens form will make the microlens material exposure, just as independent lens be successively set on array have a few and receive the light pulse.By come the lens of selective reception incident light with the reflectivity mask.This mask has the transparent region corresponding with the part that will expose of composograph and does not answer reflector space corresponding to exposed portion with image.Because lens arra extends laterally, therefore can come rendering image with a plurality of light pulses.

By making the complete radiation mask of projectile energy, allow the part of the mask that energy passes through to form a plurality of independent light cones of describing the height diverging light of floating image profile, just as image is delineated out the profile by single lens.Therefore, only need single light pulse just can in the lenticule sheet material, form whole composograph.Alternatively, a beam position system (such as galvanometer xy scanner) can substitute reflection mask, is used for local irradiation lens arra and draw composite image at array.Because this techniques enable spatially is limited to some zone, therefore only there is the minority lenslet illuminated in the interior array at any given time.Thereby those irradiated lenslets make the microlens material exposure form the required height of composograph at sheet material formation disperses light cone.

Lens arra itself can be processed by a plurality of discrete lenslets, or adopts etch process, produces the monolithic lens arra.The material that is suitable for lens is those materials that do not absorb the light of incident wavelength.Each lens in the array preferably have the numerical aperture greater than 0.3, and greater than 30 microns and less than 10 millimeters diameter.These arrays can have antireflecting coating, can produce inner damaged backreflection effect to lens material in order to reduce.In addition, can also strengthen with effective negative focal length many single lens suitable with this lens arra with size the diversity of the light that leaves array.Select the shape of each lenslet in the monolithic array, make it have high-NA and high fill-factor greater than 60% is provided approximately.

Fig. 4 incides synoptic diagram on the lenticule sheet material with dissipate energy.To each lenticule, all (or wherein) forms image I on the different piece of material layer, because each lenticule " is seen " energy of incident from different visual angles.Like this, in material layer, form the unique image relevant with each lenticule.

After the imaging, according to the dimension of object that extends, the image complete or part of this object can appear in the radiation-sensitive materials of each lenticule back.Actual object is reproduced as image in the microsphere back degree depends on the energy density that incides on this microsphere.The part of the object that extends can be enough far away apart from the lenticule zone, so that the energy density that incides on those microspheres is lower than the required radiation level of this material modification.In addition, to the image that spatially extends, when using the lens imaging of fix N A, all parts that are not sheet material all will be exposed under the incident radiation of all parts that are used for the extension object.Therefore, those parts of object will not change in radiosensitive medium, the parts of images of this object only occur in the lenticule back.Fig. 5 is the skeleton view of a lenticule sheet material part, and this figure is presented on the sample image that forms in contiguous each lenticular radiation-sensitive layer, and the image that records further is shown from the variation that copies to partial replication fully of composograph.Fig. 6 and Fig. 7 are the optical microscopy maps of the lenticule sheet material of the imaging according to the present invention, and wherein radiation-sensitive layer is aluminium lamination.As shown in the figure, some images are complete, and other images then are partly.

These composographs can also be considered to the result of a plurality of images (comprise part with complete) stack, and all these images are from the different visual angles to real-world object.Can form a plurality of distinctive images by the micro lens arra, all lens all " are seen " object or image from different vantage points.In each micro lens back, depend on the direction of picture shape and reception imaging energy source, the skeleton view of synthetic image in material layer.Yet, be not lens see all be recorded in the radiation-sensitive materials.Only have figure or the object part being seen by lens and enough energy change radiation-sensitive materials are arranged to be recorded.

" object " of wanting imaging is by the profile of describing " object " or by using mask to utilize intense light source to form.For the image that makes such record has synthetic outward appearance, must radiation in wider angular range from the light of object.When from the light of object radiation from a single point of object and in roomy angular range during radiation, all light have all carried the information of relevant this object (only from this a single point), although this information is the viewing angle from light.Consider now that light must be gathered the radiation wide range from the point that forms object in order to obtain the relative complete information of relevant this object that light carries.The angular range of the light that sends from object in the present invention, is by the optical element control of inserting between object and microlens material.Select these optical elements to form the necessary best angle scope of composograph to provide.The optimal selection of optical element is to form a light cone, and its vertex of a cone ends at the position of object.Best cone angle is greater than about 40 degree.

Dwindle object with the micro lens, from the light focusing of object by on the energy-sensitive coating of micro lens back.The focal beam spot of lens back or the physical location of image depend on the direction of the incident ray that comes from object.From the part that each light cone that a bit emits of object shines many micro lens, only has the permanent image that is just recorded this point of object by those micro lens of enough energy exposure.

To formation according to multiple composograph of the invention process be described with geometrical optics.As mentioned above, the imaging process of the following stated is preferred embodiment of the present invention, but and the embodiment of nonexcludability.

A. generate the composograph that appears in one's mind above sheet material

Referring to Fig. 8, projectile energy 100 (being light in the present embodiment) directive light diffuser 101 is so that any inhomogeneous factor homogenising in the light source.Catch the scattered light 100a of diffusion and make its collimation with collimator 102, with equally distributed light 100b directive divergent lens 105a.Light 100c disperses to lenticule sheet material 106 from divergent lens.

The energy that incides the light of lenticule sheet material 106 is focused on the material layer (being radiation-sensitive coating 112 in an illustrated embodiment) by each lenticule 111.This focus energy makes radiation-sensitive coating 112 modifications so that image to be provided, and its size, shape and outward appearance depend on the interaction between optical radiation and the radiation-sensitive coating.

Structure as shown in Figure 8 will provide the sheet material with composograph, the observer will see that composograph appears above sheet material (will in following description) in one's mind, because if divergent rays 100c passes lens and extends back, then can intersect at the focus 108a of divergent lens.In other words, if begin by each microsphere and return the track of describing imagination " imaging light " by divergent lens from material layer, these light will in the junction of 108a place, present composograph at this so.

B. watch the composograph that appears in one's mind above sheet material

The light that can utilize the homonymy (reflected light) from the observer and/or inject sheet material with observer's opposite side (transmitted light) from the sheet material is watched the sheet material with composograph.Fig. 9 is that observer A with the naked eye sees the synoptic diagram that appears the composograph above sheet material in one's mind when watching under reflected light.Naked eyes can be remedied to twenty-twenty vision, but can not otherwise be aided with (for example) magnifier or special viewer.When illuminating, light reflects from the imaging sheet material to be reflected light (can be collimation or diffusion) as the photo material, and the material layer that the mode of reflection is injected by light determines.According to definition, it is different from the not imaging moiety of material layer that the image that forms in material layer seems, so just can see image.

For example, light L1 can be reflected back the observer by material layer.Yet material layer may not be reflected back the observer with light L2 from the imaging moiety on this material layer fully, perhaps reflection ray not.Therefore, the observer can realize at 108a place disappearance light, and it is synthetic can to produce the composograph that seems to appear in one's mind at the 108a place above sheet material.In brief, light can reflect from imaging moiety whole sheet material in addition, namely relatively dark composograph can occur at the 108a place.

The material that also can be not imaging absorbs or the transmission incident light, and the material of imaging reflection or partially absorb incident light, forms the required contrast effect of composograph in order to provide.Composograph under these backgrounds is compared with the remainder of sheet material and is seemed brighter, and it is relatively dark that remainder then seems.This composograph can be called as " real image ", because be the image that is produced at focus 108a place by actual light.Can select as required the multiple combination of these possibility situations.

As shown in figure 10, some imaging sheet material also can pass through viewed in transmitted light.For example, when the imaging moiety of material layer is translucent but not imaging moiety is not translucent, most of light L3 can be absorbed or reflect by material layer, and transmitted light L4 then can pass the imaging moiety of material layer, and by lenticule directive focus 108a.Composograph can occur at the focus place, in this example, this composograph is compared with the remainder of sheet material and is seemed brighter.This composograph can be called as " real image ", because be the image that is produced at focus 108a place by actual light.

Alternatively, if the imaging moiety of material layer is not translucent and remainder material layer is translucent, image-region disappearance transmitted light seems the composograph darker than the remainder of sheet material with formation so.

C. generate the composograph that appears in one's mind below sheet material

Also can form and seem on sheet material the composograph that suspends with observer's opposite side.This appear in one's mind below sheet material floating image can by with convergent lens but not divergent lens shown in Figure 8 105 form.Referring to Figure 11, projectile energy 100 (being light in the present embodiment) directive diffusing globe 101 is so that any inhomogeneous factor homogenising in the light source.Then collect diffused ray 100a and make its collimation with collimator 102, with light 100b directive convergent lens 105b.Light 100d incides on the lenticule sheet material 106 between the focus 108b of convergent lens and convergent lens from convergent lens.

The energy that incides the light of lenticule sheet material 106 is focused on the material layer (being radiation-sensitive coating 112 in an illustrated embodiment) by each lenticule 111.This focus energy makes radiation-sensitive coating 112 modifications so that image to be provided, and its size, shape and outward appearance depend on the interaction between light and the radiation-sensitive coating.Structure as shown in figure 11 will provide the sheet material with composograph, and will be as mentioned below, and the observer will see that composograph appears in one's mind below sheet material, continue to extend because if converging ray 100d passes sheet material, then intersect at the focus 108b of divergent lens.In other words, if the imagination " image light " is passed each microsphere from convergent lens 105b, and pass the image on material layer relevant with each lenticule, they will be in the junction of 108b place so, and this point is exactly the place that composograph occurs.

D. watch the composograph that appears in one's mind below sheet material

Also can under reflected light and/or transmitted light, watch and have the sheet material that seems to appear in one's mind the composograph below sheet material.Figure 12 is the synoptic diagram that seems to appear in one's mind the composograph below sheet material under reflected light when watching.For example, light L5 can be reflexed in observer's eye by material layer.Yet material layer may not reflex to the imaging moiety of light L6 from this material layer observer's eye fully, perhaps reflection ray not.Therefore, the observer can realize at 108b place disappearance light, and it is synthetic can to produce the composograph that seems to appear in one's mind at the 108b place below sheet material.In brief, light can reflect from imaging moiety whole sheet material in addition, namely relatively dark composograph can occur at the 108b place.

Also can be that the material of not imaging absorbs or the material reflection of transmission incident light and imaging or partially absorb incident light, form the required contrast effect of composograph to provide.Composograph under these backgrounds is compared with the remainder of sheet material and is seemed brighter, and it is relatively dark that remainder then seems.Can select as required the multiple combination of these possibility situations.

Some imaging sheet material also can pass through viewed in transmitted light, as shown in figure 13.For example, if the imaging moiety of material layer is translucent and part not imaging is not translucent, so most of light L7 can be absorbed or reflect by material layer, and transmitted ray L8 can pass the imaging moiety of material layer.With these light (being called " image light " herein) along with extend with the opposite direction of incident light can be at 108b place formation composograph.Composograph can occur at the focus place, in this example, this composograph is compared with the remainder of sheet material and is seemed brighter.

Alternatively, if the imaging moiety of material layer is not translucent and remainder material layer is translucent, image-region disappearance transmitted light seems the composograph darker than the remainder of sheet material with formation so.

E. composograph

The composograph of making according to principle of the present invention can look like (the meaning that they have length and width) of two dimension, and seems to be positioned at sheet material below, sheet material plane or sheet material top; Perhaps look like three-dimensional (meaning that they have length, width and height).As required, three-dimensional composograph can only be revealed in below or the top of sheet material, or with in sheet material below, the sheet material plane and any array mode of sheet material top manifest.Term " in the sheet material plane " only refers to the plane of sheet material when sheet material keeps flat usually.That is to say, use in this article this phrase place, concerning the sheet material of non-flat forms, at least part of composograph that is presented in the sheet material plane can be arranged also.

Three-dimensional composograph can not be presented on the single focus, but presents as the composograph with continuous focus, and wherein focus extends on the point of opposite side from a side (or passing sheet material) of sheet material.By the relative position of mobile sheet material or the energy (rather than a plurality of different lens are provided) successively, thereby imaging on the material layer at different focuses place can preferably realize this effect.The spatial complex image of gained roughly is comprised of many a single points.This image can have spatial dimension in any one with respect to the sheet material plane in three Cartesian coordinatess.

In another kind of effect, can make certain zone of composograph shift-in lenticule sheet material, composograph disappears in this zone.This class image is made to be similar to such as the method for low suspension example, in this example, sets up the opaque mask that contacts with microlens material stops a microlens material part with part imaging light.When watching this class image, can be with a certain zone of image shift-in, contact mask reduces or removal imaging light in this zone.As if in this zone, image is " disappearance ".

Composograph formed according to the present invention can have the visual angle of non-constant width, and namely the observer can and watch in the wide range between the axis and see composograph on the sheet material plane.Use the lenticule sheet material that is formed as the glass microspheres of 70-80 micron by the average diameter of individual layer, and formed composograph when to use numerical aperture be 0.64 non-spherical lens, can be visible in conical visual field, the central shaft of this taper shape visual field is determined by the optical axis of projectile energy.Under ambient lighting, the composograph that so forms can both be seen in the taper surface of about 80-90 degree full angle.Use diversity imaging len less or that NA is lower can form less half-angle taper.

The image that uses method of the present invention to form also can be configured to have limited visual angle.In other words, only have from specific direction or from departing from the less angle of this direction and watch just and can see this image.Can the method described in the example 1 form such image with being similar to hereinafter, difference is in regulating and incides the light on the terminal non-sphere lens so that only have the part lens to be shone by laser emission.Projectile energy shines so that limited taper diverging light incides on the lenticule sheet material the part of lens.To the lenticule sheet material that aluminium applies, only just can see composograph in limited watching in the taper, as the Dark grey image on the light grey background.This image looks like and floats with respect to the lenticule sheet material.

Example

The present invention will further describe by following examples, for simplicity, and can be with reference to some accompanying drawing.

Example 1

This example has been described the embedding lens sheet that contains the aluminium bed of material, and seems to appear in one's mind the composograph above sheet material.Use the optical module of type shown in Figure 14 to form floating image.This optical module is Spectra Physics Quanta-Ray by model

TMThe Nd:YAG laser instrument 300 of DCR-2 (10) forms, and works under the Q-switch pattern with 1.06 microns fundamental wavelengths.The pulse width of this laser instrument is generally 10-30 nanosecond.The luminous energy that emits from laser instrument changes directions through the tilting mirror 302 of 99% reflectivity, ground glass diffusing globe 304, beam-expanding telescope 306 and (numerical aperture is 0.64, focal length be 39.0 millimeters) non-spherical lens 308 of 5 times.Light from non-spherical lens 308 out after directive XYZ dressing table 310.This dressing table is comprised of three linear dressing tables, can derive from Aerotech Inc. (Pittsburgh, Pennsylvania) by trade name ATS50060.A linear dressing table is used for making non-spherical lens mobile along the axis (Z axis) between aspheric surface focus and the lenticule sheet material, and other two dressing tables can move sheet material with respect to optical axial on two mutually orthogonal transverse axis.

Laser directive ground glass diffusing globe 304, any light beam unevenness that causes in order to eliminate hot focus.Next-door neighbour's diffusing globe, 5 times of beam-expanding telescopes 306 will make the divergent rays from diffusing globe collimate, and enlarge this light beam, and it is radiated on the whole non-spherical lens 308.

In this example, non-spherical lens is arranged on the top, XY plane of XYZ dressing table, so that lens focus 1 centimeters above lenticule sheet material 312.Energy density apparatus on the sheet material plane has the porose energy meter of machinery cover to control, and this porose energy meter can derive from Gentec by trade name ED500, Inc. (Saint-Fey, Quebec, Canada).Regulate the output of laser instrument so that on the lighting area of the energy meter of focus 1 centimeters of distance non-spherical lens, obtain about every square centimeter of 8 millijoules (8 millijoules/centimetre

2) energy density.The sample 312 of embedding lens sheet that will contain the aluminium radiation-sensitive layer of 80 nanometer thickness is fixed on the XYZ dressing table 310, so that the face that aluminium applies non-spherical lens 308 dorsad.

Can derive from Aerotech by trade name U21, the controller of Inc. (Pittsburgh, Pennsylvania) provides the required control signal of movement of XYZ dressing table 312, and the control voltage of the pulse of laser instrument 300 is provided.By containing the cad file writing controller of the required x-y-z coordinate information of synthetic image, movement directive and laser instrument ignition order, can mechanical stage.Describe the image above microlens material on the space by the movement of adjustment X, Y and Z dressing table and with the pulse of laser, form arbitrarily compound composograph.Be the laser of 10Hz for pulsed frequency, dressing table speed is adjusted to 50.8 cm per minute.Will in contiguous lenticular aluminium lamination, form continuous synthetic thread like this.

When watching this lenticule sheet material under ambient light, image is Dark grey under the contrast of light grey background.When focus with when having interval between the sheet surface of globule to be fixed as 1 centimetre, the image that obtains is the plane composograph that seems to appear in one's mind about 1 centimeters above sheet material.In addition, composograph is with respect to observer's the movement of watching the visual angle can show suitable size, and therefore, the observer can watch the different aspect of composograph at an easy rate, and the aspect of seeing depends on the visual angle.

Example 2

In this example, use contain the transparent reflector radiation-sensitive layer expose the lens sheet structure, seem to appear in one's mind composograph below the lenticule sheet material in order to formation.The optical module that uses in example 1 also can use in this example.With respect to non-spherical lens 308 the lenticule sheet material is set, so that lens almost contact with the lenticule sheet material.Laser instrument output be adjusted under non-spherical lens, obtain about 14 millijoules/centimetre

2Expose lens sheet by U.S. Patent No. 3,801, the 183 described microspheres that are partially submerged into form, and have zinc sulphide (ZnS) dielectric mirror of vapor deposition in microsphere one side.ZnS layer nominal thickness is 60 nanometers.Identical with example 1, laser instrument is worked under 10Hz, and the speed with 50.8 cm per minute moves sheet material simultaneously, thereby forms continuous synthetic thread at the lenticule sheet material.Can describe " spherical " pattern (circle with four inscribe arcs) by the dressing table system.

Under ambient light, above-mentioned spheroid shows dark image under the contrast of white/yellow background.Dark composograph seems to appear in one's mind about 39 millimeters places below sheet material.The composite diagram the position of image is corresponding to the focal position of non-spherical lens, in this example this focal position in the lens back about 39 millimeters places.

Example 3

This example has been described with lens arra and has been replaced single non-spherical lens, forms composograph in the lens sheet having exposing of aluminium radiation-sensitive layer.Use the optical module of type shown in Figure 15 to form unsteady composograph.Optical module is comprised of Q-switch laser instrument 300,99% catoptron 302, optical diffuser device 304 and beam-expanding telescope 306.These elements of the optical module that this example uses are described identical with example 1.The optical module of this example also comprises two-dimensional lens array 407, reflection mask 409 and negative biconcave lens 411.Some zones of reflection mask 409 are transparent, with the area coincidence of the microlens material 412 that will be exposed to laser radiation, the remaining surface of reflection mask then is opaque or reflection.

When under ambient light, watching the imaging lenticule sheet material that obtains, can above this sheet material, about 1 centimeters present unsteady image.This image presents Dark grey under the contrast of light grey background.

Example 4

In this example, the light that is sent by scattering source obtains divergent light source after reflection.This scattered reflection body is approximately 5 millimeters ceramic bead by diameter and forms.Use in this example the optical module of type shown in Figure 16.It comprises and the similar Q-switch Nd:YAG of laser instrument described in the example 1 laser instrument 500, is used in addition dwindling the incoming laser beam size to the telescope 502 of about 1 mm dia.Then with light being enough to the angle directive ceramic bead 504 of off-normal, thereby illuminate ceramic bead 504 towards about 1/4th hemisphere of lenticule sheet material 512.The scattered radiation that infrared camera is passed in observation can confirm this.

Under ambient light, composograph appears about 25 millimeters places above sheet material in one's mind, and presents the composograph of Dark grey under the contrast of light grey background.This image has large movement with respect to observer's viewing location.Under transmitted ray, bright composograph appears about 25 millimeters places above sheet material in one's mind.

Example 5

In this example, the material layer that embeds lens sheet is comprised of the multilayer optical laminates, and these optical layers overlapping pieces have carried out tuning for the particular color in the visible spectrum.Use vacuum vapor deposition method and plasma polymerization effect thin layer to be deposited on the one side of microlens substrate, obtaining by the sequence of layer that chromium/plasma polymerization butadiene/silicon dioxide/aluminium forms, and make the chromium layer adjacent with the embedding lens.Regulate the thickness of each material to obtain the color of red, green and blue part in the visible spectrum.

Table 1 provides the concrete thickness of the various materials of preparation.

Table 1: multi-ply construction

| Sample | Cr (nanometer) | PP (nanometer) | SiO 2(nanometer) | Al (nanometer) | Color |

| 1 | 4 | 97 | 0 | 80 | Blue |

| 2 | 4 | 65 | 65 | 80 | Light blue |

| 3 | 4 | 89 | 65 | 80 | Green |

| 4 | 4 | 165 | 20 | 80 | Red/blue |

Then, the microlens substrate of coating is laminated on the backing, and the multilayer layer component is contacted with laminate.Then the liner of lenticule sheet material is removed so that embed the front surface of lens be exposed to table in the light to color.

Also the optical module described in the use-case 1 makes the imaging samples of this example.In this example, aspheric focus is positioned at lenticule sheet material top 1 centimeters.Adjust the output of laser instrument, in order to obtain on lenticule sheet material surface 5 millijoules/centimetre

2Energy density.Adjust the multilayer layer overlapping piece in the optical characteristics of irradiation area.To be similar to the mode described in the example 1, describe the spheroid pattern in the multilayer layer overlapping piece, to form image.

Under ambient lighting, under the contrast of the background color of lenticule sheet material, irradiation area presents light yellow to orange.All composographs seem all to appear in one's mind above sheet material, and move with respect to the observer.

Example 6

This example has been described the tuning laminates of multilayer of the second type as radiation-sensitive layer, is used for forming colored composograph.The microlens substrate preparation optical layers overlapping piece that is being formed by the embedding lens sheet.Use vacuum vapor deposition method thin layer to be deposited on the one side of microlens substrate, to obtain by chromium/cryolite/aluminium (Cr/Na

3AlF

6/ Al), chromium/silicon dioxide/aluminium (Cr/SiO

2/ Al) or chromium/magnesium fluoride/aluminium (Cr/MgF

2/ the sequence of layer that Al) forms is as shown in following table 2.Adjust dielectric substance SiO

2, Na

3AlF

6And MgF

2Thickness, to obtain the multiple color in visible spectrum.Table 2 provides the concrete thickness of the various materials that prepare in multiple sample.

Table 2: multi-ply construction

| Sample | Cr thickness (nanometer) | Na 3AlF 6Thickness (nanometer) | SiO 2Thickness (nanometer) | MgF 2Thickness (nanometer) | Al thickness (nanometer) | Color | The imaging energy density (millijoule/centimetre 2) |

| A | 4.8 | 200 | 0 | 0 | 83 | Blue | 12.7 |

| B | 4.2 | 0 | 135 | 0 | 83 | Mazarine | 8.6 |

| C | 4.2 | 0 | 0 | 259 | 83 | Aqua | 8.6 |

| D | 4.2 | 0 | 275 | 0 | 83 | Purple | 7.5 |

| E | 4.2 | 0 | 160 | 0 | 83 | Green | 7.5 |

| F | 4.2 | 0 | 225 | 0 | 83 | Orange-sepia | 7.5 |

Then the microlens substrate that applies is laminated on the backing, so that the multilayer layer component contacts with laminate.Then the liner of lenticule sheet material is removed so that embed the front surface of lens be exposed to table in the light to color.

Optical module described in the example 1 is used for making these imaging samples.In this example, final non-spherical lens is arranged on the position that almost contacts with sample, in order to the composograph that seems to appear in one's mind below sheet material to be provided.Regulate laser energy to obtain forever to change the separately energy density of multilayer layer component optical characteristics, as shown in table 2.To be similar to mode described in the example 1, go out to comprise the character " SAMPLE " of literal and numeral for the image displaying in this material.Under ambient lighting, this composograph presents dark color under the contrast of the background color of lenticule sheet material, and its outline line is white/yellow.All composographs all seem to appear in one's mind about 39 millimeters places below sheet material, and move with respect to the observer who watches sheet material.

Example 7

In this example, use silver atoms number percent be 50 with zinc atom number percent be 50 phase-change alloy (Ag

50Zn

50), the tuning double-deck laminates that is comprised of chromium and silicon dioxide forms colored composograph as radiation-sensitive layer in embedding lens sheet.Phase-change alloy is not by the radiation ablation that is applied, and tuning double-deck laminates has improved the spectral reflectivity of blue portion in the electromagnetic visual spectrum.On the radiosensitive spacer layer that is deposited upon closed lens sheet, it is similar to be used for the operation that the thin layer with the multilayer layer overlapping piece is deposited on the microlens substrate in its depositional mode and the example 5.At first, respectively with chromium layer and silicon dioxide layer vacuum moulding machine on the polymer pad lamella, make its thickness be respectively 40 nanometers and 260 nanometers.Next, the Ag of spray deposited one deck 80 nanometer thickness on silicon dioxide layer

50Zn

50Alloy.Then this sample is by lamination with peel off the light transmission part that makes the lenticule sheet material and expose.

When watching under environment (reflection) light, sheet material looks like bluish violet.The optical module that use is similar to example 1 makes Ag

50Zn

50The radiation-sensitive layer imaging.Use replaces the Q-switch laser instrument as energy source with the continuous wave Nd:YAG laser instrument of 1.06 micron wave length work.In optical module, come the gating pulse width with acousto-optic modulator.Optical module by type shown in Figure 14 sends first order diffraction beam.The sample of closed lens sheet is fixed on the XYZ dressing table.Regulate the laser energy of input acousto-optic modulator, so that the power on microlens material is 810 milliwatts.Acousto-optic modulator is set to obtain the 20Hz pulse of 100 microsecond pulse width.Aspheric surface positive lens described in example 1 is arranged on apart from 12 millimeters places, microlens material surface.When radiation-sensitive layer is exposed to laser emission lower time, with XYZ dressing table rendering image.

When watching sheet material under ambient lighting, it is light blue that imaging region is, and the about 12 millimeters places above the lenticule sheet material of floating.

Example 8

In this example, use contains the replica lens structure of copper radiation sensitive layer as the lenticule sheet material.Use is in U.S. Patent No. 5,254, type described in 390 copy sheet material as lenticular sheet material.The radiation-sensitive layer vacuum evaporation of copper is to the flat surfaces of sheet material, and thickness is 80 nanometers.Little microlens material that copies is exposed under the laser emission such as example 1 described optical module.Final non-spherical lens is set, and focus is at 6.5 millimeters places on distance microlens material surface.Regulate the output of laser instrument, in order to provide in sheet surface be approximately 7 millijoules/centimetre

2Energy density.When the XYZ dressing table moved with the speed of 50.8 cm per minute, the pulsed frequency of laser was set to 10Hz.Describe " spheroid " pattern (circle with four inscribe arcs) at sample.

When under ambient lighting, watching this sheet material, under the contrast of coppery radiation-sensitive layer, can see the coppery image of the spheroid that floats.This composograph seems to appear in one's mind about 6 millimeters places above sheet material.

Example 9

This example has been described plane composograph and the combination that seems to appear in one's mind the composograph below sheet material.Use is at the optical configuration described in the example 1, make contain 80 nanometer thickness aluminium radiation-sensitive layers expose the imaging of lenticule sheet material.Non-spherical lens is arranged on the position that almost touches the lenticule sheet material, regulates the output of laser instrument, make its sample surface produce 4 millijoules/centimetre

2Energy density.Controller is programmed, in order to describe to comprise the character " SAMPLE " of literal and numeral.The absorption mask is placed on the top of open type sheet material.By using common photoprinter to make this mask at clear sheet printing comprise literal and the character " 3M " of numeral in a row.The character radiation-absorbing that comprises literal and numeral, then transmission laser radiation of peripheral region.Setting has the lens sheet that exposes of this absorption mask, so that " SAMPLE " character that forms is above mask position.

When watching under ambient lighting, character " SAMPLE " seems to appear in one's mind about 39 millimeters places below sheet material, and unexposed character " 3M " then seems to appear in one's mind in the sheet material plane.Only under the contrast of the dark character picture of " SAMPLE " character, just can watch " 3M " character.

Example 10

This example has been described the sheet material with compound 3-D view.Use in this example the embedding lenticule sheet material of the aluminium radiation-sensitive layer that contains 80 nanometer thickness.The optical module that use is used in example 1.The lenticule sheet material is attached on the XY plane of XYZ translation dressing table, and non-spherical lens is attached on the Z axis.The numerical aperture of this non-spherical lens is 0.64, and focal length is 39 millimeters.Controller is programmed, and is 5 centimetres the cubical profile of isogonism in order to describe long cube diagonal line (distances between cubical two relative angles).This cubical relative position and orientation as programming in the controller, are placed on about 5 millimeters places, sheet surface top with an end of synthesis of cubic volume image, and the other end of synthesis of cubic volume image are placed on this surface 5.5 centimeters.Cube graph is looked like to be orientated, make this cubical one jiao of observer the most close.

In describing the cubical process of isogonism, control is from the energy of each pulse of laser instrument so that no matter between divergent lens and the sheet material between be separated with much, all sample surface produce 8 millijoules/centimetre

2Constant energy density.Laser instrument is worked under pulsed frequency 10Hz, and X, Y and Z dressing table move with the speed of 50.8 cm per minute.Describe continuously the cubical figure of isogonism by the space of controller above the lenticule sheet material.

When watching under ambient lighting, under the contrast of light grey background, isogonism synthesis of cubic volume image is Dark grey, appears in one's mind from the teeth outwards between square 5 millimeters to 5.5 centimetres.And when the observer changed it and watches the angle, the isogonism cube was presented in the space above the lenticule sheet material and rotates, and made some seem under different visual angles before that the cuboid sides of bluring exposed.

Example 11

This example has been described the floating image that can make its disappearance.That is to say, by changing the visual angle, composograph can be disappeared or viewed arriving again.Use contains the embedding lens sheet of the aluminium radiation-sensitive layer of 80 nanometer thickness.Use is similar to those optical modules in the example 1 to form image, adjusts non-spherical lens to the distance between the sheet material, makes focus be positioned at lenticule sheet material top 1 centimeters.Controller is programmed, in order to producing " spheroid " pattern (circle with four inscribe arcs), and regulates the output of laser instrument so that sample surface form 8 millijoules/centimetre

2Energy density.Sample originally with it, the projected square part of translucent band is attached to the surface that embeds lens sheet.The projected square part of this band is set, so that in the imaging process of spheroid, the part that is covered by a part and the translucent band in the zone of laser imaging overlaps.

When watching the imaging sheet material under ambient light, the spheroid pattern that floats of watching is Dark grey under the contrast of light grey background, and appears 1 centimeters above sheet material in one's mind.By changing the visual angle, " spheroid " will move into or shift out the zone that translucent band hides.When spheroid moves into masked areas, just disappeared at this regional spherical part.When spheroid shifts out masked areas, again occur in the part of this regional spheroid.When composograph moved into masked areas, this composograph was not only to fade away, but just in time complete obiteration when moving into masked areas.